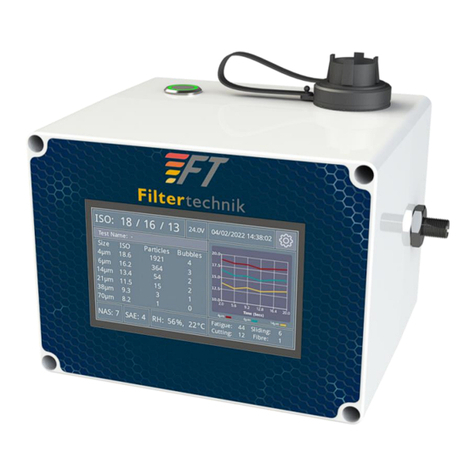

Etari ET-111 User manual

2 IN 1 COATING THICKNESS GAUGE

OPERATING INSTRUCTIONS

MODEL: ET-111

www.etari.de

When the UV LED function is turned on, it will radiate intense UV light

during operation. Since UV light can be harmful to eyes, do NOT look

directly into the UV light, even through an optical instrument. In case of

the light reection, UV protective glasses are required to use in order to

avoid damage by the light.

CAUTION

* Do not use the unit near any device which

generates strong electromagnetic radiation or

near a static electrical charge, as these may

cause errors.

* Do not use the unit where it may be exposed

to corrosive or explosive gases. The unit may be

damaged, or explosion may occur.

* Do not keep or use this unit in an environment

where it will be directly illuminated by sunshine,

or where it condensation. If you do, it may be deformed, its insulation may

be damaged, or it may no longer function according to specication.

* Do not place the meter on or around hot objects (70°C/158°F). It may

cause damage to the case.

* If the meter is exposed to signicant changes in ambient temperature,

allow 30 minutes for temperature stabilization, before taking measurement.

DANGER

INTRODUCTION

This instrument is a 4 digit, portable, easy to use and compact-sized digital

“ferrous” or “non-ferrous” coating designed for simply one hand

operation. Meter comes with backlight LCD display and Auto Power O (60

seconds approx.) to extend battery life.

SAFETY INFORMATION

It is recommended that you read the safety and operation instructions

before using the coating thickness gauge.

* Condensation may form on the sensor when

going from a cold to hot environment. Wait for 10

minutes for condensation to dissipate before

taking measurements.

*This unit is not constructed to be waterproof and

dustproof. Do not use it in a wet or very dusty

environment.

*In order to take accurate measurement, make

sure the sensing tip contacts the coated surface

tightly without tilting.

* Please make sure there is no air bubbles between

substrate and coating.

*Substrate Zeroing Calibration: Must be implemented for each

use.

*Two point calibration:Must implement for frequent testing points to

increase measuring accuracy.

*The enclosed zeroing plates are only suitable for the use of calibration of

coating thickness meter itself. Apart from that, the meter should be

performed two point calibrationmethods to get accurate readings before

use.

The zeroing on specic material substrate still needs to be done before

taking formal measurements, such as Iron, Steel, Bronze, Copper, Nickel,

Zinc, and SUS304 and so on, which is to avoid the measuring errors that

cause by the dierence of individual substrates.The end users can get

much more accurate measuring readings on the specic metal under test

by doing two calibration methods.

WARNING

ELECTROMAGNETIC FIELD INTERFERENCE

This instrument uses magnetic eld method to measure the coating

thickness on ferrous metal base. If this meter was placed in the

environment with 20mG (mini Gauss) or above, the accuracy would be

aected. Suggest that the meter should to put far away from the interfered

source at least 30cm.

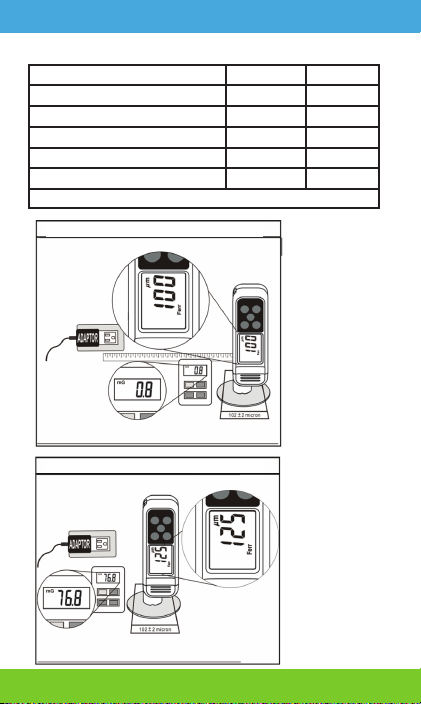

Electromagnetic eld strength:(unit = mini Gauss)

Any product with coil inside should be considered.

Electromagnetic Source 0 cm 30 cm

Cellular Phone Charger 50 ~ 500 < 1

Notebook Power Supply 100 ~ 1000 < 5

LCD Display 10 ~ 100 < 1

Fan 100 ~ 1000 < 5

Reading Lamp 400 ~ 4000 < 10

Recommended operating conditions ( >30cm)

Abnormal operating conditions (<30cm )

Operating Environment: -13°F to 122°F (-25°C to 50°C) at < 75% R.H.

Storage Temperature: -13°F to 140°F (-25°C to 60°C), 0 to 80% R.H. with

battery removed from meter.

Temperature Coecient: 0.1x (specied accuracy) / °C (< 18°C or >28°C)

Auto Power O: 1 minute.

Standby Consuming Current:< 6µ A

Battery: 1.5V (AAA size) x 2pcs.

Battery Life: 17 hours (continuity) typical with alkaline battery.

Low Battery Indication: The“ ”is displayed when the battery

voltage drops below the operating level.

Dimensions: 120mm (H) x 40.4mm(W) x 29.2mm(D).

Weight: Approx. 100g (including battery).

SPECIFICATION

ELECTRICAL

Detectable Substrate Material:Ferrous metal (iron, steel) and

Non-Ferrous metal (copper, aluminum, zinc, bronze,brass, etc.)

Ferrous Thickness Range: 0 to 80.0mils, 0 to 2000µm.

Non-Ferrous Thickness Range: 0 to 40.0mils,0 to 1000µm.

Display Resolution: 0.1mils/1µm.

Ferrous Accuracy: ±4dgts on 0 to 7.8mils.

±(3%+4dgts) on 7.9mils to 80.0mils.

±10dgts on 0 to 199µm.

±(3%+10dgts) on 200µm to 1999µm.

Non-Ferrous Accuracy: ±4dgts on 0 to 7.8mils.

±(3%+4dgts) on 7.9mils to 40mils.

±10dgts on 0 to 199µm.

±(3%+10dgts) on 200µm to 1000µm.

Response Time: 1 second.

GENERAL

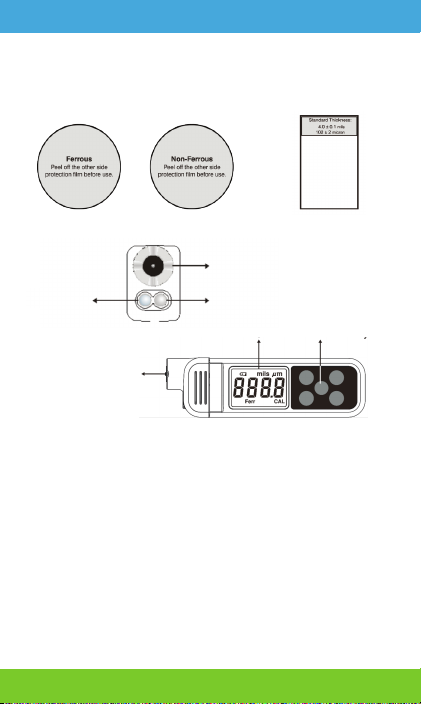

Sensing Tip

LightingUV-Lighting

DEFINITION

Peel o the protection lms from foil before rst use.

Zeroing Plate

Ferrous is steel

plate

Non-ferrous is

Aluminum plate

Standard Coating Plate

Peel o the both

sedi of protection

lm before use

Power on and o:

1. Keep the sensing tip of the meter away from any substrate or any

magnetic eld.

2. The Gauge automatically powers up and Measuring when probe is pressed.

3. Auto Power O (APO):

Leave the gauge without operation for 1 minute, power turns o

automatically.

Measuring:

1. Press the sensing tip of the gauge to contact coated surface tightly. Wait

for the reading to appear and measurement is completed. (One sound“Beep”

announced)

2. If the coating thickness is out of range, the meter shows "----".

INSTRUCTION

LCD Function Key

Sensing Tip

Attention!

The calibration and resetting to factory settings is only possible in

automatic mode A.

* During calibration, Auto Power O function will be inactivated. If the

LCD display "----", it can not zero the substrate, one point calibration or

two-point calibration.

* When it is calibrated by user, its max calibrated value is

43.3 mils /1100µm.

Substrate Zeroing Calibration:

Press the sensing tip of the probe to contact uncoated surface tightly. Wait

for the reading to appear and measurement is completed (one“Beep”

sound announced), then you can move the Gauge away. Press“0”button

(no longer than 2 seconds) to calibrate substrate material or foil.

LCD displays 0 μm.

One Point Calibration:

1. Press the sensing tip of the probe to contact coated

surface tightly.Wait for the reading to appear and measurement is

completed (one“Beep”sound announced), then you can move the Gauge

away.

2. Press “CAL” button over 3 sec into calibration mode. LCD will blink “CAL”

icon.

3. In calibration mode, use

▲

or

▼

button to adjust

readings until it matches the known standard’s thickness (4.0 mils /

102µm).

4. Press “CAL” button to exit one point calibration and return to measuring

mode“CAL”o.

CALIBRATION

FUNCTION KEY

“ ”

Push“ ”button each time, the display changes in the following

sequence:Lighting →UV light →OFF, it can be operated in ON or O

mode.

“ ”

1. Press“ ”button to turn on or o backlight function. It can benet

users for reviewing display in dark environment.

2. Press“ ”button over 3 seconds to switch between mils and μm.

(1 mils = 25.4 μm)

3. In calibration mode, use

▲

or

▼

button to adjustreadings until it

matches the standard’s thickness (102 μm).

4. Press“CAL” button to exit two point calibration and return to measuring

mode.“CAL”o.

Press“CAL” button over 3 sec to enter calibration mode. LCD will display

“CAL” blinking.

Two Point Calibration (sucient for calibration)

* During two point calibration, the foil and standard coating plate 4.0 mils

/ 102µm can be replaced by uncoated substrate and a standard coating

plate with known-thickness.

1. Press the sensing tip of the probe to contact

Zeroing Plate uncoated surface tightly. Wait for

the reading to appear and measurement is

completed (one“Beep”sound announced) Press“0”

button (no longer than 2 seconds) to calibrate

substrate material or foil. LCD displays 0 μm.

2. Press the sensing tip of the probe to contact

Standard Coating plate 102µm, coated surface

tightly.Wait for the reading to appear and

measurement is completed (one“Beep”sound

announced), then you can move the Gauge away.

“F/N“

Press“F/N”button each time, the display changes in the

following sequence: Auto→Ferrous→

(Auto Mode and Ferrous Fixed Mode and Non-Ferrous Fixed Mode.)

“0“

Quickly press“0”button for substrate zeroing calibration.

Press“0”button over 3 seconds to clear Calibrating Point.

“CAL“

1. When power is on, press“CAL”button over 3 seconds to start

calibration.

complete calibrating procedure.

“▲”

In calibration mode, press“▲”button to increase Display's values.

“▼”

1. In calibration mode, press“▼”button to decrease Display's values.

Calibrating Point Clearance:

Reset to factory settings

In measuring mode, press “0” button over 4 seconds,

LCD will display“oooo”and start cleaning and zeroing

substrate, one point and two point calibration.When

calibration is not operated properly, the clearance

function helps users to start calibrating again.

Non-Ferrous

1.Power is supplied by 2pcs 1.5V (AAA SIZE).

2.The “ ”appears in the display when

battery replacement is needed.

3.Remove the battery cover by gently sliding it

onwards the bottom of the meter.

4.Remove the batteries from battery

compartment.

5.Replace with 2 new AAA batteries with

polarity as indicated on the bottom of Battery

Compartment.

6.Replace the Battery Cover.

CAUTION:

When not in use for long periods remove battery. Do not store in locations

with high temperatures, or high humidity.

Cleaning

Periodically wipe the case with a damp cloth and detergent, do not use

abrasives or solvents.

Installing and Replacing Battery

MAINTENANCE

Table of contents

Other Etari Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

SIGLENT TECHNOLOGIES

SIGLENT TECHNOLOGIES SSA3000X Series Programming guide

Rotronic

Rotronic Pt 100 RTD CALIBRATION PROCEDURE

ZIEHL

ZIEHL TR660IP operating manual

Campbell

Campbell DMM600 instruction manual

Sekonic

Sekonic LITEMASTER PRO Service manual

Hanna Instruments

Hanna Instruments HI 83214 instruction manual