Eton America ROVER GT User manual

ETON America

ROVER GT

SERVICE MANUAL

ROVER GT (UK2)

ROVER GT 7 / 2007

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

1

Table of Contents

1. INFORMATION...................................................................................................................................... 3

1.1 Safety .................................................................................................................................................3

1.2 Notes..................................................................................................................................................3

1.3 Specifications.....................................................................................................................................4

1.4 VIN & Engine Number......................................................................................................................6

1.5 Standard Torque Values.....................................................................................................................7

2. MAINTENANCE..................................................................................................................................... 8

2.1 Maintenance Schedule.......................................................................................................................8

2.2 Maintenance Record ..........................................................................................................................8

2.3 Fuel Lines & Filter.............................................................................................................................9

2.4 Throttle Operation..............................................................................................................................9

2.5 Throttle Cable Adjustment.................................................................................................................9

2.6 Air Cleaner.......................................................................................................................................10

2.7 Spark Plug........................................................................................................................................10

2.8 Idle Speed.........................................................................................................................................11

2.9 Drive Chain......................................................................................................................................11

2.10 Braking Systems ............................................................................................................................12

2.11 Wheels & Tires..............................................................................................................................13

2.12 Steering System .............................................................................................................................13

2.13 Toe-In.............................................................................................................................................13

2.14 Gear Oil..........................................................................................................................................14

3. ENGINE REMOVAL AND INSTALLATION........................................................................................ 15

3.1 Service Information .........................................................................................................................15

3.2 Engine Removal...............................................................................................................................15

3.3 Engine Installation...........................................................................................................................15

4. FUEL AND LUBRICATION SYSTEMS................................................................................................ 17

4.1 Trouble Shooting .............................................................................................................................17

4.2 Fuel Tank.........................................................................................................................................18

4.3 Carburetor........................................................................................................................................18

4.4 Engine Oil Level & Changing .........................................................................................................20

4.5 Oil Pump removal / Installation.......................................................................................................22

5. ENGINE COMBUSTION SYSTEM...................................................................................................... 26

5.1 Service & General Information........................................................................................................26

5.2 Trouble Shooting .............................................................................................................................26

5.2 Trouble Shooting .............................................................................................................................27

5.3 Top End Removal............................................................................................................................28

5.4 Cylinder Head Removal...................................................................................................................30

5.5 Cylinder Head Assembly.................................................................................................................33

6. CYLINDER & PISTON......................................................................................................................... 36

6.1 Service Information .........................................................................................................................36

6.2 Trouble Shooting .............................................................................................................................36

6.3 Cylinder & Piston Removal.............................................................................................................37

6.4 Piston Installation.............................................................................................................................41

7. TRANSMISSION SYSTEM.................................................................................................................. 44

7.1 Service Information .........................................................................................................................44

7.2 Shift Mechanism C.D.I.....................................................................................................................45

7.3 Automatic Variable Speed Transmission (C.V.T.)..........................................................................45

7.4 C.V.T. Belt.......................................................................................................................................46

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

2

7.5 Electrical Starter Mechanisim..........................................................................................................46

7.7 C.V.T. Reassembly..........................................................................................................................50

8A. TRANSMISSION GEAR SET............................................................................................................ 52

8A.1 Service Information.......................................................................................................................52

8A.2 Trouble Shooting...........................................................................................................................53

8A.3 Gear Removal ...............................................................................................................................53

8A.4 Gear Set and Bearing Inspection...................................................................................................54

8A.5 Gear Set Installation......................................................................................................................55

8B. SHIFTING GEAR BOX...................................................................................................................... 56

8B.1 Service Information.......................................................................................................................56

8B.2 Trouble Shooting...........................................................................................................................57

8B.3 Transmission Assembly Drawing.................................................................................................58

8B.4 Shift Mechanism ...........................................................................................................................59

8B.5 Gear Box Assembly ......................................................................................................................60

9. STEERING SYSTEM............................................................................................................................ 61

9.1 Steering System Drawing..................................................................................................................61

9.2 Trouble Shooting...............................................................................................................................61

9.3 Steering Wheel Removal...................................................................................................................62

9.4 Steering System Removal......................................................................................................................62

10. WHEEL AND BRAKE SYSTEM......................................................................................................... 67

10.1 Wheel and Brake System Drawings ..............................................................................................67

10.2 Troubleshooting.............................................................................................................................68

10.3 Wheel Removal & Installation.......................................................................................................68

10.4 Drive Mechanism & Rear Brake Removal....................................................................................69

10.5 Front Hydraulic Disc Brake System..............................................................................................72

11. BODY COVERS AND EXHAUST SYSTEM....................................................................................... 77

11.1 Body Cover Drawings....................................................................................................................77

11.2 Cage & Body Cover Removal .......................................................................................................77

11.3 Exhaust System Drawing...............................................................................................................79

11.4 Exhaust System Removal ..............................................................................................................80

11.5 Servicing the Spark Arrestor..........................................................................................................80

12. ELECTRICAL SYSTEM...................................................................................................................... 82

12.1 Trouble Shooting ...........................................................................................................................82

12.2 Ignition Coil...................................................................................................................................84

12.3 Ignition Timing..............................................................................................................................84

12.4 Battery Inspection and Maintenance..............................................................................................84

12.5 Wiring Diagram.............................................................................................................................87

13. TROUBLESHOOTING................................................................................................. 88

13.1 Engine Does Not Start ...................................................................................................................88

13.2 Poor Performance at Low Idle.......................................................................................................89

13.3 Poor Performance at High Speed...................................................................................................89

13.4 Loss of Power ................................................................................................................................90

13.5 Poor Handling................................................................................................................................91

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

3

1. INFORMATION

1.1 Safety

Gasoline is extremely flammable and is explosive under certain conditions. Do not smoke or allow sparks or

flames in your work area.

Never run the engine in a closed area. The exhaust contains poisonous carbon monoxide gas that may

cause loss of consciousness and lead to death.

The battery electrolyte contains sulfuric acid. Protect your eyes, skin and clothing. If you contact it, flush

thoroughly with water and call a doctor if electrolyte gets in your eyes.

Engine and exhaust pipe become very hot and will remain hot for one hour after the engine is shut off.

Do not perform service on parts that are hot.

Used engine oil and gear oil may cause personal damage after repeated or long exposure to skin.

Keep out of reach of children. Recycle or dispose of engine and gear oil properly at a proper facility.

1.2 Notes

All information, illustrations, directions and specifications included in this publication are base on the latest

product information available at the time of approval for printing.

These symbols will appear throughout the manual to indicate important information or tasks.

CAUTION – Safety notification. Proceed carefully.

ADJUSTMENTS – Requires inspection, adjustment, or torque.

FLUIDS – Lubrication or check and replace fluids.

MULTIMETER – Diagnostics and electrical testing.

MEASUREMENT – Gap and size measurements.

SPECIAL TOOL – Uncommon tools may be required.

GENERAL MAINTENCE PART – These parts may need to be replaced often. Part numbers will be

provided when applicable.

ETON America, LLC reserves the right to make changes at any time without notice and without incurring

any obligation whatever. No part of this publication may be reproduced without written permission.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

4

1.3 Specifications

Component

Rover GT

(UK2)

Engine

Type Four cycle liquid cooled

Displacement 88.4cc

Bore / Stroke φ47.0 * 51mm

Compression Ratio /

Pressure 10.2 : 1

Torque / BHP 6.5hp @ 6500rpm / 48BHP

Starting Electrical

Transmission

Type Automatic (C.V.T. V-Belt)

Chassis

Overall Length 2110mm / 83.0"

Overall Width 1000mm / 39.4"

Overall Height 1110mm / 43.7"

Wheel Base 1375mm / 54.1"

Seat Height 710mm / 28.0"

Dry Weight 185kg / 408lbs

Suspension

Front Swing A-arm

Dual Adjustable Shocks

Rear Swing Arm

Adjustable Shock

Brakes

Front Dual Hydraulic Disc

Rear Hydraulic Disc

Tires

Front 18/7-10

Rear 18/8-10

Tire

Pressure

Front Min 3.2psi / 0.23kg/cm2

Max 4.0psi / 0.28kg/cm2

Rear Min 3.2psi / 0.23kg/cm2

Max 4.0psi / 0.28kg/cm2

Wheels

Bolt Pattern 4 x 110mm (P.C.D)

Carburetor

Make/Size TK SVR 22mm (Manual

Choke)

Main Jet 0.95mm

Pilot Jet 0.32mm

Air Mixture Adjustment Back out 1 1/2 – 1 3/4 turns

Idle Speed Idle 1700 - 1900rpm

Sprockets

Specifications are subject to change without notice.

Continued on next page.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

5

Front 520x12t

Rear 520x32t

Chain #520

Battery Size

Jell Acid (Maintenance

Free) 12V-4AH/5AH - GTX5L

Fluids

Fuel Type Unleaded Gasoline 92 octane

Volume 11 liters / 2.9gal

Engine Oil Type SAE 20W - 40

Volume 0.9 liters / 0.23gal

Transmission Type SAE 80/90 weight

Volume 300cc / 10.2oz

Spark Plug

NGK CR7HSA/NGK

Champion Z9Y (Not recommended)

Electrode

Gap 0.6-0.7mm / 0.023"

Specifications are subject to change without notice.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

6

1.4 VIN & Engine Number

The unit’s serial numbers are available directly on the unit. See the pictures below.

The frame VIN number is stamped on the right side of the frame near the front right wheel.

The engine VIN number is stamped on the left side of the crankcase.

Frame Number

Engine Number

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

7

1.5 Standard Torque Values

NOTE: Maximum metric torque value is shown. Do not exceed maximum torque value.

ENGINE

Cylinder head nut 25 N/m (13.3 – 18.4 lbf-ft)

Spark plug 12 N/m (5.2 - 8.9 lbf-ft)

Cylinder head bolt 30 N/m (14.8 - 22.1 lbf-ft)

Alternator bolt 12 N/m (5.9 - 8.9 lbf-ft)

FRAME

Handlebar upper holder bolt 24-30 N/m (17.7-22.1 lbf-ft)

Steering shaft nut 50-60 N/m (36.9-44.3 lbf-ft)

Steering shaft bushing holder nut 24-30 N/m (17.7-22.1 lbf-ft)

Wheel rim bolt 18-25 N/m (13.3-18.4 lbf-ft)

Tie rod lock nut 35-43 N/m (25.8-31.7 lbf-ft)

King pin nut 30-40 N/m (22.1-29.5 lbf-ft)

Handlebar lower holder nut 40-48 N/m (29.5-35.4 lbf-ft)

Front wheel bolt 24-30 N/m (17.7-22.1 lbf-ft)

Front axle nut 30-35 N/m (22.1-25.8 lbf-ft)

Front brake arm nut 4-7 N/m (3.0- 5.2 lbf-ft)

Rear brake arm nut 7-12 N/m (5.2- 8.9 lbf-ft)

Rear axle nut 60-80 N/m (44.3-59.0 lbf-ft)

Rear wheel bolt 24-30 N/m (17.7-22.1 lbf-ft)

Exhaust muffler mounting bolt 30-35 N/m (22.1-25.8 lbf-ft)

Engine hanger bolt 24-30 N/m (17.7-22.1 lbf-ft)

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

8

2. MAINTENANCE

2.1 Maintenance Schedule

The maintenance internals in the follow table are based upon average riding conditions. Riding in unusually dusty

areas requires more frequent servicing. This table applies to units covered by this service manual. E-TON

recommends that all maintenance and inspections be performed ONLY by a qualified and fully trained technician.

INITIAL

SERVICE

REGULAR SERVICE

EVERY YEAR

(First week) (Every 30 operating days)

Fuel Line I

Throttle Operation I I I

Air Filter system & Element I C R

Spark Plug I R

Carburetor Idle Speed I I I

Drive Chain I, L I, L I

Brake Shoe Wear I I I

Brake System I I I

Nut, Bolt, Fastener I I I

Wheels & Wheel Nuts I I I

Steering System I I

Suspension System I I

C.V.T. Air Filter C R

Waste Gas Recovery Valve I R

Intake & Exhaust Valve Adj. I

Gear & Engine Oil I R

Note –

I: Inspect and Clean, Adjust, Lubricate, or Replace (if necessary)

C: Clean

L: Lubricate

R: Replace

2.2 Maintenance Record

Maintenance Performed Date Performed By

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

Maintenance Schedule

Four Stroke Vehicles

WP-0027

Scheduled

Maintenance

300KM Every1000KM Every3000KM Every6000KM Every12000KM

200Miles600Miles2000Miles3700Miles7500Miles

NEW 1Month3Months 6Months 1Year

1Aircleanerelement I*C* R(paper) R(sponge)

2Aircleaner I

3Oilfilter(Screen) C C

4Engineoil Change I Change

5Tire,pressure I I

6Battery I I

7Sparkplug I I R

8Carburetor(idlespeed) I I

9Steeringbearingandhandles I I

10

Checktransmissionforleak‐

age I I

11Checkcrankcaseforleakage I I

12Transmissionoil Change Change

13Drivebelt/roller I R

14Fueltankswitchandlines I I

15

Throttlevalveoperationand

cable I I

16Engineboltsandnuts I I

17

Cylinderhead,cylinder,and

piston I

18

Exhaustsystem/cleaning

carbon I

19CamChain/ignitiontime I I

20Valveclearance I I I I I

21Shockabsorbers I I

22Front/Rearsuspension I I

23Main/Sidestands I I/L

24Crankcase(PCV)Valve I I

25

Brakemechanism/brakelin‐

ing(pad) I I

26

TightenallBolts/Nuts&Fas‐

teners

I I

*=Cleanorreplacetheaircleanerelementmoreoftenwhenthevehicleisoperatedondusty

#=Maintenanceshouldbeperformedmoreoftenifthevehicleisfrequentlyoperatedathigh

speedforprolongedtimeandafterthevehiclehasaccumulated50,000miles.

roadsorinaheavilypollutedenvironment.

Code:

I=Inspection,clean,andadjust

R=Replace

C=Clean(replacedifnecessary)

L=Lubricate

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

9

2.3 Fuel Lines & Filter

Inspect the fuel lines for deterioration, damage, or leakage, and

replace if necessary.

Check the fuel filter for accumulated dirt and debris. Replace as

needed. Filter replacement is also recommended at the

beginning of each riding season.

Filter assembly: Part # 812555

Filter element: Part # 800002

2.4 Throttle Operation

•Inspect the throttle for smooth operation in all open and

closed positions. Ensure that there is no wear, damage, or

kinking in the throttle cable; replace it if necessary.

•To lubricate cable, disconnect the throttle cable at the upper

end. Lubricate the cable with commercially available lubricant to

prevent premature wear and binding of the cable in the case.

•To replace a damaged or worn cable, order part # 812469.

2.5 Throttle Cable Adjustment

•The cable should be adjusted to allow for 1/8" free travel

before the throttle engages the carburetor throttle slide.

•To adjust the cable's free travel, loosen the locking nut of

the cable adjuster, and turn the adjuster wheel until there is

1/8" free travel in the lever.

•Tighten the locking nut to secure the adjusting ring.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

10

2.6 Air Cleaner

•Unscrew the air cleaner cover screws.

•Pull out the air filter element from the air cleaner case.

Wash the element in non-flammable solvent and squeeze

out the solvent thoroughly.

•Let it dry.

•Soak the filter element in gear oil, and then squeeze out the

excess oil.

•Install the element into air cleaner carefully.

2.7 Spark Plug

To change the spark plug, do the following:

1. Stop the engine and wait for it to cool, 30-60 min. (Never work on a hot engine. A hot engine and exhaust can present

a fire and burning hazard.)

2. Locate the spark plug at the front of the engine.

3. Remove the Spark plug lead wire by gently pulling on the plug wires boot. (Do not pull on the wire itself as this could

cause damage to the wire).

4. Remove the old spark plug using the supplied plug wrench and screwdriver

by turning the plug counter clockwise.

5. Set the electrode gap on the new plug to 0.6m-0.7mm / 0.023” using a feeler

gauge.

6. Insert the new plug by hand and tighten finger tight by turning the plug in a

clockwise direction. Use caution not to cross thread the plug in the head.

7. Use the plug wrench to tighten the plug another ¼ to ½ turn. Caution:over

tightening the plug can cause the thread in the engine head to be stripped; under

tightening the plug can cause compression loss and possible cylinder head

failure.

8. Reinstall the plug wire by pressing the wire boot over the plug until it is

completely seated on the spark plug.

ETON recommends that you replace your spark plug at the beginning of

each riding season.

Note: ETON recommends the use of NGK CR7HSA

Plug MFG MFG Num Plug Gap Part

NGK CR7HSA 0.6-0.7mm / 0.023” # 811777

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

11

2.8 Idle Speed

Air/Fuel Ratio adjusting procedure:

Step 1: Air adjusting screw.

Turn adjusting screw all the way in then back off

¾ to 1¼ turn on 70cc engine.

1 to 1½ turns on 90cc engine.

Step 2: Adjust idle RPM. (Warm Engine)

Connect an RPM gauge. Turn the adjustment screw in or out to

adjust the engine idle speed to between 1700—1900 RPM.

Turning the idle adjustment screw clockwise will raise the RPM;

turning it counterclockwise will lower the RPM.

Idle Speed: 1800 ± 100RPM

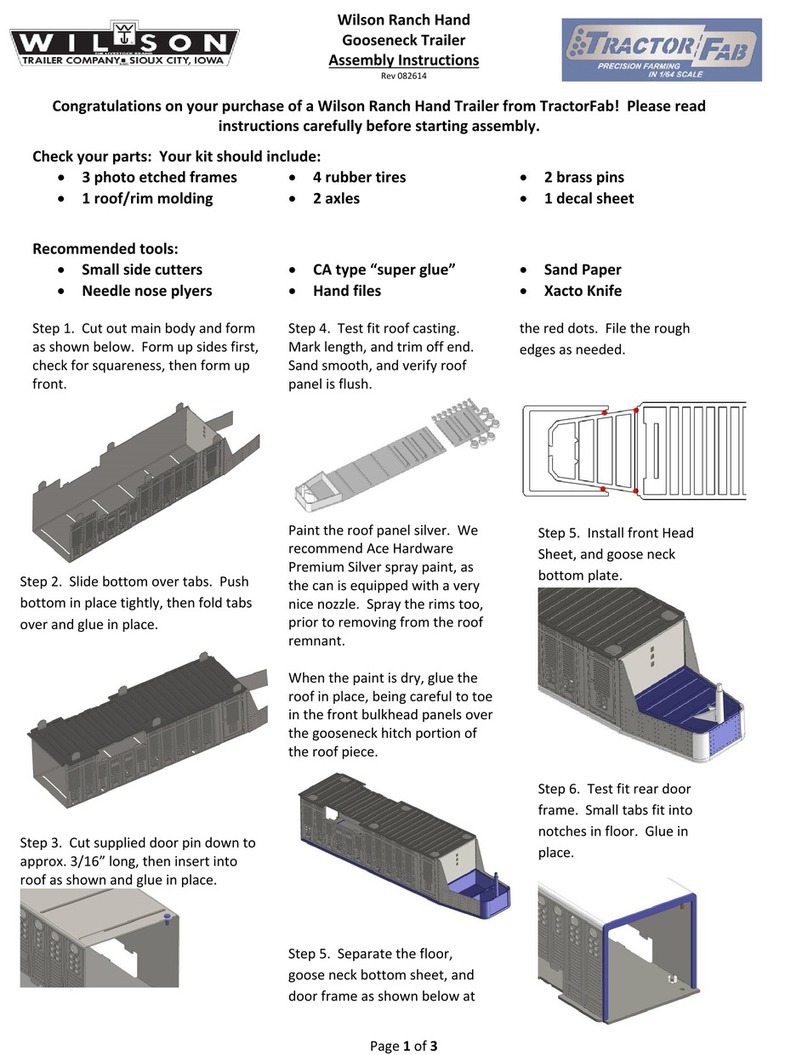

2.9 Drive Chain

Inspect the chain slack. The standard is 10-25mm or 0.394-0.984

in.

The drive chain will stretch with use and will require periodic

adjustments. To check the chain tension, remove the chain guard

and measure the slack. The amount of slack in the chain should

not exceed 10-25mm (0.394-0.984 in).

Inspect the drive and axle sprockets for damaged or broken

teeth. Replace as needed. Inspect the chain links for damaged,

worn or loose rivets. Repair or replace as needed.

Chain Slack Adjustment:

Loosen the axle position lock bolts slightly and turn the chain

adjuster nut to take up the excess slack in the chain. Once the

chain has been adjusted to the proper tension retighten the

axle position locking bolt.

The chain should be kept well lubricated to prevent excess

wear and premature failure. We recommend that you lubricate

the chain every 20 hours of operation, or more frequently if

needed, with a high quality chain lubricant.

Air mixture adjusting screw

Chain adjusters

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

12

When the drive chain becomes very dirty, it should be

removed, cleaned, and lubricated. Use commercial chain

lubricant to lubricate the drive chain.

Clean the drive chain with kerosene and wipe it dry. Inspect the

drive chain for worn or damaged links and rivets. Replace the chain

if it is worn excessively or damaged.

Inspect the sprocket teeth. If there is excessive wear or

damage, replace the sprocket.

Engine Sprocket - Part #: 812478

Drive Axle Sprocket - Part #: 812597 (520x32t)

2.10 Braking Systems

Inspect the front parking brake lever (the right hand lever) and cable

for excessive wear or other damage. Replace or repair if

necessary. Measure the slack of the brake lever at the end of

the brake lever. The standard of slack is 15-25 mm (0.591-

0.984 in).

Adjuster

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

13

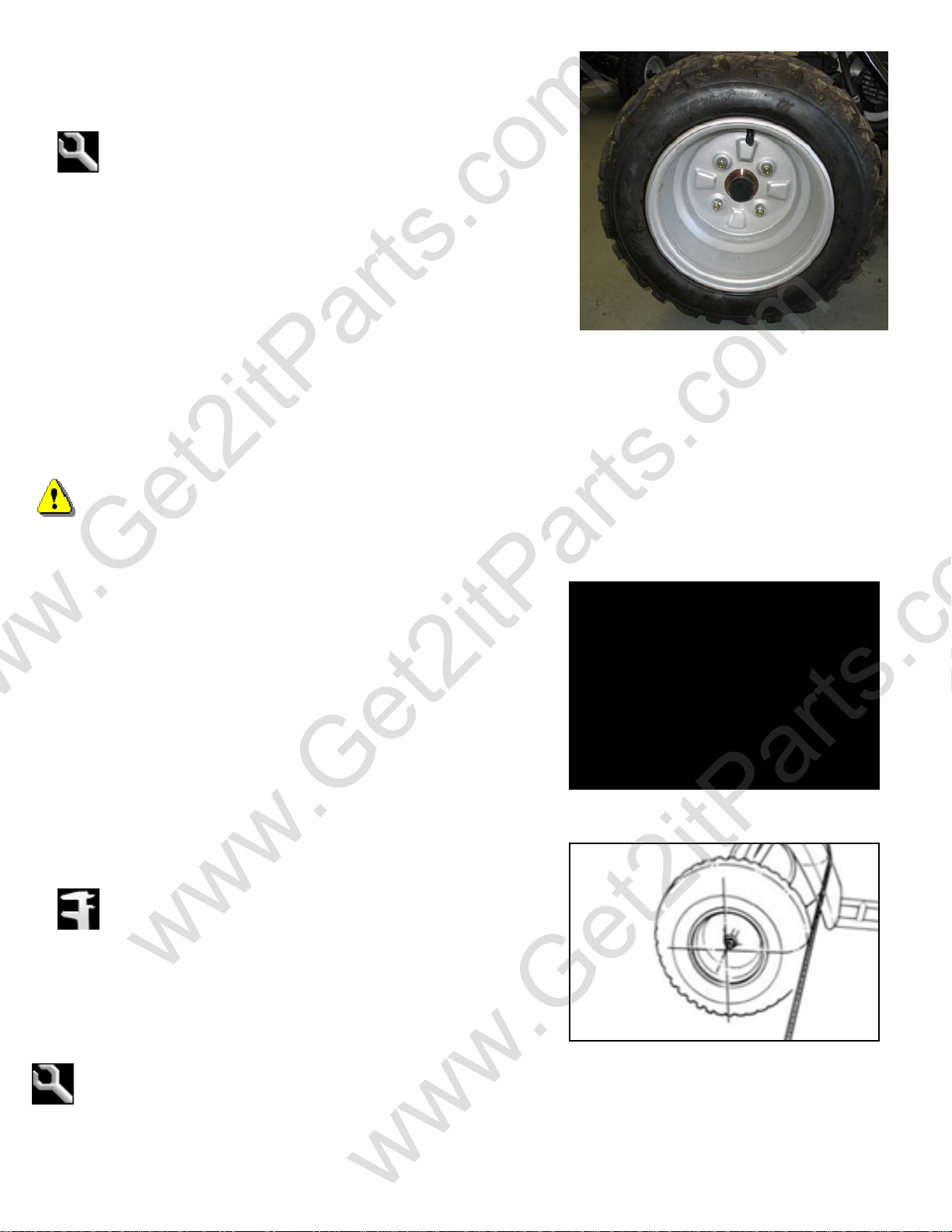

2.11 Wheels & Tires

•Inspect the tire surfaces for cuts, nails, or other sharp

objects.

•Check the tire surfaces at cold tire condition. The

standard tire pressure is 2.2±0.3 psi. (0.15

kg/cm2)

2.12 Steering System

Check the slack of the steering shaft with the front wheels facing

straight ahead. When there is excessive slack, inspect the tie-rod,

kingpin bushing and ball joint.

NOTE – This procedure should be performed on all units

during setup.

2.13 Toe-In

•Park the vehicle on level ground and leave the front wheels

facing straight ahead.

•Mark the centers of the tires to indicate the axle center

height.

•Measure the distance between the marks.

•Carefully move the vehicle back, and rotate the wheels

180°, so the marks on the tires are aligned with the axle

center height on the other side.

•Measure the distance between the marks. Calculate

the difference in the front and rear measurements.

•Toe-in: 5±10mm (0.197±0.394 in)

If the toe-in is out of standard, adjust it by changing the length

of the tie-rods equally. Loosen the locking nuts and turn the

tie-rod while holding the ball joint.

Tighten the lock nuts.

Torque: 35-43 N/m (2.40-2.95 lb/ft)

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

14

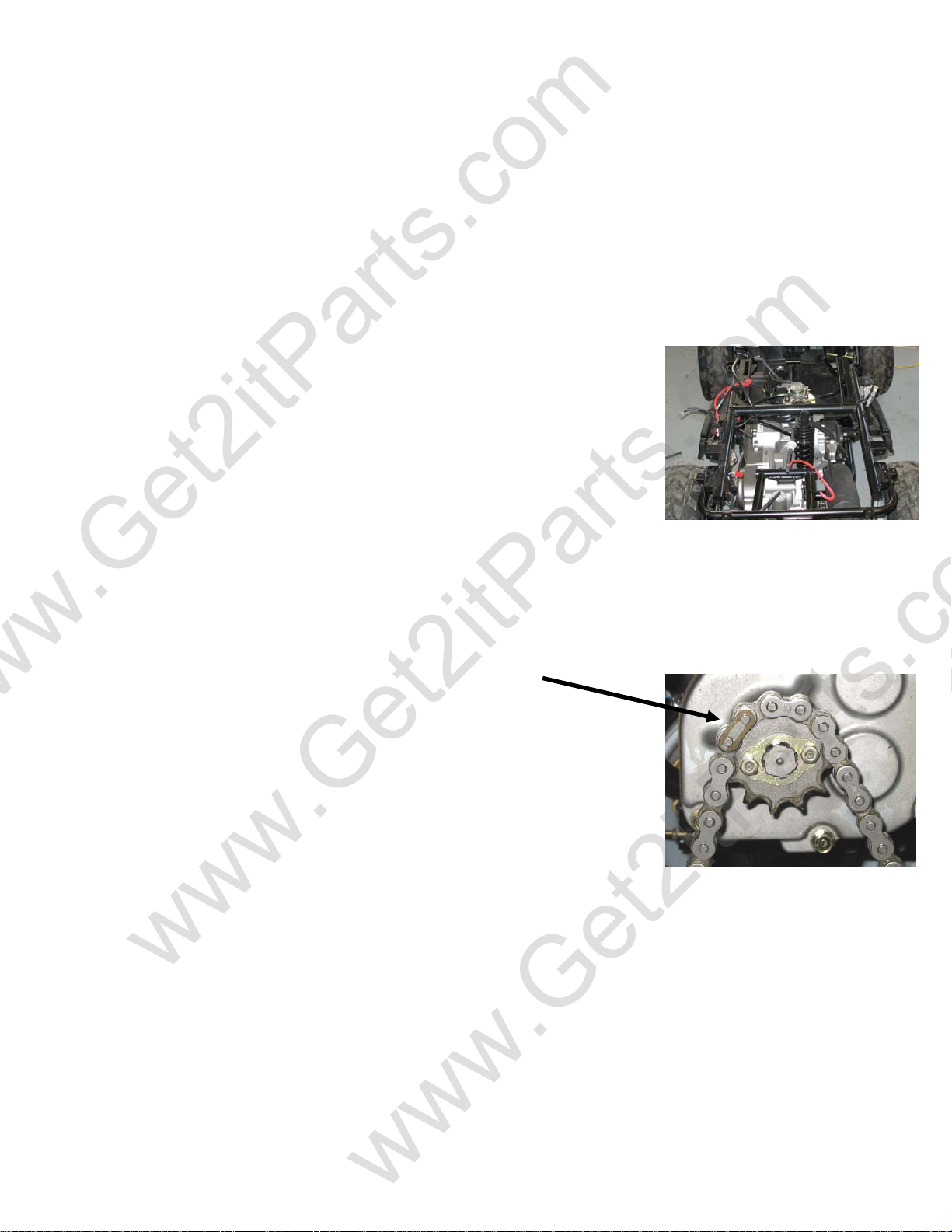

2.14 Gear Oil

Gear oil needs to be changed every year.

1. Place an oil catch pan under the unit directly below the

transmission box.

2. Remove the transmission box drain plug located on the

bottom of the transmission box on the underside

of the unit.

3. Remove the transmission box fill hole plug locate on top of

the transmission box near the oil tank bracket on the left hand

side of the unit.

4. Allow the oil to drain completely (15-30 min).

5. Reinstall the drain plug and tighten. Torque to 7-10lbf-ft

6. Fill the transmission box with of SAE 80-90 gear oil

• Capacity = 300cc / 10.2oz

7. Reinstall the fill hole plug and finger tighten

8. Dispose of used oil at a proper recycling station as required by

law.

Bottom of engine

Drain Bolt

Front of engine

Top of engine

Fill Plug

Front of engine

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

15

3. ENGINE REMOVAL AND INSTALLATION

3.1 Service Information

NOTE: The engine should only be removed when repair conditions warrant its removal. Engine removal is a

complex task that should be performed only by a qualified technician or mechanic.

3.2 Engine Removal

1. Remove the seat, side panels and fenders. (See Section 11)

2. Disconnect the spark plug cap from spark plug.

3. Remove the exhaust muffler assembly.

4. Disconnect the throttle cable from the carburetor by removing the two

screws on top of the carburetor.

5. Disconnect the wire connections:

a. Carburetor auto-choke (If installed)

b. Carburetor manual choke cable (If installed)

c. Starter motor

d. A/C generator

e. C.D.I. Leads (Label before disconnecting)

f. Disconnect the shifting motor

g. Label & disconnect the shift sensor leads

h. Disconnect the engine ground wire on the (LH) side of the

engine

6. Disconnect the fuel line from the carburetor.

7. Remove the drive chain cover.

8. Remove the drive chain retaining clip and master link.

9. Remove the drive chain.

10. Remove the three engine hanger nuts and bolts.

11. Carefully remove the engine from the right side of frame.

3.3 Engine Installation

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

16

Engine installation is basically removal in reverse.

1. Replace the engine in the frame from the right side.

2. Reinstall the engine hanger bolts and torque to 24-

30 N/m (1.64-2.06 lb/ft).

3. Reinstall the drive chain, and connect with the

master link and retaining clip.

4. Reinstall the chain guard.

5. Reconnect the wire connections:

1. Carburetor auto-choke (If installed)

2. Carburetor manual choke cable (If installed)

3. Starter motor

4. A/C generator

5. Reconnect C.D.I. leads

6. Reconnect the engine ground wire on the

(LH) side of the engine

7. Reconnect the shift motor

8. Reconnect the shift sensor leads

Note: Use care when rerouting the cables and wires so as not to pinch or bend them.

6. Reconnect the throttle cable.

7. Reinstall the exhaust muffler assembly.

Note: Replacement of the exhaust gasket with a new gasket is recommended.

8. Reconnect the fuel line.

9. Replace the spark plug cap.

10. Test-start the engine.

11. Test the shifting function.

12. Reinstall fenders, side panels, and seat.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

17

4. FUEL AND LUBRICATION

SYSTEMS

4.1 Trouble Shooting

•No fuel in tank

•No fuel to cylinder

•Too much fuel going into cylinder

•No spark at plug

•Air cleaner clogged

•Improper adjustment of the idle speed screw

•Ignition malfunction

•Bad fuel/air mixture ratio

•Air filter dirty

•Intake leaks

•Fuel tank cap breather clogged

•Main jet or pilot jet clogged

•Fuel filter clogged

•Fuel flows restricted

•Float level in carburetor set too low

•Lean mixture/rich mixture

•Faulty float needle valve

•Float level set too high

•Carburetor air duct is clogged

Engine does not start.

Engine idles roughly, stalls, or runs poorly.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

18

4.2 Fuel Tank

REMOVAL

•Remove the fuel tank cap and rear bed assembly.

•Disconnect the fuel line from the carburetor.

•Unscrew the fuel tank mounting bolts.

Warning: Gasoline is highly flammable

Note: Keep gasoline away from flames or sparks.

Wipe up spilled gasoline at once.

4.3 Carburetor

REMOVAL

Note: Turn fuel petcock to “off” position

•Remove the air filter assembly.

•Disconnect the fuel line and choke cable or lead wire.

Unscrew the intake pipe mounting bolts at the

carburetor

•Remove the carburetor

DISASSEMBLY

•Remove the carburetor cap.

•Remove the throttle cable from the throttle valve while

depressing the throttle valve spring.

•Remove the needle clip retainer, the jet needle, and

needle clip.

•Inspect the throttle valve and jet needle surface for

wear, scratches or dirt.

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

This manual suits for next models

1

Table of contents

Popular Utility Vehicle manuals by other brands

Wilson Electronics

Wilson Electronics 082614 Assembly instructions

Montracon

Montracon MT45 Operator's handbook

Club Car

Club Car Turf 1 2006 owner's manual

Polaris

Polaris RANGER XP 900 2013 owner's manual

Textron Specialized Vehicles

Textron Specialized Vehicles TRACKER LX6 EFI Repair and service manual

Bailey

Bailey Pursuit owner's manual