ESP Safety UPES-50D User manual

UPES-50D

Digital RS485 Multi-Channel Controller

Operating Manual

2

TABLE OF CONTENTS

Description of UPES Controller……………………………………………………..2

Basic Specifications………………………………………………………………….4

UPES Device………………………………………………………………………...5

Pre-Starting Procedure………………………………………………………………7

Operating Procedure………………………………………………………………...8

UPES Display Information for Gas Detectors……………………………………...10

UPES Display Information for Flame Detectors…………………………………...11

Front Panel LED Indicators………………………………………………………...12

Operating Mode Alarms of the Power Supply……………………………………...13

UPES Installation Clearance Consideration………………………………………...14

System Functionality………………………………………………………………..14

Device Search Options……………………………………………………………...15

Possible Malfunctions and Corrections……………………………………………..16

Description of the UPES Programming Tree Diagrams…………………………….18

UPES Menu in the Absence of the channel boards…………………………18

UPES Menu with the Channel Boards Installed…………………………….21

UPES Channel Programming ………………………………………… …...22

UPES Channel Board Com-Ports Operation Mode Setting ………………...25

UPES Channel Copy Settings……………………………………………….26

UPES Sensor Search………………………………………………………...27

UPES Sensor Search by Address…………………………………………....29

UPES Sensor Search by Type of Sensors…………………………………....31

UPES Sensor Search by List of Sensors……………………………………..33

UPES Sensor Search by All Types (Automatic)……………………………..35

UPES and PC Exchange Protocol……………………………………………………36

Power Cable Connection Diagram…………………………………………………...48

Wiring Diagrams for Flame Detectors Connections..………………………………..48

Wiring Diagrams for Gas Detectors Connection……………………………………..49

UPES Markings……………………………………………………………………….49

Transportation and Storage…………………………………………………………...50

Preventive Maintenance………………………………………………………………50

Warranty………………………………………………………………………………51

3

Description of UPES Controller

UPES-50D (hereinafter –UPES) is designed to operate with primary detectors via Modbus

RS485 signals. The input signal exceedance of the set threshold levels is controlled by audible

and LED alarms as well as connected peripheral devices via relay outputs for RS-485 interface

transmission of all channel data in Modbus RTU protocol format.

UPES is installed outside the explosion hazard zones and shall be operated at temperatures from

- 10 to 50 °C and relative ambient air humidity up to 95% at 35°С. UPES functional capabilities

enable to power up to 16 primary detectors: SGOES, TGAES Rx, TGAES Tx, SSS-903, IPES

IR/UV, IPES IR3.

The UPES multi-channel controller consists of a control panel capable of connecting up to 16X8

devices via RS485. From 1 to 128 devices can be connected to the UPES50D controller using

Modbus RS485. The UPES controller can only provide power supply to no more than 16

primary detectors by itself at 24VDC each. If more than one device is to be connected to each

channel card, an additional power supply will be necessary. The UPES can only power one

device per channel. Each Channel of the UPES has 2 dry contact relays for the first alarm

threshold and for the second alarm threshold. There is also a common dry contact relay for the

third alarm threshold for all channels. All dry contacts relays provide current switch up to 2A at

220VAC.

4

Basic Specifications

Table 1. Basic Specifications

Relative humidity at temperature 35 C, %

up to 95

Ambient temperature range

from -10 up to +50 C

Input voltage range with various power

supply units

power supply

unit of BP-1

design

187-242 V 50 Hz (main power) or

direct current with voltage

18-32 V (backup power)

power supply

unit of BP-10

design

130-242 V 50 Hz (main power) or

direct current with voltage

180-340 V (backup power)

UPES power from DC power supply with

voltage not more than, V

24

UPES commutated current at AC voltage 220

V, А

up to 3

Length, mm

266

Width, mm

482

Height, mm

132

Weight, kg, not more than

17

Ingress protection

IP54

Fig. 1. UPES dimensions

Front panel

Direction of module replacement

Module handles

Modules

Terminal blocks for

cable connection

UPES control panel is designed as a standard

3U19”- type unit to be mounted in a rack

5

UPES Device

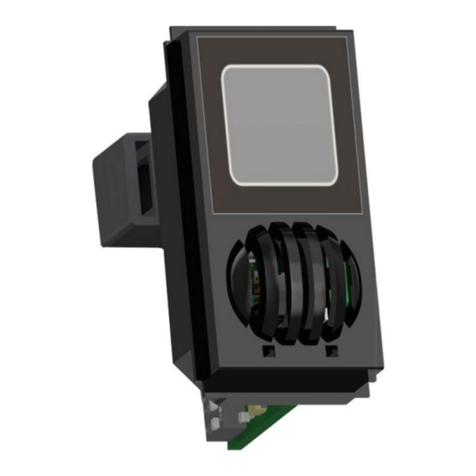

Fig.2. UPES Device

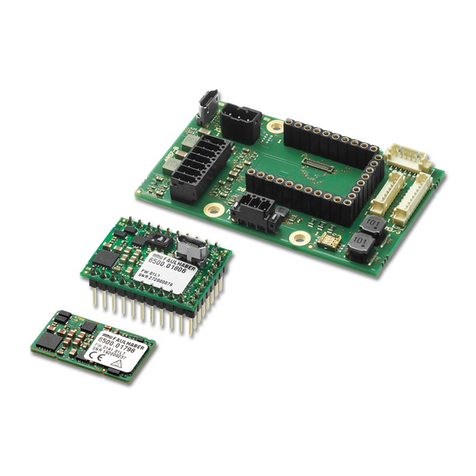

1. CPU board

2. 8 channel boards with 2 communications lines RS485

3. Power supply unit

Fig.2.1. Front View

1. Interconnection board

2. Blind panel

2

3

1

2

1

6

Fig. 2.2. UPES Rear View

1. 2-channel board

2. Processor board

3. Power supply unit

4. Main power socket, 220V input voltage

5. Backup power socket, 220V input voltage.

6. Fault relay

7. Third threshold relay

8. Ground terminal

Fig.2.3. Interconnection Board

1. UPES ON/OFF button

2. LED display

3. Buzzer

4. Keyboard

Each channel of the threshold device has a corresponding LED group:

2 green –Activating +24V at the output of the module;

4 red –exceeding specified thresholds;

2 blue-status indication of the RS-485 bus lines;

2 yellow –indication of sensor malfunction.

Moreover, in case of concentrations of any threshold of any channel are exceeded, an

audible alarm, which is built in UPES, is activated.

5

4

6

7

8

1

3

2

2

1

3

4

7

Pre-starting Procedure

Prior to installation it is necessary to perform visual inspection. Pay attention to the following:

1) signs of damages;

2) availability of all fixture elements;

3) Availability of grounding devices.

Installation shall be performed in accordance with a duly established project of onsite allocation

pursuant to the installation diagram with due account for threshold device design. When

performing installation, consider the following:

1) Local Electrical Installation Regulations

2) Local Safety Regulations on Consumer Electrical Installation Operation;

4) This Operating Manual.

In order to connect UPES to a personal computer via RS-485 communication channel, it is

possible to use any shielded twisted pair cables. In this case, signal wires are connected to

contacts “485А” and “485В”, and the shield is connected to contact “GND”, located at the

terminal block on the controller module rear side. In order to connect UPES to the network and

external actuation and signaling devices, it is possible to use any cables, cords or wires rated for

operational voltage and current specified in this OM.

UPES shall be grounded by means of a screw clamp located at the bottom of the power unit rear

wall. Upon completion of installation, check the following: - insulation resistance, which shall be

not less than 0.5 MOhm; - grounding device resistance, which shall be not less than 4Ohm.

When installing UPES, provide free space above and under it in a rack with height not less than

the threshold device height (132 mm)

8

Operating Procedure

Each of the eight channel modules can communicate with sensors by two RS-485 lines with

MODBUS addresses from 1 to 16, and transmit information to the central processor unit (CPU)

on the concentration and the state of each of the sensors.

The sensors are connected to the module via two separate lines or in a "ring" in accordance with

the requirements of the project. The module supports connection of up to eight sensors on each

RS-485 line and provides power supply for one sensor for each channel. When you connect to

UPES more than 16 sensors, they must be fed from a separate power supply of + 24V.

One port —communication with sensors via an independent port, 16 sensors

(MODBUS address from 1 to 16) can be connected to the port. The state of the

sensors connected to the port is displayed on the first relay set;

Hot swap —communication with the sensors through the first port. In case of

failure of the first port communication is transferred to the second port (MODBUS

address from 1 to 16). When you activate the first port the communication is

restored in the initial mode;

Ring —communication with sensors via the first port, where the ring integrity is

controlled. When the ring is open, communication between the primary transducers

is performed via two ports (MODBUS address from 1 to 16);

Two independent ports —communication with the sensors via two independent

ports, 8 sensors can be connected to each port. The state of the sensors connected to

the first port is displayed on the first relay set and the state of the sensors connected

to the second port —on the second relay set. The first MODBUS port: 1-8, the

second MODBUS port: 9-16.

The module has two relays on the output with "dry" contacts (relay of first and second threshold)

for each channel.

The boards generate the signals for L3 threshold and Fault relay that are common for all UPES,

the "Fault" LEDs lit up individually for each board of the connected primary transducers of the

RS-485 lines , in case of the sensor failure. Two-channel boards have LED status indication of

the RS-485 lines and continue their work in the absence or failure of the CPU. The channel

module at first-time start-up receives from the CPU the internal number, in accordance with the

location in the UPES enclosure.

For each primary detector the user assigns the MODBUS addresses which are connected to odd

(1-8) and to even (9-16) channels. The CPU remembers the numbers of the boards and the

MODBUS addresses of the sensors connected to each port and when the power is turned off or

lost (failed) recovers the device configuration. To search for sensors and system initialization

assign MODBUS addresses to the sensors from 1 to 16 for each channel board.

The CPU controls the entire block, display, transfers the RS-485 information to the "top level"

on concentration and the state of each of the sensors connected to each channel board. CPU is

controlled with the keyboard, located on the front panel, as well as using the command and

address registers from your PC.

9

When you enable the UPES the "test mode" starts, in which the front panel LEDs start flashing

alternately.

After pressing the "Control" button or in 30 seconds channel modules begin checking the RS-485

lines and consecutive scanning of sensors in accordance with the set MODBUS addresses.

When it detects information about gas concentration exceeding the threshold, the priority

scanning of this sensor is performed and the information is displayed on it, it immediately turns

on threshold LEDs and the threshold relay with the set delay.

NOTE:

It is NOT possible to connect on single-sensor-board gas detectors and flame detectors,

including working on different channels of one card in mode 2 port.

Work algorithm:

1) Connect the device 1 IPES - fire detection trigger two alarm thresholds. Lights up on the

display «Fire»

2) connect the 2 devices and more IPES -

• If a fire one device triggered 1 alarm threshold settings and displayed on the display the

inscription «Attention»;

• When processing with two or more triggers 1 and 2 the alarm threshold, the display you-usual

inscription «Fire»

10

UPES Display Information for Gas Detectors

The display shows the following information: gas detector

1 2 3 4 5 for SGOES

C

h

a

n

1

-

1

0

о

1

5

1

0

0

.

0

0

L

E

L

↑

↑

P

R

O

6 7 9 8

1 2 3 4 5

For TGAES Rx (receiver)

C

h

a

n

1

-

7

о

7

0

L

E

М

С

Н

4

6 7 8

For TGAES Tx (transmitter)

____________________________________________________________________________

1-channel;

2-serial number of the channel board

3- serial number of the sensor connected to the channel board

4 - operating mode of the channel board o- "ring", - " hot swap", -"two

independent channels", - "one channel".

5 - MODBUS address of controlled sensor;

6-gas concentration;

7-measurement units;

8- measured gas type;

9–actuation alarm of one (↑) or two thresholds (↑↑).

C

h

a

n

1

-

8

о

8

S

o

u

r

s

e

T

G

A

11

UPES Display Information for Flame Detectors

The display shows the following information: flame detector

1 2 3 4 5

C

h

a

n

1

-

7

о

7

n

o

r

m

a

F

R

E

6 7

C

h

a

n

1

-

7

о

7

F

i

r

e

F

R

E

C

h

a

n

1

-

7

о

7

F

a

u

l

t

F

R

E

1-channel;

2-serial number of the channel board

3- serial number of the sensor connected to the channel board

4 - operating mode of the channel board o- "ring", - " hot swap", -"two

independent channels", - "one channel".

5- MODBUS address of controlled sensor;

6- mode;

7 –Flame detector

12

Front Panel LED Indicators

The front panel contains LEDs of each of the eight channel modules:

1 - green LEDs indicating turning on of + 24V at the output of the channel

2 - red LEDs indicating the 1-st threshold

3 - red LEDs indicating the 2-st threshold

4- blue LEDs indicating the RS-485 bus lines state

5- yellow LEDs indicating the sensor faults

RS-485 bus line state indication LEDs are turned on at the time of receipt of request from the

channel board to the sensor and are turned off at the time of the receipt of the correct answer

from the requested sensors or upon the expiry of the set time of waiting for a response from the

sensor.

Light up of one of the "Fault" LEDs indicates a failure of one of the sensors in the bus line, or

the absence of response from one of them within the prescribed period of time.

At the back of the UPES there are screw terminal connectors to connect the bus lines from

sensors and cables from the external actuation devices (fans, valves, buzzers, etc.). There are also

mount hole for connecting the network and backup power supply and link with PC through RS-

485 communication channels.

Structurally, the UPES is a unified frame in size of 3U × 19 " (482 × 266 × 132 mm) built in

accordance with the bus structured and modular approach. In the frame there is a power supply

module, CPU module and up to eight two-channel modules. The power supply provides a relay

switch of main supply to 24 VDC reserve power supply.

In the power supply the primary main power supply takes precedence over the primary reserve

power supply for the detector. In the absence of ≈ 220V 50 Hz or in case of the failure of the

primary main power supply, the power supply unit ensures smooth transition to the reserve

supply, generating a sound signal and light indication on the UPES front panel (built-in red and

green LEDs in the UPES power buttons).

UPES is switched ON by continuous (2 sec) pressing on the power button on the front panel of

the device after the feeding of the primary and reserve power supply.

The power supply unit controls voltage outputs of primary power supply transducers and ply and

current consumption from them, compliance with the predetermined voltage limits of all the

reserve power supplies. Overrun of predetermined parameters is signaled by red light indication

on the UPES front panel, as well as sound signals with a simultaneous 24 V supply voltage

dump.

The power supply monitoring system has a separate secondary power source and a 5 V back-up

source with estimated operating time up to 30 seconds.

13

Flashing LEDs illuminating buttons in any color with a frequency of 1 Hz indicates that the

power supply is switched off.

Flashing red button illumination with a frequency of 1 Hz indicates that the power supply

is switched off due to fault in the power supply or overloading of secondary power

sources.

Flashing LEDs illumination button (yellow) with a frequency of 1 Hz indicates that the

power supply is turned off, but one of the input voltage (backup or primary) is absent.

Continuous illumination of LED buttons (any color) indicates that the power supply is

turned on.

Continuous illumination of LED button (yellow) indicates that the power supply is turned

on, but one of the input voltage (back-up or primary) is absent, when the power supply

switches from the back-up source short signals with a frequency of 1 Hz are generated.

Continuous illumination of LED buttons (green) indicates that the power supply is turned

on and all input voltages are connected (back-up or primary).

In all modes, connection or disconnection of any input voltage is indicated by the single sound

signal for 1 second.

Operating Mode Alarms of the Power Supply

Indication Mode

UPES Power Supply

Intermittent green illumination of the

UPES power button

UPES is not turned on, all input

voltages are connected

Intermittent yellow illumination of the

UPES power button

UPES is not turned on

One of the 220V input voltages is

absent

Steady green illumination of the UPES

power button

UPES is turned on.

Supply voltage, the primary and back-

up are connected and normal.

Output voltage of primary

transducers-OK.

Output voltage of secondary

transducers-OK.

Steady yellow illumination of the UPES

power button

Generation of short signals once a

second

UPES is turned on.

Powered by redundant power supply

220V.

Steady yellow illumination of the UPES

power button

There are no sound signals

UPES is turned on.

Powered from the main source

220V

The main and back-up supply in UPES has no commutation through switches, so the power

supply shall be connected to UPES through an external switching device.

The gas analyzer can also be connected with external devices with the cable for the industrial

interface RS-485, RS-422 (4 twisted pairs) cable with armor in the form of corrugated steel can

be used in hazardous areas.

14

To connect the UPES to the PC via the RS-485 communication the shielded twisted pair can be

used.

The external grounding conductor shall be thoroughly cleaned, and its connection with the

external grounding clamp shall be protected from corrosion by applying lubrication grease.

The control panel shall be grounded with a screw clamp located at the bottom of the back wall of

the power supply unit.

At the end of the installation it is required to check:

-insulation resistance, that shall not be less than 0.5 MOhm;

-resistance of the earthing device, that shall not be more than 4 Ohm.

UPES Installation Clearance Consideration

When installing the control panel in a rack there shall be empty space above it and below it that

shall be at least the height of the control panel (132 mm).

System Functionality

Connect the UPES to the detectors and verify its functionality.

For this purpose it is required to release two screws at the top of the front panel of the device,

unscrew the front panel and press ON.

After switching ON the UPES, the central board processor determines whether channel cards are

available. The ("Initializing channels") appears on the display (Fig. 1).

Figure 1. Cyclogram of the messages displayed on the display when UPES is initialized

15

When the search for the channel boards is complete, the test program is initiated. The ("Autotest

Elektronstandart-Pribor") message is displayed on the display in the top row as a crawl line, and

in the bottom line the software version and year of manufacture is displayed. LEDs of the

channel cards initialized flash on alternately. In 30 seconds testing stops. Autotest can be

interrupted by pressing the ("Test") button.

Search Options

If the central board has not found any channel card, the (“Error! No Channel card”) message

appears on the display.

The central board controller transmits the search command to the channel boards sensors

connected. The central board controller alternately scans the search condition of each channel

card. If the UPES autotest has been interrupted by pressing the ("Test") button, the channel

boards expect sensor initialization for 20 seconds, and in this case the indicator in the bottom line

displays the (“Sensors Warm-up”), and in the top line the number of the channel card connected

is changed alternately. After the channel card has completed waiting for warm-up, the sensor

search program starts. If in the channel card memory the MODBUS addresses and sensor types

have been recorded, the channel card controller searches for sensors per this list, otherwise the

search is performed by screening all sensor types in the MODBUS addresses from 1 to 16. The

status of the search for each channel card is displayed alternately on the display. The top line

displays the channel number and the search percentage completion, and in the bottom line

displays the search mode:

(“Search”) search all types of sensors in all the MODBUS addresses from 1 to 16

("Address search") search sensors in the MODBUS addresses specified by the

operator;

(“Search by type”) — search sensors by the types of sensors specified by the

operator:

oSSS —SSS-903, gas analyzer,

oSGO —SGOES-М11, SGOES gas analyzer,

oFRE –IPES fire detector,

oPGU —primary universal transducer,

oSSM –ССС-903МЕ gas analyzer.

oTGA –TGAES gas analyzer

(“Search per the list”) search sensors by the MODBUS address specified by the

operator and sensors corresponding to its type.

The channel card controller having found all the sensors, will display the number of the sensors

found during the next search state scan performed by the central board. The indicator for this

card will display the channel number and number of sensors in the top line and in the bottom line

—the (“Sensors Found”) message. The central board controller will scan the search status of

each channel board until all boards have completed their sensors search. The channel board

controller having completed the sensors search automatically enters into the scan mode for the

parameters modified by the sensors and thresholds state monitoring.

Once all the channel boards have completed the sensors search program, the central board

controller prompts for the MODBUS addresses of each channel board, types of the sensors

found, gas codes, and units of measurement. Having received this information, the central board

switches to the scan mode of the measured parameters and the sensors monitoring mode. If the

16

channel board has not found any sensor, the UPES indicator in the bottom line for this channel

board will display the (“No sensors”) message.

Working with the UPES menu, channel programming , modes setting in various device

configurations, and all the modes are given in the tree diagrams in the next pages.

Possible Malfunctions and Their Corrections

Possible malfunctions and their correction is described in Tables 6 and 7.

Table 6

Fault

Possible Reasons

Correction

The channel does not

appear on the display,

LEDs are not lit

No supply voltage.

Faulty rail fuses.

Backup power circuit fault.

Replace rail fuses, installed inside

the plug on the back of the power

supply unit (2A, 2 units).

Replace the fuses (12.5A, 2 units),

mounted on the back of the power

supply unit

Yellow LED is lit

continuously

Communication line

failure.

Faulty wire

Restore the line.

Repair or replace the wire

The LED is not lit when

the sound alarm and

relay trigger

The LED is faulty

Replace the LED.

The authorized specialist shall

perform this operation.

The threshold is

exceeded, but external

devices are not

switched on

The relay is faulty

Damaged external

communication lines

Consult with the manufacturer's

specialist.

Repair the corresponding module.

The authorized specialist shall

perform this operation.

Fix damage

Table 7.Power Supply Unit Fault Alarm

Fault

Possible Reasons

Correction

The UPES power button

is intermittently lit in

red, the intermittent

sound signal is

generated.

UPES is switched ON

UPES is switched off

Malfunction or overload of

one of secondary power

supplies

Press and hold the UPES power

button for 2 seconds

If the situation repeats:

1. Check the correct installation of

the sensors.

2. If there are no doubts in

correctness of installation, see. p. 3.

3. When the power is off remove all

boards from UPES, in case of

repeated emergency after switching

on, the unit shall be repaired

The UPES power button

is intermittently lit in

red

UPES does not switch

on

Malfunction or overload of

one of secondary power

supplies

Unit repair

17

Fault

Possible Reasons

Correction

Short-term red flashes

of the UPES power

button, short beeps

UPES does not switch

on

All input voltage 220V is

lost when the UPES has

already been on

Connect the power supply to UPES

Short-term red flashes

of the UPES power

button, no sound signals

UPES does not switch

on

All input voltage 220V is

lost when the UPES has

already been off

Connect the power supply to UPES

18

Description of the UPES Menu with Tree Diagrams

The UPES menu in the absence of channel boards

Depending on the UPES state, availability of channel boards, availability and condition of

sensors there may be various menu items. In order to enter the menu, press the(“Prog”) button.

If there are no channel boards in UPES, there is only one menu for setting —("UPES

Programming") (Fig.T1).

In this mode, the UPES only the interface language, the exchange rate with the top-level system,

and UPES MODBUS address can be set.

To configure the interface language use the (“Prog”) button to select "Language" and the "+" and

"−" buttons to select the desired language and press the (“Test/Enter”) button. To exit from any

menu item without setting the selected value by press the (“Control/Exit”) button.

To set the UPES exchange speed with the top-level system, select the button ("Prog") button of

the (“Exchange rate”) menu and use the "+" and "−" buttons to select the desired exchange rate.

The following exchange rates are possible with the top-level system: 4800, 9600, 19200, 57600

baud. To save the set exchange rate, press the (“Test/Enter”), and the selected value will be in

the square brackets.

To set the UPES MODBUS address in the top-level system select the (Modbus address) menu.

The available range of addresses to set is from 1 to 247. Select the address required with the «+»

and «−» buttons. Select and press the «+» or «−», to move the Modbus addresses faster. For the

selected address to be set and recorded in the controller memory, press the (“Test/Enter”) button,

the selected Modbus address value will be in square brackets.

19

Figure T1.

20

To reset the UPES settings, select the (“Reset Settings”) with the "+" and "-" buttons to select

("Yes") and press the ("Prog") button. The UPES settings with be set to their default values. By

default, UPES has the following settings:

Interface language is English;

Exchange rate is 9600 baud.

Modbus address —1;

Exchange rate between the channel boards and primary detectors —9600 baud.

The UPES setup menu is similar to the menu when there are no channel boards (fig.Error!

Reference source not found.), except that if there are channel cards, the menu items

related to exchange rate setting of the channel boards are added.

The exchange rate between the channel boards and the sensors is set similarly to the speed

UPES exchange rate with the top-level system.

The exchange rate between the channel boards and primary transducers —2400/4800/9600

(default)/19200 baud. The exchange rate for the channel card is set for both ports.

Table of contents