1. GENERAL SECURITY INFORMATION

1.1 APPLICATIONS

The employment of peristaltic pumps to transfer liquids or gases has many advantages:

thanks to its operating principle it is the only pump able to carry fluids without any direct

contact with the product.

A new tube for each product can be employed, avoiding heavy cleaning.

By using a peristaltic pump you can sterilize on-line the vessels connected with the tube

and sterilize the whole system.

The product is gently carried without stress, centrifugations or turbulent actions which

could damage it; this is an additional advantage of this pump.

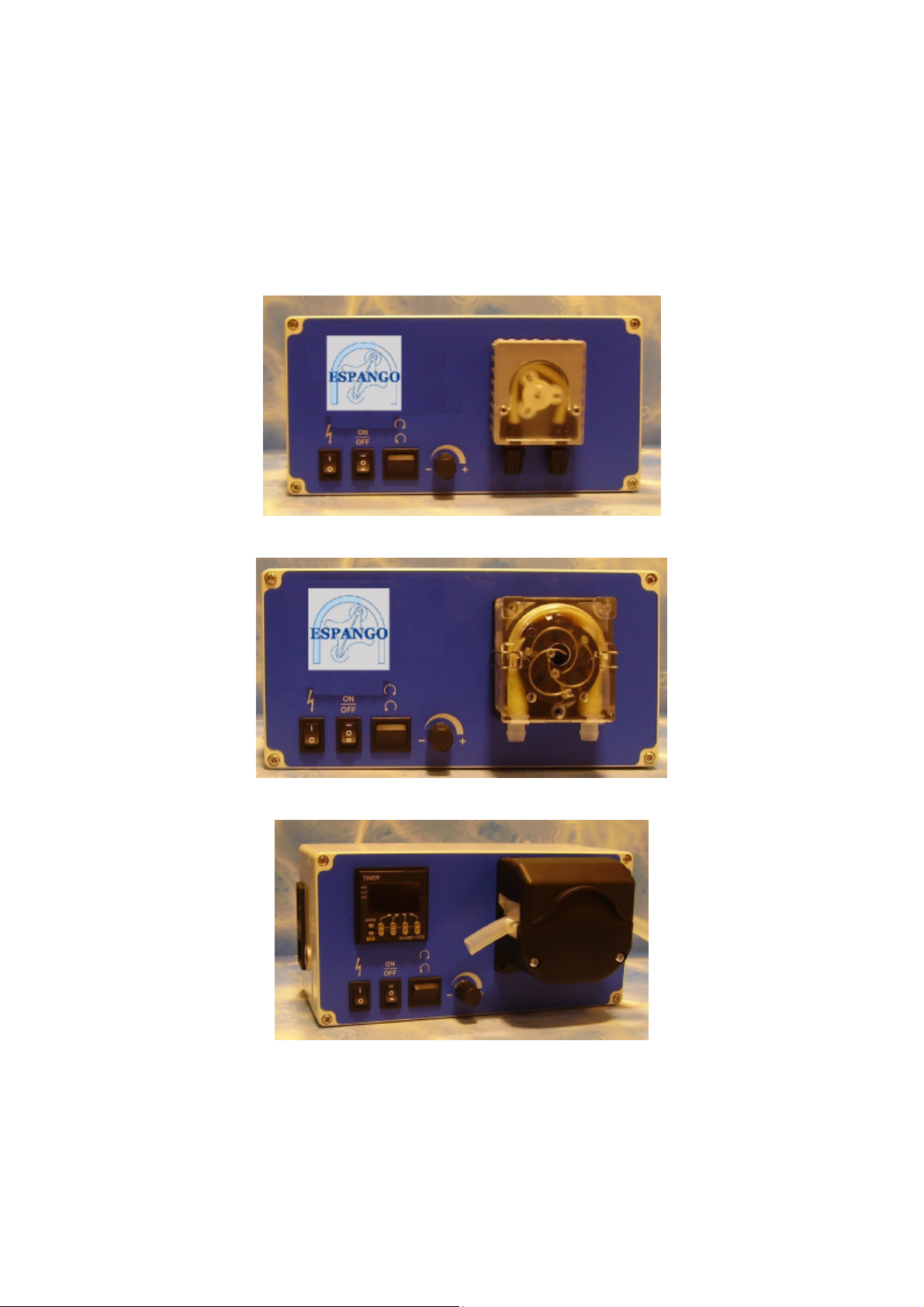

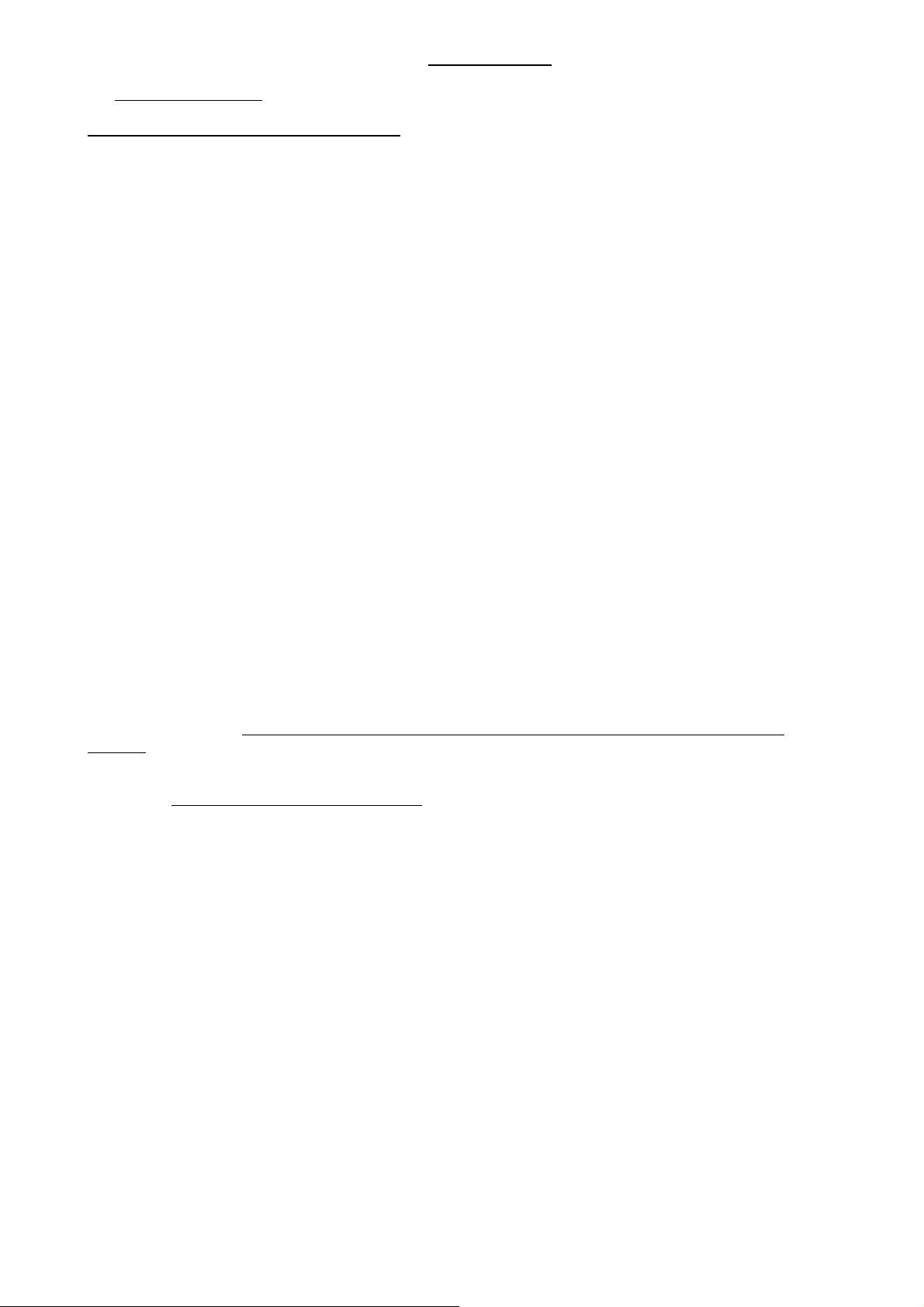

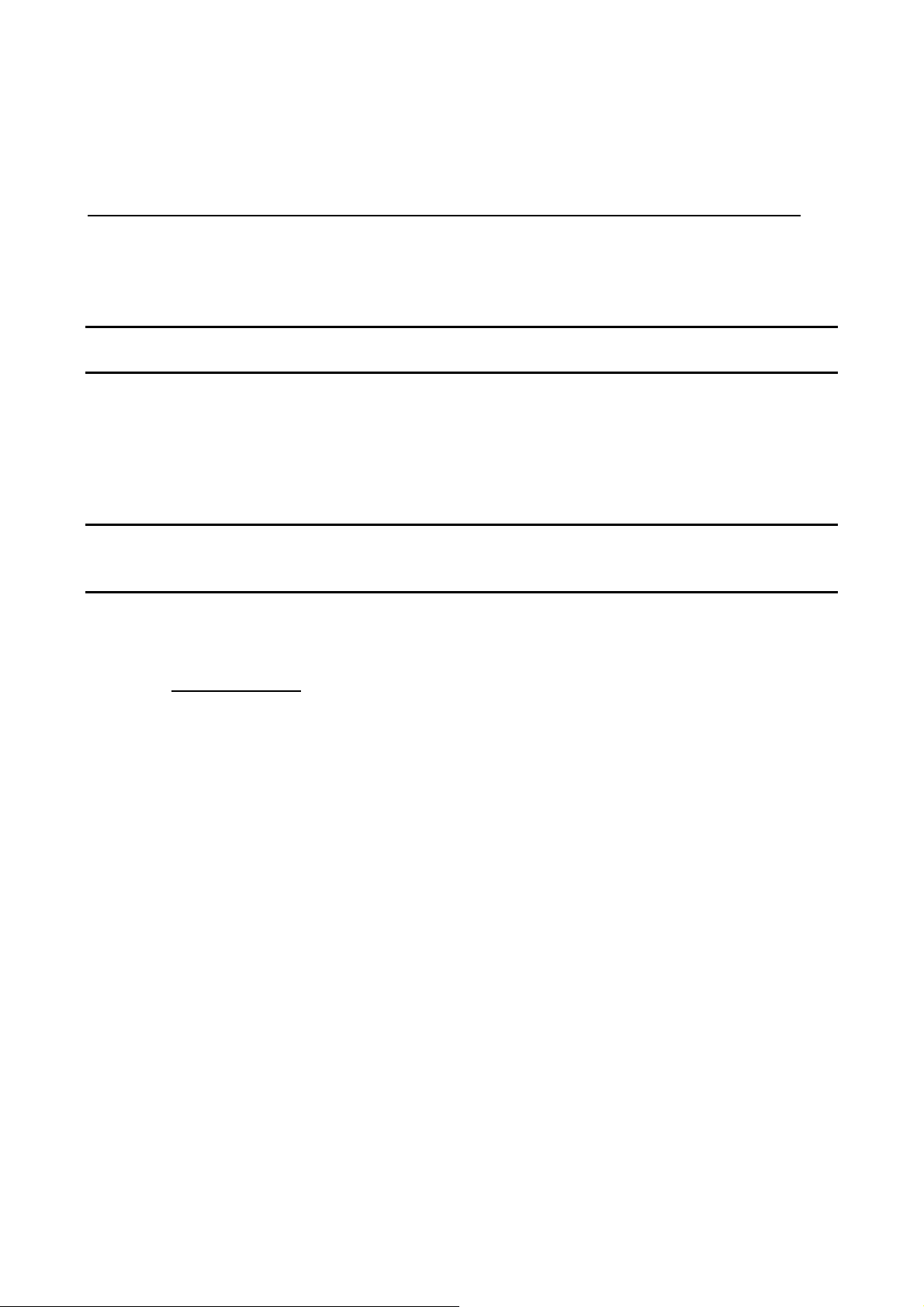

. The peristaltic pump IPL 10 is designed to be used in a laboratory or for industrial

purposes.

. The tube can be quickly replaced.

. The high rpm motor, coupled with a precise control system, guarantees an uniform

conveyance of the product.

. The speed of the pump IPL 10 is adjustable and it allows a precise control of the

pumped volumes.

. This pump is reversible. The rotation can be freely chosen. Even if the pump can run in

both rotation directions, it is better to use the “clockwise” one.

1.2 SAFETY

The safety –respect for people, environment and materials –mostly depends on the

behaviour of the employees who use the pump.

Please, carefully read this manual before starting to work with the pump. The respect of

our instructions will avoid errors which could be dangerous, especially concerning the

health and the environment.

When using this pump, the operator has always to refer to the present manual.

It has always to be available to all the people charged to use this pump.

We recommend to keep a copy of the manual close to the pump.

For safety reasons the equipment has always to be used by a qualified staff.

Before switching the pump on, please verify that the cable and the plug are not damaged;

in case they are, don’t connect the pump to the mains.

The voltage of the pump has always to be the same of the mains voltage.

Whatever action on the electric components has to be executed by qualified staff and the

pump has to be under security conditions (switched off, cable unplugged).

Only original parts and accessories must be used. We strongly discourage the employment

of not original spare parts, which can bring to unknown risks.

The characteristics and the safety of the pump can be granted only if all the required

controls, the maintenance and the repairs are executed by our authorized staff.

The manufacturer assumes no responsibility in case repairs are not executed by his

Technical Service or if not original parts or accessories should be used.

The manufacturer assumes no responsibility in case of misuse of the pump.