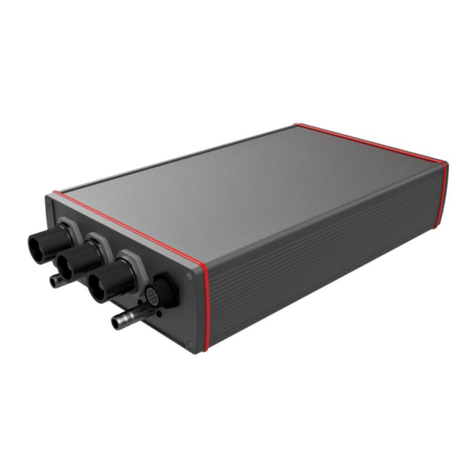

Etatron eSelect-CD1 Instructions for use

EN OPERATING INSTRUCTIONS AND MAINTENANCE

FR

UNI EN ISO 9001:2008

www.etatronds.com

eSelect-CD1

(IT) DIRETTIVA "RAEE"2002/96/CEESUCCESSIVA MODIFICA 2003/108/CESUI RIFIUTI DI APPARECCHIATURE ELETTRICHE

EDELETTRONICHE

Il simbolo sotto riportato indica che il prodotto non può essere smaltito come normale rifiuto urbano. Le Apparecchiature Elettriche ed

Elettroniche (AEE) possono contenere materiali nocivi per l'ambiente e la salute e pertanto devono essere oggetto di raccolta

differenziata: smaltite quindi presso apposite discariche o riconsegnate al distributore a fronte dell'acquisto di una nuova, di tipo

equivalente o facente le stesse funzioni. La normativa sopracitata, alla quale rimandiamo per ulteriori particolari e approfondimenti,

prevede sanzioniper losmaltimento abusivodidetti rifiuti.

(UK) WASTE OF ELECTRICAL AND ELECTRONIC EQUIPMENT DIRECTIVE (WEEE, RAEE in Italy) 2002/96/EC AND

SUBSEQUENTAMENDMENT2003/108/EC

The marking shown below indicates that the product cannot be disposed of as part of normal household waste. Electrical and

Electronic Equipment (EEE) can contain materials harmful to health and the environment, and therefore is subject to separate waste

collection: it must be disposed of at appropriate waste collection points or returned to the distributor against purchase of new equipment

of similar type or having the same functions. The directive mentioned above, to which make reference for further details, provides for

punitiveactionsin case of illegal disposal of such waste.

(FR) DIRECTIVE "RAEE" 2002/96/CE ET MODIFICATION SUCCESSIVE 2003/108/CE CONCERNANT LES REBUTS

D'APPAREILLAGESÉLECTRIQUESETÉLECTRONIQUES

Le symbole ci-dessous indique que le produit ne pas être éliminé comme un normal déchet urbain. Les Appareillages Électriques et

Électroniques (AEE) peuvent contenir des matériaux nocifs pour l'environnement et la santé et doivent donc faire l'objet de collecte

différenciée: éliminés donc auprès de décharges prévues à cet effet ou rendus au distributeur pour l'achat d'un nouveau, de type

équivalent ou ayant les mêmes fonctions. La réglementation susmentionnée, à laquelle nous vous renvoyons pour les détails et les

approfondissements ultérieurs,prévoitdes sanctionspourlamise endéchargeabusivedesditsrebus.

(ES) DIRECTIVA "RAEE" 2002/96/CE Y MODIFICACIÓ N SUCESIVA 2003/108/CE SOBRE RESIDUOS DE APARATOS ELÉ

CTRICOSY ELECTRÓ NICOS

El símbolo que se muestra abajo indica que el producto no puede eliminarse como un residuo urbano normal. Los Aparatos Eléctricos y

Electrónicos (AEE) pueden contener materiales nocivos para el medio ambiente y la salud y por tanto tienen que ser objeto de

recogida selectiva: por consiguiente tienen que eliminarse en vertederos apropiados o entregarse al distribuidor cuando se adquiera

uno nuevo, del mismo tipo o con las mismas funciones. La normativa mencionada arriba, a la que remitimos para más detalles y

profundizaciones,prevésancionespor la eliminaciónclandestinadedichosresiduos.

(PR) DIRETRIZ "RAEE" 2002/96/CE E MODIFICAÇÃO POSTERIOR 2003/108/CE SOBRE RESÍDUOS DE

EQUIPAMENTOSELÉTRICOSE

ELETRÔNICOS

O símbolo referido abaixo indica que o produto não pode ser eliminado como resíduo urbano normal.

OsAparelhos Elétricose

Eletrônicos (AEE) podem conter materiais nocivos ao ambiente e à saúde e, portanto, devem

ser objeto de coleta seletiva: eliminados, portanto,

através de depósitos apropriados ou pelo reenvio ao distribuidor

para a aquisição de um novo, de tipo equivalente ou que

realize as mesmas funções.

Anormativa referida acima, à qual nos referimos para detalhes complementares e

esclarecimentos, prevê

sançõesnocasodeeliminaçãoinadequadadetaisresíduos.

ENGLISH

5

TABLE OF CONTENTS

SAFETY STANDARDS.................................................................................................................................................7

User information signs .................................................................................................................... 7

CONTROLLER DESCRIPTION....................................................................................................................................8

TECHNICAL CHARACTERISTICS ..............................................................................................................................8

HINTS AND WARNINGS..............................................................................................................................................9

Warning .......................................................................................................................................... 9

Shipping and Transporting............................................................................................................... 9

Proper use of the controller............................................................................................................. 9

Risks .............................................................................................................................................. 9

Assembling and dismantling the equipment.....................................................................................10

ESELECT-CD1 SERIES ENCLOSURES, MOUNTING, COMMISSIONING AND OVERALL DIMENSIONS............10

Wall mounting enclosure eSelect-CD1 .............................................................................................10

Overall dimensions.........................................................................................................................11

Electrical wiring connectors ...........................................................................................................11

Connecting conductivity sensor......................................................................................................11

Connecting to main power supply / PARALLEL CONNECTIONS ........................................................12

Example connection controller-motor dosing pump relays OUT 1-2...................................................12

DISPLAY DESCRIPTION ...........................................................................................................................................13

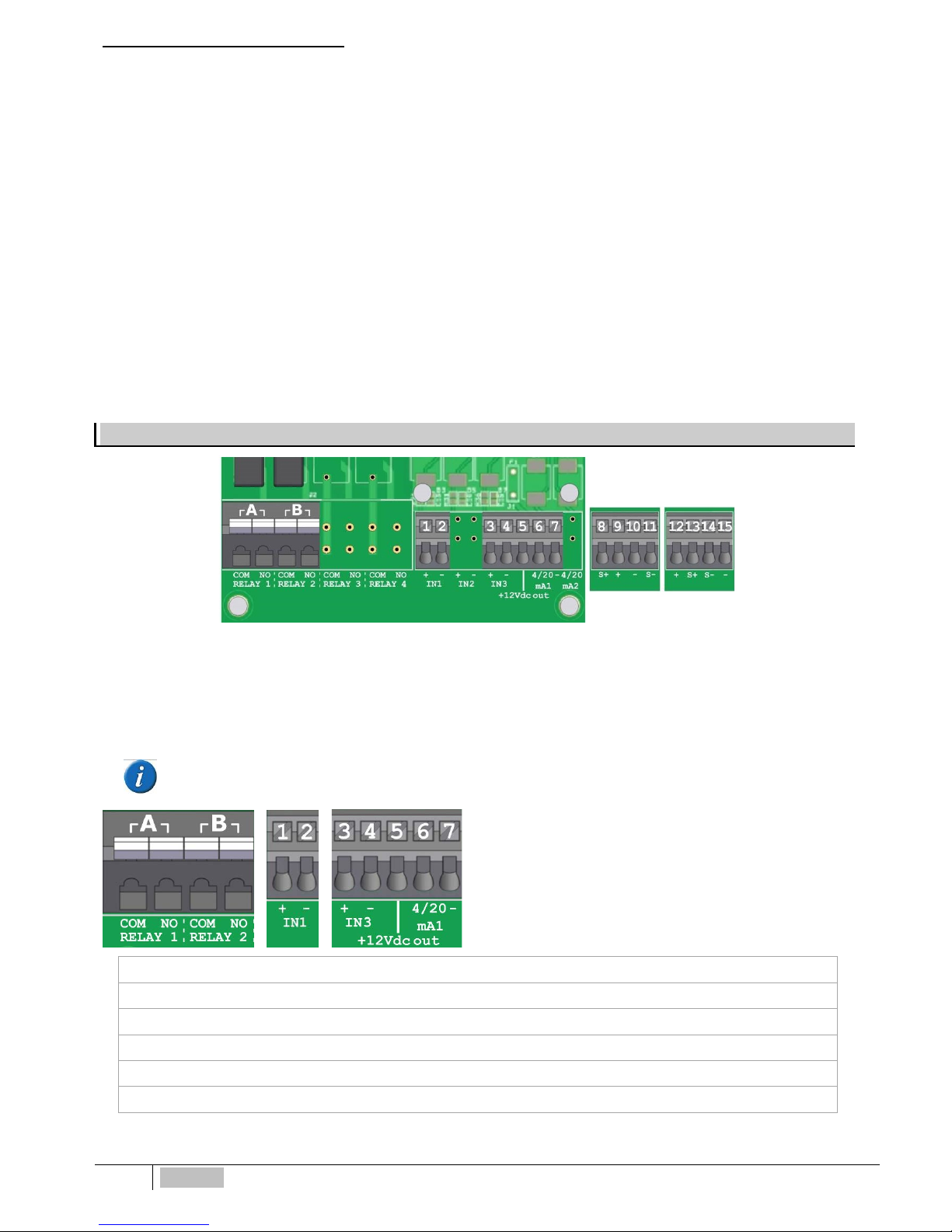

TERMINAL BOARD ELECTRICAL WIRING..............................................................................................................14

OPERATING MODES GLOSSARY............................................................................................................................15

PROGRAMMING FUNCTIONS ..................................................................................................................................17

INPUTS / OUTPUTS DIAGRAM FUNCTIONS ...........................................................................................................17

INITIAL DISPLAY .......................................................................................................................................................18

Selecting Language ........................................................................................................................18

Selecting Conductivity (EC) “K” factor............................................................................................18

TEMPERATURE settings..................................................................................................................19

Programming MENU ........................................................................................................................19

MAIN MENU > BASIC PROGRAMMING MENU...................................................................................................20

SETPOINT 1 EC CONDUCTIVITY > BASIC MENU.............................................................................................20

SETPOINT 2 EC CONDUCTIVITY > BASIC MENU..............................................................................................21

SENSOR CALIBRATION > BASIC MENU...............................................................................................................22

SETTINGS > BASIC MENU......................................................................................................................................22

MAIN MENU > EXPERT PROGRAMMING MENU................................................................................................23

SETPOINT 1 EC CONDUCTIVITY > EXPERT MENU...........................................................................................23

SETPOINT 2 EC CONDUCTIVITY > EXPERT MENU...........................................................................................25

4-20MA ANALOG CURRENT OUTPUT FUNCTION SELECTION > EXPERT MENU ............................................27

4-20mA EC CONDUCTIVITY > AUX FUNCTION ..............................................................................27

4-20mA EC Conductivity > DOSING SETPOINT.................................................................................27

SENSOR CALIBRATION > EXPERT MENU............................................................................................................28

6

ENGLISH

SETTINGS > EXPERT MENU ................................................................................................................................29

CONDUCTIVITY SENSORS AND MAINTENANCE...................................................................................................30

CONDUCTIVITY sensors NOTES.......................................................................................................30

CONDUCTIVITY sensors maintenance ..............................................................................................30

CONDUCTIVITY sensors range.........................................................................................................31

TROUBLESHOOTING................................................................................................................................................31

ENGLISH

7

eSelect-CD1 CONTROLLER SERIES INCLUDES SCREWS FOR WALL MOUNTING

eSelect-CD1 series is NOT provided with sensors, which are available upon request.

ETATRON D.S. declines any responsibility in case the controller is used with other brandprobes and sensors

SAFETY STANDARDS

User information signs

WARNING: ignoring safety information can endanger life or result in serious injury!

CAUTION: ignoring safety information can result in injuries to persons or damage systems or materials!

HIGH VOLTAGE: ignoring this sign can result in death or serious injuries to persons!

NOTE or INFORMATION SOURCE

- this symbol “pointing finger” indicates programming steps.

- if no keys are pressed within 60 seconds, controller will display current measurements

Qualified and authorized personnel must carry out any work or repair on the unit: manufacturer declines any responsibility for

consequences in case this rule is not complied.

Unqualified personnel should keep away from the plant and/or hazard areas.

The official operator of the system or the plant, when installing the unit, is responsible to fulfil the above rules.

8

ENGLISH

CONTROLLER DESCRIPTION

The eSelect-CD1 is a compact system with ELECTRICAL CONDUCTIVITY (EC) controller. In many cases, conductivity is linked directly

to the total dissolved solids (T.D.S.): conductivity provides an approximate value for the TDS concentration, usually to within ten-percent

accuracy. eSelect-CD1, along with the high quality performance in terms of measurements and functions thus satisfying most of the

requirements for an instrument, it offers many features thus making it extremely versatile and easy to operate. Conductivity measurement are

in micro Siemens features 4 K factor ranges (Cell Constant) suitable for following K:

Controller covers ranges from costant K 1 up to 20.00 mS and even 100.00 mS (latter with graphite sensor electrodes) and costant K 5

ranges 2.000 μS;

BENEFIT: The above feature allow dealers to stock one type for all controller thus reducing stock value or saving problems when

issuing orders to manufacturer.

Two types of programming menu:

•Basic making life easier for those home applications such small swimming pool or water treatment systems;

•Expert for professionals giving the opportunity to refine measurements and safety functions.

A friendly user menu programming it is almost self-explanatory and the elegant wide display allows easy vision.

TECHNICAL CHARACTERISTICS

Conductivity EC Measuring range and

K factor (cel

constant):

▪ K 1 ranges up to 20.00 mS and even 100.00 mS (latter with graphite sensor

electrodes) / Hysteresis / PWM point = 500 μS

Resolution 10 μS

▪ K 5 ranges up to 2.000 μS / Hysteresis / PWM point = 50 μS

Resolution 1 μS

▪ K10 ranges up to 200 μS / Hysteresis / PWM point = 0,50 μS

Resolution 0,1 μS

▪ K 0.1 ranges up to 100.00 mS / Hysteresis / PWM point = 5000 μS

Resolution 100 μS (only with graphite sensor electrodes)

Temperature setting: automatic with combined conductivity + PT100 or NTC system

Temperature probe range: – 20 ....100°C

▪ Resolution 0.1% °C ▪ Accuracy: ± 0.5% °C

Power supply / Power consumption: Universal power supply 100÷250 Vac / 5W at 240 V AC

Microprocessor technology: SMD components mounting, digital controls keypad 6 key

Linearity, Stability Reproducibility: ±0.5 % under standard conditions

Display: back-lit custom display (126x64); Display visible area 70x37 mm

Delay: Delay time relay activation, programmable for each set-point (999 sec.)

Start-up Delay: Delay time relay when switching ON, programmable on each set-point

PARAMETER

VALUE

Measure

Conductivity up tol 20mS

Type of probe

PTFE with graphite electrodes, k=1

Power supply

100

÷

240 Vac – 50/60 Hz – 6W

Display

Graphic 128x64 (visible area 70x37 mm)

Power supply protection

The whole power pack (there is no fuse)

Temperature probe

PT100, 0,1°C resolution

External casing

ABS, IP65

Inputs

Level, Proximity

Relay outputs

2 relay outputs (set-point 1 and set-point 2) ON-OFF or PWM type

Relay outputs features

maximum 5A on resistive load, maximum 1A on inductive load, 230Vac

mA outputs

1 mA galvanically separated output

mA outputs features

500 ohm maximum load impedence

Alarm

Overdosing alarm

Accessories

Wall mounting kit

Measures

120 x 200 x 90,5

Weight

Net weight: 1230 gr -Gross weight: 1255 gr

Front controls

Polycarbonate adhesive

Working temperature

0

÷

50 °C

ENGLISH

9

Power consumption / Nominal current: 230V=6W, 100mA / 24Vac-dc=7W, 300mA / 12Vdc=7W, 600mA

Internal electrical protection: power supplier guarantees electrical protection (instead of fuse)

Level / Remote relay control Chemical additive level (level switch not included)

Outputs:

Output RELAY 1 (set-point 1) ON-OFF or PWM mode voltage free contact 5Amax 230Vac

Output RELAY 2 (set-point 2) ON-OFF or PWM mode voltage free contact 5Amax 230Vac

FLUX sensor (proximity switch) It blocks output operations in case of no flow into the sensor cell

Unit load

Resistive load 5A max 230 V AC / Inductive load 1A 230 V AC

Insulation voltage relay output: > 3000 Vac

Relay contact lifespan > 105switching operations (at 3 A /230Vac)

0/4...20 mA output EC Adjustable (500 Ωmax input impedance), galvanic separation

Noise Level: Irrelevant

Working temperature: Ideal working temperature 5°C÷40°C, withstand 0°C÷45°C.

Environmental Conditions: Possibly dry environment, altitude up to 2000m, Relative humidity 80% for

temperatures up to 31°C decreasing linearly to 50% relative humidity at 40°C.

Pollution degree 2.

Transport and storage conditions: – 5÷60°C possibly dry environment

HINTS AND WARNINGS

Please read the warning notices given in this section very carefully, because they provide important information regarding safety in

installation, use and maintenance of the unit.

• Keep this manual in a safe place, so that it willalways be available for further consultation.

• The company manufactured the unit in accordance with best practice. Both its lifetime and electrical and mechanical reliability will

be enhanced if it is correctly used and subjected to regular maintenance.

Warning

Qualified and authorized personnel must carry out any intervention or repair for the unit; manufacturer declines any responsibility

for consequences in case this rule is not complied.

Shipping and Transporting

Shipment is always at the purchaser's risk. Claims for any missing materials must be made within 15 (fifteen) days of goods arrival,

while claims for defective materials will be considered within 30 (thirty) days from the same date. ETATRON D.S. authorized personnel must

previously agree the return of the equipment or other materials.

Proper use of the controller

• Controller must be used only for the purpose for which it has been expressly designed, namely the controlling and measuring

physical-chemical values.

• Any different use of it must be considered improper therefore dangerous.

• All other applications or modifications are prohibited.

• The equipment is NOT designed for use in explosion-hazardous locations.

• The unit can only be used for applications where technical requirements meet the ones of ETATRON D.S. characteristics and

specification data shown in the present operating booklet.

• The vendor is not liable for damage deriving from improper and/or unreasonable use of the unit.

Risks

• After unpacking the equipment, ensure it is in good shape and form. In case of doubt, do not use it and contact qualified personnel. Keep

out of reach of children packing materials (plastics bags, polystyrene, etc.) being potential sources of danger. However, save packaging: it

can be useful for future shipments.

• Before connecting the equipment ensure voltage ratings corresponds to local power supply. You will find these characteristics in the product

label placed on the equipment and packing.

10

ENGLISH

Caps (A) x 4

• The electrical installation must comply with the standards and rules in force in the country where it is utilised.

• Use of electrical equipment always implies observance of some basic rules:

1 - Do not touch the equipment with wet or damp hands or feet;

2 - Do not operate the equipment with bare feet (example: swimming pool equipment);

3 - Do not leave the equipment exposed to the action of the atmospheric agents;

4 - Do not allow the equipment to be touched by children or used by unskilled individuals without supervision;

• When commissioning the unit or in case of emergencies or improper functioning, the controller should be switched off

immediately. Disconnect the power cable from the main power supply! Contact our technical assistance for any necessary repairs,

use only original spares! Failure to respect this condition could render the equipment unsafe to use.

• When carrying out any repairs or opening the unit, ensure to disconnect it from power supply.

• When there is no longer use requirement of installed equipment, ensure to disconnect it from power supply.

1. Disconnect power from mains or from the single-pole switch-contact.

2. Take all due safety precautions during unit service (gloves, goggles, overalls, etc.).

Assembling and dismantling the equipment

ASSEMBLY:all ETATRON D.S. controllers are fully assembled. For the wall mounting, please proceed as follows.

DISMANTLEMENT: before dismantling the unit or carrying any operation, disconnect power.

ESELECT-CD1 SERIES ENCLOSURES, MOUNTING, COMMISSIONING AND OVERALL DIMENSIONS

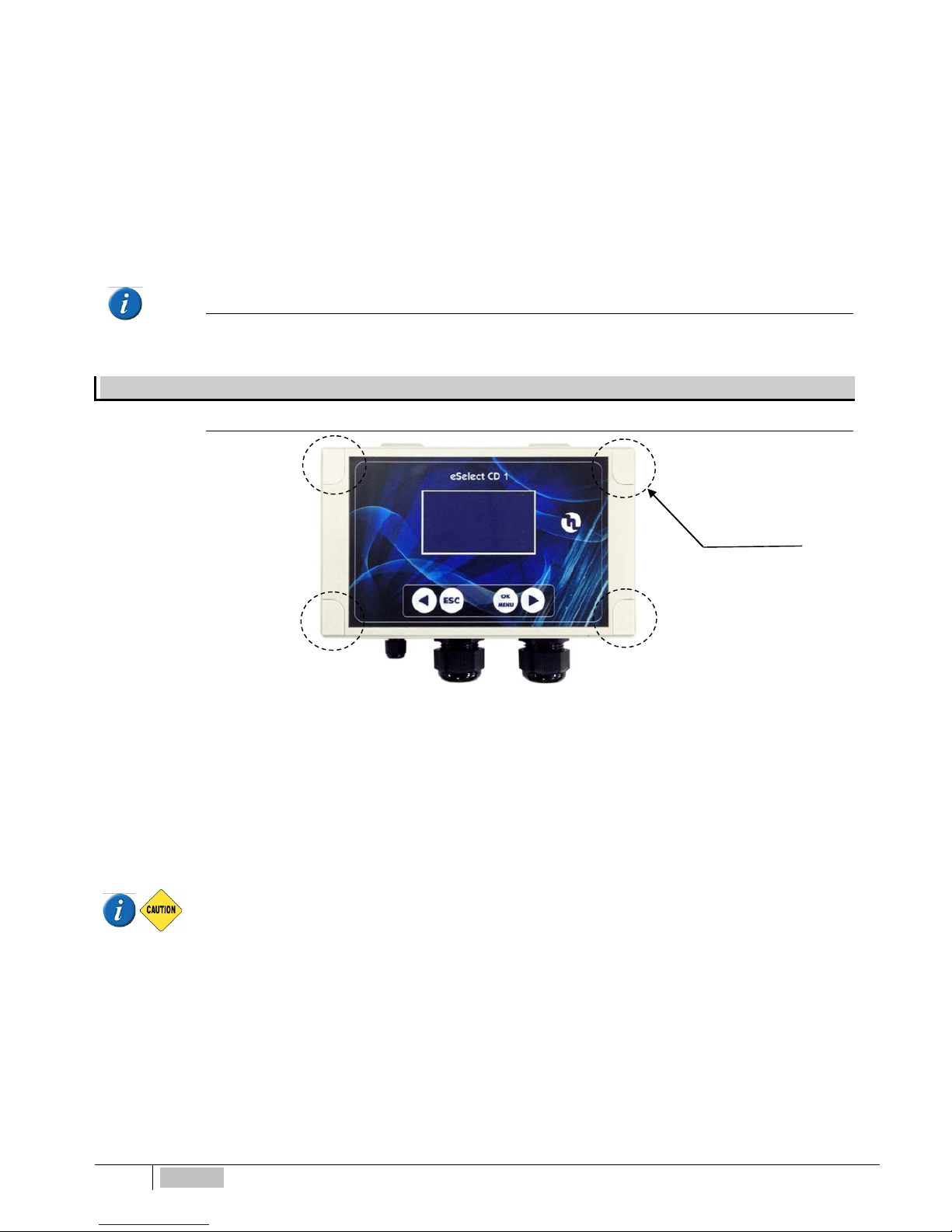

Wall mounting enclosure eSelect-CD1

eSelect-CD1 enclosure ABS plastic 200w x 106h x 90,5d

To access the 4 wall mounting points remove the 4 mounting point closures (A) located in each corner of the controller.

The enclosure features 4 captive screws for a quick opening/closing of the lid thus allowing easy access for commissioning and

service and also guarantees a perfect seal for long time operation

a. - Install the unit in a dry place and well away from heat sources; max environmental temperatures 40°C.

b. - Carefully observe regulations in force in the various countriesas in regards electrical installations.

c. - Mount the controller on the wall using the screws and dibbles provided with the unit

VERY IMPORTANT NOTE FOR ENCLOSURE: when handling the unit bear in mind not to pull, drag, or mistreat the flat cable

connecting the pcb display placed on the lid with main pcb.

ENGLISH

11

Overall dimensions

Electrical wiring connectors

eSelect-CD1 is provided with 2 multiple cable glands for various input and output cable wirings. Complying with International

electrical wiring rules., we advice not to connect more then one equipment on each pin.

CONNECTORS GLANDS USE:

Cable gland 1: Power cable

Cable gland 2 and 3: Recommended use for:

•Set-points relay outputs

•mA output

•Level probes for chemical tanks

•12Vdc input

•Flow sensor

•AUX output

•Conductivity sensor

•Temperature Sensor

Connecting conductivity sensor

eSelect-CD1 works with simple conductivity 2-electrode open sensors, with AISI 316 and Graphite electrodes.

NOTE FOR CONDUCTIVITY SENSORS

eSelect-CD1 works with simple conductivity 2-electrode open sensors, AISI 316 OR Graphite electrode.

FOR CONDUCTIVITY SENSORS with internal temperature sensor: due to the various types on the market, in case operator wished

to use such sensor, use PT100 temperature sensors, please contact ETATRON D.S. service or Local Dealer to get the right

configuration. eSelect-CD1 is NOT suitable for inductive EC sensors!

Install conductivity sensor into the system or an off-line holder and connect to Terminal board (see page 13) before connecting to

mains. We recommend using a new electrode or at least in good conditions (not old).

Connect Conductivity sensor to internal terminal board.

PLEASE NOTE:

eSelect-CD1 automatically adjust itself for various conductivity ranges by adapting the controller to the different probes cell constant

“K” characteristic. However, at the beginning of programming and in “Expert Menu Set-point1” user can adjust the required K factor.

It is always RECCOMENDED and mandatory to use the correct K probe according to the range in which the controller is working.

1

3

2

12

ENGLISH

- Controller covers ranges from costant K 1 up to 20.00 mS and even 100.00 mS (latter with graphite sensor electrodes) and costant

K5 ranges 2.000 μS;

The controller will adapt also the Measurement and Display resolution according to the type of probe used;

CONTROLLER SENSOR “SENSOR CALIBRATION”, check pages 22 and 26

“SENSOR CONFIGURATION AND RANGE” check page 8

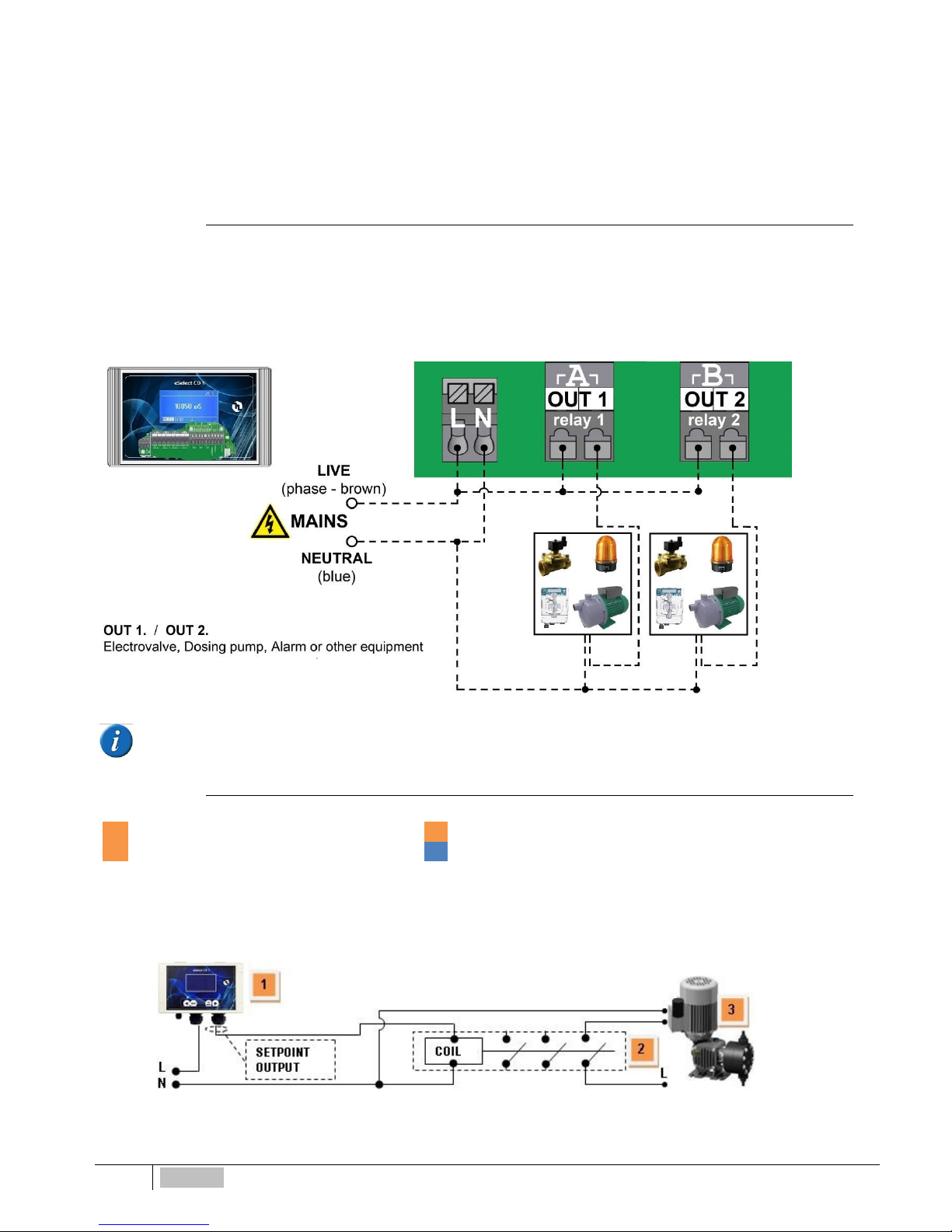

Connecting to main power supply / PARALLEL CONNECTIONS

PARALLEL CONNECTIONS: when connecting the unit to main power supply in parallel with other inductive equipment (motors,

pumps, blowers, solenoid and motorized valves), these gears must be electrically isolated and with a proper Ground system, to prevent

damages from inductive voltages when switching ON-OFF.

•try to use a power switch in order to have separate connections via contact relay or relay.

•when this is not possible, contact ETATRON technical service.

EXAMPLE CONNECTION CONTROLLER-DOSING PUMP RELAY OUTPUTS 1-2-3-4

ETATRON controllers are equipped only with clean contact relays to drive actuators (e.g.pumps) as shown in the above diagram. In

case installator

wishes to drive actuators directly from mains, wiring must respond according to local electrical rules and ensuring the

following requirements: Max 3A, Max voltage 250Vac or 30Vdc.

Example connection controller-motor dosing pump relays OUT 1-2

1

CONTROLLER

3

SINGLE PHASE MOTOR METERING PUMP

2

POWER RELAY SWITCH 230V MAX 10A

4

TRI-PHASE MOTOR METERING PUMP

L = one phase of mains network N = neutral r - s -t= represent each phase of tri-phase mains system

SINGLE-PHASE CONNECTIONS DIAGRAM THROUGH POWER RELAY SWITCH

THREE-

ENGLISH

13

PHASE CONNECTIONS DIAGRAM THROUGH POWER RELAY SWITCH

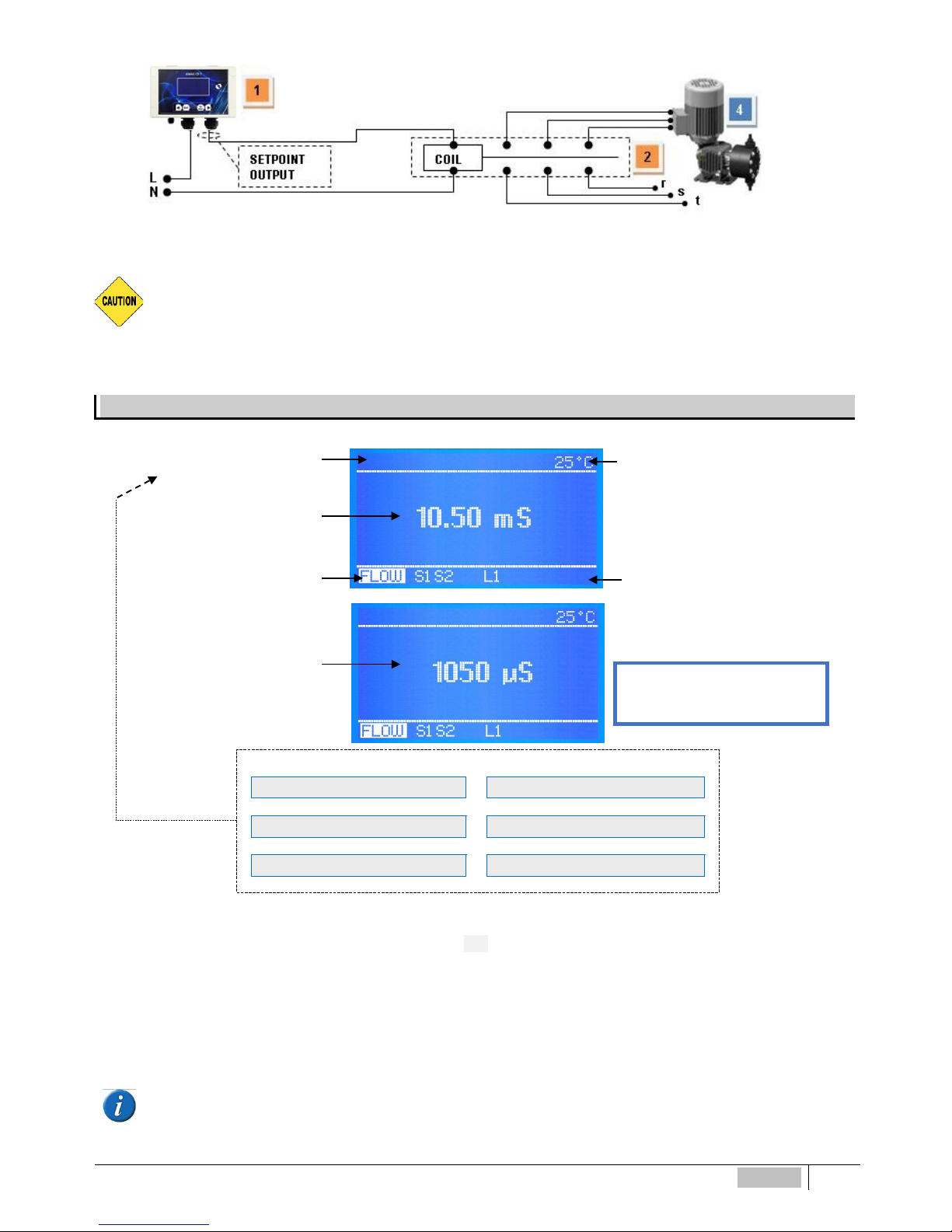

DISPLAY DESCRIPTION

* Info showing as follows:

ALARM MAX - SETPOINT 1

OVERDOSING - SETPOINT 1

ALARM MIN - SETPOINT 1

OVERDOSING - SETPOINT 2

NO LINK

OVERDOSING - 4-20mA

If there are more than one function active, messages appear in a continuous cycle lasting 3 sec. for each item. ALARM or

OVERDOSING messages will disappear once measurements are restored according to programmed settings whilst Overdosing icon will

remain; to delete activated icons from the display, keep pressing on ESC.

When messages appear, temperature status will NOT be shown.

Temperature value**: in case the temperature has been set with Manual mode, the temperature value will correspond to the one

selected. In case has been selected the PT100 mode and such temperature sensor has been connected, the temperature value shown will

correspond to the actual value in the system.

NO LINK: communication break down between controller and display

WHEN OPENING THE LID FOR SERVICING THE UNIT, ALWAYS DISCONNECT POWER SUPPLY!!!

KEEP IN MIND: unit with universal voltage 100

÷

250Vac (±10%) or 9

÷

24Vdc. If the actual voltage is constantly at the limit

(lower or higher), or when spikes are much higher than mentioned range, the unit input is electronically protected against

Voltage fluctuations; outside the above mentioned ranges, controller will not function

and circuit boards must be replaced.

We RECOMMEND using voltage protections, checking system ground and, when connecting in parallel other equipment,

using “power switch”. A plant not built according to correct electrical rules, without a ground system, with frequent ON/OFF

operations, could affect directly the circuit boards.

eSelect-CD1 series power and control boards software are linked together via 485 protocol: when in place of the temperature

display is shown “NO LINK” it means there is a problem between the two boards in that case check the electrical flat cable and

wiring connection between the them and contact immediately ETATRON service.

RX measurement

Other unit status here***

Temperature value**

Conductivity measurement

mS / range 20 mS

Messages showing here*

Controller status

Conductivity measurement

µS / range 2000 µS

Back-lit custom display (126x64)

Display visible area 70x37 mm

14

ENGLISH

Other status icons shown at bottom line***

Here are displayed some other messages status such as:

S1 S2 L1 ALARM OVERDOSING FLOW “BASIC MENU”“EXPERT MENU”

“BASIC MENU” “EXPERT MENU” these messages appear during programming steps as reminders.

Controller is set as default with * BASIC MENU * which is a simple programming for not professional user keeping all the functions

to a very basic simple menu.

* EXPERT MENU * features other parameters to select thus refining the unit operation and safety functions although programming

is still user friendly.

S1 S2 indicating the correspondent active Set point. When selecting “Mode Timed Pulses” (Pulse With Modulation) during set

point step, the message S1… S2 will flash during PWM operations but when the set point is NOT active there will not be any message.

** FLOW ** shows the absence of water flow into the sensor holder: this is valid only when using a Proximity switch and the “Flow

sensor” is enable which is possible only when using “Menu Expert”.

L1 L2 indicate the “Level” control of external chemical tanks and are only shown once the floating level probe/s are connected to

the terminal block pins IN1 and IN2: when the level into the tank is lower than the level probe floater, this will enable the Status message.

When switching ON the controller for the first time, it will appear a list of all the programming keys function.

Controller covers ranges from costant K 1 up to 20.00 mS and even 100.00 mS (latter with graphite sensor electrodes) and costant

K 5 ranges 2.000 μS. Display will show µS values but in case setpoint value exceed 1999 µS, it will show 2.00 mS (decreasing the value will

return to µS reading). Selecting K5 (5.000) range setpoint value 100 µS.

TERMINAL BOARD ELECTRICAL WIRING

WHEN OPENING THE LID FOR SERVICING THE UNIT, ALWAYS DISCONNECT POWER SUPPLY!!!

- Unscrew the front panel and carefully open the lid

- eSelect-CD1 series is provided with 2 m cable already wired; in case user wishes to replace the cable with a longer one, connect

the mains to neutral, phase, unit switches ON, initially display quickly shows the instrument latest software review.

The terminal board is built with special pin for top safety: ensure to twist well the wire ends, use a small screwdriver to

press the safe

ty on top of the slot where insert the wire ends and, according International electrical rules, we do not

recommend to connect more then one equipment on each pin.

Out A Pin COM / N.O.RELAY1 Set-point 1 ON-OFF / output relay PWM timed pulses

Out B Pin COM / N.O.RELAY2 Set-point 2 ON-OFF / output relay PWM timed pulses

Pin 1 + / Pin 2 -IN 1 Digital Input Level switch for chemical tank

Pin 3 + / Pin 4 -IN 3 Proximity Switch input BLACK +/ BLUE –wires

Pin 5 + +12Vdc out Proximity Switch input 12Vdc BROWN wire

Pin 6 / Pin 7 4/20mA 4-20mA proportional output for mA dosing pump or data device

ENGLISH

15

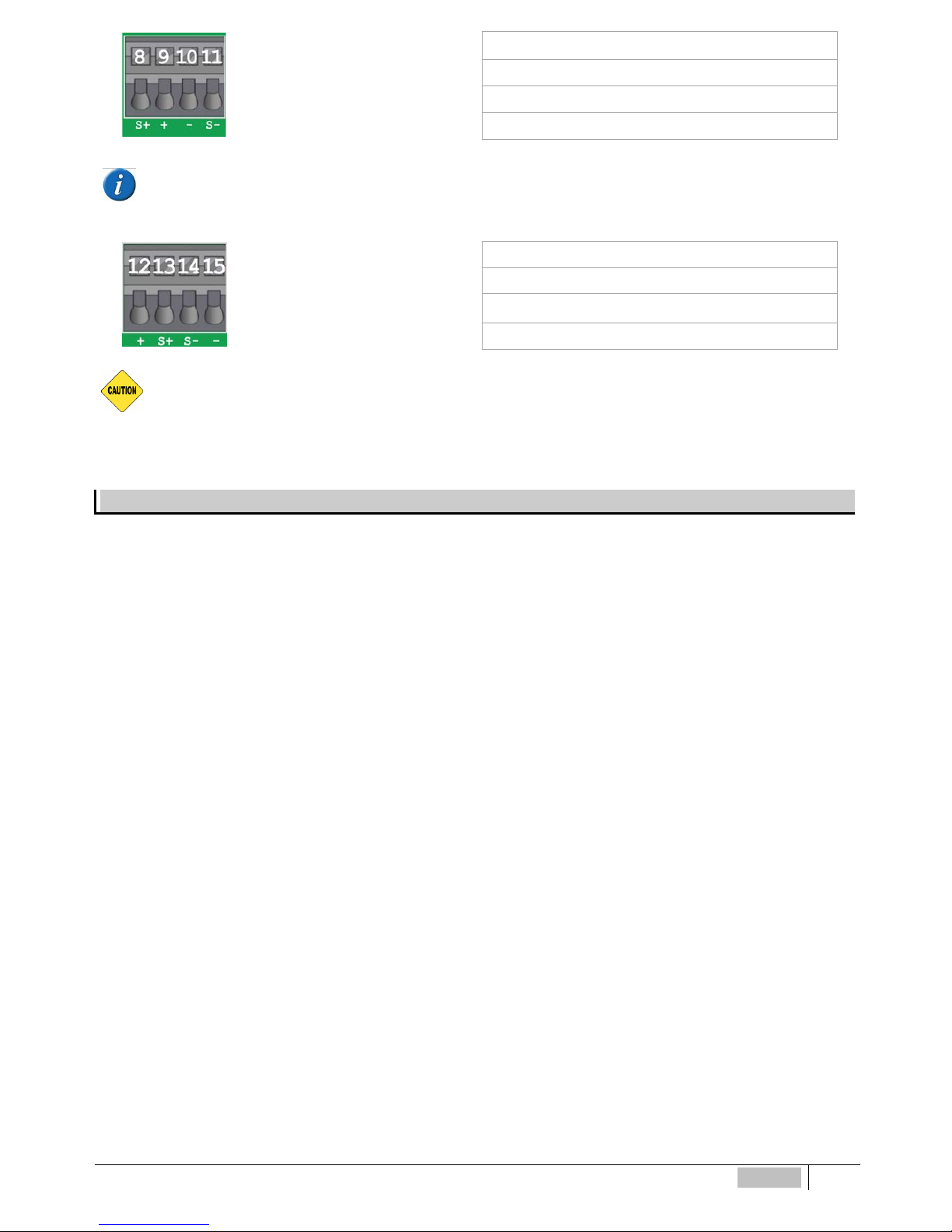

Conductivity sensor 2 wires

DO NOT CONNECT BRAIDED WIRE

Pin 8 = S+ RED or WHITE

Pin 9 = +

Pin 10 = –

Pin 11 = S– WHITE or RED

eSelect-CD1 works with simple conductivity 2-electrode open sensors, AISI 316 OR Graphite electrode. FOR CONDUCTIVITY

SENSORS with internal temperature sensor: due to the various types on the market, in case operator wished to use such sensor,

please contact ETATRON service or Local Dealer to get the right configuration for connecting to terminal board. eSelect-CD1 is

NOT suitable for inductive EC sensors!

Temperature probe PT100

DO NOT CONNECT BRAIDED WIRE

Pin 12 = + RED

Pin 13 = S+ BLUE

Pin 14 = S– GREEN

Pin 15 = – YELLOW

KEEP IN MIND: unit with universal voltage 100

÷

250Vac (±10%) or 9

÷

24Vdc. If the actual voltage is constantly at the limit (lower

or higher), or

when spikes are much higher than mentioned range, the unit input is electronically protected against Voltage

fluctuations; outside the above mentioned ranges, controller

will not function and circuit boards must be replaced. We

RECOMMEND using voltage protections, checking system ground and, when connecting in parallel other equipment, using “power

switch”. A plant not built according to correct electrical rules, without a ground system, with frequent ON/OFF operations, could

affect directly the circuit boards.

OPERATING MODES GLOSSARY

ON-OFF mode

•Unit is provided with ON-OFF mode which will activate (or deactivate in case of reverse mode ON) output relays Constant / ON-OFF

dosing pumps mode or other ON-OFF equipment.

BENEFITS: it will work with most of ON-OFF equipment, which are also cost effective.

DISAVANTAGES: due to dosing equipment high output performance rate (frequency for dosing pump and peristaltic dispensers with motor

rpm), this will result to a slight different values between actual measurement in the system and what controller shows.

USING EXTRA ON-OFF RELAY OUTPUT

•ON-OFF Relay probably will connect a dosing pump; the free available relays can connect an alarm device (buzzer and light),

programming different values then the ones for dosing pumps.

BENEFITS: increase safety measurements ensuring warning in case parameters are out of control.

DIRECT / REVERSE DIRECTION MODE

•Set points relays Direction mode are set as default as follow:

Set point 1 EC (conductivity measure: DIRECT mode, meaning that output is active when measured value is lower than selected set-

point. Set point 2 is set with REVERSE direction mode output is active when measured value is higher than selected set-point..

ALARM HIGH / LOW FUNCTION

•Alarm function allows selecting two points high and low passed which controller will go into alarm. Set point 2 relay can function as Alarm

connecting and diving an alarm device or other equipment (only Alarm High or Low).

BENEFITS: increase safety measurements ensuring warning in case parameters are out of control.

HYSTERESIS

•Hysteresis is useful during ON-OFF mode set-point adjustment operations and is used to activate or deactivate output relays when

selected hysteresis is reached. Hysteresis is useful when there are too many and/or quick changes around set point, which could damage

connected equipment. Increasing Hysteresis will allow moving away from set point according to required value.

Example with range 2000 μS: if selected set-point is 700 μS EC and Hysteresis set to 100 μS, the two active points are 600 μS and

800 μS: within this range, set-point is OFF and outputs are blocked, outside this range set-point is ON (always in accordance with direct

or reverse mode).

BENEFITS: ensuring good control the systems without stressing connected equipment.

DISAVANTAGES: user must remember that programmed hysteresis is slightly different from required set point.

16

ENGLISH

DELAY

•Delay time blocks relay outputs (max 999 sec. programmable) to ensure that the outputs are active only when the sensors

measurements are stable thus allowing the best results in terms of chemical balance.

TIMED PULSES MODE (PWM) PULSES WITH MODULATION TIME/PAUSE

•Timed Pulsesalso known as PWM “pulses with modulation” time/pause allows proportional mode on each ON-OFF set-point activating

corresponding pulses with Start/Stop time cycle variation according to measured value in respect to set-point.

Window Width (example range 2000 μS): pulses are timed ON and OFF according to the distance from selected set-point,

programmable, example: if selected set point is 700 μS EC and measured value is 600 μS, PWM mode will start after reaching 650 μS

with Time/Pause pulses and decreasing the active time while reaching set point value.

Cycle Time: PWM mode cycle 60 seconds (programmable): example set point 700 μS = active time 60 sec - pause time = 0 sec.; 675

ppm active time= 30 sec / pause time 30 sec.....and decreasing active time accordingly while reaching set point value. Cycle time

depends on many variables such as: distance from injection point to treating system, how fast or slow set point must react, chemical

concentration, etc....

Active Time MIN programmable: it sets the minimum time in which PWM is active; it overrules selected settings. Times Pulses function is

adjusted via 3 functions following the formula:

Active Time according to selected formula = (measured value – set point) / window width * cycle time If the result of the formula is < the

selected Active Time Min, the latter with overrule the first, example range 2000 μS: measured 600 μS -set point 700 μS / Window Width

0.50 *Cycle time 60 sec=active time 4 sec.

In case user has selected Active time min 5 sec., this will be minimum time of PWM and not 4 sec.

BENEFITS: a simile-proportional function more accurate then ON-OFF mode using simple equipment such as Constant dosing pumps and

peristaltic dispensers.

DISAVANTAGES: not as accurate as mA mode, user needs an accurate selection of dosing unit flow rate.

PROPORTIONAL ANALOG CURRENT OUTPUT 4÷20 mA

•4÷20mA1 and mA2 programmable proportional mode: at 4 mA corresponds selected set-point, at 20 mA corresponds the max

measured distance from selected set point. The active time on the mA outputs is calculated according to the following relation: 0 sec:4

mA / 1 sec:20mA. Analog mA outputs connections are galvanic separated. Controller allows choosing between AUX (driving data logger

or data recorder or other equipment) and Dosing set point (driving dosing pumps) or all equipment suitable to work with mA signal).

BENEFITS: best results because pulses are extremely accurate in relation to measured levels.

DISAVANTAGES: user needs a specific dosing pump for such operational mode.

OVERDOSING TIME

•Over dosing time-out alarm allows to select a period of time in which set point must be reached. If during this time set point is not

reached, controller will block outputs operations including mA outputs (dosing pump), Alarm is ON shown on display and will activate a

signalling device connected to alarm relay.

BENEFITS: to prevent excess of chemical addition.

START-UP DELAY

•Start-up Delay time “freezes” the relay outputs when switching ON the unit thus allowing sensors to polarize ensuring correct

measurements (programmable).

FLOW SENSOR “PROXIMITY SWITCH” FUNCTION

•Flow Sensor: in case, no water is running through the sensor cell holder (and eventually into the systems), flow sensor (proximity switch)

will deactivate all outputs ensuring that no extra chemical is added.

TEMPERATURE

•Manual temperature compensation. 0÷100°C. Selecting TEMP.PROBE (latter temperature sensor) compensates temperature/electrode

measurements, always giving the exact value against the current temperature.

ENGLISH

17

PROGRAMMING FUNCTIONS

Set-Points

Output Relay 1 - 2

2 set-points ON-OFF Independent setting to activate Constant / ON-OFF

mode dosing pumps or On-Off equipment.

Set point adjusts set-point value (ON-OFF mode).

Hysteresis It selects a measuring range around set-point value,

blocking output relays (ON-OFF mode)

Direct - Reverse It selects output dosing relay dosing direction.

PWM Proportional mode with

modular pulses Proportional time/pause pulses output will activate a

Constant / ON-

OFF mode dosing pumps or other

equipment.

Delay on set point It selects a delay time (999 seconds adjustable) before

activating relay output.

Alarm Min /Alarm Max Alarm function selects alarm Lowest and Highest level

passed which alarm relay will be ON or OFF.

mA output It allows to select Conductivity (μS) levels corresponding to min. / max mA output analogical signal. It activates a

dosing pump suitable to process a remote mA signal or chart recorder or Data logger.

Calibration Calibration menu for Conductivity sensor.

System

Settings

Flow sensor It activates (ON) or deactivates (OFF) flow sensor (proximity switch) input.

Manual temperature It selects manual temperature compensation. 0÷100°C (Auto-Temp=OFF).

Auto-temperature

Compensation It compensate the temperature/electrode sensor thus always measuring

the exact value against the current temperature.

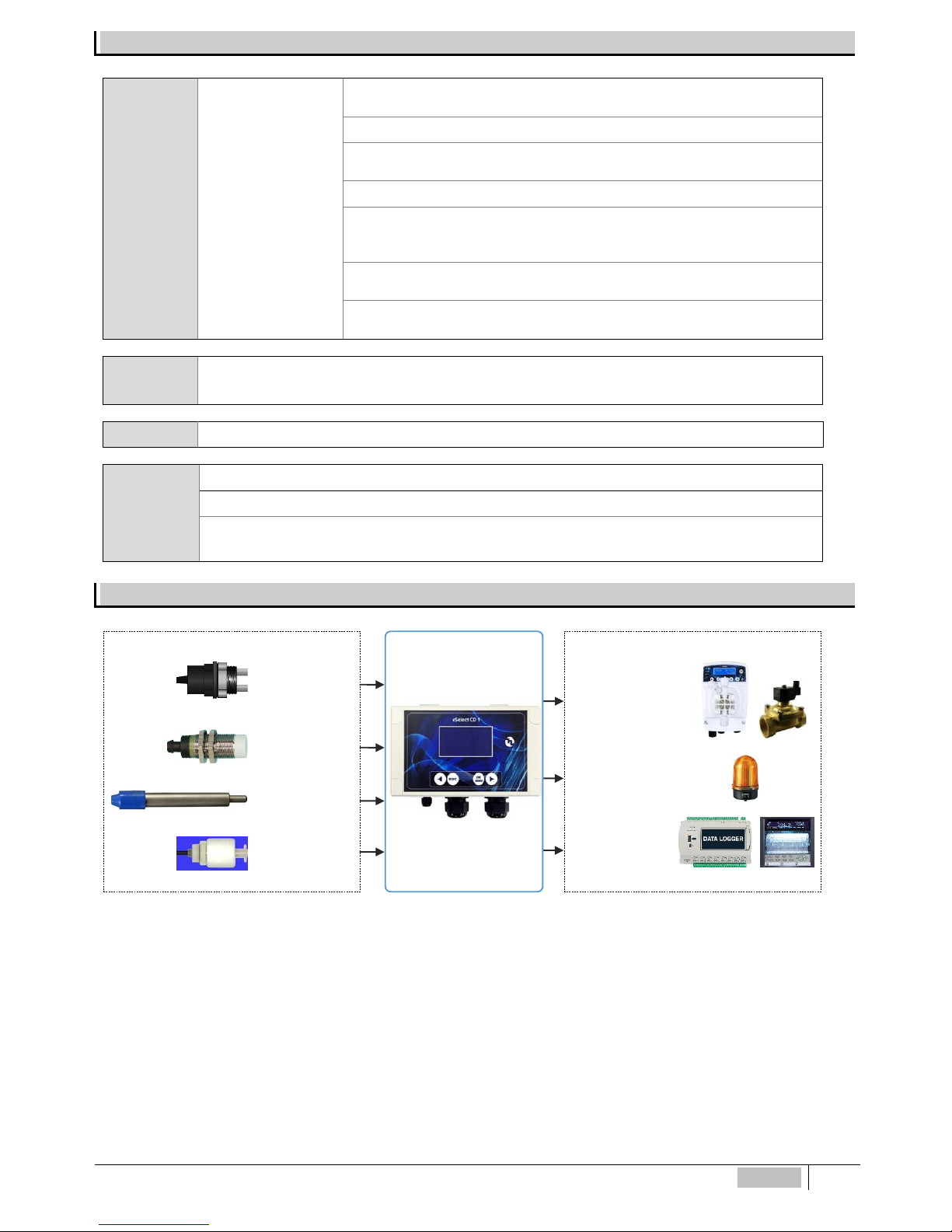

INPUTS / OUTPUTS DIAGRAM FUNCTIONS

INPUTS TO...........

EC

probe

Proximity

switch

Temperature

sensor

Level probe

for chemical

tanks

OUTPUTS TO...........

Set point 1-2

dosing pumps,

solenoid valves or

other equipment

Alarm output

(using Set point 2)

mA ouputs:

data logger:

chart recorder;

dosing pumps

18

ENGLISH

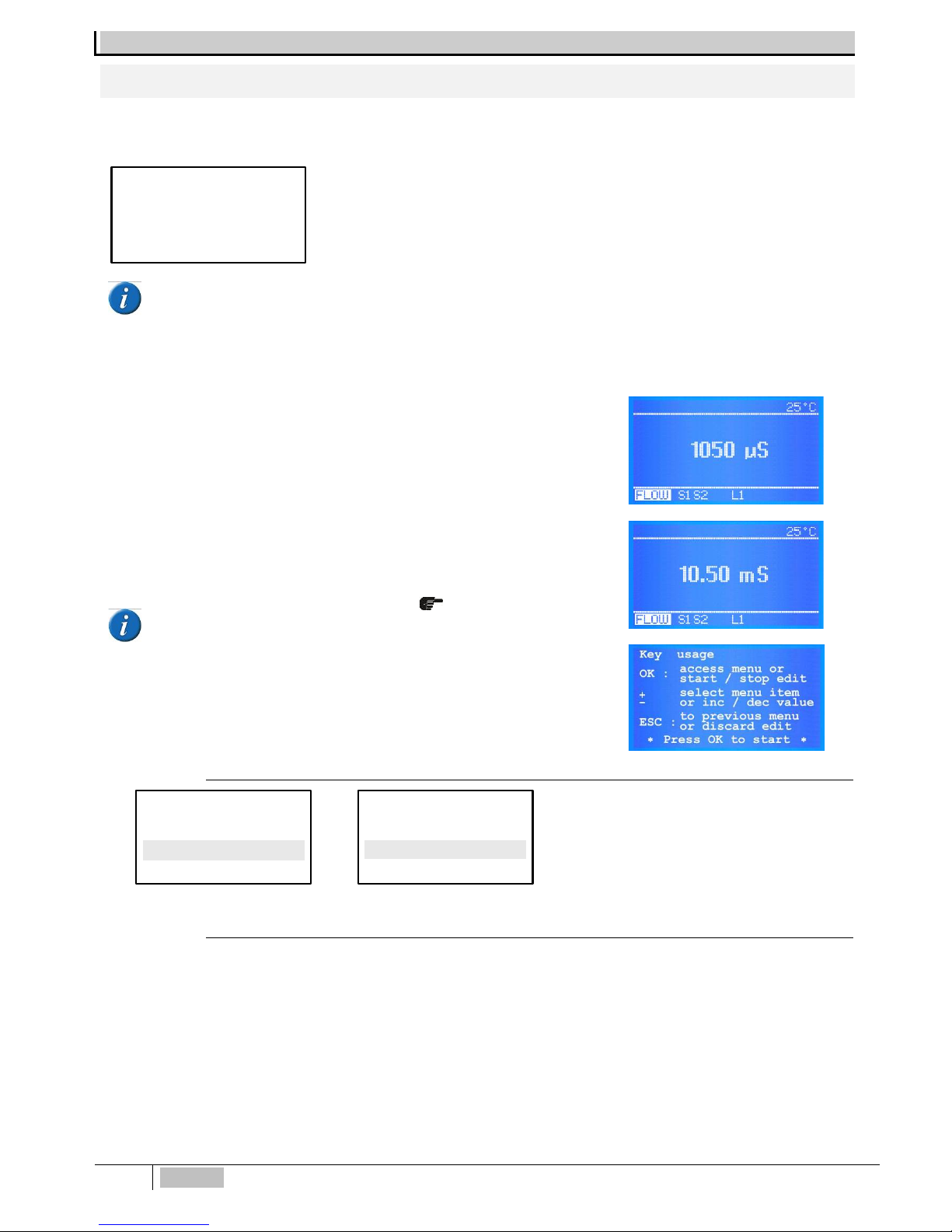

INITIAL DISPLAY

NOTES FOR PROGRAMMER: try not to press the keys continuously. First, read the manual before programming or have the

booklet handy so to be sure to perform a correct selection.

IMPORTANT: if keys are not pressed during 60 seconds, controller will display current measurements.

For rapid advancement, keep pressed firmly either one of ◄► keys

When the controller is turned ON there will be displayed at the bottom the latest software upgrade.

Software is subject to revision without further notice.

Controller will get set for measurements and ready to work.

at this point there could be some here are displayed some other messages status such as:

S1 S2 L1 ALARM OVERDOSING FLOW *BASIC MENU* *EXPERT MENU*

which could be ON due to actual measurements, just go ahead with programming.

Display shows pH, Redox mV and Chlorine ppm measurements. If controller has been already programmed, display shows

previously selected set points.

INITIAL DISPLAY

shows measurements according to the K range selected in the next

paragraph.

If the controller has been already programmed, display will show previously

selected programs.

CONTINUOS MEASUREMENT DISPLAY

shows when parameter measurements, function

status and alarm indications.

When the controller is turned ON for the first time, th

ere will be displayed a list of all the

programming function keys which will not appear in the next switching ON operations.

CAREFULLY READ KEY USAGE THEN PRESS

OK to start

For rapid advancement

keep pressed firmly either one of the ◄► keys

Selecting Language

◄

►

◄

►

The controller has 2 languages: English and

Italian, selected by using the keypad arrows.

Selecting Conductivity (EC) “K” factor

Conductivity EC value automatically adjust itself for various conductivity ranges by adapting the controller to the probes cell costant

“K” characteristic.

Controller covers ranges from cell costant K 1 up to 20.00 mS and even 100.00 mS (latter with graphite sensor electrodes) and

costant K 5 ranges 2.000 μS. Display will show µS values but in case setpoint value exceed 1999 µS, it will show 2.00 mS (decreasing the

value will return to µS reading). Selecting K5 (5.000) range setpoint value 100 µS.

IMPORTANT: the above μS ranges are just indicative: for example a K1 probe can make good measurements below 1000 μS, only

resolution will be less accurate. However the same concept doesn’t apply the other way for high ranges.

Lingua

Italiano

Language

English

ETATRON D.S.

MODEL ESELECT-CD1

Rev. X . X

ENGLISH

19

K selections starts from 1.000 and pressing ◄► value can reach up to 20.000 or down to 0,000.

K1 select 1.000

K5 select 5.000

Controller will adapt Measurement and Display resolution according to the type of probe used as shown in page 13;

IMPORTANT: once selected EC probe K factor, ENSURE, to connect the proper Conductivity sensor.

In case, the user wished to change the EC K RANGE, even during operations:

from

∗

BASIC

∗

menu, move to > SETTINGS > CALIBRATION > EC probe K factor

from

∗

EXPERT

∗

menu, move to > MAIN MENU > CALIBRATION > EC probe K factor

Press ESC to return to MAIN MENU or Press ESC ESC to CONTINUOS MEASUREMENT display.

TEMPERATURE settings

Manual temperature compensation 0÷100°C.

Press ◄► to show the environmental temperature.

Se

lecting AUTO compensation temperature/electrode

measurements, always giving the exact value against the current

temperature.

Press ◄► to show the environmental temperature to calibrate

sensor.

Programming MENU

eSelect-CD1 series allows choosing between:

•BASIC programming: simplified mode for not professional operators

•EXPERT programming: complete programming including functions for a more refined control and results

Once selected the programming menu, Menu and submenus will change accordingly.

To help operator to choose the correct menu here following the main difference between the two menus:

Setpoint 1-2 Setpoint Value - Dosing Mode - Mode ON/OFF or Timed Pulses - Alarm

MIN/MAX - Priming > Calibration > Settings

Setpoint 1-2 Setpoint Value - Dosing Mode - Mode ON/OFF or Timed Pulses -

Hysteresys - Delay - Temperature correction Alarm MIN/MAX - Overdosing - Startup

Delay - Priming > 4-20mA > Calibration > Settings

Press OK/MENU

display shows BASIC mode (default):

◄

►◄

►

Selecting either one of the two menus, will change

the Main Menu programming accordingly.

In case the user wished to change the operating Menu, after the initial selection and even during operations, move to > SETTINGS

menu than go to > PROGRAMMING steps.

◄

►

Press ESC

to return to MAIN MENU or press ESC ESC

for CONTINUOS MEASUREMENT display.

After selecting, e.g. choosing EXPERT, at first display will still show Basicbut as soon as moving to other steps it will change

to Expert, and vice versa.

CONTROLLER SETTINGS

Temperature

XX°C

CONTROLLER SETTINGS

Temp. Probe

Manual

CONTROLLER SETTINGS

Temp.Probe

Auto

EC METER SETTINGS

EC probe K factor

1.000

CONTROLLER SETTINGS

Programming

BASIC

CONTROLLER SETTINGS

Programming

EXPERT

Select Menu

Settings

Menu

EXPERT

Menu

BASIC

Select Menu

EXPERT

Select Menu

BASIC

20

ENGLISH

MAIN MENU > BASIC PROGRAMMING MENU

These are all the steps included in the MAIN MENU loop visualization with BASIC menu programming:

◄

►

◄

►

◄

►

◄

►

Selecting EC probe K range , Setpoint 1 - 2 and Calibration programming will follow range values.

Press OK/MENU

to confirm selection and to approach next submenu.

Press ESC to return to CONTINUOS MEASUREMENT display.

SETPOINT 1 EC CONDUCTIVITY > BASIC MENU

Keep in mind that the value displayed is automatically adjust

ed to the selected

conductivity range cell constant “K” characteristic in previous paragraph SELECTING

CONDUCTIVITY “K” FACTOR

Set point will activate output relays for dosing pumps or other

equipment once selected set-point level is reached. Display will

show µS values but in case setpoint value exceed 1999 µS, it

will show 2.00 mS (decreasing the value will return to µS

reading). Selecting K5 (5.000) range setpoint value 100 µS

Direct mode operation: output is active when measured value is

lower than selected set point thus driving connected equipment.

Reverse mode works the opposite way.

Unit is provided with ON-OFF mode which will activate (or deactivate in case of reverse mode ON)

output relays such as Constant / ON-OFF mode dosing pumps or other On-Off equipment.

*SELECTING MODE “ON-OFF” NEXT PROGRAMMING STEP “ALARM MIN”

*Timed Pulses also known as PWM “pulses with modulation” time/pause allows proportional mode

on each ON-OFF set point activating corresponding pulses on output relay according to measured

value and always relating to the previous hysteresis selected settings. Default activating point at

1000 μS (range 0-20.000 μS DEFAULT); 100 μS (range 0-2000 μS); 0,10 μS (range 0-200 μS);

10000 μS (range 0-200.000 μS)

For more accurate “Timed Pulses” PWM settings, select “Expert” menu from initial settings

* BACK TO SETPOINT PROGRAMMING STEPS FROM EITHER “ON-OFF” OR “TIMED PULSES” MODE

MENU SETPOINT 1

Setpoint Value

100 µS

∗BASIC MENU ∗

MENU SETPOINT 1

Setpoint Value

1000 µS

∗BASIC MENU ∗

MENU SETPOINT 1

Mode

Timed Pulses

∗BASIC MENU ∗

MENU SETPOINT 1

Working Mode

Reverse

∗BASIC MENU ∗

MENU SETPOINT 1

Working Mode

Direct

∗BASIC MENU ∗

Select Menu

Setpoint 1 (EC)

MENU SETPOINT 1

Mode

ON/OFF

∗BASIC MENU ∗

Select Menu

Settings

Select Menu

Calibration

Select Menu

Setpoint 2

Select Menu

Setpoint 1

Table of contents

Other Etatron Controllers manuals

Popular Controllers manuals by other brands

RYTEC

RYTEC System 4 Installation & owner's manual

Fisher

Fisher 657 Sizes 80 instruction manual

Martin

Martin M6 Series Guide

Delta Electronics

Delta Electronics Programmable Logic Controller DVP-EH2-L instruction sheet

Nico Technology

Nico Technology 1201L-1K RTD user manual

DTI

DTI HV-500 Technical description

Siemens

Siemens SIMOTION P320-4 E manual

i2Systems

i2Systems Lightlink LL-105-R Setup guide

Bollfilter

Bollfilter 2200 Operating and installation instructions

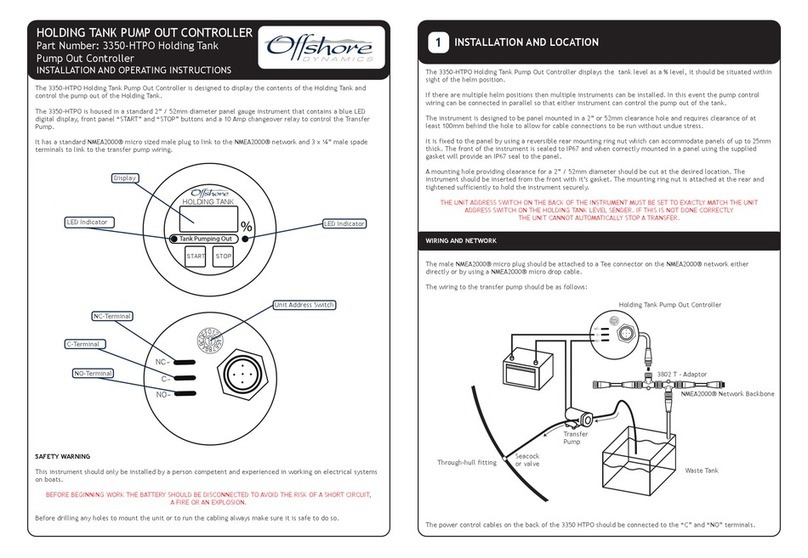

Offshore

Offshore 3350-HTPO Installation and operating instructions

Mold-Masters

Mold-Masters TempMaster M2 Plus Series user manual

Rain Bird

Rain Bird IC System Design guide