1

CONTENTS

1 Safety Instruction ................................................................................................................................................. 2

2 Introduction ......................................................................................................................................................... 3

3 Characteristic ....................................................................................................................................................... 3

4 Technical Data ..................................................................................................................................................... 3

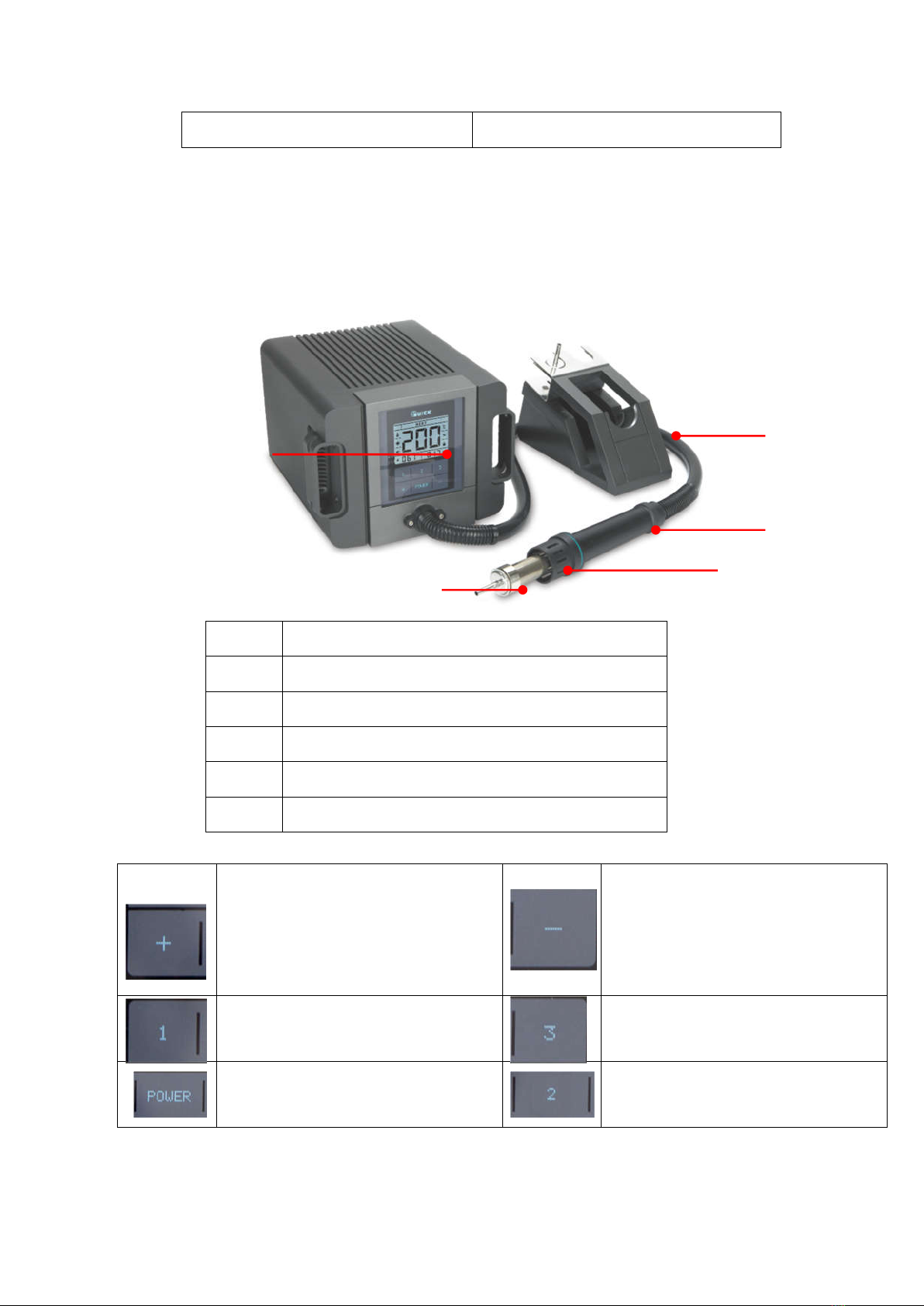

5 Part Description ................................................................................................................................................... 4

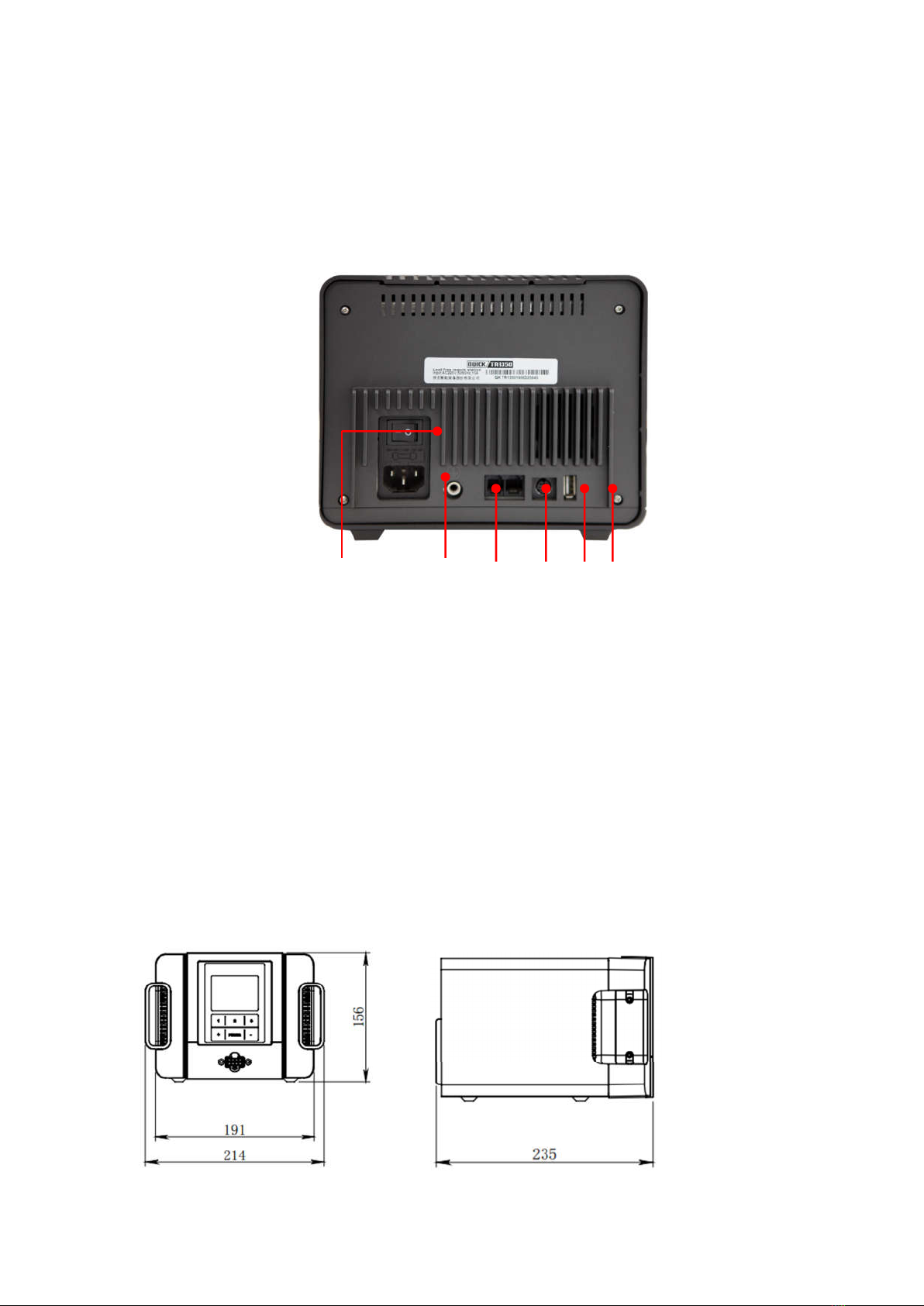

6 Connection and Dimension.................................................................................................................................. 5

6.1 Connection .................................................................................................................................................... 5

6.2 Dimension ..................................................................................................................................................... 5

7 Operation Process ................................................................................................................................................ 6

7.1 Turn ON/OFF ................................................................................................................................................. 6

7.2 Foot Switch Function .................................................................................................................................... 6

7.3 Sleep and Work Mode .................................................................................................................................. 6

7. 4 Break Sleep Method .................................................................................................................................... 7

8 Menu Setting ........................................................................................................................................................ 7

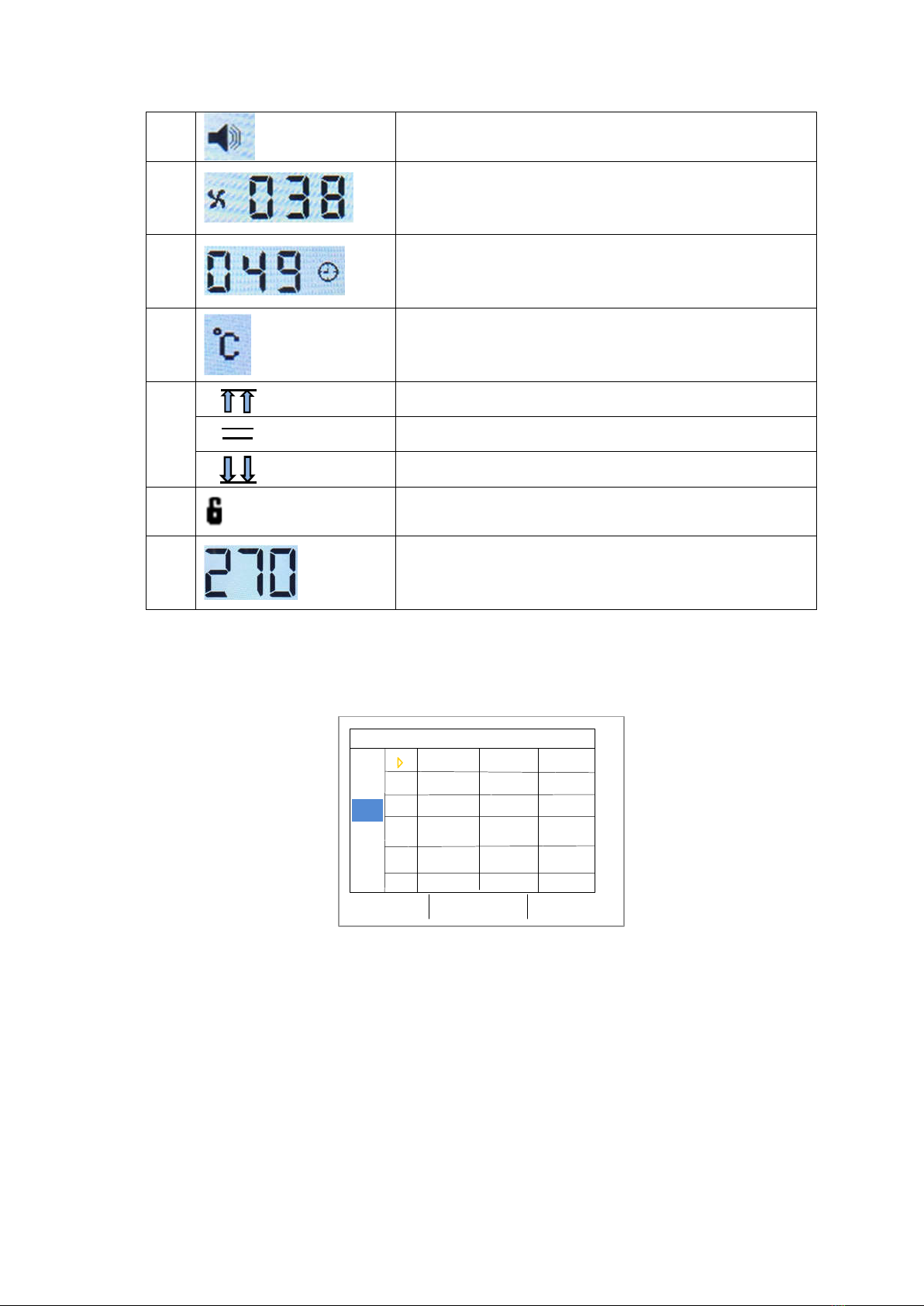

8.1 Main Menu ................................................................................................................................................... 7

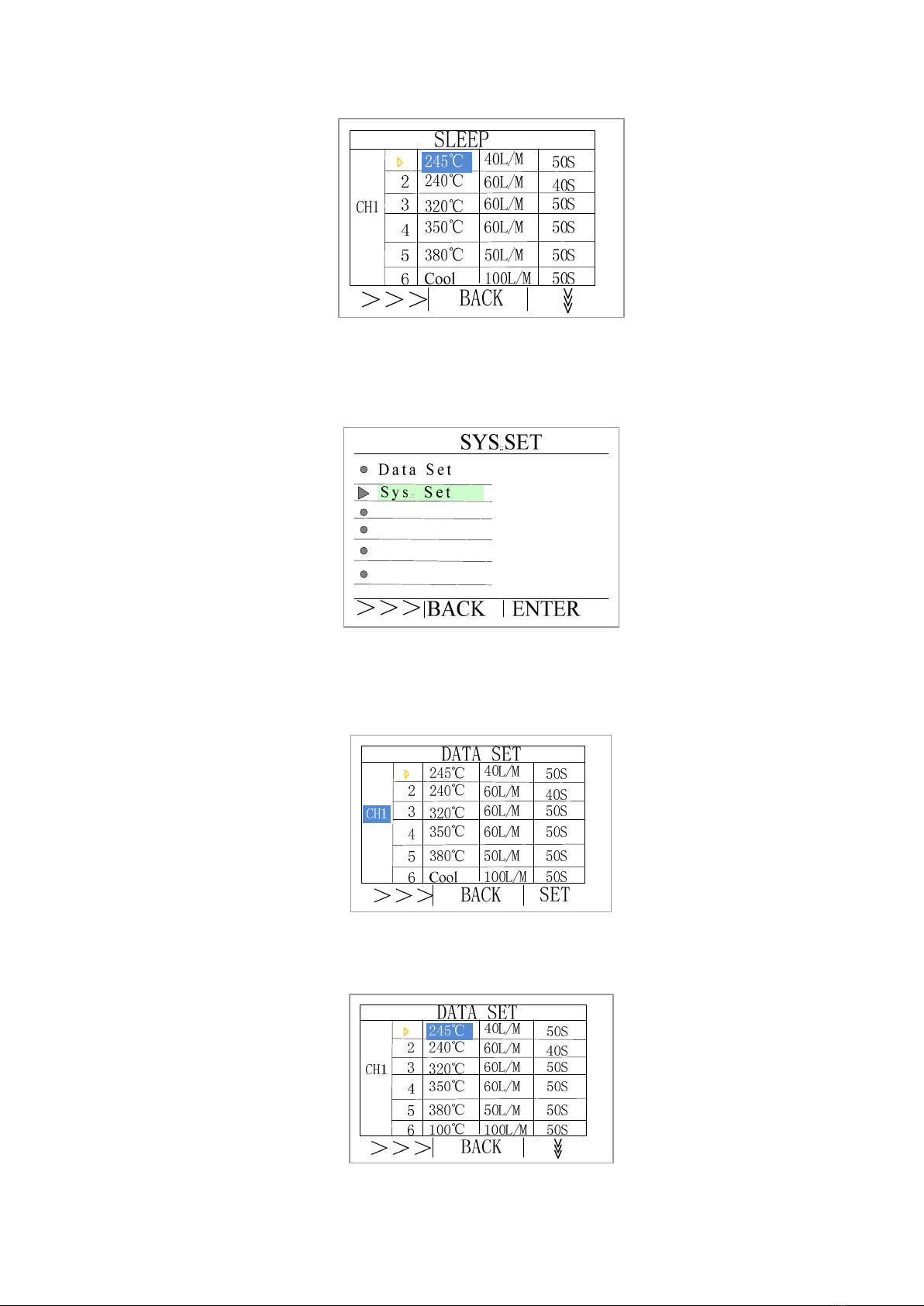

8.2 Data Set Menu .............................................................................................................................................. 9

8.3 System Set Menu ........................................................................................................................................ 10

8.3.1 Password .............................................................................................................................................. 10

8.3.2 Unit ...................................................................................................................................................... 10

8.3.3 Alarm Temperature ............................................................................................................................. 11

8.3.4 ESD Test ............................................................................................................................................... 11

8.3.5 Key Tone .............................................................................................................................................. 11

8.3.6 Address ................................................................................................................................................ 12

9 Maintenance ...................................................................................................................................................... 12

10 Error Symbol ................................................................................................................................................... 13