Flo CN-IC1-12 Quick start guide

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 1 1-5JULY2021

Flō i-Controller

Visograph Navigation for

Version 201.05

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 2 1-5JULY2021

Table of Contents

IMPORTANT: Read Before Continuing ............................3

Introduction Screens........................................................4

File Descriptions.......................................................4

Main Menu.......................................................................5

Schedules .........................................................................5

Zone Thermostat Control.........................................6

Set points .........................................................................6

Zone Thermostat Control.........................................7

System Status...................................................................8

Temperature Status.................................................8

Zone Thermostat Control.........................................9

Compressor Status...................................................9

Chilled Water Status ..............................................11

Water Source Heat Pump (WSHP) ........................ 11

Operation Mode Status .........................................12

Condenser Status...................................................12

Water Source Heat Pump ..................................... 13

Condenser Information......................................... 13

Optional Equipment Status....................................13

VAV Status............................................................. 14

ERV Status ............................................................. 14

Power Exhaust Status............................................ 15

Zone Thermostat Status........................................ 15

Energy Meter Status ..............................................15

Alarms ............................................................................16

Alarm Status...........................................................16

Alarm History .........................................................18

Alarm Resets ..........................................................18

Sensor Status..................................................................19

Network Information .....................................................20

Modbus Network...................................................20

BACnet Network ....................................................20

Network Options....................................................21

Field Tech Menu ............................................................22

Sensor Offsets................................................................23

Pressure Sensors Offsets .......................................24

VAV Offsets............................................................24

Test Mode Descriptions.................................................24

System Test Modes........................................................25

Water-Cooled Condenser......................................26

Chilled Water Unit .................................................26

Air Balancing..........................................................26

Compressor Test Mode .........................................26

Damper Test Mode................................................27

Condenser Fan Test Mode.....................................27

Heat Test Mode .....................................................27

Reheat/ Reclaim Test.............................................27

Operational Test Modes ................................................28

Occupancy .............................................................28

Dehumidification ...................................................28

Comfort Cooling.....................................................28

Heat Test Mode .....................................................28

Fan Only Test Mode...............................................28

Feature Tests Modes .....................................................29

Sensor Verification.........................................................29

I/O Verification ......................................................29

Clear All Test Modes ......................................................31

Sensor Settings...............................................................31

Set Damper Positions and Exhaust Fan Interlocks.........32

Damper Positions...........................................................33

Input and Output Status ................................................34

Input Status............................................................34

Output Status.........................................................35

VAV Status .............................................................36

Demand Control Ventilation (DCV)................................36

Overrides........................................................................37

Input Overrides:.....................................................37

Output Overrides:..................................................38

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 3 1-5JULY2021

Compressor Overrides: ......................................... 39

Condenser Overrides: ........................................... 39

Other Overrides .....................................................40

VAV Overrides....................................................... 41

Energy Recovery Wheel (ERV) Overrides...............41

Hydronic Heating Overrides...................................41

Chilled Water Overrides.........................................42

Water Condenser...........................................................43

IMPORTANT:Read Before Continuing

i-Controller Unit Types: Some unit types such as Water-Source Heat Pumps and Chilled Water Units have screens that are

specific to that unit type. Refer to the ‘Additional Unit Types’ section for these specialized screens.

Working with Building Management Systems: Once an i-Controller Modbus or BACnet connection is established to the

Building Management System (BMS) and the controller is ONLINE, the BMS is the Master controller. All set point and

schedule changes are to be made at the BMS. Changes can be made on the i-Controller but are temporary and will be

overwritten by the BMS.

To make a temporary setting change perform the following steps:

1. Unplug the RS485 Connector from the i-Controller.

2. Wait at least 90 seconds, until the BMS Status on the Network Info screen on the Visograph reads Offline.

3. Adjust the necessary settings for testing or change the desired variable. (For instructions on how to navigate the

Visograph, please refer to the instructions below).

4. When testing/changes are complete, plug the RS485 Connector back into the RS485 port.

5. Once the Modbus/BACnet connection has been re-established and the controller shows Online on the Network

Info screen, double check the changed variable to ensure that it is correct.

6. If the changed variable has been over-written, then the variable change needs to be made at the BMS.

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation for Version 201.04

EXTERNAL 1-5JULY2021

Introduction Screens

Introduction screens are displayed during controller

startup.

Figure 1. Introduction Splash screen

T8: Go to Main Menu

T2 + T3: Go to Version Info

Figure 2. Invalid Parameter File Message

Figure 3. Version Information screen

T2: Go to Overrides

T8: Go to Main Menu

File Descriptions

These are the base files used for the firmware and

controller parameters.

1. ISaGRAF Version: The version of the base program

inside the i-Controller. This field should match the

CRM field “Revision #” for a given unit.

2. VisoGraph Version: The version of the screens

shown on the Visograph.

3. Parameters Version: The version of the parameters

file loaded into the i-Controller.

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 5 1-5JULY2021

Main Menu

The Main Menu provides easy access to controller

information. When an alarm is present, the Alarm Bell

indicator is displayed. When one or more overrides are

present, the Warning indicator is displayed. The Main

Menu also displays the Date and Time and will indicate

when the unit is in a Test Mode.

To navigate the menu options, press the corresponding

key on the Visograph below the menu item number.

1. Schedule –Set weekly schedule for “Occupied” and

“Unoccupied” times.

2. Set Points –Define set points for cooling, heating,

and dehumidification modes during occupied and

unoccupied modes of operation.

3. Status –View temperature, compressor, and

operation mode status.

4. Alarms –View alarm status, sensor status, and

alarm resets.

5. Network Info –View controller IP settings and run

time, change controller Modbus address, and

change the Flō i-Controller date and time.

6. Field Technician Options –Parameters to be set by

a certified field technician only (password

protected). Press the (T1-T7) keys to access the

menu item.

Figure 4. Main Menu

T1: Go to Schedule

T2: Go to Set Points

T3: Go to Status

T4: Go to Alarms

T5: Go to Network Info

T8: Go to Logo screen

Schedules

A schedule is used to activate/ deactivate an event on a

specified day/ time. To create a scheduled event, use the

arrow and enter keys to select the day of the week of the

occurrence. Select the occupied or unoccupied period

and enter the hours and minutes for the event.

NOTE: See Important notice on page 5 before modifying

schedules.

Each day of the week is listed next to a corresponding

occupied time “Occ-Time” and unoccupied time “UnOcc-

Time”. The Flō unit will operate in “Occupied Mode” in

between the “Occ-Time” and “UnOcc-Time” listed for the

day of the week.

Each time on the schedule should correspond with the

store hours. All hours should be set in military time on a

24hr basis. (For Example: on Mondays, the occupied time

starts at 8:00am and the unoccupied time begins at

10:00pm. The above screen should read next to the “M”

8:00 under the “Occ-Time” and 22:00 under the “UnOcc-

Time”.) See Figure 5.

Figure 5. Monday 8am to 10pm Schedule

To change the occupied and unoccupied times:

1. Using the and buttons (T4 and T6,

respectively) navigate to the hour or minute that

you wish to change.

2. Press the (T5) button and the value should

blink.

3. Using the and buttons increase and

decrease the value as desired.

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 6 1-5JULY2021

4. Once the desired value has been reached press the

button to set the value.

5. Repeat steps 1-4 until all values in the schedule

have been updated.

6. Once all changes have been completed, press the

(T1) button to return to the Main Menu.

Figure 6. Schedule Configuration screen

T1: Go to Main Menu

T4: Scroll Up/Increase Value

T5: Enter (Select and Set Value)

T6: Scroll Down/Decrease Value

Zone Thermostat Control

Units configured to use a 2-Stage zone thermostat have

the option to use internal schedule or an external source

for an occupancy schedule. If internal schedule is used,

see above to set schedule. If the schedule is from an

external source, the display will be noted as shown below

and the schedule will need to be set from the external

source.

Figure 7. External Schedule Configuration screen

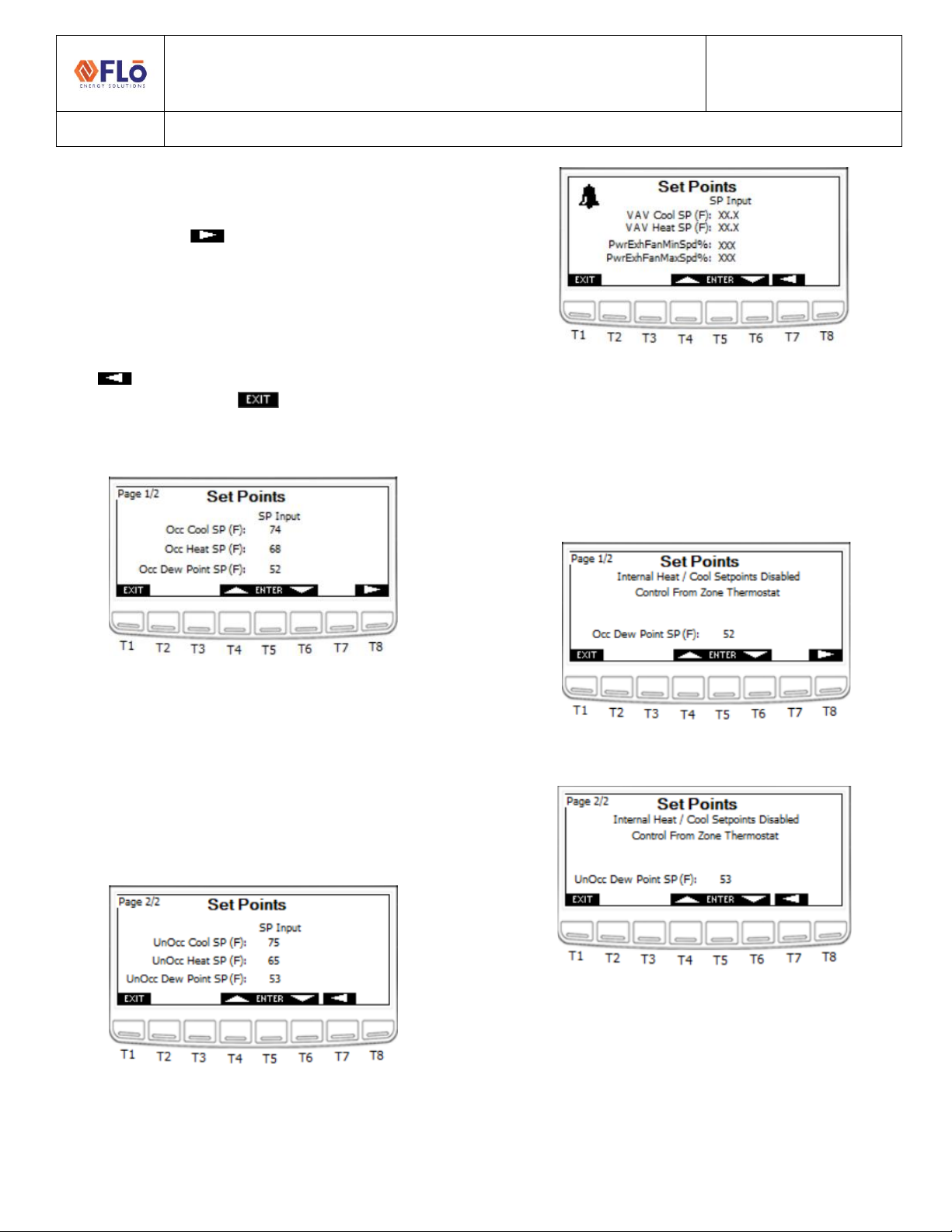

Set points

Set points are used as the cut in/ out for various i-

controller functions. The i-Controller Set Point

configuration section has 3 navigation screens.

The “Set Points” option should only be used if operation

set points are not being communicated to the Flō i-

Controller from a Building Management System (BMS).

If the Flō i-Controller is connected to a BMS over Modbus,

the set points shown on this screen will be automatically

updated with the set points entered in the BMS. The VAV

Set Points will only appear if VAV controls are connected

to the Flō unit. The set points limitations are as follows:

Cool SP: 60 - 85F

Heat SP: 50-80F

Dew Point SP: 48-60F

There must be a minimum of 4-degrees between the

heating and cooling set points. If set points are inputted

too close together, the program will automatically adjust

the set points per the following rules:

Outdoor Air Temp > 60 ˚F: Heating Set Point = Cooling Set

Point - 4 ˚F

Outdoor Air Temp < 50 ˚F: Cooling Set Point = Heating Set

Point + 4 ˚F

1. If the Flō i-Controller is not connected to a BMS,

perform the following steps to modify the set

points.

2. Using the and buttons (T4 and T6,

respectively) navigate to the “Occupied” set points

that you wish to change.

3. Press the (T5) button and the value should

blink.

4. Using the and buttons increase and

decrease the value as desired.

5. Once the desired value has been reached press the

button to set the value.

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 7 1-5JULY2021

6. Repeat steps 1-4 until all “Occupied” values have

been set.

7. Press the (T8) button to view the

“Unoccupied” set points.

8. Repeat steps 1-4 until all “Unoccupied” values have

been set.

9. Once all changes have been completed, press the

(T7) to return to the “Occupied” set points

screen or press the (T1) button to return to

the Main Menu.

Figure 8. Occupied Set Points - screen 1

T1: Go to Main Menu

T4: Scroll Up/Increase Value

T5: Enter (Select and Set Value)

T6: Scroll Down/Decrease Value

T7: Go to Previous Page

T8: Go to Next Page

Figure 9. Unoccupied Set Points - screen 2

Figure 10. VAV & Power Exhaust Fan Set Points - screen 3

Zone Thermostat Control

Units configured to use 2-Stage zone thermostats have

the internal heating and cooling setpoints disabled for

both Occupied and Unoccupied modes. However, the

internal Dew Point set point is still active for both modes.

Figure 11. Occupied Set Point screen 1 with TSTAT active

Figure 12. Unoccupied Set Point screen 2 with TSTAT active

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 8 1-5JULY2021

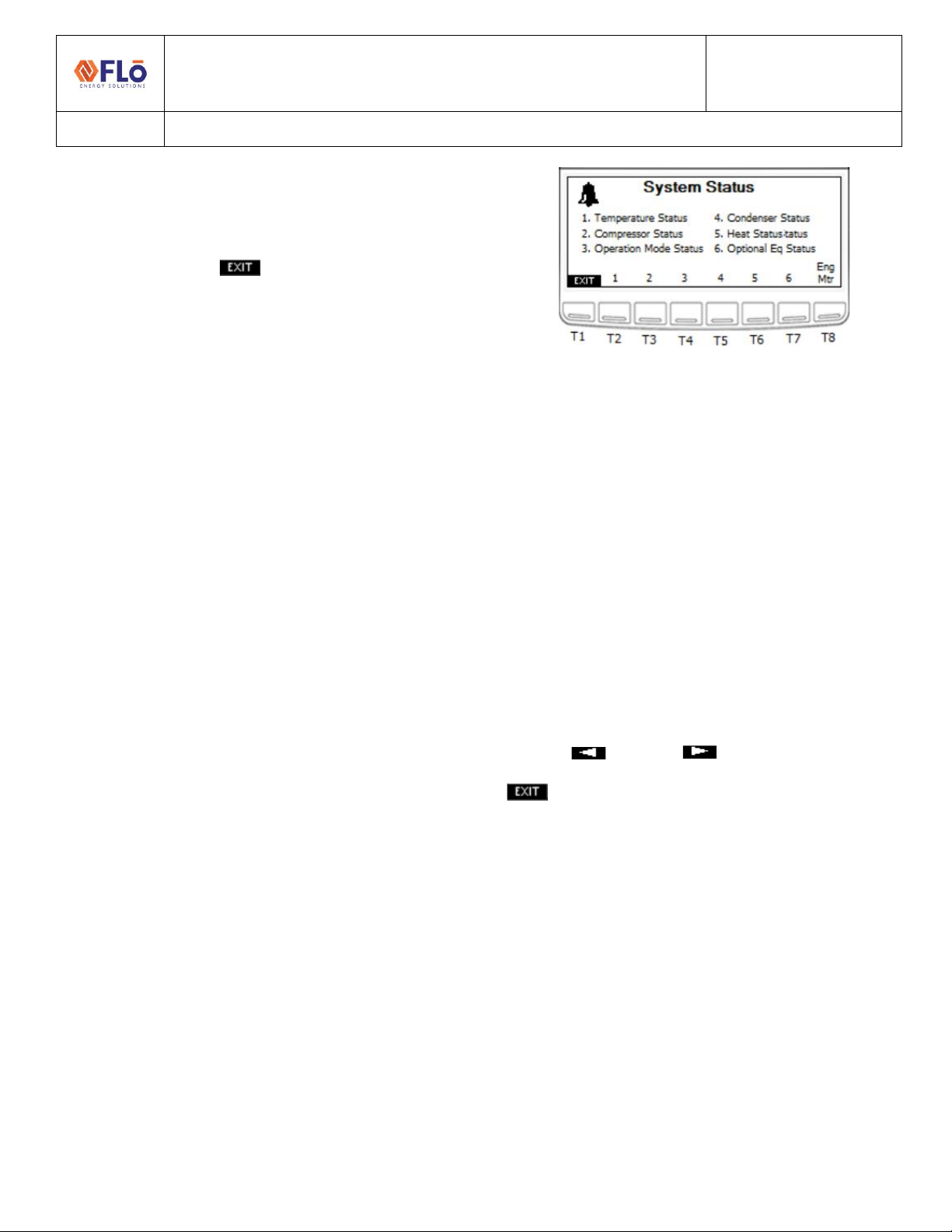

System Status

To navigate to the System Status menu options, press the

corresponding key on the Visograph below the menu

item number. Press the (T1) button to return to the

Main Menu.

1. Temperature Status –View the current

temperature in the treated space, space dew point,

supply duct temperature, return air temperature,

or outdoor conditions.

2. Compressor Status –View the current compressor

and suction pressure status.

3. Operation Mode Status –View the current

operation mode (Dehumidification, cooling, or

heating), reheat or reclaim status, current

occupancy, and other key system parameters.

4. Condenser Status –View the current condenser

fan status.

5. Heat Status –View the current heating operation

mode and stage status.

6. Optional Eq Status** –View current status of

optional connected equipment. This includes VAV

zones, ERV wheels, Power Exhaust, or Zone

thermostat inputs. Status will only appear if

optional equipment is present.

7. Energy Meter –View current power consumption.

** If Equipped

Figure 13. System Status screen

T1: Go to Main Menu

T2: Go to Temperature Status

T3: Go to Compressor Status

T4: Go to Operation Mode

T5: Go to Condenser Status

T6: Go to Heat Status

T7: Go to Optional Equipment Status**

T8: Go to Energy Meter**

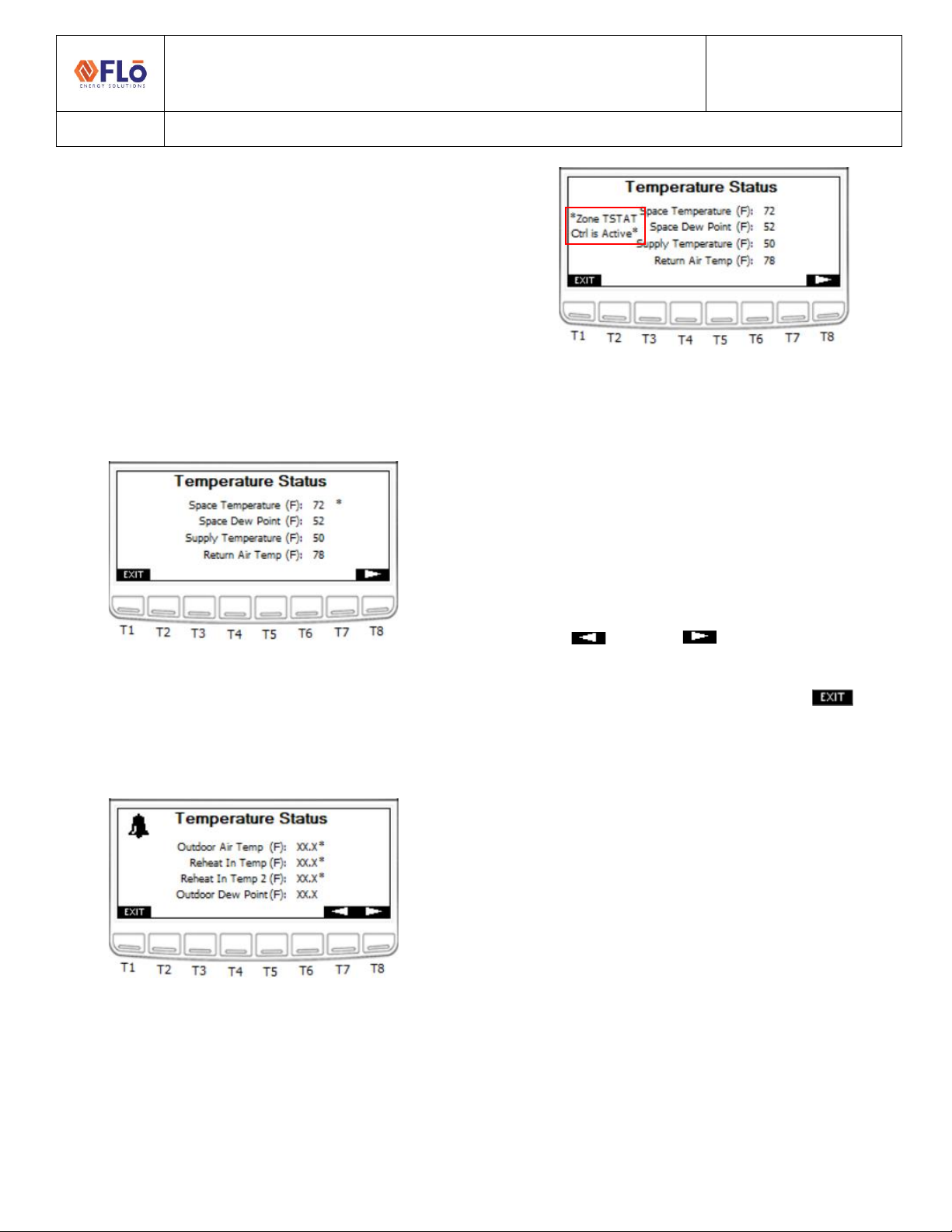

Temperature Status

There are 2 temperature status screens that display the

reading of various temperature sensors throughout the

unit. NOTE: when an asterisk (*) is displayed to the right

of the value, the value is in override.

Use the (T7) and (T8) buttons to navigate

between the two “Temperature Status” pages. Press

(T1) to return to the System Status Menu.

1. Space Temperature: Temperature reading from

temperature probe mounted in the space.

2. Space Dew Point: Dew point calculated from the

temperature and humidity probe readings

mounted in the space.

3. Supply Temperature: Temperature reading from

temperature probe mounted in the supply air duct.

4. Return Air Temperature: Temperature reading

from temperature probe mounted in the return air

duct.

5. Outdoor Air Temperature: Temperature reading

from temperature probe mounted in underneath

the rain hood on the Flō unit.

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 9 1-5JULY2021

6. Reheat/Reclaim In Temp: Temperature reading

from temperature probe mounted in the

Reheat/Reclaim Stage 1 inlet.

7. Reheat/Reclaim In 2 Temp**: Temperature

reading from temperature probe mounted in the

Reheat/Reclaim Stage 2 inlet.

8. Outdoor Dew Point**: Dew point calculated from

the temperature and humidity probe readings

mounted underneath the rain hood of the Flō unit.

** If Equipped

Figure 14. Temperature Status screen 1 with Overrides Present

T1: Go to System Status Menu

T7: Previous Page

T8: Next Page

Figure 15. Temperature Status screen 2 with Overrides Present

Zone Thermostat Control

Units configured to use 2-Stage zone thermostats note

the control option on the Temperature Status screen.

Figure 16. Temperature Status screen 3 with TSTAT active

Compressor Status

There are 4 Compressor Status screens; however, Status

screens are only displayed for compressors equipped in

the unit. The Suction Pressure Status will only appear if

Compressor 2 is a digital scroll compressor (when 4

compressors are present), Compressor Status screens 3

and 4 will only be displayed when the unit is equipped

with a third and fourth compressor.

Use the (T7) and (T8) buttons to navigate

between the two “Compressor Status” pages. The second

“Compressor Status” page is only available if the Flō unit

contains more than two compressors. Press (T1) to

return to the System Status Menu.

1. Dig Comp # Operating Capacity: Digital

Compressor operating percentage.

2. Fixed Compressor # Status: Fixed Compressor

operating status; “ON” or “OFF”.

3. Suction Pressure for Comp #: Suction pressure

reading from the pressure transducer located on

the denoted Digital Compressor.

4. Suction Pressure Set Point: Suction pressure set

point set based on the current control strategy.

5. Compressor # Status: This will display the status of

each compressor. Possible status values include:

oOK: Compressor is running properly.

oComp High Dis Trip: Activated when a

compressor’s discharge pressure has

exceeded the safety limit (550PSI by

default). Compressor will instantly shut

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 10 1-5JULY2021

down and lock out until discharge drops to

an acceptable level.

oComp Low Suction Trip: Activated when a

compressor’s suction pressure dropped

below the safety limit (75PSI by default).

Compressor will instantly shut down and

lock out until suction rises to an acceptable

level.

oNo Comp Proof: Activated when the

compressor signal is on, but suction

pressure and discharge pressure are within

20PSI of each other.

oLow Suct Press: Activated when the suction

pressure decreases below the lower pressure

limit (80PSI).

oHigh Suct. Press: Activated when the suction

pressure increases above the upper pressure

limit (varies per mode) during dehumidification

or cooling call.

oHigh Dis Press Alarm: Activated when the

suction pressure increases above the upper

pressure limit (500PSI).

oSuct. Trans Fail: Activated when the suction

transducer reading is out of range.

oDis Trans Fail: Activated when the discharge

transducer is out of range.

oGradual Shutdown: Activated when the

discharge pressure of a digital compressor is

above the warning limit. Digital compressor will

gradually reduce capacity in 20% increments

until discharge pressure drops to an acceptable

level.

oOA Temp Comp Lockout: Activated when the

outdoor air temperature is too cold to allow

compressors to run.

oEconomizer Lockout*: Activated when

economizer mode is active.

Figure 17. Compressor Status screen 1

T1: Go to System Status Menu

T7: Previous Page

T8: Next Page

Figure 18. Compressor Status screen 2

Figure 19. Compressor Status screen 3

Figure 20. Compressor Status screen 4

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 11 1-5JULY2021

Chilled Water Status

Chilled Water Units will have a Chilled water status screen

in place of the Compressor status screen.

Figure 21. System Status screen

Figure 22. Chilled Water Status screen

Figure 23. Chilled Water Status screen 2

Water Source Heat Pump (WSHP)

When the unit is a WSHP the ‘Suction Pressure Setpoint’

will be replaced ‘Discharge Pressure Setpoint’ while the

unit is heating operation.

Figure 24. WSHP Compressor Status while in Heating

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 12 1-5JULY2021

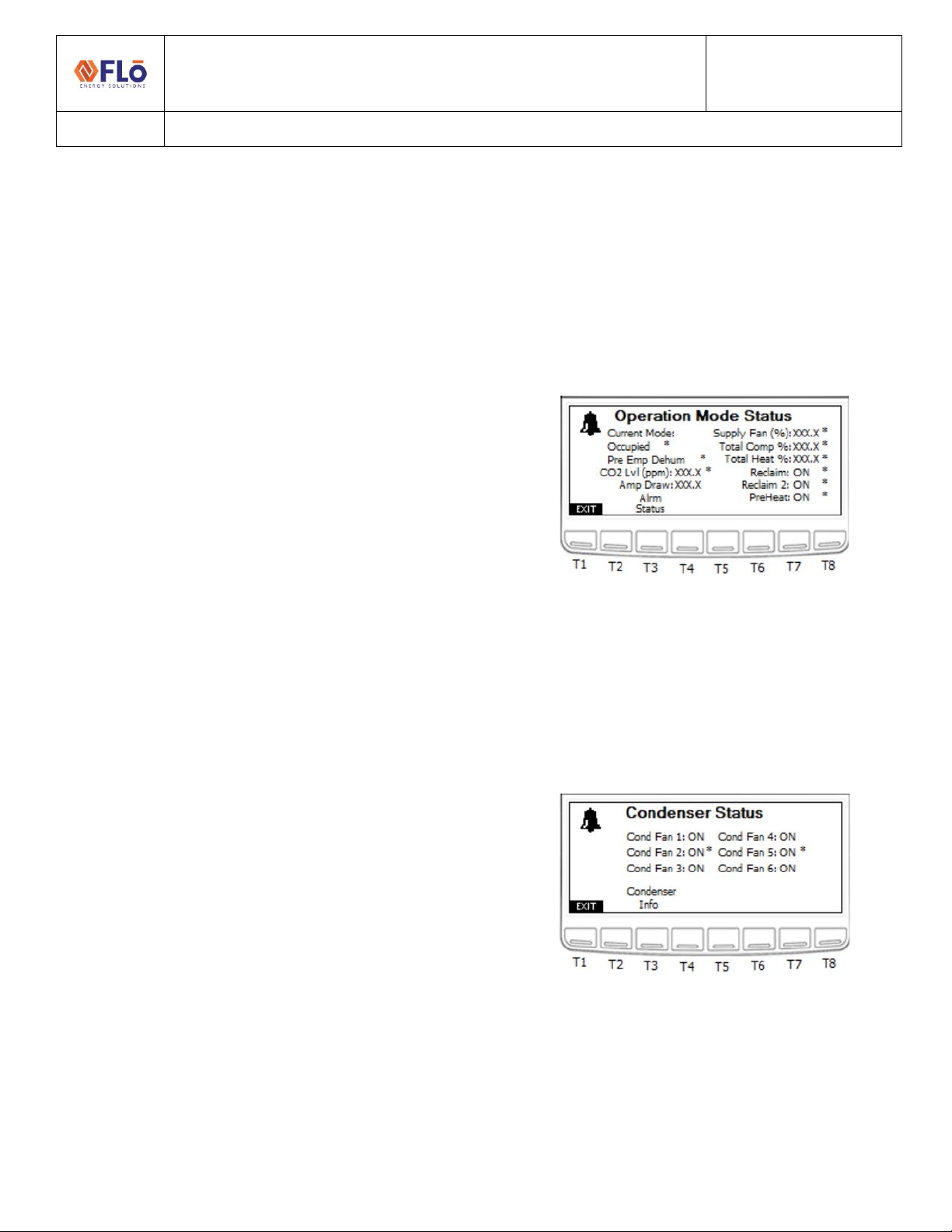

Operation Mode Status

From the System Status Menu Press T4 to enter the

Operation Mode Status page.

1. Occupancy Mode: “Occupied” or “Unoccupied”

Mode will display based on the occupancy

schedule.

2. Current Mode: The second line will display the

unit’s operation mode. One of the following will

appear, based on the unit’s operation.

oStandby

oFan-Only

oHeat

oCool

oDehum

oDehum + Heat

oDehum + Cool

oPre-Emptive Dehum

oShutdown

oNet Disable

oReturn Temp Control**

oEcon Mode**

oHydronic Freeze Protection Heat (only on units

with Hydronic Heat equipped)

3. Amp Draw: Amperage reading from the 1-phase

current transducer.

4. Supply Fan Status: Status of the supply fan

operation will a value from 0-100%.

5. Compressor Capacity: Total compressor capacity

will display a value from 0-100%.

6. Heat Capacity: Total heat capacity will display a

value from 0-100%.

7. Reheat/Reclaim Status: Reheat or Reclaim Stage 1

“ON” or “OFF” when the coil is activated and

deactivated.

8. Reheat/Reclaim 2 Status**: Reheat or Reclaim

Stage 1 “ON” or “OFF” when the coil is activated

and deactivated.

9. Pre-Heat Status: If the pre-heat option is selected,

the pre-heat status will display “ON” or “OFF”.

10. CO2 Level (ppm)**: If a CO2 sensor option is

chosen, the CO2 level will be displayed in parts per

million (ppm). This is the CO2 control value. If more

than one CO2 sensor is being used, this value

represents the max CO2 value.

** If Equipped

Figure 25. Operation Mode Status screen

T1: Go to System Status Menu

T3: Go to Alarm Status

Condenser Status

The Condenser Status screen shows the status of all

condenser fans present on the unit.

Figure 26. Condenser Status screen

T1: Go to Status Menu

T3: Condenser Info

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 13 1-5JULY2021

Water Source Heat Pump

When the unit is a WSHP the Condenser Status screen will

display information for the water source condenser.

Figure 27. Condenser Status screen 1 when WSHP

Figure 28. Condenser Status screen 2 when WSHP

Condenser Information

The Condenser Info describes the condenser fan

sequence and operation.

Figure 29. Condenser Info screen

T1: Go to Condenser Status Menu

Optional Equipment Status

To view current status of optional connected equipment,

press T7 from the System Status Menu. Optional

equipment includes VAV zones, ERV wheels, Power

Exhaust, or Zone thermostat inputs. Status will only

appear if optional equipment is present.

Figure 30. Optional Equipment Status screen

T1: Go to Status Menu

T2: Go to VAV Status Menu

T3: Go to ERV Status Menu

T4: Go to Power Exhaust Status Menu

T5: Go to Zone Tstat Status Menu

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 14 1-5JULY2021

VAV Status

From the System Status Menu press the T7 button to

enter the Optional Equipment Status Menu page and

then T2 for VAV Status page.

1. VAV # Control Temp: The calculated control

temperature for the associated zone. If more than

one temperature sensor is being used for the

associated zone, this value represents the

calculated average of the temperature readings.

2. VAV Fan #: VAV Fan Status for associated zone.

Value will be “ON” or “OFF.”

3. VAV Fan Speed #: VAV Fan Speed for associated

zone. Value will be 0-100%.

4. VAV Booster #: VAV Booster Heater status for

associated zone. Value will be “ON” or “OFF.” If

modulate heat is being used, the value will be 0-

100%.

5. VAV Damper #: VAV Damper position for

associated zone. Value will be 0-100%.

The VAV Status screen displays state of VAV inputs and

outputs.

Figure 31. VAV Status screen

T1: Go to Status Menu

ERV Status

From the System Status Menu press the T7 button to

enter the Optional Equipment Status Menu page and

then T3 for ERV Status page.

The ERV Status screen displays state of ERV inputs and

outputs.

Figure 32. ERV Status screen

T1: Go to Status Menu

1. Free Dehum Mode: Displays whether the unit is

in “Free Dehum” Mode.

2. ERV Wheel: ERV Wheel Status. Value will be

“ON” or “OFF.”

3. ERV Power Exhaust: ERV Power Exhaust Status.

Value will be “ON” or “OFF.”

4. ERV Bypass Damper: ERV Bypass Damper

Position. Value will be “ON” if the damper is

open, or “OFF” if the damper is closed.

5. ERV Store Exhaust: ERV Store Exhaust Status.

Value will be “ON” or “OFF.”

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 15 1-5JULY2021

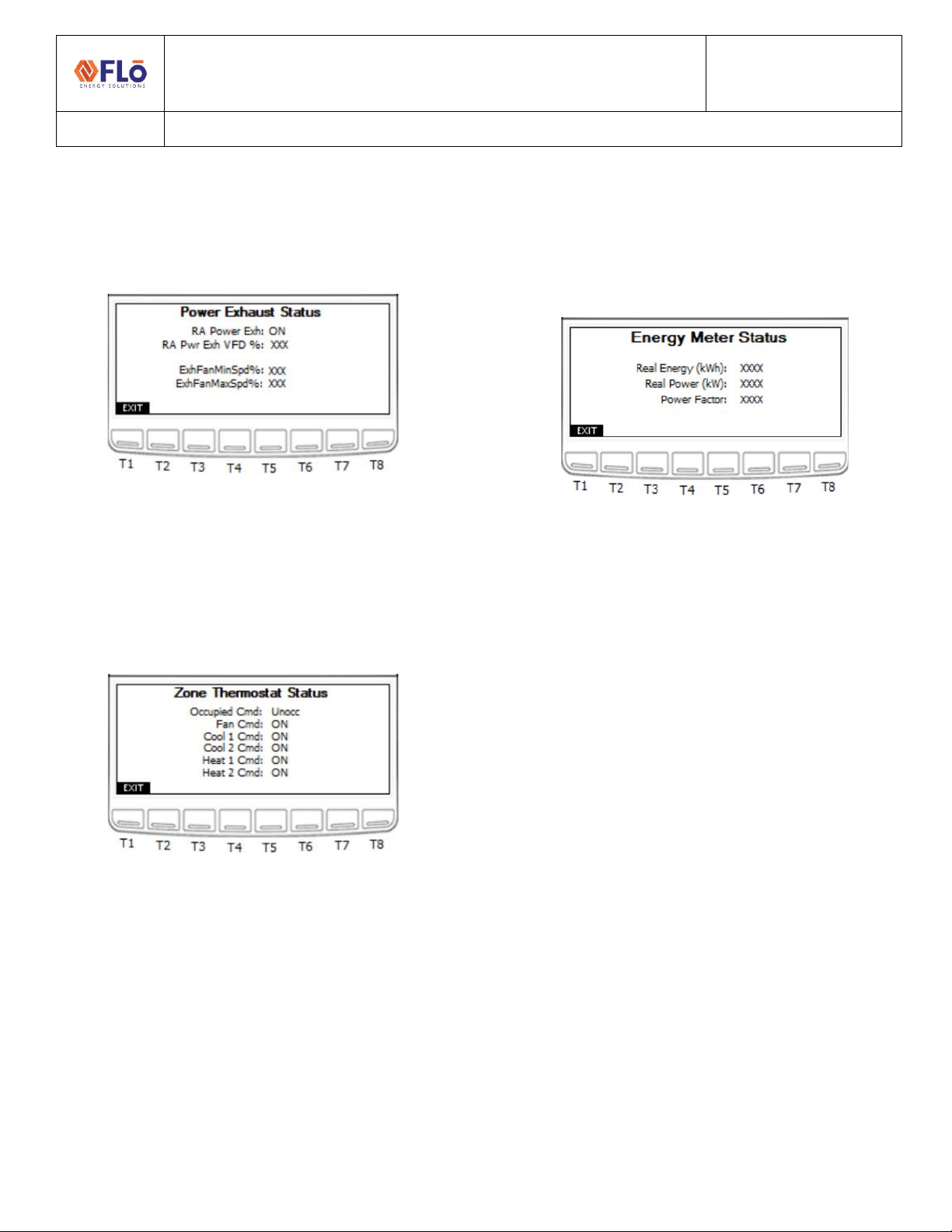

Power Exhaust Status

The Power Exhaust Status screen shows the exhaust fan

output status and current minimum and maximum speed

set points.

Figure 33. Power Exhaust Status screen

T1: Go to Optional Equipment Menu

Zone Thermostat Status

The Zone Thermostat Status screen shows the input

status of the 2-stage zone thermostat.

Figure 34. Zone Thermostat Status screen

T1: Go to Optional Equipment Menu

Energy Meter Status

When the unit is equipped to monitor energy conception,

the Energy Meter Status will display the unit consumption

and power factor.

Figure 35. Energy Meter Status screen

T1: Go to Status Menu

1. Real Energy (kWh): Displays the Real Energy

usage, in kilowatt-hours.

2. Real Power (kW): Displays the Real Power usage,

in kilowatts.

3. Power Factor: Displays the power factor.

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 16 1-5JULY2021

Alarms

To navigate to the following menu options, from the Main

Menu press T4 to enter the Alarms Menu page.

1. Alarm Status –View the status of alarms.

Navigate to this page when the bell in the upper

left corner appears to view which alarm has been

activated.

2. Sensor Status –View the status readings of

sensors. If a sensor failure is the cause for an

alarm, this page will show which sensor has

failed.

3. Alarm History –Displays a list of alarms and the

last time they transitioned from OFF to ON.

4. Alarm Reset –Contains necessary resets for

certain alarms. If a fan fail occurs, once the

problem has been resolved this page contains the

reset necessary to continue operation.

Figure 36. Alarms screen

T1: Go to Main Menu

T2: Go to Alarm Status

T3: Go to Sensor Status

T4: Go to Alarm History

T5: Go to Alarm Reset

Alarm Status

Press T1 to return to the Alarms Menu. Each alarm will

display “ALARM” when an alarm is present and “OK”

when no alarm is present.

1. Clogged Filter Alarm: Alarm activated when the

filters in the unit need to be replaced.

2. Fan Status: Alarm activated when a fan fail occurs.

3. Overflow Alarm: Alarm activated when a smoke

detection signal is sent from the space. This alarm

will cause the unit to shut down.

4. Phase Loss Alarm: Alarm activated when improper

voltage is supplied to the unit. This alarm will cause

the unit to shut down.

5. Smoke Det. Alarm: Alarm activated when a smoke

detection signal is sent from the space. This alarm

will cause the unit to shut down.

6. CO2 Level Status*: Alarm is activated when the

CO2 level in the space increases above the specified

ppm limit.

7. Ref Lk Status*: Alarm is activated if there is a leak

in the store’s refrigeration system. A digital signal is

received from the refrigeration rack controller that

signifies a leak has been detected. Once the signal

is received, the OAD of the Flō unit will open to

100% to flush the store.

8. Heat Status: Alarm is activated if a temperature

increase has not occurred after heat mode has

been activated for a certain period of time.

9. Sensor Failure: Displays “YES” when a sensor

failure is present.

10. Reclaim Status*: Notice is activated if the

reheat/reclaim inlet temperature has not increased

at least 5 ˚F, after heat reclaim has been enabled

for 15-minutes. Notice is automatically reset upon

heat reclaim disable. This notice will not trigger an

alarm in the unit.

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 17 1-5JULY2021

11. Comp Status: This will display the status of each

compressor. Possible status values include:

If multiple alarms are present, only the highest

priority alarm will appear. Alarms are listed top-to-

bottom by priority (with ‘Suct Trans Fail’ being the

highest priority, and ‘OK’ being the lowest).

oSuct Trans Fail: Activated when the

suction transducer reading is out of

range.

oDis Trans Fail: Activated when the

discharge transducer is out of range.

oComp High Dis Trip: Activated when a

Comp Proof Fail and High Dis Pressure

alarm activate together.

oNo Comp Proof: Activated when the

compressor signal is on, but suction

pressure and discharge pressure are

within 20PSI of each other.

oHigh Suct. Press: Activated when the

suction pressure increases above the

upper pressure limit (varies per mode)

during dehumidification or cooling call.

oLow Suct Press: Activated when the

suction pressure decreases below the

lower pressure limit (80PSI).

oHigh Dis Press Alarm: Activated when the

suction pressure increases above the

upper pressure limit (500PSI).

oOK: Compressor is running properly.

oComp Low Suction Trip: Activated when

a compressor’s suction pressure drops

below the safety limit (75PSI by default).

Compressor will instantly shut down and

lock out until suction rises to an

acceptable level.

oGradual Shutdown: Activated when the

discharge pressure of a digital

compressor is above the warning limit.

Digital compressor will gradually reduce

capacity in 20% increments until

discharge pressure drops to an

acceptable level.

oOA Temp Comp Lockout: Activated when

the outdoor air temperature is too cold to

allow compressors to run.

oEconomizer Lockout*: Activated when

the economizer is active.

*If Equipped.

Figure 37. Alarm Status screen 1

T1: Go to Alarm Menu

T8: Go to Next Page

Figure 38. Alarm Status screen 2

T1: Go to Alarm Menu

T7: Go to Previous Page

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 18 1-5JULY2021

Alarm History

The Alarm History will display a timestamp next to each

alarm indicating the last alarm occurrence.

Figure 39. Alarm History screen 1

Figure 40. Alarm History screen 2

Alarm Resets

Press T1 to return to the Alarms Menu. If a fan fail occurs

and the problem has been resolved, the fan fail alarm

needs to be reset to start normal operation. To reset the

fan, fail alarm, perform the following steps:

1. Using the and buttons (T4 and T6,

respectively) ensure that the “OFF” value is

highlighted.

2. Press the (T5) button and the value should

blink.

3. Using the and buttons increase and

decrease the value until “ON” appears.

4. Once the desired value has been reached press

the button to set the value.

5. Once the value has been set to “ON” the fan fail

alarm has been reset and the fan is ready for

operation.

6. The value will automatically reset to “OFF” after

5 seconds. Values will display as “ON/OFF” for

Fan Fail Reset, or “YES/NO” for Clear Alarms.

Figure 41. Alarm Resets screen

T1: Go to Alarms Menu

T4: Change value to ON

T5: Enter (Select and Set Value)

T6: Change value to OFF

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 19 1-5JULY2021

Sensor Status

Press T1 to return to the Alarms Menu. Each sensor status

will display “FAIL” if the sensor has failed and “OK” when

the sensor is still operational. Use the (T7) and

(T8) buttons to navigate between the two “Sensor Status”

pages.

The Outdoor Humidity and CO2 sensors on the first page

are optional and will not appear on the screen if these

options are not included on the unit.

There are three Sensor Status screens. Screen 3 is only

visible if the unit contains VAV, a hydronic heating coil, a

second space Temp, or a 2nd Dehum Probe.

Figure 42. Sensor Status screen 1

T1: Go to Alarms Menu

T7: Previous Page

T8: Next Page

Figure 43. Sensor Status screen 2

Figure 44. Sensor Status screen 3

Technical Guide

CN-IC1-12

Title:

i-Controller Visograph Navigation REV.201.05

EXTERNAL 20 1-5JULY2021

Network Information

The Network Information screens to displaythe Firmware

Version, Expansion Board status (Online/ Offline),

Building controller status (Online/ Offline), i-Controller

Address (Modbus or BACnet), Baud Rate, IP Address, and

Parameter File version.

The Network Information screen displays the Flō i-

Controller IP address, and status of the connection to the

Building Management System (BMS). If the Flō i-

Controller is connected to the BMS the status will show

“Online”, otherwise, it will show “Offline” if the BMS is

offline or the i-Controller is not connected.

For units on a Modbus network, this screen displays the

Modbus address (configurable), and the Modbus baud

rate. To change the Modbus address:

1. Using the and buttons (T4 and T6

respectively) navigate to the value that you wish

to change.

2. Once the value is highlighted, press the (T5)

button and the value should blink.

3. Using the and buttons increase and

decrease the value as desired.

4. Once the desired value has been reached press

the button to set the value.

5. Once all changes have been completed, press the

(T1) button to return to the Main Menu.

Modbus Network

The Modbus and BACnet Network information screens

display the communication status, address and

parameter version.

Figure 45. Modbus Network Information screen 1

T1: Go to Main Menu

T4: Scroll Up/Increase Value

T5: Enter (Select and Set Value)

T6: Scroll Down/Decrease Value

T8: Network Options

BACnet Network

Figure 46. BACnet Network Information screen 1

Table of contents

Popular Controllers manuals by other brands

BRONKHORST

BRONKHORST FLOW-SMS Series instruction manual

Smarttech

Smarttech LPC-2.DI6 user manual

Emerson

Emerson Control Link Installation and operation manual

PowerTech

PowerTech MP3768 instruction manual

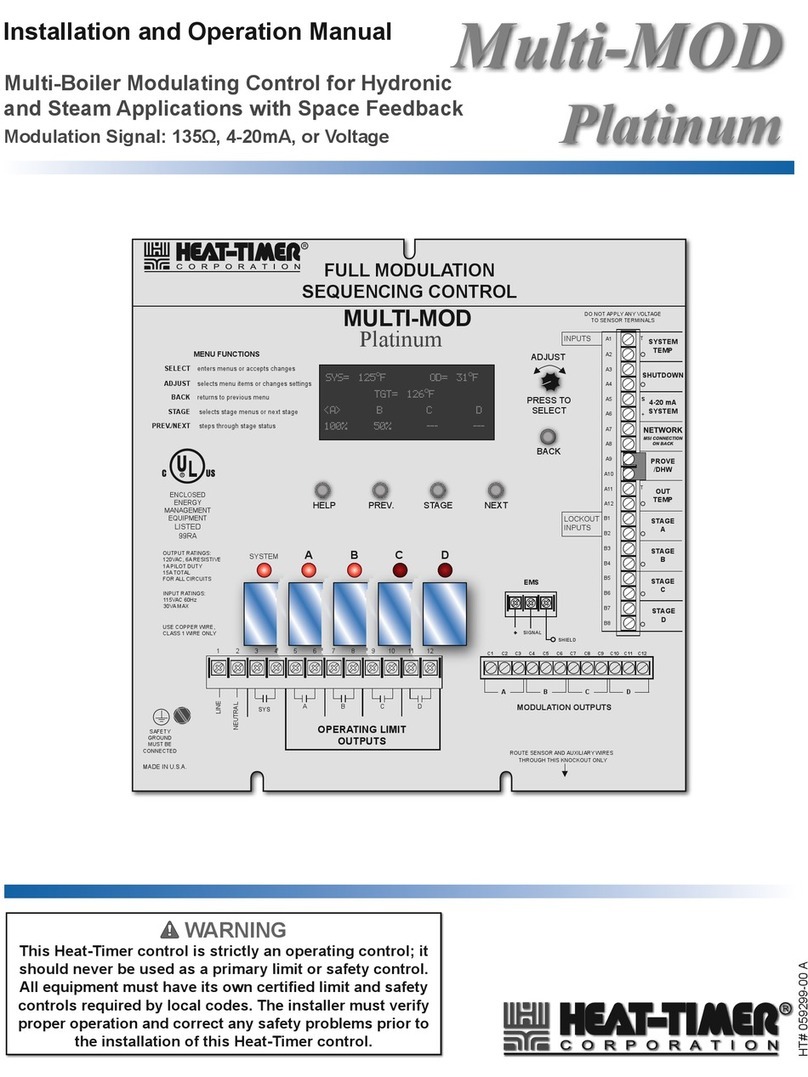

heat-timer

heat-timer Multi-MOD Platinum Installation and operation manual

Elsema

Elsema Eclipse MC240 Setup and Technical Information