www.valortrailers.com PHONE:208-810-4900 5

the wheel. This tendency can be made dramatically worse with a tall, high center of

gravity load.

Overloading a vehicle should never be permitted. Overloading results in tire

blowouts, spring breakage, frame damage, diminished braking capacity, and will

severely alter the vehicle's normal handling characteristics. All vehicles are designed

with a maximum load capability. To best utilize these vehicles in the safest manner the

loads as shown on the certificate label should not be exceeded.

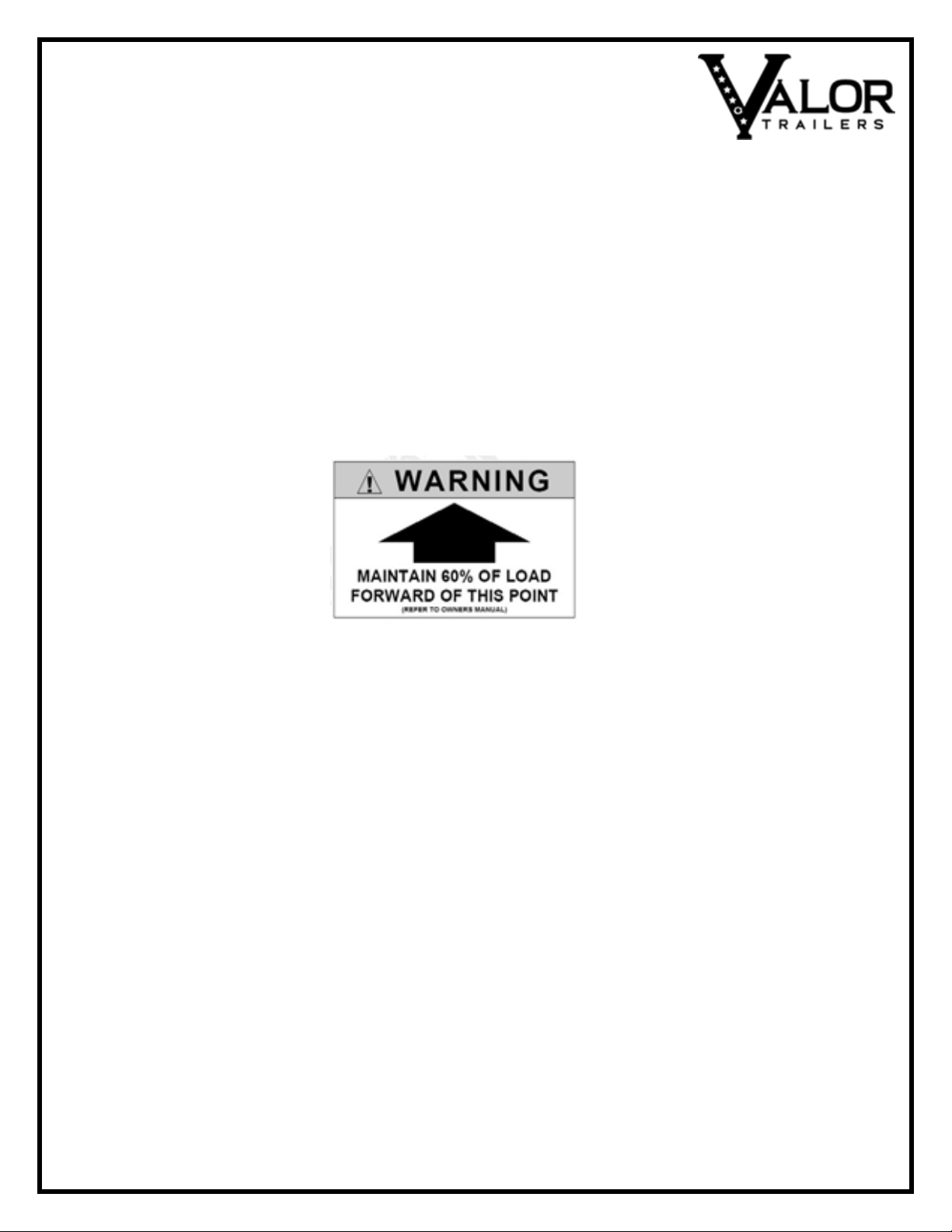

Adequate tongue weight is required for trailers to tow correctly. Inadequate tongue

weight can cause a "whipping action" particularly in shorter wheel base trailers. Too much

tongue weight can overload tow vehicle hitch resulting in reduced steering load and loss

of steering control. Selecting the correct tow vehicle is crucial for the application.

Always maintain enough braking and stopping distance. Erratic or unequal brake

action from side to side on either tow vehicle or trailer can cause handling problems in

braking situations. A balance between tow vehicle and trailer on brake application and

release timing and synchronized pressure will reduce push/pull characteristics which

when excessive, may result in jackknife. The use of properly matched brake lining is

recommended to enhance safer braking.

Proper alignment of both tow vehicle and trailer wheels will add significantly to the

handling characteristics of the combination and allow the driver to utilize all the design

responses of the vehicle to make evasive maneuvers in the safest manner.

Irregular terrain, steep grades and crowned roads, especially rural roadways,

freeways, exit ramps, curves, bumps and depressions introduce forces into a tow vehicle/

trailer combination that could result in an accident if proper precautions and driving

techniques are not followed. Even a vehicle that meets all maintenance and load

requirements can become hazardous when excessive speeds and certain roadway

characteristics are combined.

While on a downgrade, the force of gravity works against the driver in

maintaining control of the vehicle, particularly if the road surface is wet or slick from

snow and ice or loose material. On upgrades, the problem is spinning out due to

insufficient traction at the drive wheels, particularly on snow and ice.

Great care must be taken to avoid excessive use of brakes on long downgrades.

Overheated brakes are dangerously inefficient. It is very dangerous to brake on a

downgrade using only the trailer brakes. If this is done, the trailer brakes heat up and

fade and the tow vehicle brakes alone will not be able to stop the combination by

themselves. Drivers should reduce speed, downshift and use engine compression as

the principal means of controlling speed on long grades and using all brakes so

brake temperatures can be held to a safe level.