Esterline SOURIAU UTS LC Series User manual

ASSEMBLY INSTRUCTIONS

UTS LC Series

BT 304

3

Contents

Tool & Material .................................................... 4

UTS LC Component details ................................ 5

UTS LC Dimensions ............................................ 5

Assembly Instructions for

UTS1JC18LCN & UTS6JC18LCN ....................... 6

A - Cable preparation ....................................... 6

B - Backshell screwing for UTS1JC18LCN ........ 9

C - Backshell screwing for UTS6JC18LCN ........ 10

Assembly Instructions for UTS718LCN ............... 12

Cleaning & Inspection ........................................ 14

Safety Considerations ......................................... 15

UTS LC Series |BT304

4

UTS LC Series |BT304

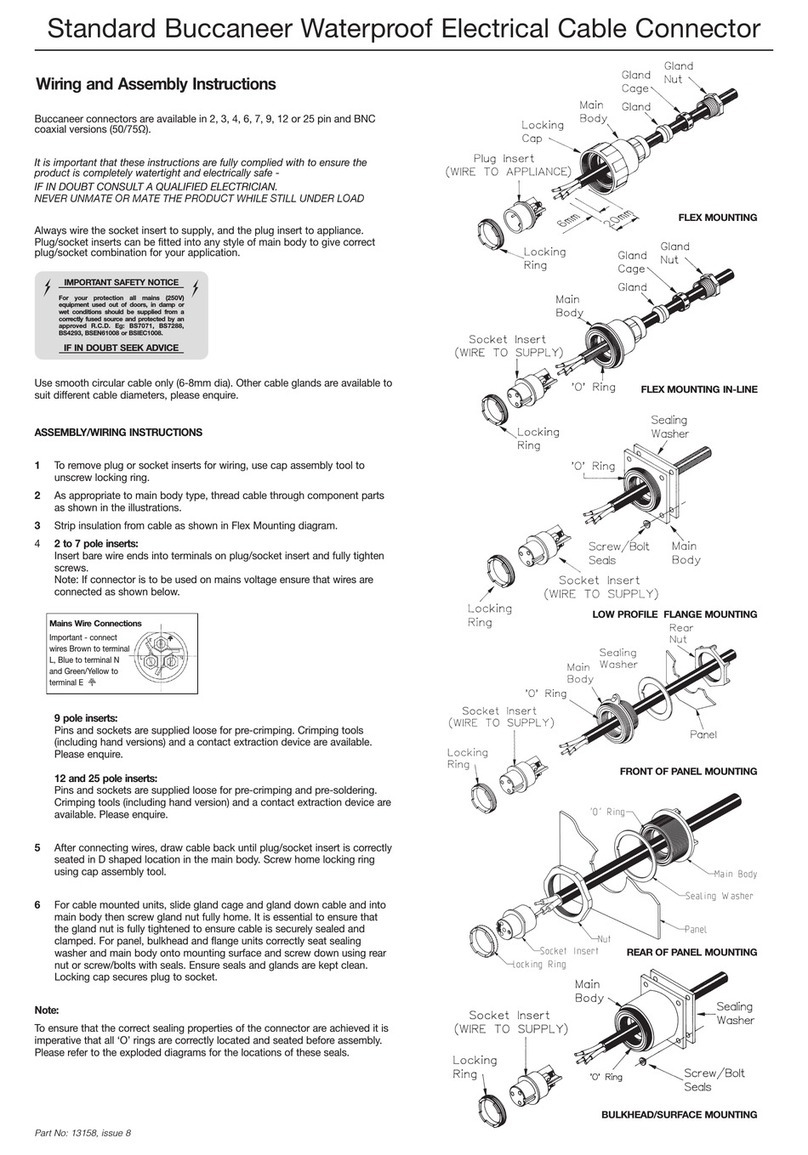

The following tools and materials are necessary for preparation, assembly, inspection, and maintenance of the connector and cable assembly.

Follow the tool instruction for operation and safety guidelines.

Tools

• Cable jacket strip tool

• Aramid Fiber Shears

• Fiber Stripping Tool

• 15 mm U–wrench

• 28 mm U–wrench

• 36.5 mm U–wrench

• Nipper (Oeticker Standard pincers with

straight jaws 14100082)

• Heat gun (optional)

Material

• LC contact: the UTS LC connector range can

adapt all kind of LC contact as dened per

IEC 61754-20

• Cable: the UTS LC connector range can

adapt all type of standard cable from 3 to

6mm outer diameter.

• Above these diameter limits some

adaptations are necessary

• Suggested glue: LOCTITE®480 PRISM

Instant Adhesive

Assembly Instructions

The assembly should be done in a dust free

and dried environment, in accordance with

ber optics good practices.

Make sure that all components are free from

contamination.

The assembly instruction is only a guideline

and the assembly/manipulations are under the

responsibility of the assembler. Any change of

product or material is under the responsibility

of the assembler.

Tool & Material

Accessories

Sealing Caps

Part number

UTS618DCG2

Part number

UTS18DCG2

For UTS1JC18LCN & UTS718LCN

For UTS6JC18LCN

OR OR

WITH

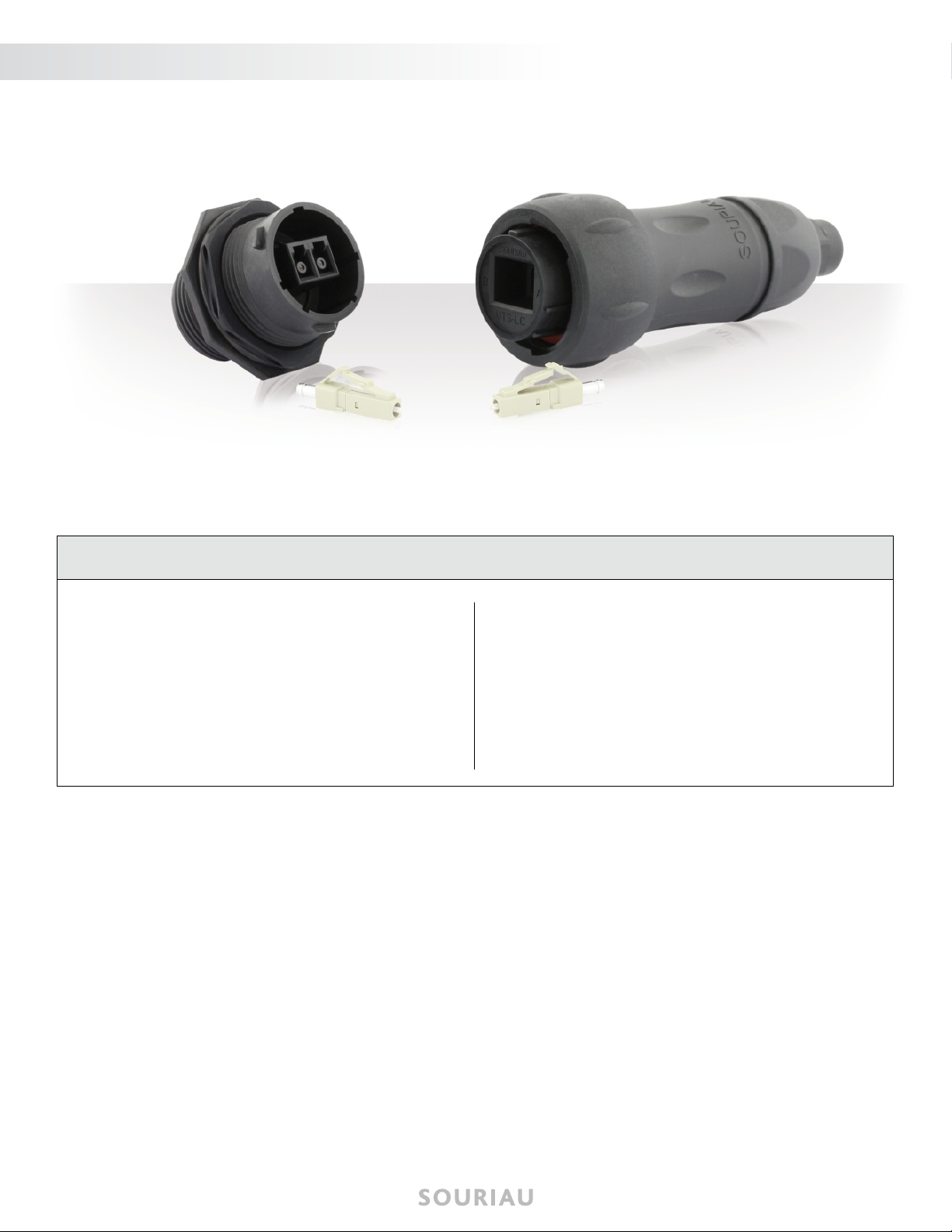

Receptacle Plug

Connector type Backshell Part number

Male insert Female insert

Free hanging receptacle Cable gland UTS1JC18LCN -

Plug Cable gland - UTS6JC18LCN

Jam nut receptacle Without UTS718LCN -

Connector Part Numbers

5

UTS LC Series |BT304

Dimensions

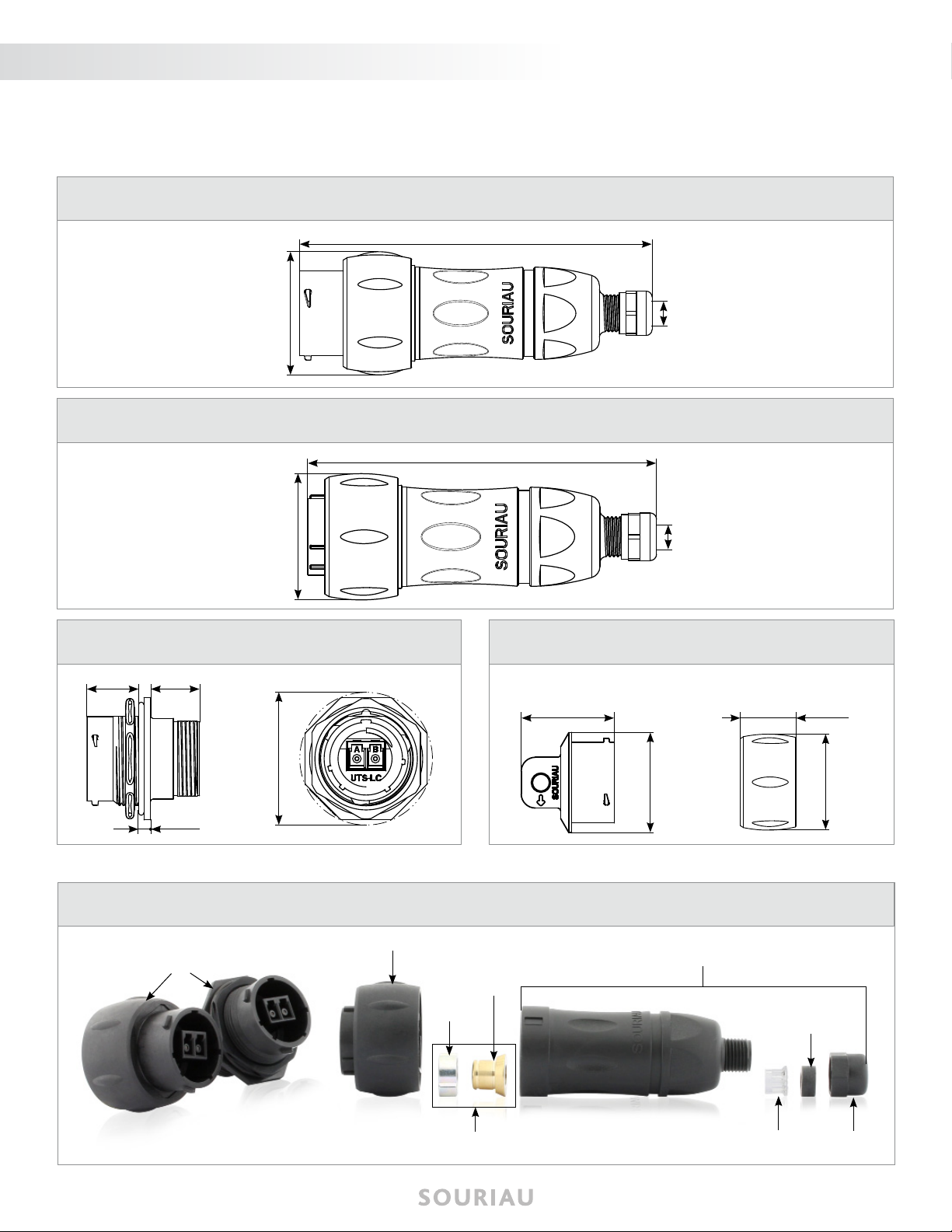

Free Hanging Receptacle -UTS1JC18LCN

122 max

Ø 42.5 max

Ø 6 max

Plug - UTS6JC18LCN

Ø 6 max

112 max

Ø 42.5 max

Sealing Caps

UTS18DCG2

for UTS1JC18LCN & UTS718LCN

UTS618DCG2

for UTS6JC18LCN

Jam nut receptacle - UTS718LCN

18.5 max 17.5 max

5 max

Ø 45.5 max

Plug Backshell

Tensile strength system

Ear

Claw Nut

Gasket

Crimp

support

Receptacles

UTS1JC18LCN, UTS6JC18LCN, UTS718LCN overview

Ø 35.7 max

34 max

Ø 42.5 max

24 max

6

UTS1JC18LCN & UTS6JC18LCN

Cable preparation

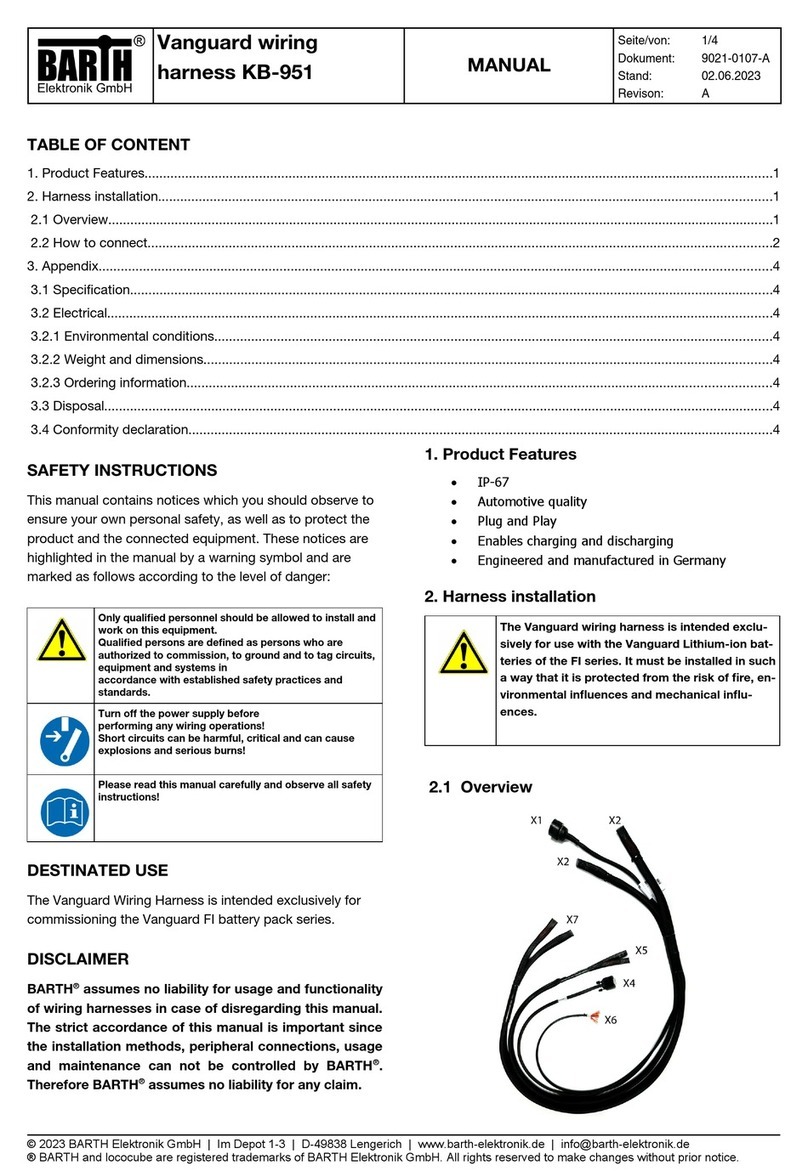

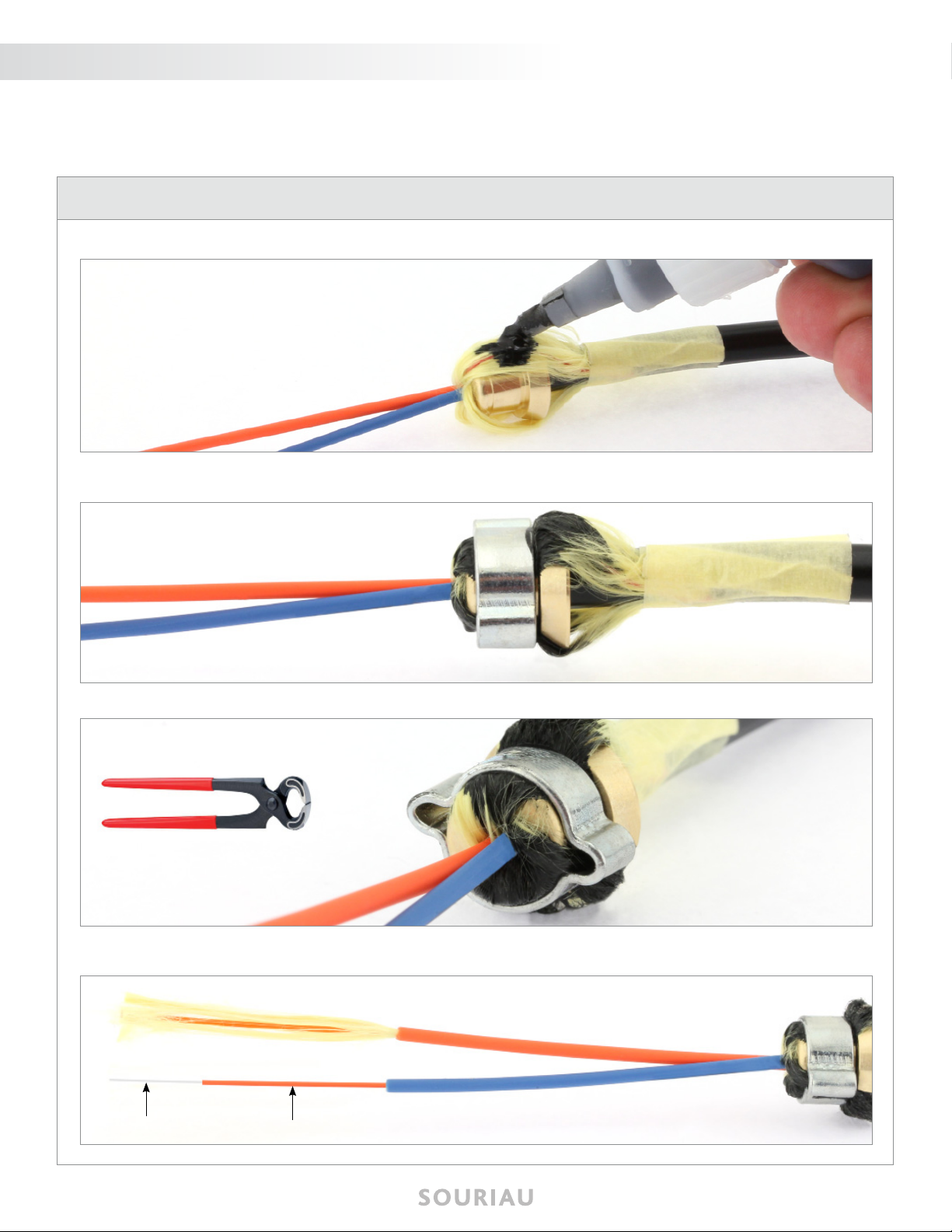

1.Slide the backshell onto the cable allowing 50 cm at the end of the cable for stripping the cable. Make sure to orient each component as

shown in the UTS LC Component details section.

2.Using the cable jacket strip tool, strip the jacket to the dimension given in gure below, exposing the kevlar strength members and ber.

3.Using the shears, trim the kevlar strength members to the length given in gure below.

4.Fix the Kevlar using an adhesive tape on the “individual bers” to facilitate the insertion of the crimp support.

5.Slide the crimp support (large diameter end rst) over the bers and the kevlar strength members until it bottoms on the cable outer jacket.

6.Separate the kevlar strength members in two groups. Use an adhesive tape to x the kevlar strength members on the jacket.

Fiber tube protection: 100±1 mm

Kevlar: 40±1 mm

UTS LC Series |BT304

Assembly Instructions

7

UTS1JC18LCN & UTS6JC18LCN (Continued)

8.Before the instant adhesive begins to harden,quickly slide the ear clamp over the ber, orient the Clamp according the picture.

Push the strength members back over the clamp until it bottoms on the rear ange of the support.

7.Apply the instant adhesive on the ber and cover the crimp support. (e.g. Loctite 480 PRISM).

9.Crimp the both ear of the Clamp using the Nipper. Remove the kevlar strength members using using the shears.

Check the good crimping by pulling manually.

10.Strip the ber buffer according to your LC supplier recommendations and make sure to reach the nal desired lengths for the individual

bers as described on the pictures below.

Bare ber Fiber buffer

UTS LC Series |BT304

8

UTS LC Series |BT304

UTS1JC18LCN & UTS6JC18LCN (Continued)

Assembly Instructions (Continued)

11.Terminate the LC contact on the ber according to your supplier instruction for gluing, cliving and polishing.

12.Fix the cable in a tool to avoid the rotation.

Free hanging receptacle UTS1JC18LCN

Free hanging receptacle UTS1JC18LCN: 95±1 mm

Plug UTS6JC18LCN: 85±1 mm

Plug UTS6JC18LCN

9

UTS LC Series |BT304

UTS1JC18LCN & UTS6JC18LCN (Continued)

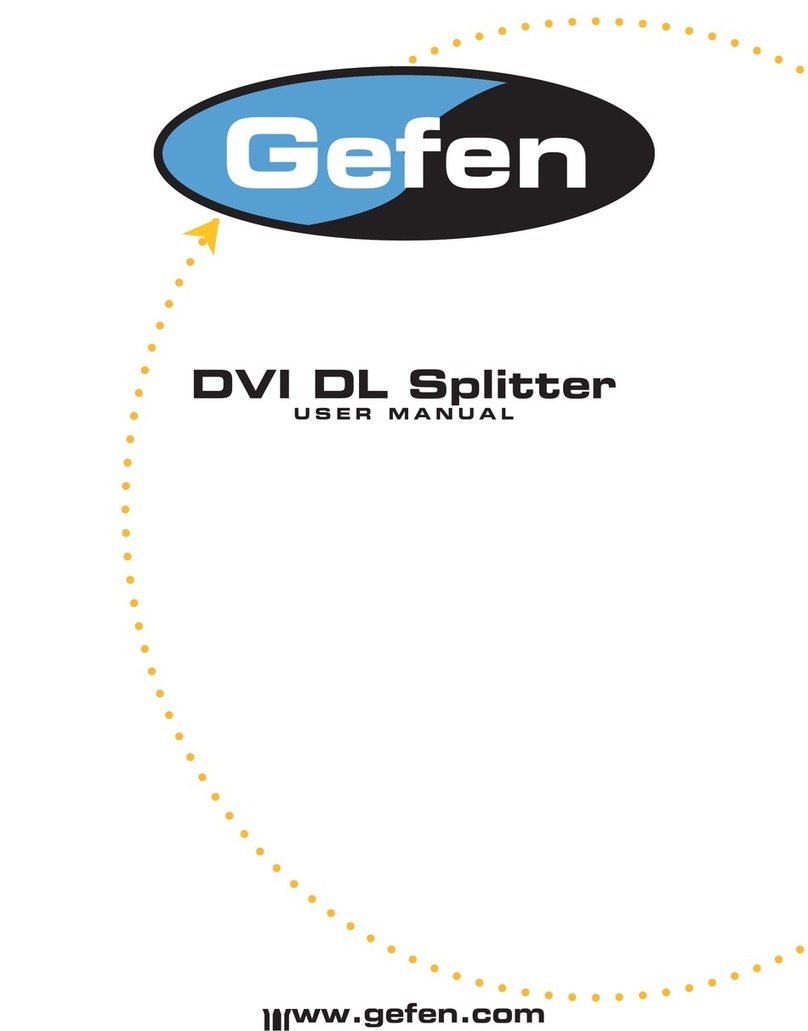

Backshell screwing for UTS1JC18LCN

13.Plug the two LC: Make sure that each LC contact is in the right cavity A or B.

You need to hear a “click”.

1. Slide the blackshell and screw it using a 28 mm U-wrench. Tightened the backshell with a 4 Nm torque.

2. Control: Pull on the cable to ensure that the retention system bottoms in the backshell.

3. Screw the head nut using a 15 mm U-wrench. Tightened the head nut with a 2 Nm torque.

10

1.You need a receptacle counter-part. Orient the polarization keys before you start mating the connectors.

2.Coupling plug with receptacle

3.Slide the blackshell and screw it using a 28 mm U-wrench. Tightened the backshell with a 4 Nm torque.

4.Control: Pull on the cable to ensure that the retention system bottoms in the backshell.

UTS LC Series |BT304

Backshell screwing for UTS6JC18LCN

Assembly Instructions (Continued)

11

Use the caps, UTS618DCG2 for plug or UTS18DCG2 for receptacle to protect the LC contacts from surrouding contamination.

You need to hear a “click”.

5.Screw the head nut using a 15 mm U-wrench. Tightened the head nut with a 2 Nm torque.

UTS LC Series |BT304

Backshell screwing for UTS6JC18LCN (Continued)

Recommendation

12

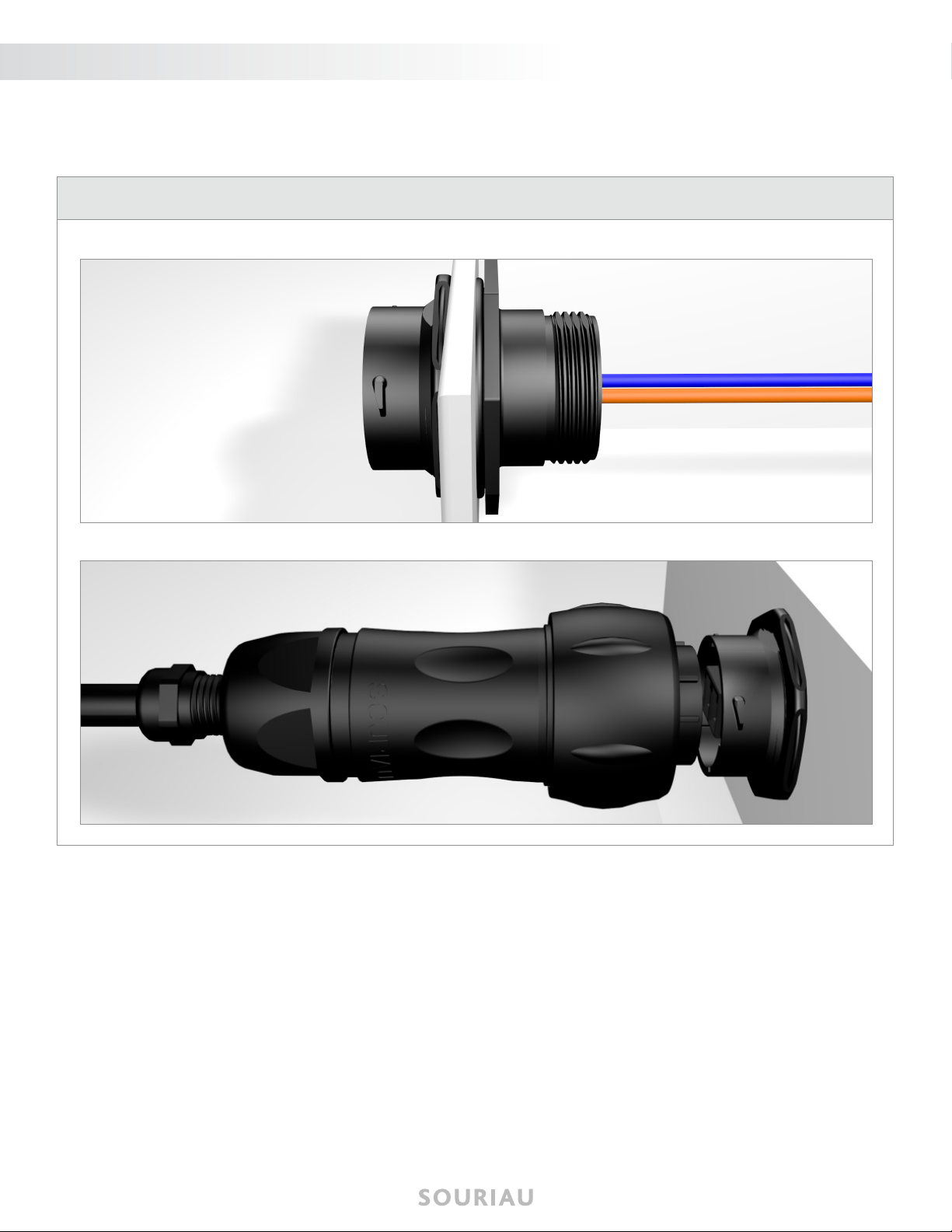

4.Seat o-ring, place receptacle in the panel cut-out.

O-ring

UTS718LCN

Jam nut

Panel thickness:

3.2mm max

30.35 mm

31.85 mm

1.Strip the ber buffer according to your LC supplier recommendations and make sure to reach the nal desired lengths for the individual

bers as described on the pictures below.

Bare ber Fiber buffer

2.Terminate the LC contact on the ber according to your supplier instruction for gluing, cliving and polishing.

3.Plug the two LC in the receptacle. Make sure that each LC contact is in the right cavity A or B.

You need to hear a “click”.

UTS LC Series |BT304

Assembly Instructions for UTS718LCN

Assembly Instructions (Continued)

13

5.Tightened the jam nut with a torque of 5 Nm, using a 36.5 mm U- wrench.

6.Coupling.

UTS LC Series |BT304

Assembly Instructions for UTS718LCN (Continued)

14

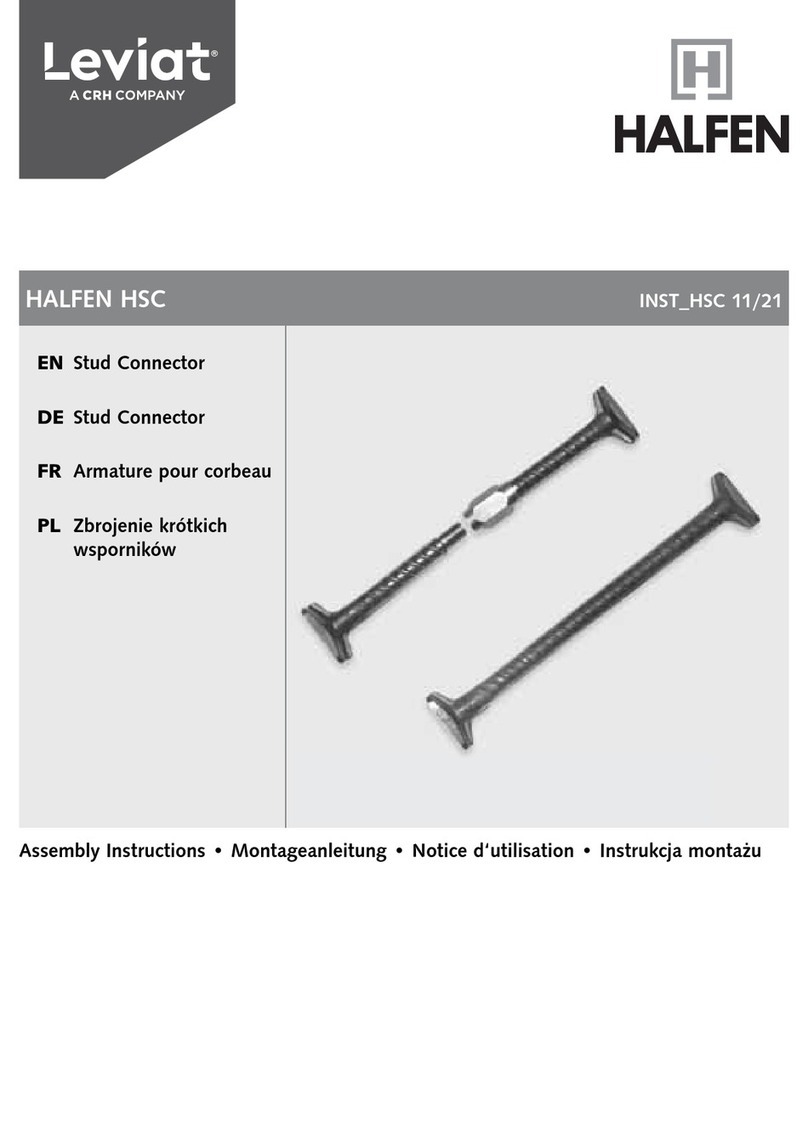

Cleaning and visual inspection of a termini endface is part of the good practices for ber optics.

This is necessary to ensure the good optical performances of an LC contact inside a UTS LC connector.

Please note that most of the standard inspection and cleaning tool on the market can be used for maintenance of an LC contact mounted in an

UTS LC connector.

1 Inspection

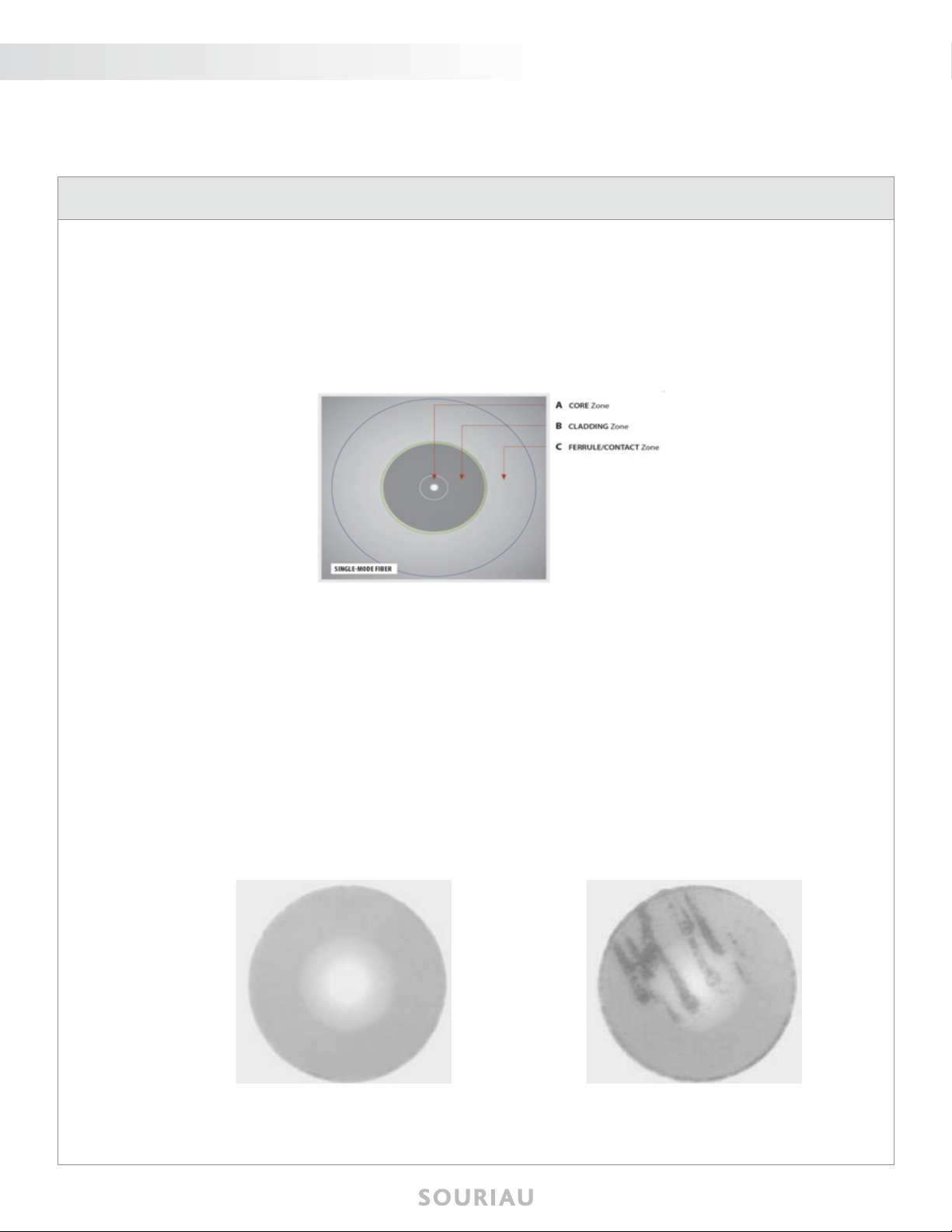

A- Use a ber optic video probe (magnication X200 minimum) to inspect the termini endface for contamination,

chips, pits, scratches and shatters in the core and in the inner of the cladding (see gure below).

2 Cleaning

A- Use a lint free tip moistened with 99% reagent grade isopropyl alcohol or optical quality cleaning uid to clean

the termini endface. Always wipe in one direction, not back and forth.

B- Dry the termini endface with a dry tip.

C- Re-inspect the termini endface with a ber optic video probe (Magnication x200 minimum) and verify that

the contamination has been removed.

D- If the contamination is still present then repeat step A & B.

E- If after repeated attempts, the contamination is still present and cannot be removed like minor scratches, chips

or pits then re-polish the optical contact (refer to the LC supplier instruction).

B- If dirt, debris or other surface contamination is identied then clean (see below).

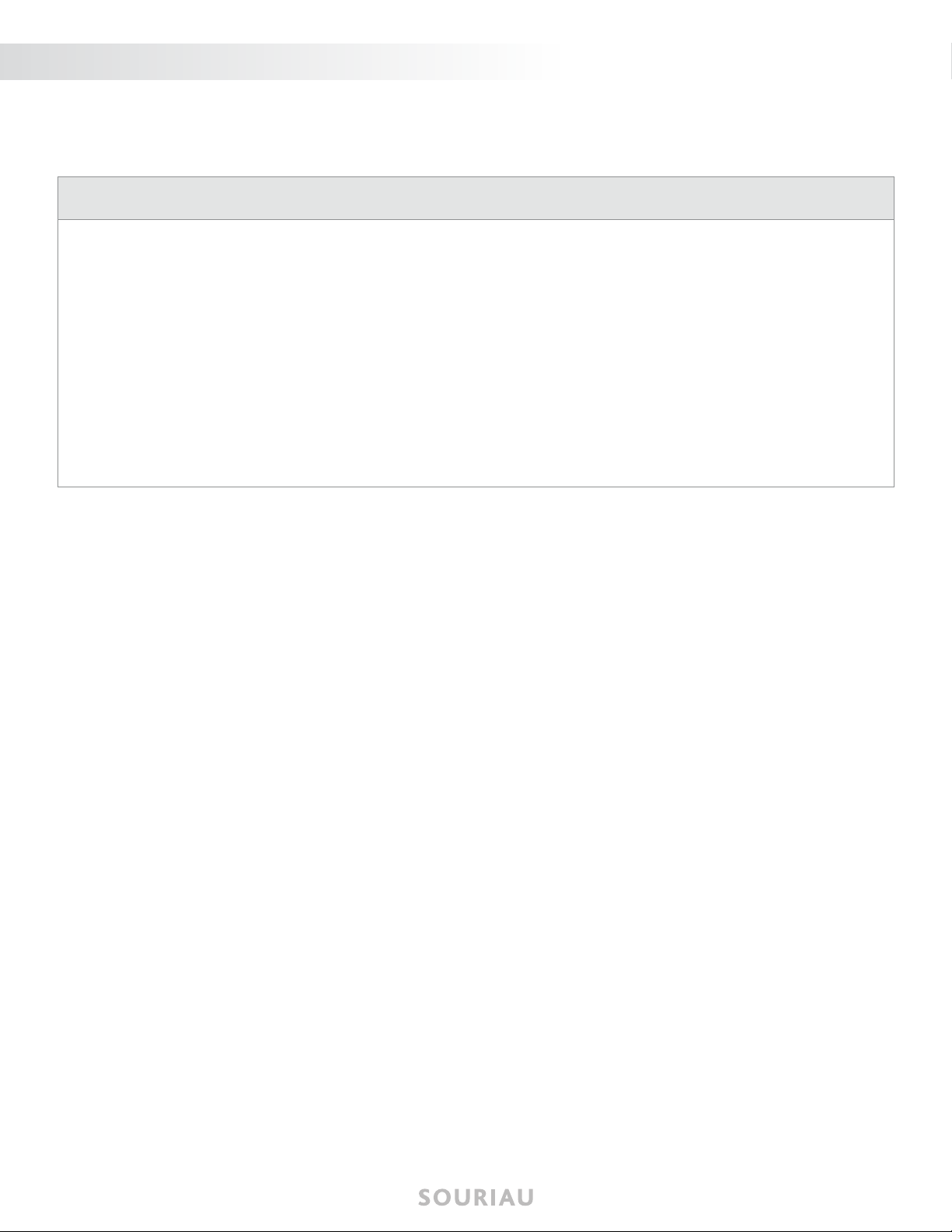

E.g. Magnication X 400 of two multimode bers

For more details, please refer to the acceptance criteria and cleaning procedures dened by IEC for multimode or singlemode connector

termini endface

Clean and good termini endface Contaminated or scratched termini endface

UTS LC Series |BT304

Cleaning & Inspection

Maintenance

15

A- Safety glasses to protect your eyes from accidental injury are strongly recommended when handling chemicals and cutting bers.

Pieces of glass ber are very sharp and can damage the cornea of the eye.

B- Glue

Glue may cause eye and skin irritation. Avoid contact with eyes, skin or clothing. Avoid prolonged or repeated breathing of vapor.

Use with adequate ventilation.

C- Fiber Precautions

Cleaved glass bers are very sharp and can pierce the skin easily. Do not let cut pieces of ber stick to your clothing or drop in the work

area where they can cause injury later. Use tweezers to pick up cut or broken pieces of the glass bers and place them in a debris container.

Keep your work area clean.

D- Laser Precautions.

Laser light is invisible and can damage your eyes. Never look into the end of a ber which may have a laser coupled to the opposite end.

UTS LC Series |BT304

Safety glasses

Safety Considerations

www.souriau-industrial.com

INDUTSLCBT01 © Copyright SOURIAU 2014 - SOURIAU is a registered trademark

All information in this document presents only general particulars and shall not form part of any contract. All rights reserved to SOURIAU for changes without prior notication or public announcement. Any duplication is prohibited, unless approved in writing.

This manual suits for next models

3

Table of contents

Other Esterline Cables And Connectors manuals

Popular Cables And Connectors manuals by other brands

Philips

Philips SWA2529 Specifications

Farnell

Farnell TRC-8543 manual

Philips

Philips SWV3433W Specification sheet

Datalogic

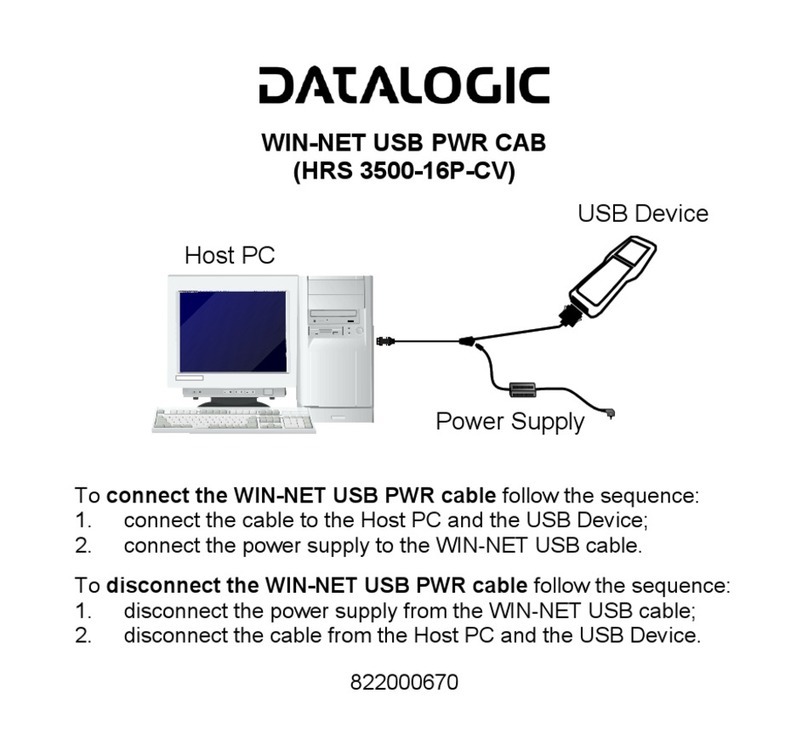

Datalogic Win-Net Vehicle PWR Cab HRS 3500-16P-CV quick start guide

Staubli

Staubli KBT21/M40-C Series Assembly instructions

Speaka Professional

Speaka Professional 1497182 operating instructions