HOLDING TANK PUMP OUT CONTROLLER

Part Number: 3350-HTPO Holding Tank

Pump Out Controller

INSTALLATION AND OPERATING INSTRUCTIONS

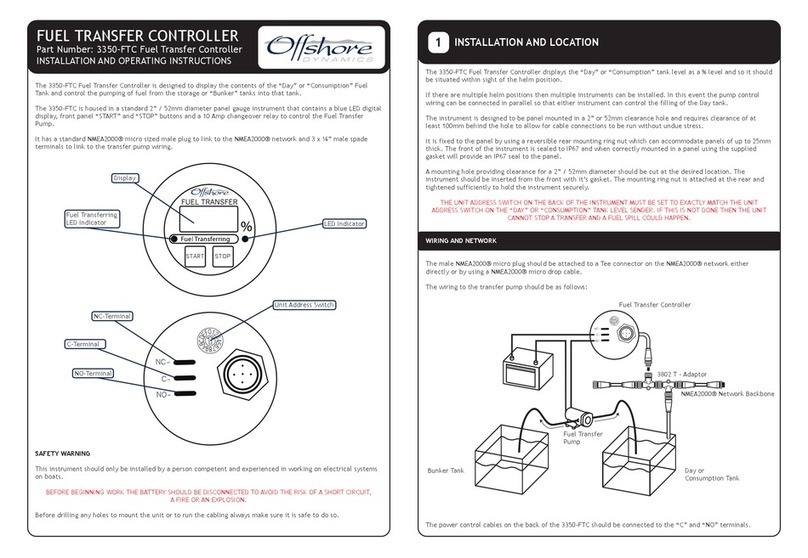

The 3350-HTPO Holding Tank Pump Out Controller is designed to display the contents of the Holding Tank and

control the pump out of the Holding Tank.

The 3350-HTPO is housed in a standard 2” / 52mm diameter panel gauge instrument that contains a blue LED

digital display, front panel “START” and “STOP” buttons and a 10 Amp changeover relay to control the Transfer

Pump.

It has a standard NMEA2000® micro sized male plug to link to the NMEA2000® network and 3 x ¼” male spade

terminals to link to the transfer pump wiring.

SAFETY WARNING

This instrument should only be installed by a person competent and experienced in working on electrical systems

on boats.

BEFORE BEGINNING WORK THE BATTERY SHOULD BE DISCONNECTED TO AVOID THE RISK OF A SHORT CIRCUIT,

A FIRE OR AN EXPLOSION.

Before drilling any holes to mount the unit or to run the cabling always make sure it is safe to do so.

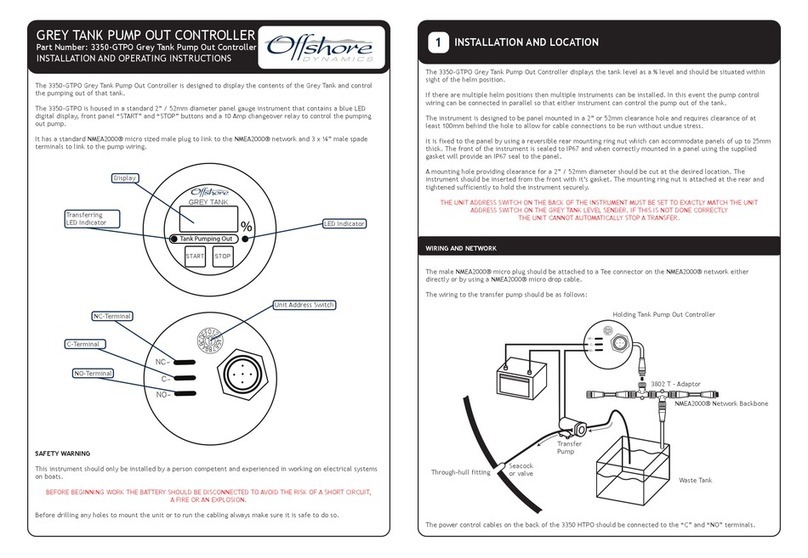

The 3350-HTPO Holding Tank Pump Out Controller displays the tank level as a % level, it should be situated within

sight of the helm position.

If there are multiple helm positions then multiple instruments can be installed. In this event the pump control

wiring can be connected in parallel so that either instrument can control the pump out of the tank.

The instrument is designed to be panel mounted in a 2” or 52mm clearance hole and requires clearance of at

least 100mm behind the hole to allow for cable connections to be run without undue stress.

It is fixed to the panel by using a reversible rear mounting ring nut which can accommodate panels of up to 25mm

thick. The front of the instrument is sealed to IP67 and when correctly mounted in a panel using the supplied

gasket will provide an IP67 seal to the panel.

A mounting hole providing clearance for a 2” / 52mm diameter should be cut at the desired location. The

instrument should be inserted from the front with it’s gasket. The mounting ring nut is attached at the rear and

tightened sufficiently to hold the instrument securely.

THE UNIT ADDRESS SWITCH ON THE BACK OF THE INSTRUMENT MUST BE SET TO EXACTLY MATCH THE UNIT

ADDRESS SWITCH ON THE HOLDING TANK LEVEL SENDER. IF THIS IS NOT DONE CORRECTLY

THE UNIT CANNOT AUTOMATICALLY STOP A TRANSFER.

WIRING AND NETWORK

The male NMEA2000® micro plug should be attached to a Tee connector on the NMEA2000® network either

directly or by using a NMEA2000® micro drop cable.

The wiring to the transfer pump should be as follows:

The power control cables on the back of the 3350 HTPO should be connected to the “C” and “NO” terminals.

INSTALLATION AND LOCATION

1

LED Indicator

LED Indicator

Display

STARTSTOP

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

NC

C

NO

Unit Address Switch

3802 T - Adaptor

Holding Tank Pump Out Controller

NMEA2000® Network Backbone

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

NC

C

NO

Through-hull fitting

Seacock

or valve

Waste Tank

Transfer

Pump

NC-Terminal

C-Terminal

NO-Terminal

Tank Pumping Out

HOLDING TANK