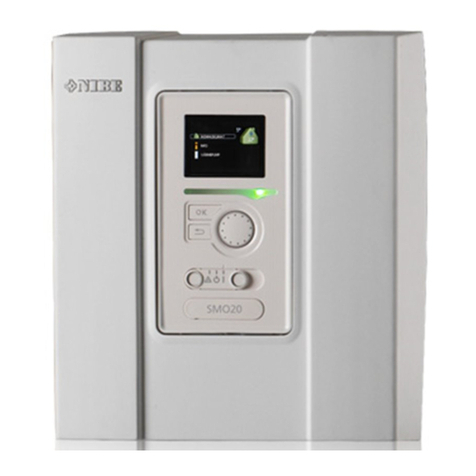

1NIBE SMO 10

General

System diagram ______________________________________ 3

Principle of operation _________________________________ 3

Abbreviations ________________________________________ 3

Front panel

Display______________________________________________ 4

Switch ______________________________________________ 5

Offset heating curve __________________________________ 5

Right keypad ________________________________________ 5

Left keypad__________________________________________ 5

Room temperature

Heating control system ________________________________ 6

Default setting _______________________________________ 6

Changing the room temperature manually _______________ 6

Setting with diagrams _________________________________ 7

Dealing with malfunctions

Low temperature or a lack of hot water __________________ 8

The hot water temperature does not reach the desired level

for ”Extra hot water” _________________________________ 8

High hot water temperature____________________________ 8

Low room temperature________________________________ 8

High room temperature _______________________________ 8

Switch position “ ”______________________________ 9

Alarm indications on the display _______________________ 10

Resetting the miniature circuit breakers _________________ 11

General information for the installer

Suspension _________________________________________ 12

Inspection of the installation __________________________ 12

Docking____________________________________________ 12

Changing menu type_________________________________ 12

Additional power without heat pump___________________ 12

Quick guide – menu setting additional power ____________ 12

Connection_________________________________________ 13

Docking – Hot water heating

Function ___________________________________________ 14

Connecting hot water heating_________________________ 15

Quick guide – menu settingsHot water heating___________ 15

Docking – Oil addition

Function ___________________________________________ 16

Connection oil addition_______________________________ 17

Quick guide – menu settingsOil addition ________________ 17

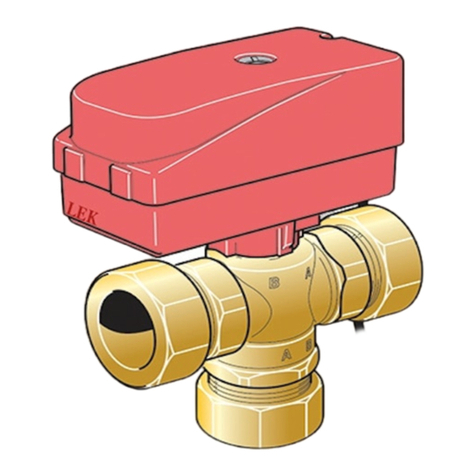

Docking – Immersion heater after

three way valve

Function ___________________________________________ 18

Connecting immersion heater after three way valve _______ 19

Quick guide – menu settings immersion heater

after three way valve_________________________________ 19

Docking – Exhaust air heat pump

Function ___________________________________________ 20

Connecting the exhaust air heat pump__________________ 21

Quick guide – menu settings when docking to

exhaust air heat pump _______________________________ 21

Docking – Pool heating

Function ___________________________________________ 22

Pool heating connection ______________________________ 23

Quick guide – menu settings pool heating _______________ 23

Docking – Gas boiler

Function ___________________________________________ 24

Connecting a gas boiler ______________________________ 25

Contents

Docking – Several heat pumps

Function ___________________________________________ 26

Quick guide – menu settingsseveral heat pumps__________ 26

Connecting several heat pumps________________________ 27

Docking – Extra shunt group

Function ___________________________________________ 28

Connecting extra shunt group _________________________ 29

Quick guide – menu settings extra shunt group __________ 29

Function description – Heating

Function ___________________________________________ 30

Quick guide – menu settings Heating ___________________ 31

Function description – Extra hot water

Function ___________________________________________ 32

Quick guide – menu settingsExtra hot water _____________ 32

Electrical connections

Screened 3 core cable between SMO 10

and a heat pump ___________________________________ 33

Connecting the outside sensor_________________________ 34

Connection of the flow and return line sensors___________ 34

Max boiler temperature/hot water heating_______________ 34

Load monitor _______________________________________ 35

External alarm ______________________________________ 35

Tariff ______________________________________________ 35

Terminal diagram ____________________________________ 36

Starting

Start-up with NIBE Air/water heat pump_________________ 38

Start-up without NIBE Air/water heat pump______________ 38

Menus to know _____________________________________ 38

Menu management

Changing parameters ________________________________ 39

Key lock ___________________________________________ 39

Quick movement ____________________________________ 39

Menu tree

Menu explanation

Main menus ________________________________________ 44

1.0 Hot water temp. _________________________________ 45

2.0 Supply temp. ____________________________________ 46

3.0 Supply temp. 2* _________________________________ 47

4.0 Outdoor temp. __________________________________ 48

5.0 Heat pump______________________________________ 48

6.0 Room temperature* ______________________________ 49

7.0 Clock __________________________________________ 49

8.0 Other adjustments _______________________________ 50

9.1.0 Heat pump settings _____________________________ 52

9.2.0 Add. heat settings ______________________________ 53

9.3.0 Operating settings. _____________________________ 54

9.4 Quick start ______________________________________ 56

9.5.0 Alarmlog______________________________________ 56

9.6.0 System Info____________________________________ 56

Technical specifications

Dimensions and setting-out coordinates_________________ 57

Component locations ________________________________ 58

List of components __________________________________ 59

Temperature sensor data______________________________ 59

Electrical circuit diagram ______________________________ 60

Accessories _________________________________________ 62

Enclosed kit ________________________________________ 63

Technical specifications _______________________________ 63