Etneo Q200 User manual

Scientific technological Center

Via Bovio 6 –28100 Novara - NO - Italy

www.etneo.com

Lead Free Soldering Pot

INSTRUCTION MANUAL

Q200/400

1. Safety Instruction

WARNING

Please read this instruction manual before operating the unit for avoiding the accident

The unit must use three grounding cord and socket for good ground, including the prolonging

power cord

Do not use the unit to other task except to melt the soldering tin

The highest temperature can be up to 400℃. When changing some parts of the unit, please switch

off the power supply and after it has cooled down

Do not use the unit near the flammable gas and the other flammable materials

The unit must be put on the flat workbench and not incline it when working. Make sure the

workbench is heat resistant

When using the unit, do not do some actions may be harmful to the body or damage the other

objects

Do not touch the metal parts before the unit cooling down

When moving the unit, it must switch off the power supply and after the unit has cooled down

Please do not make bold to change the unit

Do not dampen the unit

When the unit is not in using for a period of time, it must switch off the power supply.

NOTE

No leave the solder pot at side when it is still highly heat and not has other person at side for

avoiding accident

No use the unit in the damp surrounding

No use the unit with the broken power cord

When the temperature is above 300℃, it will oxide the soldering tin and shorten the life of the

unit. Use the unit at the as lower temperature as possible

When using the unit for the fist time, please set a lower temperature (such as 300℃) at fist, and

then wait unit the temperature is stable, it can adjust the temperature to higher point (such as

400℃)

The unit must be maintained by the special persons when it is in malfunction. Or else, you can

contract with our company or the agent.

2. Summary

It is a lead free design with closed-loop sensor controlling temperature. The pot is made of special alloy

metal and the heater element encompasses around the pot. So the power efficiency is high and the heating

is rapid and the temperature is stable and not fluctuating with the voltage. With good heat conduct and

heat insulation, it avoids the blight to the machine, PCBs and other elements.

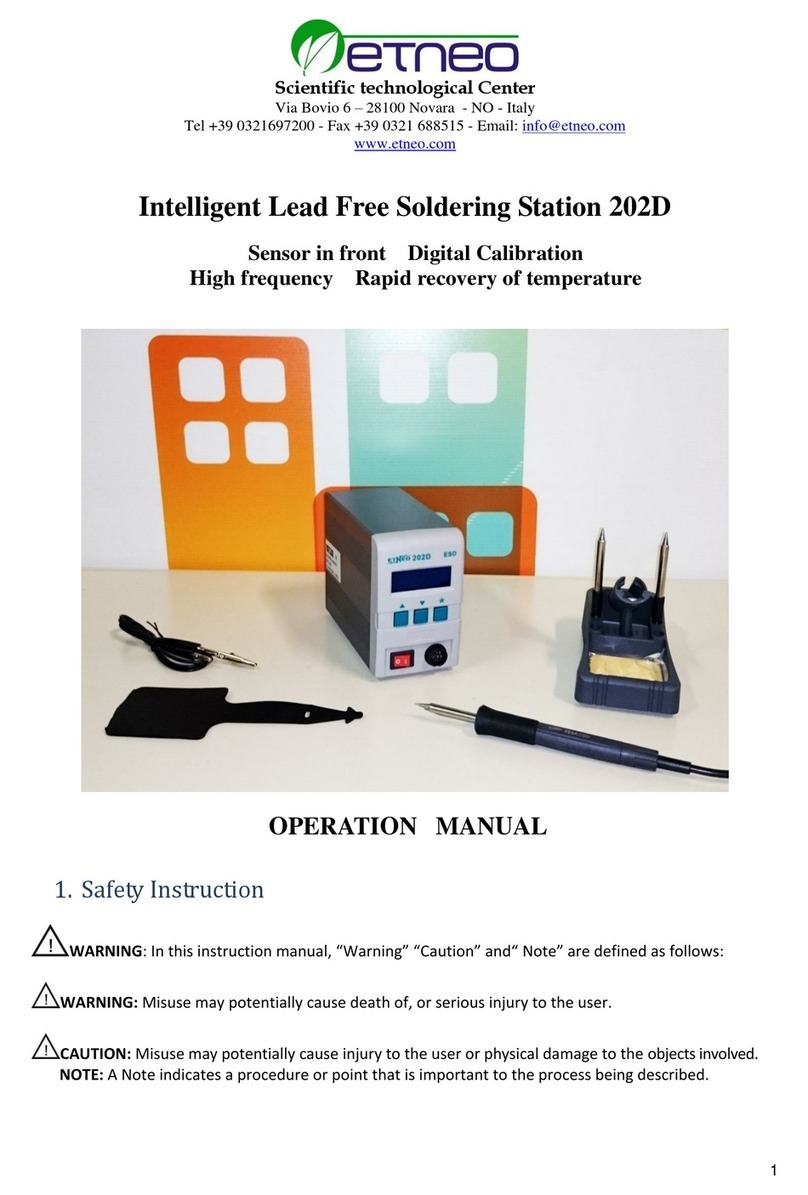

Temperature

adjusting knob

Calibration hole

Pot

Power switch

3. Characters

Closed-loop sensor controls the temperature and zero triggering without interfering with the

voltage

With the special metal (anti-erosion and heat-resistant) and the life putting into service for lead

free is long

Heating speed is rapid and the temperature is stable and accuracy

Smart design and it is easy to use.

4. Specifications Q200/Q400

Power: 200/400W

Size of the solder pot: ¢36 H40mm / ¢54 H38mm

Temperature range: 150℃~500℃/ 150℃~450℃

Temperature stability: ±5℃

Weight: 1kg /1.34kg (including power cord)

Dimension: 91(L)*150 (W)*75 (H) mm / 190(L)*115 (W)*75 (H) mm

5. Operation

Warning: the using voltage must be identical with the rated voltage of the escutcheon.

1) Put the solder pot on the flat workbench which is heat-resistant or put a metal plate under the

solder pot

2) Put condign soldering tin to the pot and the maximal position of the soldering tin must be

under the pot’s top 5mm

3) Connect with the three wire-grounding socket

4) Turn on the power knob and then the unit comes to heat. At the time, the red LED is on

5) Adjust the temperature-adjusting knob to the needed temperature scale

6) It needs spend some time to melt the soldering tin, such as ten minutes from 25℃to 300℃. It

can put into service when the soldering tin has melted and the LED is twinkle or darkle. If there

are some oxides floating on the surface, it must clear off the oxides and keep the soldering tin

clean

7) It must turn off the power switch to cool the unit after finishing work

6. Temperature calibration

It should be recalibrated after replacing the pot or the heating element.

1) Set the temperature of the unit to 300℃

2) When the temperature of the unit stabilizes, dip the outer temperature sensor of the

thermometer into the pot and view the value when the temperature of the thermometer

stabilizing

3) If the value of the thermometer’s temperature is not 300℃, calibrating the temperature. Use a

straight –edge (-) screwdriver or small plus (+) screwdriver to adjust the screw (marked CAL)

until the thermometer indicates a temperature of 300℃. Turn the screw clockwise to reduce

the temperature and counterclockwise to increase the temperature

4) If the temperature still has some departures, you can repeat calibration in according with the

above steps.

7. Maintenance

A. Judge the heater or the sensor has been in malfunction as the following:

1) If the setting temperature of the solder pot is high but the soldering tin’s temperature in

the pot still is about room temperature after heating a period of time. Besides, the red LED

is on all the time. At the moment, it can judge the heater element is in malfunction

2) Turn on the power switch, the red LED is not on and the solder pot is not heating. If the

power supply and the fuse are both in gear, at the moment, it can judge the sensor is in

malfunction

B. Because the pot may be eroded after using a period of time, it must check the pot periodically

Suggest: If using lead soldering tin, it should check at least one time each year (as the setting

temperature is 250℃and the work time is five days each week and eight hours every day)

If using lead-free soldering tin, it should check at least one time each half-year (as the

setting temperature is 250℃and the work time is five days each week and eight hours

every day)

Note: when the heater or the sensor has been in malfunction, it must be maintained by the

special person or contact with our company or agent.

This manual suits for next models

1

Table of contents

Other Etneo Soldering Gun manuals

Popular Soldering Gun manuals by other brands

Elenco Electronics

Elenco Electronics SL-5 instruction manual

Würth

Würth Powerjet Translation of the original operating instructions

Weller

Weller WTBR 1000 manual

Hakko Electronics

Hakko Electronics 936 instruction manual

Weller

Weller WXPP Translation of the original instructions

Steren

Steren CAU-260 instruction manual