Eton VECTOR ST 250 User manual

Other Eton Offroad Vehicle manuals

Eton

Eton EXL-50 - SERVICE User manual

Eton

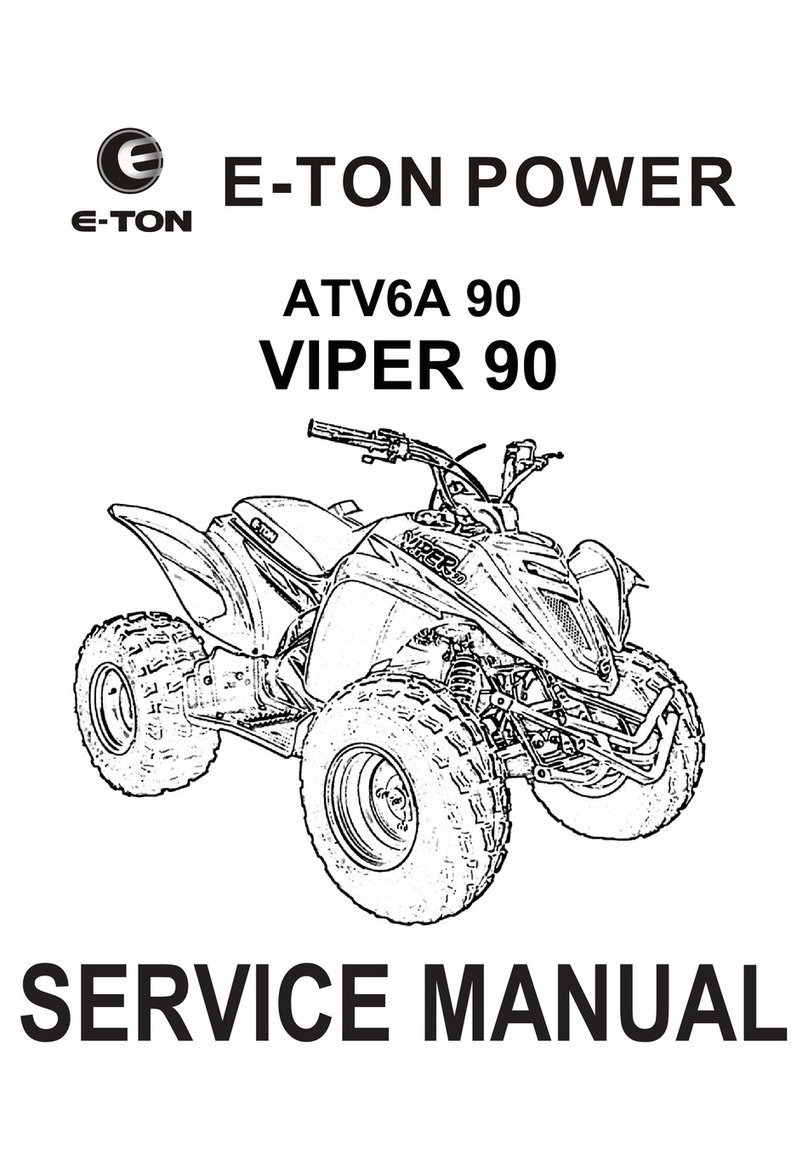

Eton ATV6A 90 User manual

Eton

Eton Viper 90R User manual

Eton

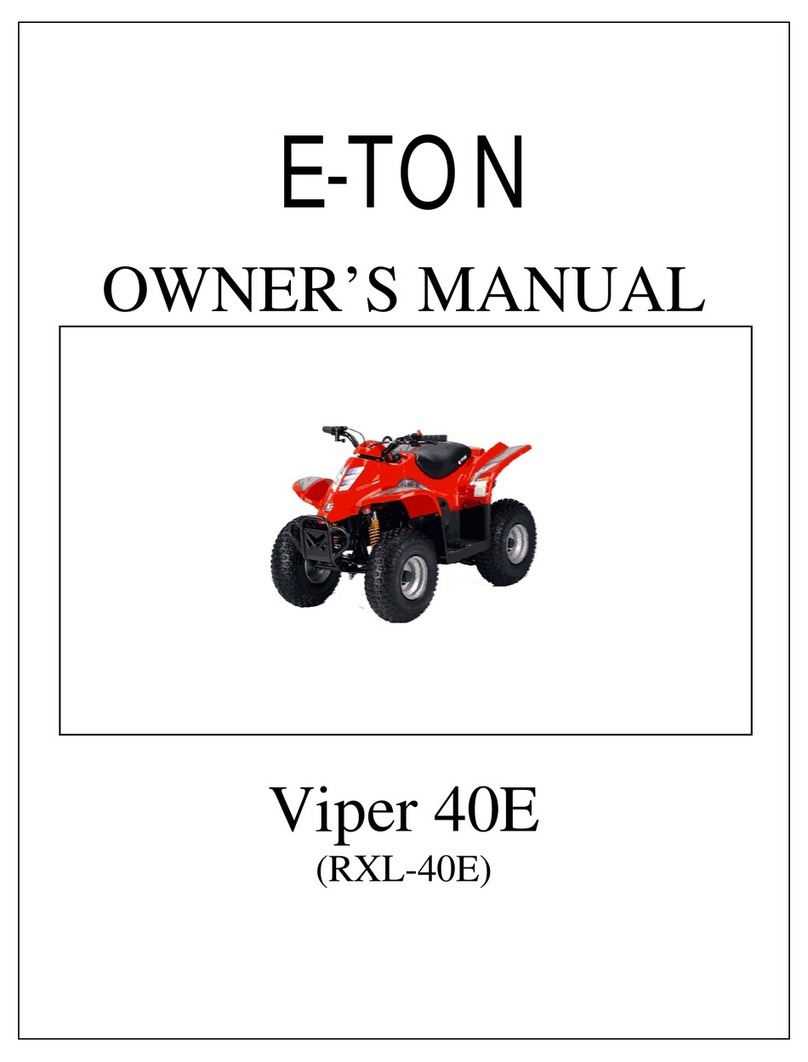

Eton Viper 40E (RXL-40E) User manual

Eton

Eton ATV3F-150 - SERVICE User manual

Eton

Eton ATV RXL 50 User manual

Eton

Eton Lightning-AXL50 User manual

Eton

Eton Yukon II CXL-150 User manual

Eton

Eton Viper Jr. (RXL-40) User manual

Eton

Eton VIPER 50M User manual

Eton

Eton Viper 150 User manual

Eton

Eton Viper 70 User manual

Eton

Eton CXL-150 - SERVICE User manual

Eton

Eton IXL 40 User manual

Eton

Eton ROVER User manual

Eton

Eton DXL90 User manual

Eton

Eton CXL-150 User manual

Eton

Eton DXL90 User manual

Eton

Eton VIPER 50 ST - SERVICE User manual

Eton

Eton Vector 250R User manual