ESS Sfoam Dust Suppression 10 20/05/2020

Mechanical Installation

Install the SFoam Junior/Senior at ground level on a level site with good access to

the required services.

The SFoam Junior/Senior unit comes complete with Ø25 mm male screwed BSP

connections for the water and air lines and a Ø12 mm N.B. tube connection for the

chemical line.

It is recommended that the unit be situated as close as practicable to the chemical

storage tank, tote or drum. A flooded suction condition is preferred.

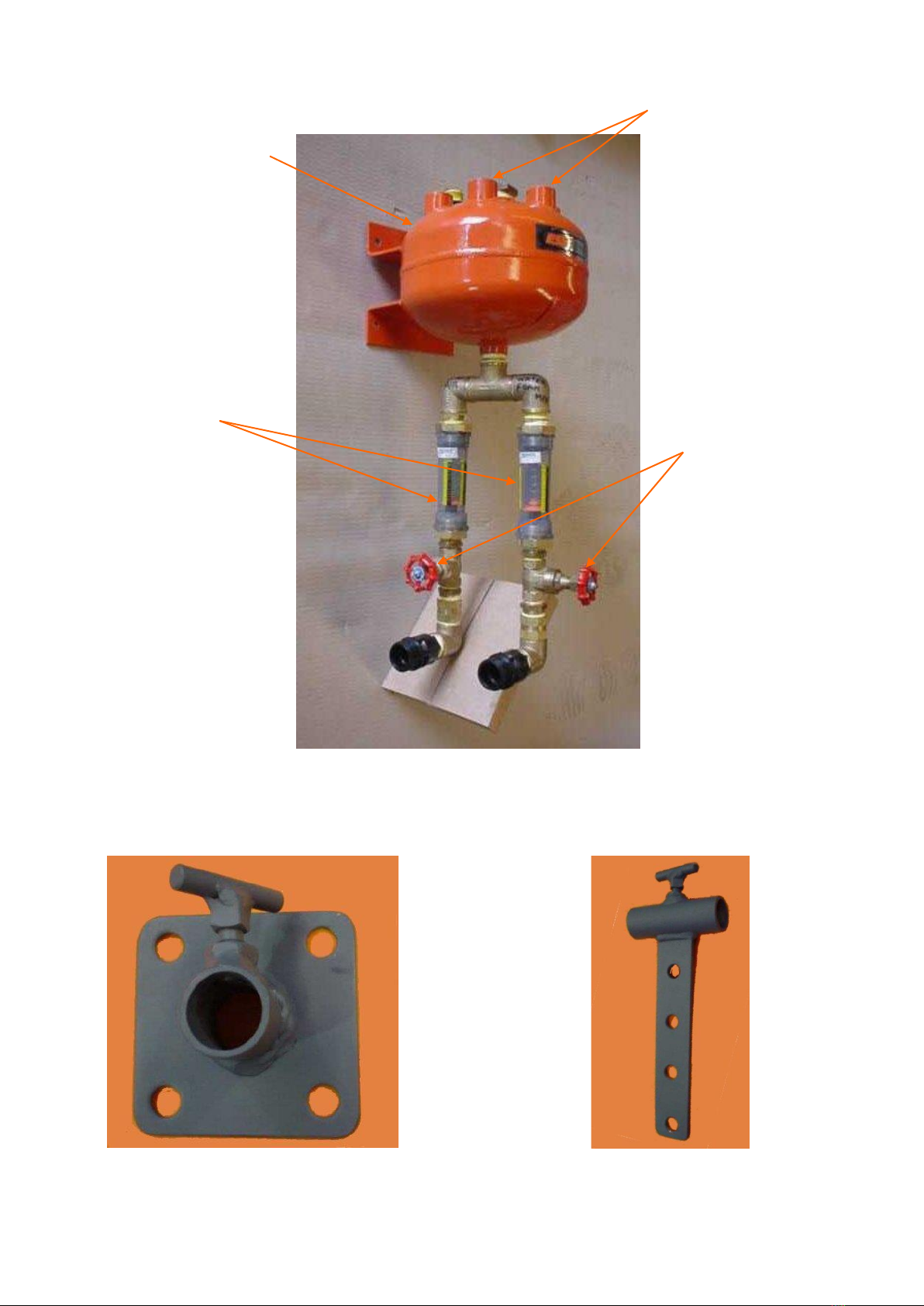

Each expansion chamber should be installed such that the foam delivery lines are

located at the top of the chamber and the solution and air inlets are located at the

bottom of the chamber. The expansion chambers should be located as close as

possible to the dose points.

Install a non-return valve to the air line on the inlet side of the expansion chamber.

When connecting the solution and air supply line to the expansion chambers, ensure

that the air line is connected to the Omega 510 flow meter and the solution line is

connected to the omega 505 flow meter. Note: It is recommended that each inlet

or delivery hose/pipe be a minimum of Ø20mm inside diameter with individual

foam delivery lines to be of lengths less that 15 meters.

Ensure that all pipe/hose lines are secured safely and tidily using weld-on double

pipe clamps or similar.

Connect the SFoam suction tube to the dosing feeder by unscrewing the securing

ferrule. For drums, fit the foot-valve to the end of the tube and place inside the drum.

For Bulki-Bins, a Camlock adapter must be attached to the container outlet and the

suction tube fits over the tail of the adaptor. For suction tube lengths greater than 2

metres, pre-fill the line with chemical to reduce delay at start-up. Note: The

maximum recommended suction tube length is 4 metres.

Select the desired solution concentration by turning the adjusting screw on the

dosing feeder and read the graduated scale. Note: DO NOT ADJUST SOLUTION

CONCENTRATION WHILE THE DOSING FEEDER IS OPERATING, THIS WILL

DAMAGE THE DOSING FEEDER.

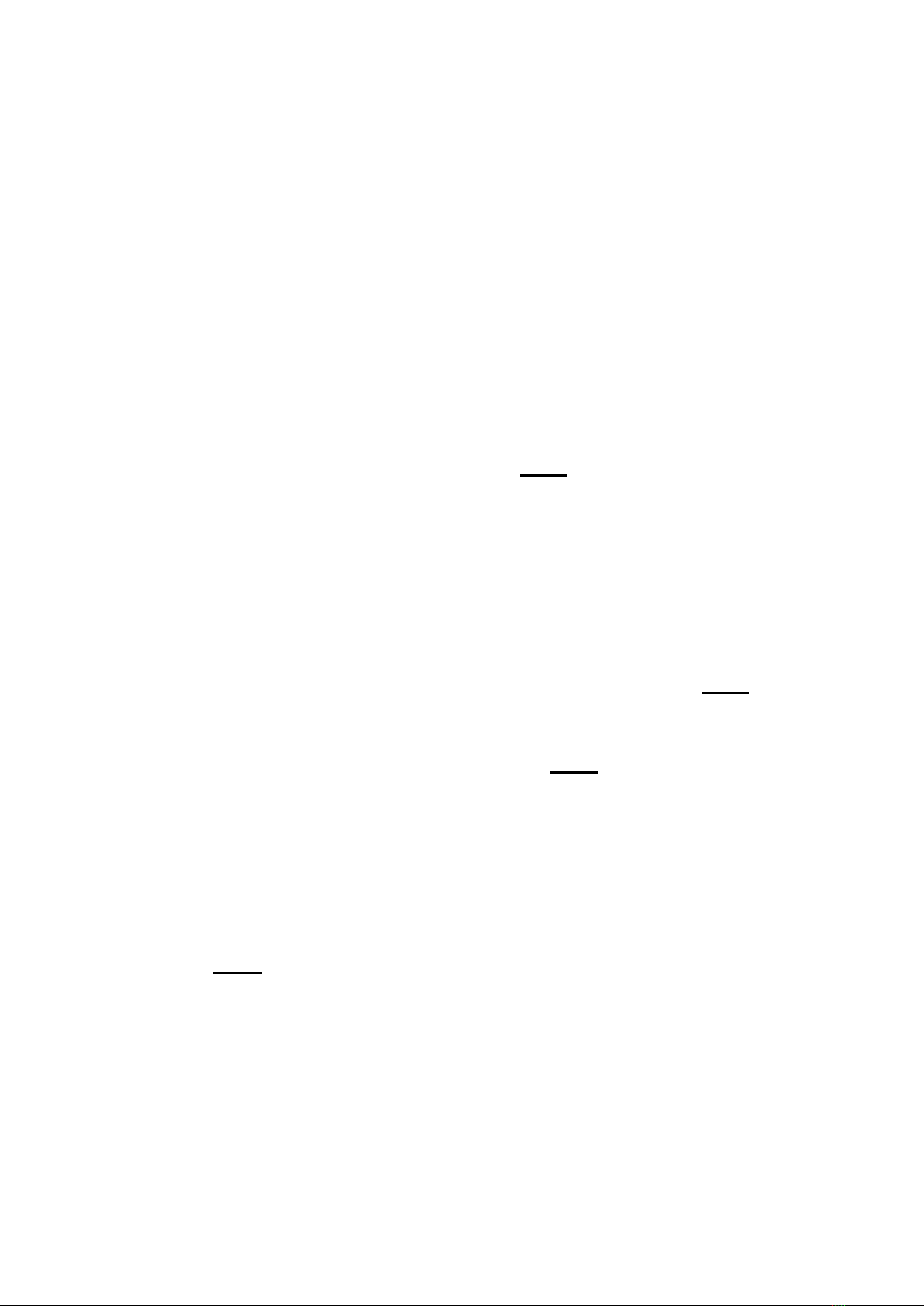

Refer to appendix A for details regarding the typical setup of dose points utilising the

various brackets and nozzle types available.

Electrical installation

Note: All electrical installation work should be undertaken by an electrician or

other suitable qualified electrical person.

The SFoam unit will accept 90 to 260Vac single phase power. Refer to the electrical

schematic in Appendix E for further details.

A 24Vdc field switch such as a proximity probe, ultrasonic detector or photoelectric

cell can also be used to automatically start/stop the SFoam unit. Such a device

should be connected across terminals 2 and 6. A volt free N.O. contact may also be

used. Refer to Appendix E for further details.