Etabeta electronics JNR 90L BEAM G User manual

The following points have to be considered during the inspection:

1) All screws for installing the devices or parts of the device have to be tightly connected

and must not be corroded.

2) There must not be any deformations on the housing, color lenses, fixations and

installation spots (ceiling, suspension, trussing).

3) Mechanically moved parts must not show any traces of wearing and must not rotate with

unbalances.

4) The electric power supply cables must not show any damage, material fatigue or sediments.

Further instructions depending on the installation spot and usage have to be adhered by a

skilled installer and any safety problems have to be removed.

In order to make the lights in good condition and extend the life time, we suggest a regular

cleaning to the lights.

1) Clean the inside and outside lens each week to avoid the weakneness of the lights due to

accumulation of dust.

2) Clean the fan each week.

3) A detailed electric check by approved electrical engineer each three month, make sure

that the circuit contacts are in good condition, prevent the poor contact of circuit from

overheating.

We recommend a frequent cleaning of the device. Please use a moist, lint- free cloth. Never

use alcohol or solvents.

There are no serviceable parts inside the device. Please refer to the instructions under

“Installation instructions”.

Should you need any spare parts, please order genuine parts from your local dealer.

MAINTENANCE AND CLEANING

10

Disconnect from mains before starting maintenance operation.

CAUTION

JNR 90L BEAM G

JNR-8124G

PR LIGHTING LTD.

http://www.pr-lighting.com

1582 Xingye Avenue, Nancun Panyu

Guangzhou, 511442 China

TEL: +86-20-3995 2888

.01.

If the device has been exposed to temperature changes due to environmental changes,

do not switch it on immediately. The arising condensation could damage the device.

Leave the device switched off until it has reached room temperature.

This device falls under protection-class I. Therefore it is essential that the device be

earthed.

The electric connection must carry out by qualified person.

The device shall only be used with rate voltage and frequency.

Make sure that the available voltage is not higher than stated at the end of this manual.

Make sure the power cord is never crimped or damaged by sharp edges. If this would

be the case, replacement of the cable must be done by an authorized dealer.

Always disconnect from the mains, when the device is not in use or before cleaning it.

Only handle the power cord by the plug. Never pull out the plug by tugging the power

cord.

During initial start-up some smoke or smell may arise. This is a normal process and

does not necessarily mean that the device is defective, it should decrease gradually.

Please don't project the beam onto combustible substances.

Fixtures cannot be installed on combustible substances, keep more than 50cm

distance with wall for smooth air flow, so there should be no shelter for fans and

ventilation for heat radiation.

If the external flexible cable or cord of this luminaire is damaged, it shall be exclusively

replaced by the manufacturer or his service agent or a similar qualified person in order

to avoid a hazard.

This device has left the factory in perfect condition. In order to maintain this

condition and to ensure a safe operation, it is absolutely necessary for the user to

follow the safety instructions and warning notes written in this user manual.

CAU T I O N

Becareful with your operations.With a dangerous voltage you cansuffer a

dangerous electric shock when touching wires!

IMPORTANT

Damages caused by the disregard of this user manual are not subject to warranty.

The dealer will not accept liability for any resulting defects or problems.

SAFETY INSTRUCTIONS

1

.10.

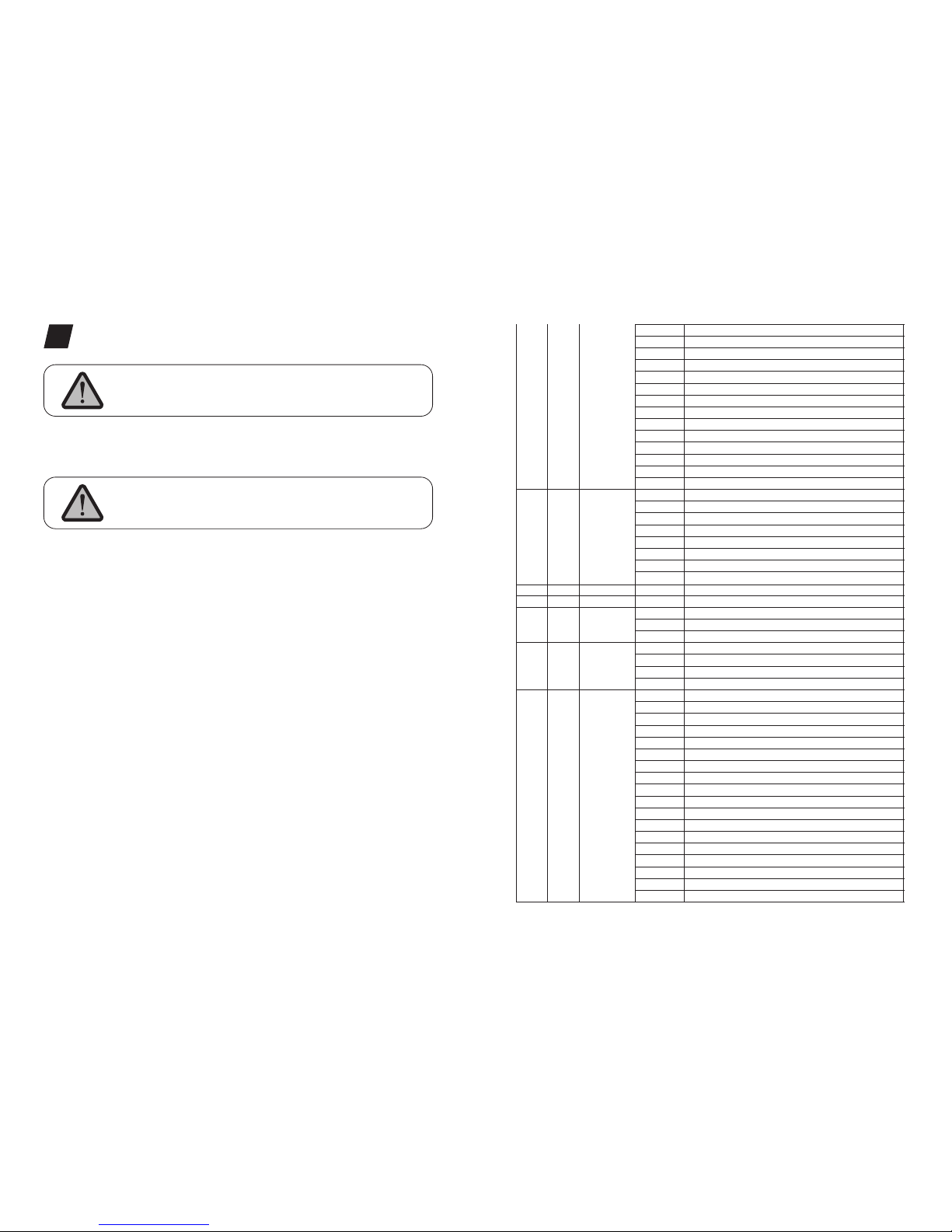

Gobo 5 shake slow to fast

Gobo 6 shake slow to fast

Gobo 7 shake slow to fast

Gobo 8 shake slow to fast

Gobo 9 shake slow to fast

Gobo 10 shake slow to fast

Gobo 11 shake slow to fast

Gobo 12 shake slow to fast

Gobo 13 shake slow to fast

Gobo 14 shake slow to fast

Gobo 15 shake slow to fast

Gobo 16 shake slow to fast

Gobo 17 shake slow to fast

Rot. gobo wheel cont. rotation slow to fast

Shutter closed

Shutter open

Strobe effect slow to fast

Shutter open

Pulse-effect in sequences slow to fast

Shutter open

Random strobe effect slow to fast

Shutter open

Dimmer 0%...100%

In(near)to out(far)

OFF

ON

Rotating from slow to fast

Max to min speed

Blackout by movement

Blackout by all wheel changing

No function

No function

No function

No function

No function

All motor reset

Scan motor reset

Colors motor reset

Gobo motor reset

Shutter&Dimmer motor reset

Other motor reset

Internal program 1

Internal program 2

Internal program 3

Internal program 4

Internal program 5

Internal program 6

Internal program 7

Internal sound program 1

122-129

130-137

138-145

146-153

154-161

162-169

170-177

178-185

186-193

194-201

202-209

210-217

218-225

226-255

0-31

32-63

64-95

96-127

128-159

160-191

192-223

224-255

0-255

0-255

0-5

6-127

128-255

0-225

226-235

236-245

246-255

0-19

20-29

30-39

40-79

80-84

85-87

88-90

91-93

94-96

97-99

100-119

120-139

140-159

160-179

180-199

200-219

220-239

240-255

Shutter

Dimmer

Focus

Prism

Speed

pan/tilt

Special

function

5

6

7

8

10

9

7

8

9

10

12

11

.02.

JNR 90L BEAM G

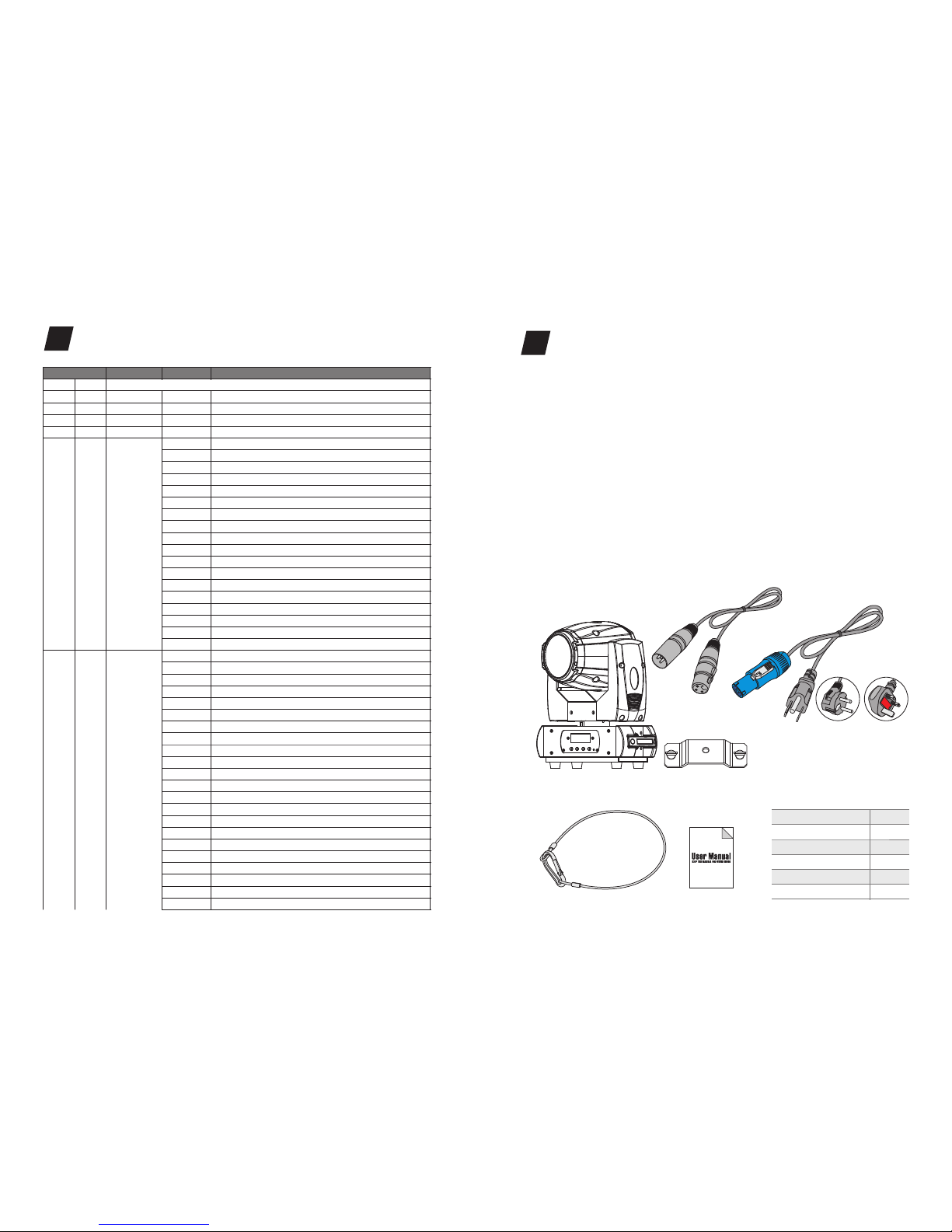

Signal Cable

Power Cable

Hanging Kit

Safety Cable

User Manual

1PC

1PC

1PC

1PC

1PC

1PC

①

②

③

④

⑤

⑥

Thank you for choosing our JNR 90L BEAM G. For your own safety, please read this

manual before installing the device. This manual covers the important information on

installation and applications. Please install and operate the fixture with following

instructions. Meanwhile, please keep this manual well for future needs.

The JNR 90L BEAM G is made of a new type of high temperature strength of

engineering plastics and cast aluminum casing with nice outlook. The fixture is

designed and manufactured strictly following CE standards, complying with

international standard DMX512 protocol. It’s available independently controlled and

linkable with each other for operation. And it is applicable for large-scale live

performances, theater, studio, nightclubs and discos.

The JNR 90L BEAM G adopts a 90W 7500K white LED lamp which features high

brightness and stability. Please carefully unpack it when you receive the fixture and

check whether it is damaged during the transportation. And please check whether the

following items are included inside the box:

UNPACKING

2

①

②

④

⑤⑥

③

Euro Standard UK Standard

USA Standard

OPTIONAL

DMX CHANNELS

9

.09.

0-255

0-255

0-255

0-255

0-7

8-15

16-23

24-31

32-39

40-47

48-55

56-63

64-71

72-79

80-87

88-95

96-103

104-111

112-127

128-189

190-193

194-255

0-4

5-9

10-14

15-19

20-24

25-29

30-34

35-39

40-44

45-49

50-54

55-59

60-64

65-69

70-74

75-79

80-84

85-89

90-97

98-105

106-113

114-121

PAN movement

Fine control of movement

movement

Fine control of movement

Open / White

Color 1

Color 2

Color 3

Color 4

Color 5

Color 6

Color 7

Color 8

Color 9

Color 10

Color 11

Color 12

Color 13

Color 14

Forwards rainbow effect from fast to slow

Color rotation stop

Backwards rainbow effect from slow to fast

Open

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Gobo 8

Gobo 9

Gobo 10

Gobo 11

Gobo 12

Gobo 13

Gobo 14

Gobo 15

Gobo 16

Gobo 17

Gobo 1 shake slow to fast

Gobo 2 shake slow to fast

Gobo 3 shake slow to fast

Gobo 4 shake slow to fast

PAN

TILT

TILT

Mode/Channel

Function Values Description

8b

1

2

3

4

16b

1

2

3

4

5

6

PAN

PAN-fine

TILT

TILT-fine

Color wheel

Gobo

wheel

.03.

Features

FEATURES & SPECIFICATIONS

3

Static gobos Colors

•

• 50000 hours life span and low power consumption

• 8/16 bit smooth and precise resolution for PAN/TILT movement

• 360°/540°/630° PAN and 90°/180°/270° TILT movement

• High resolution and high definition glass lens

• 2.5m-15m smooth linear motorized focus

• Scan position memory, auto reposition after unexpected movement

• Specific optic system with 2° projection angle

• Improved optics and flat beam field

• 1 static gobo wheel with 17 gobos plus open

• 1 color wheel with 14 colors plus open

• Variable direction rainbow effect with speed adjustable

• 8-facet prism with variable speed and direction

• 0-100% linear LED dimmer

• 25T/sec high speed LED shutter/strobe effect with variable speed

• Preset variable/random strobe and dimming pulse effect

• 10/12 DMX channels USITT DMX-512

• DMX512, master-slave, and sound activated controllable or auto operation

(7 built-in programs)

• DMX recorder and edit function integrated

• Red background LED display

• Powercon connector IN

• 3-pin XLR connectors IN/OUT

• Fan cooling system

• Constant temperature readout and management function

• 45°C max ambient temperature

• IP20 protection rating

• 55dB at 3’dB rating

• 1*hanging kit

A 90W 7500K white LED lamp

Red Blue Green

Dark

Blue Orange

Yellow

White

Rose

Carmine

UV

CTB Pink

Light

Green

Dark

Yellow

Light

Yellow

Light

Blue

.08.

For installations where the DMX cable has to run a long distance

or is in an electrically noisy environment, such as in a

discotheque, it is recommended to use a DMX terminator. This

helps in preventing corruption of the digital control signal by

electrical noise. The DMX terminator is simply an XLR plug with a

120 Ω resistor connected between pins 2 and 3,which is then

plugged into the output XLR socket of the last fixture in the chain.

Please see illustrations below.

12

3

PIN3

PIN2

120 Ω

MENU OPERATIONS

8

ADDR

AUTO

SOUN

MIC

LODA

VER

CALI

SPM

Ch14

CH16

ON/OFF

TXXX

PAN

TILT

ON/OFF

ON/OFF

VALU

SLAV

IP1~8

IP1~8

M-XX

ON/OFF

V-1.0~V-9.9

Code(088)

SP1

SP2

630/540/360

270/180/90

CH01—CH12

A001~A499

ALON (AU-A)

(AU-M)MAST

ALON (SO-A)

MAST (SO-M)

MODE

SET

DMX

REST

TEMP

De9r

P-REu

T-REu

ENTER

DMX address setting

Slave

Alone setting

Master setting

Alone setting

Master setting

Mic sensitivity

Data reload

Software version

Calibration code

Calobration channels

SP1

SP2

14CH

16 CH

Reset

Termperature reading

PAN angle options

TILT angle options

PAN inverted

TILT inverted

Func

Up

Down

Enter

LED display

MIC

2°Beam Angle LUX 0.0929=FC×

Photometric Beam Angle Data

.04.

Specifications

Input Voltage:

LED Quantities:

Control Signal:

Control Channel:

Power Consumption:

Dimensions:

Packing Dimensions:

Net Weight:

Gross Weight:

AC90-260V 50/60Hz

1*90W white LED

DMX512, master-slave and sound activated or auto operation

10/12 DMX channels USITT DMX-512

150W

270(D)*149(W)*364(H)mm

345(D)*240(W)*445(H)mm

7.4kg

8.5kg

PHOTOMETRIC DATA

4

Beam

Diameter

ø 17.5 ø 33.5 ø 50 ø 67 ø 109

0m

6829 /

73510

2°

2.5 m 5m 7.5 m 20m10m 15m

1828 /

19680

744 /

8010

461 /

4960

114 /

1230

99 /

1070

ø 144

( FC/

LUX )

cm

.07.

Regardless of the rigging option you choose for your , always be sure

to secure your fixture with a safety cable. The fixture provides a built-in rigging point

for a safety cable on the hanging bracket as illustrated above. Be sure to only use the

designated rigging point for the safety cable and never secure a safety cable to a

carrying handle.

JNR 90L BEAM G

DMX-512 CONTROL CONNECTIONS

7

Connect the provided XLR cable to the female 3-pin XLR output of your controller and

the other side to the male 3-pin XLR input of the moving head. You can chain multiple

Moving head together through serial linking. The cable needed should be two core,

screened cable with XLR input and output connectors. Please refer to the diagram below.

DMX-512 connection with DMX terminator

DMX Output

3-Pin XLR Socket

DMX Input

3-Pin XLR Socket

1:Ground

2:Data(-)

3:Data(+)

1 2

3

12

3

1

2

3

1

2

3

COMMON

DMX+

DMX-

DMX512 IN

3-PIN XLR

DMX512 OUT

3-PIN XLR

DMX IN

DMX OUT

POWER IN

FUSE

POWER SWITCH

POWER IN

DMX IN

364

193

97

179

184

152

270 149

Table of contents