Filtertechnik S120-PM User manual

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

1 of 15

S120-PM

Fuel & Oil Cleanliness Analyser

User Manual

August 2022

V1.00

© Copyright 2022 Filtertechnik

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

2 of 15

Table of Contents

Specifications........................................................................................................................................... 3

Component Identification ....................................................................................................................... 4

Inlet & Outlet Connections...................................................................................................................... 5

Electrical Connections ............................................................................................................................. 5

Operating the Unit .................................................................................................................................. 6

On/Off Switch...................................................................................................................................... 6

Touch Screen Layout ........................................................................................................................... 6

ISO Alarm Limits .............................................................................................................................. 7

Datalogging...................................................................................................................................... 8

Time Zone Adjustment.................................................................................................................... 9

RH Sensor Settings........................................................................................................................... 9

Troubleshooting .................................................................................................................................... 10

General Operational Errors ............................................................................................................... 10

Particle Counting ............................................................................................................................... 10

RH & Water Content.......................................................................................................................... 10

Particle Count ISO Codes....................................................................................................................... 11

ISO Codes (ISO4406).......................................................................................................................... 11

ISO Decimal Codes............................................................................................................................. 12

Warranty Statement.............................................................................................................................. 14

EC Declaration of Conformity................................................................................................................ 15

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

3 of 15

Specifications

Specification

Detail

Dimensions

(w)160mm x (d)145mm x (h)166mm

Weight

1.5kg

Finish

White weatherproof case

Nominal Voltage

24 VDC

Voltage Range

20-28 VDC

Cleanliness standards

ISO 4406, NAS 1638, SAE AS4059

Viscosity range

Up to 2400 cSt (as long as pressure limit is not exceeded)

Fluid compatibility

Diesel & oil (hydraulic, lubrication, mineral, synthetic)

Fluid temperature

0 to 60°C (oils)

0 to 50°C (diesel)

Ambient temperature

0°C to +40°C

Environment

IP65

Connections

1/8”BSPP, 60° coned

Pressure

0 -5 bar nominal, 100 bar maximum

Maximum humidity

97% relative humidity, non-condensing

Certification

Factory calibration certificate

CE declaration

Verification frequency

12 months recommended

PC requirements

Windows (with USB port), spreadsheet software (e.g. MS Excel)

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

4 of 15

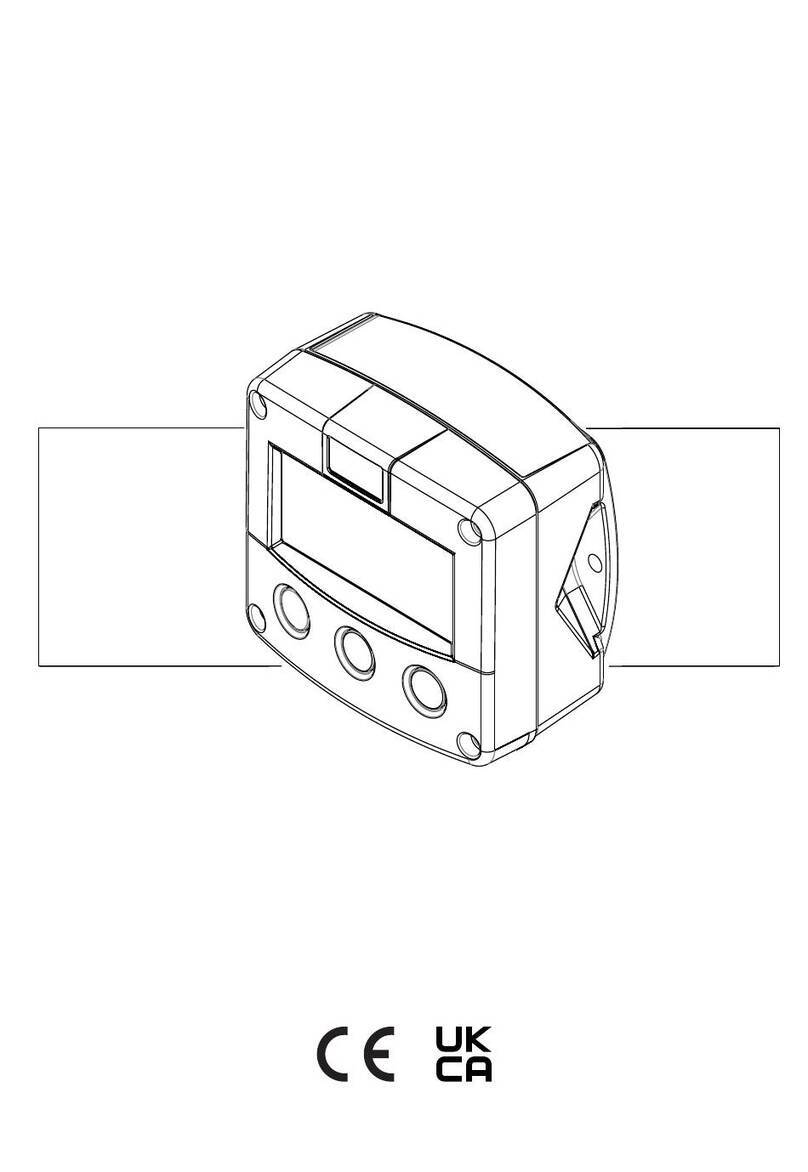

Component Identification

Key:

1.) Touch screen display

5.) Inlet/Outlet Port –1/8” BSPP Coned

2.) Inlet/Outlet Port –1/8”BSP Coned

6.) USB Port (data log download)

3.) Power Input

7.) Power Switch

4.) RH Sensor Input

1

2

3

7

6

5

4

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

5 of 15

Inlet & Outlet Connections

Flow through the unit can be in either direction. The connections provided are 1/8”BSPP threads to

ISO 228/1 with a 60° internal cone to BS 5200, suitable for connecting hydraulic hoses with female

swivel ends.

When attaching hose connections, it’s best practice to remove the front cover of the enclosure and

support the threaded fitting with a spanner where it connects to the particle counter to prevent over

tightening the fitting in the particle counter or put excessive force on the mounting plate.

Electrical Connections

Power is provided through the cable glans on the left (1) and should be 24V, connected to the 2-pin

terminal block.

The cable gland on the right (2) is for connection of an RH moisture sensor. The 4-pin terminal blocks

0V and 24V connections provide power to the sensor, where the 4-20mA outputs of the sensor are

connected to the RH and TEMP terminals to display %RH and temperature on the display.

1

2

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

6 of 15

Operating the Unit

On/Off Switch

Units have a single push

button switch which

illuminates when switched

on, powering up the display

and RH sensor if connected.

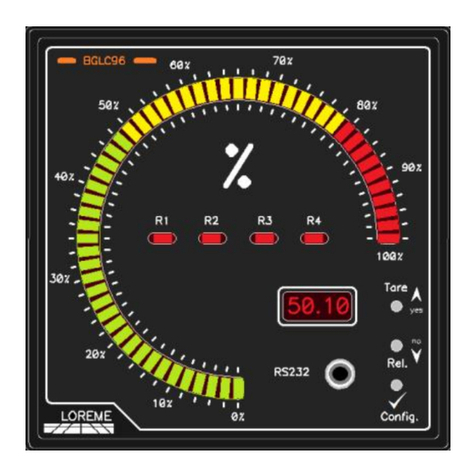

Touch Screen Layout

The main window of the touch screen displays all information provided by the particle counter and

any other sensor that may be installed, including the input voltage. The ISO code can change from

white to green or red depending on the alarm limits set.

In the top right corner of the screen is a settings icon, clicking this will open the settings page.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

7 of 15

At the bottom left of the settings page the software version is displayed.

ISO Alarm Limits

Alarm limits for low (clean) or high (dirty) can be set. Low refers to oil achieving required cleanliness

codes in all size categories. High refers to oil exceeding any one of the codes for particulate

contamination. When the oil is clean the ISO code on the main screen will turn green, when dirty it

will become red, between the two values the text is white.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

8 of 15

Datalogging

The unit contains two internal dataloggers, one for the graph and one for the tests. Whenever the

unit is switched off the graph will be reset, but this can also be done from the screen without having

to switch off the unit. The main data log tied to the sensors will hold 500 lines of data (500 polls of

the sensors) which equates to 16.6 hours of testing.

To create a new log file the button needs to be held down for a couple of seconds, until a

confirmation message is displayed.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

9 of 15

Time Zone Adjustment

The display screen is pre-set with the date and date to GMT +0 (UK time) this can be adjusted

according to your time zone if required.

RH Sensor Settings

If an RH sensor is connected to the unit this will need to be activated in the “RH Sensor Settings”

page. Here the temperature scaling can be adjusted to suit the sensor being used.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

10 of 15

Troubleshooting

General Operational Errors

Problem

Possible Cause

Solution

Unit will not

switch on.

Power supply issue.

With a multimeter check at the input terminal

block that 24V is being supplied.

Touch screen

does not

power up.

Internal connector issue.

If the switch illuminates but the screen does not

power up check the Molex connector has been

reconnected after assembly.

Screen is

behaving

erratically.

Dirt or moisture on the screen.

Wipe the screen clean to remove traces of dirt,

oil, or moisture. In most cases thick gloves will

not work with the touch screen.

Particle Counting

Problem

Possible Cause

Solution

Contamination

codes dropped

to near zero..

A blockage in

the flow path.

Check there is adequate flow rate going through the unit

(approximately 20-50ml/min).

Check/clean the suction strainer for any contamination.

Erratic count

levels.

Unstable

sample.

Check for the presence of air. Bubble counts should be

maintained below 200 bubbles/ml in each channel.

RH & Water Content

Problem

Possible Cause

Solution

Water content

is above 95%

High moisture levels

in the sample.

Damaged moisture

sensor.

Flush the unit immediately with dry oil to avoid damage

to the moisture sensor. If levels still don’t fall the sensor

could be permanently damaged.

Water content

bouncing from

near 0 to 100%.

Damaged moisture

sensor.

Permanent damaged due to excessive moisture. Sensor

will require replacing.

Temperature

not reading

correctly.

Scaling issue.

Go into the “RH Sensor Setting”menu item and make

sure the scaling has been correctly configured.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

11 of 15

Particle Count ISO Codes

ISO Codes (ISO4406)

The table below shows the ISO 4406 codes by number of particles per 1 ml of fluid sampled.

ISO 4406 Code

Counts/mL

Greater than

Up to/including

0

0

0.01

1

0.01

0.02

2

0.02

0.04

3

0.04

0.08

4

0.08

0.16

5

0.16

0.32

6

0.32

0.64

7

0.64

1.3

8

1.3

2.5

9

2.5

5

10

5

10

11

10

20

12

20

40

13

40

80

14

80

160

15

160

320

16

320

640

17

640

1300

18

1300

2500

19

2500

5000

20

5000

10000

21

10000

20000

22

20000

40000

23

40000

80000

24

80000

160000

25

160000

320000

26

320000

640000

27

640000

1300000

28

1300000

2500000

29

2500000

∞

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

12 of 15

ISO Decimal Codes

The S120 particle counter gives a greater insight into cleanliness by showing ISO decimal codes, with

the particle counts as per the below table.

Code

Counts/mL

Code

Counts/mL

Code

Counts/mL

Code

Counts/mL

Code

Counts/mL

5

0.16

10

5

15

160

20

5000

25

160000

5.1

0.176

10.1

5.5

15.1

176

20.1

5500

25.1

176000

5.2

0.192

10.2

6

15.2

192

20.2

6000

25.2

192000

5.3

0.208

10.3

6.5

15.3

208

20.3

6500

25.3

208000

5.4

0.224

10.4

7

15.4

224

20.4

7000

25.4

224000

5.5

0.24

10.5

7.5

15.5

240

20.5

7500

25.5

240000

5.6

0.256

10.6

8

15.6

256

20.6

8000

25.6

256000

5.7

0.272

10.7

8.5

15.7

272

20.7

8500

25.7

272000

5.8

0.288

10.8

9

15.8

288

20.8

9000

25.8

288000

5.9

0.304

10.9

9.5

15.9

304

20.9

9500

25.9

304000

6

0.32

11

10

16

320

21

10000

26

320000

6.1

0.352

11.1

11

16.1

352

21.1

11000

26.1

352000

6.2

0.384

11.2

12

16.2

384

21.2

12000

26.2

384000

6.3

0.416

11.3

13

16.3

416

21.3

13000

26.3

416000

6.4

0.448

11.4

14

16.4

448

21.4

14000

26.4

448000

6.5

0.48

11.5

15

16.5

480

21.5

15000

26.5

480000

6.6

0.512

11.6

16

16.6

512

21.6

16000

26.6

512000

6.7

0.544

11.7

17

16.7

544

21.7

17000

26.7

544000

6.8

0.576

11.8

18

16.8

576

21.8

18000

26.8

576000

6.9

0.608

11.9

19

16.9

608

21.9

19000

26.9

608000

7

0.64

12

20

17

640

22

20000

27

640000

7.1

0.706

12.1

22

17.1

706

22.1

22000

27.1

706000

7.2

0.772

12.2

24

17.2

772

22.2

24000

27.2

772000

7.3

0.838

12.3

26

17.3

838

22.3

26000

27.3

838000

7.4

0.904

12.4

28

17.4

904

22.4

28000

27.4

904000

7.5

0.97

12.5

30

17.5

970

22.5

30000

27.5

970000

7.6

1.036

12.6

32

17.6

1036

22.6

32000

27.6

1036000

7.7

1.102

12.7

34

17.7

1102

22.7

34000

27.7

1102000

7.8

1.168

12.8

36

17.8

1168

22.8

36000

27.8

1168000

7.9

1.234

12.9

38

17.9

1234

22.9

38000

27.9

1234000

8

1.3

13

40

18

1300

23

40000

28

1300000

8.1

1.42

13.1

44

18.1

1420

23.1

44000

28.1

1420000

8.2

1.54

13.2

48

18.2

1540

23.2

48000

28.2

1540000

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

13 of 15

8.3

1.66

13.3

52

18.3

1660

23.3

52000

28.3

1660000

8.4

1.78

13.4

56

18.4

1780

23.4

56000

28.4

1780000

8.5

1.9

13.5

60

18.5

1900

23.5

60000

28.5

1900000

8.6

2.02

13.6

64

18.6

2020

23.6

64000

28.6

2020000

8.7

2.14

13.7

68

18.7

2140

23.7

68000

28.7

2140000

8.8

2.26

13.8

72

18.8

2260

23.8

72000

28.8

2260000

8.9

2.38

13.9

76

18.9

2380

23.9

76000

28.9

2380000

9

2.5

14

80

19

2500

24

80000

>29

2500000

9.1

2.75

14.1

88

19.1

2750

24.1

88000

–

–

9.2

3

14.2

96

19.2

3000

24.2

96000

–

–

9.3

3.25

14.3

104

19.3

3250

24.3

104000

–

–

9.4

3.5

14.4

112

19.4

3500

24.4

112000

–

–

9.5

3.75

14.5

120

19.5

3750

24.5

120000

–

–

9.6

4

14.6

128

19.6

4000

24.6

128000

–

–

9.7

4.25

14.7

136

19.7

4250

24.7

136000

–

–

9.8

4.5

14.8

144

19.8

4500

24.8

144000

–

–

9.9

4.75

14.9

152

19.9

4750

24.9

152000

–

–

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

14 of 15

Warranty Statement

All products manufactured or distributed by Filtertechnik Ltd are subject to the following, and only

the following, Limited Express Warranties, and no others:

For a period of one (1) year from and after the date of delivery of a new Filtertechnik product,

Filtertechnik warrants and guarantees only to the original purchaser/user that such a product shall

be free from defects of materials and workmanship in the manufacturing process. The warranty

period for pumps and motors is specifically limited to ninety (90) days from the date of delivery. A

product claimed to be defective must be returned to the place of purchase. Filtertechnik, at its sole

option, shall replace the defective product with a comparable new product or repair the defective

product. This express warranty shall be inapplicable to any product damaged or impaired by external

forces or used for any purpose other than that for which it was originally sold.

THIS IS THE EXTENT OF WARRANTIES AVAILABLE ON THIS PRODUCT. FILTERTECHNIK SHALL HAVE NO

LIABILITY WHATSOEVER FOR CONSEQUENTIAL DAMAGES FOLLOWING THE USE OF ANY DEFECTIVE

PRODUCT OR BY REASON OF THE FAILURE OF ANY PRODUCT. FILTERTECHNIK SPECIFICALLY

DISAVOWS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED INCLUDING, WITHOUT LIMITATION, ALL

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE (EXCEPT FOR THOSE WHICH APPLY TO

PRODUCT OR PART THEREOF THAT IS USED OR BOUGHT FOR USE PRIMARILY FOR PERSONAL, FAMILY

OR HOUSEHOLD PURPOSES), WARRANTIES OF DESCRIPTION, WARRANTIES OF MERCHANTABILITY,

TRADE USE OR WARRANTIES OF TRADE USAGE.

Fax: +44 (0)115 986 8875

Web: www.filtertechnik.co.uk

Tel: +44 (0)115 9003 600

Email: sales@filtertechnik.co.uk

Filtertechnik 1 Central Park, Lenton Lane, Nottingham, NG7 2NR

Registered in England No: 03969985 VAT No: 760 821 731 Certification No. UK002838

15 of 15

EC Declaration of Conformity

Manufacturer’s Name:

Filtertechnik Ltd.

Manufacturer’s Address:

1 Central Park, Lenton Lane, Nottingham, NG7 2NR

EC Representative’s Name:

N/A

EC Representative’s Address:

N/A

Equipment Description:

Portable analysers for fuel and oil

Equipment Model Designation:

S120-PM

Application of Council Directive:

EMC Directive 2004/108/EEC

Low Voltage Directive 2006/95/EC

Batteries Directive 2006/66/EC

Referenced Standards:

EN61000-6-3: 2001

EN61000-6-1: 2001

EN61326-1: 2006

CISPR 11

EN60825-1: 2007

EN61010-1:01

I, the undersigned, hereby declare that the equipment specified above conforms to the above

Directive(s) and Standard(s).

Signature:

Printed Name:

Daniel Whittaker

Title:

Engineering Director

Date:

17th February 2022

Table of contents

Other Filtertechnik Measuring Instrument manuals