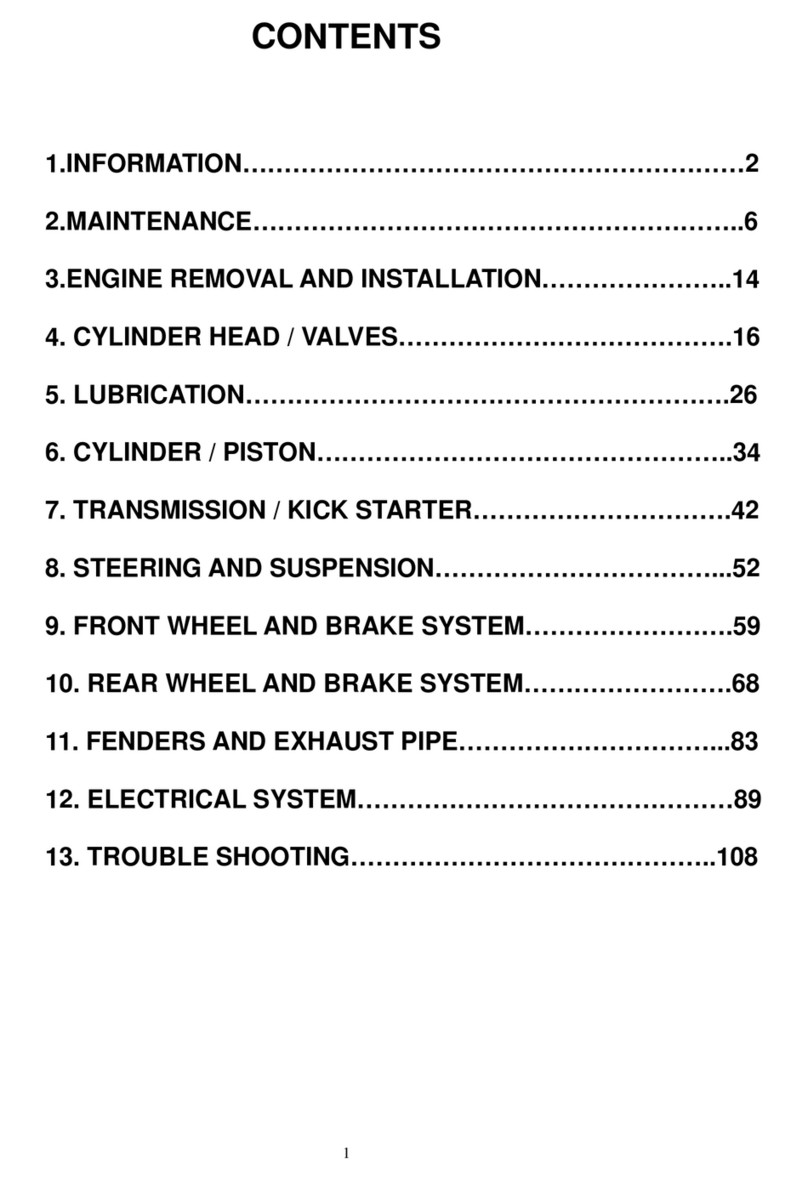

Page 8

Engine Stop Switch

The stop

switch is a red colored rocker switch located

on the left-hand handle bar.

To start and run the engine, this switch must

be placed in the on, “O”, position.

The vehicle is also equipped with a safety

brake switch which will prevent the engine

from starting until the parking brake is

engaged.

To stop your engine, place the switch to the

stop, “X”, position.

In the stop, “X”, position the ignition system is

grounded preventing the spark plug from

firing.

This switch can also be used as a safety or

emergency stop switch.

Manual choke lever (9)

All Viper models are equipped with a

manually operated carburetor choke system.

This choke is operated by the lever at the

bottom of the left hand control switch.

When first starting the engine,(cold start),

place the lever in the full left position, (Choke

closed or on) As the engine warms return the

lever to the full right position. (Choke open or

off).

Throttle lever

The throttle lever is located on the right-hand

handle bar below the grip. To operate the throttle

lever, place your right thumb on the lever and

press forward to increase your speed. To

decrease your speed, reduce your pressure on

the lever and the spring tension will

automatically reduce your speed.

The travel of the throttle lever is controlled by the

throttle stop bolt.

As your operator gains more experience, you

can increase the throttle travel to allow for

additional speed to be obtained.

To increase the throttle’s travel, thus increasing

the maximum speed, turn the throttle stop bolt

counter clockwise. To decrease the throttle’s

travel, thus decreasing the maximum speed, turn

the throttle stop bolt clockwise.

The throttle cable should be adjusted so there is

2mm, (1/8”) free travel at the lever before the

throttle starts to open.

Control Features

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com