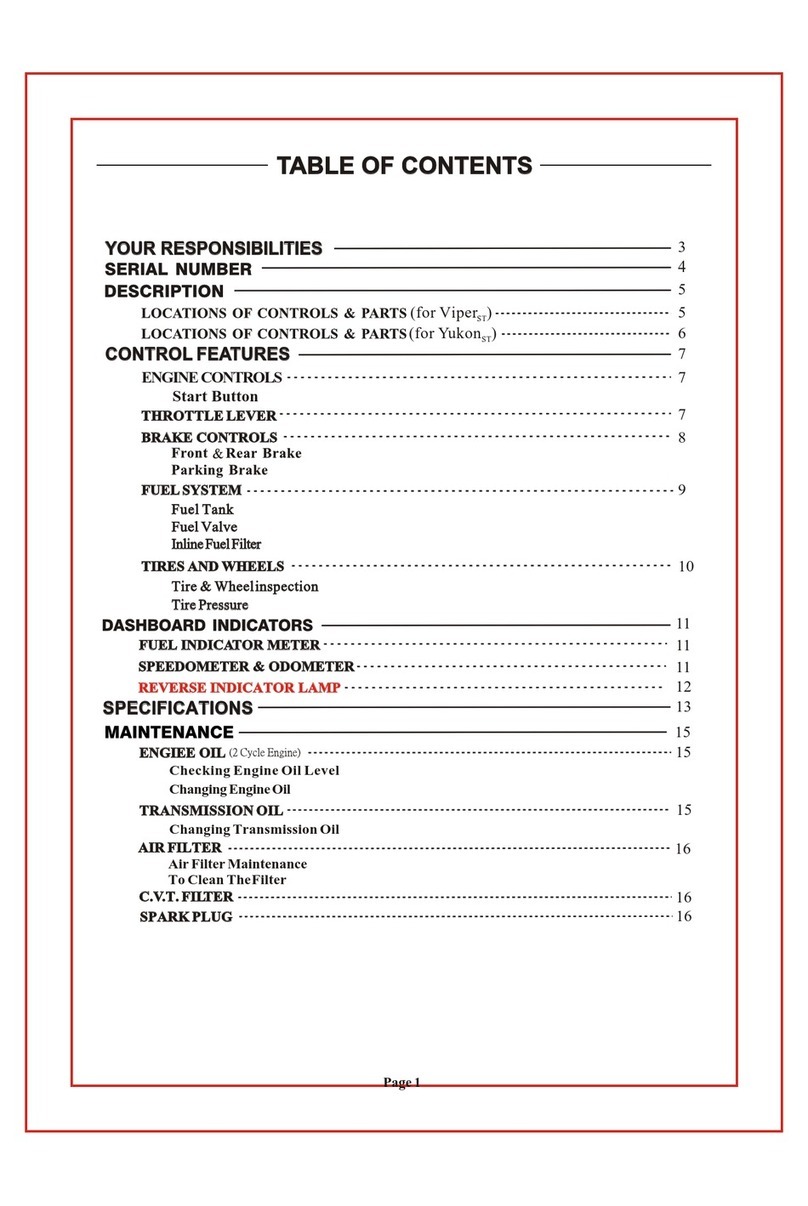

Page 8

counter clockwise. To decrease the throttle’s

travel, thus decreasing the maximum speed,

turn the throttle stop bolt clockwise.

The throttle cable should be adjusted so there

is 2mm, (1/8”) free travel at the lever before

the throttle starts to open.

Rear Brakes

This vehicle is equipped with a mechanical

drum rear brake that is both the running

brakes and the parking brake.

The brake is controlled by the long brake

lever on the left-handle bar.

The rear brake is the primary stopping brake

on your vehicle. Using the rear brake to stop

your vehicle will prevent steering control loss.

Parking Brake

The rear brake lever has a button located at

the pivot point to lock the brake in the, “O”, on

position. This should be engaged as a parking

brake whenever the vehicle is not in operation.

This feature should be engaged in order to

start the engine. The brake lever has a safety

switch built in to prevent the engine from

starting while the brake is disengaged.

If your engine fails to start, ensure that the

engine stop switch is in the on, “O”, position

and that the parking brake is engaged.

Safety Tether Switch

The Viper Jr. model is equipped with a safety

tether switch. It is located on at the rear of the

vehicle under the rear fender. The switch cap

must be fully engaged for the vehicle to run.

The cap is tied to a tether that can be worn by

the ride or control by a supervising adult. The

vehicle engine can be stopped by pulling on the

tether until the switch cap becomes disengaged.

This action will stop the engine.

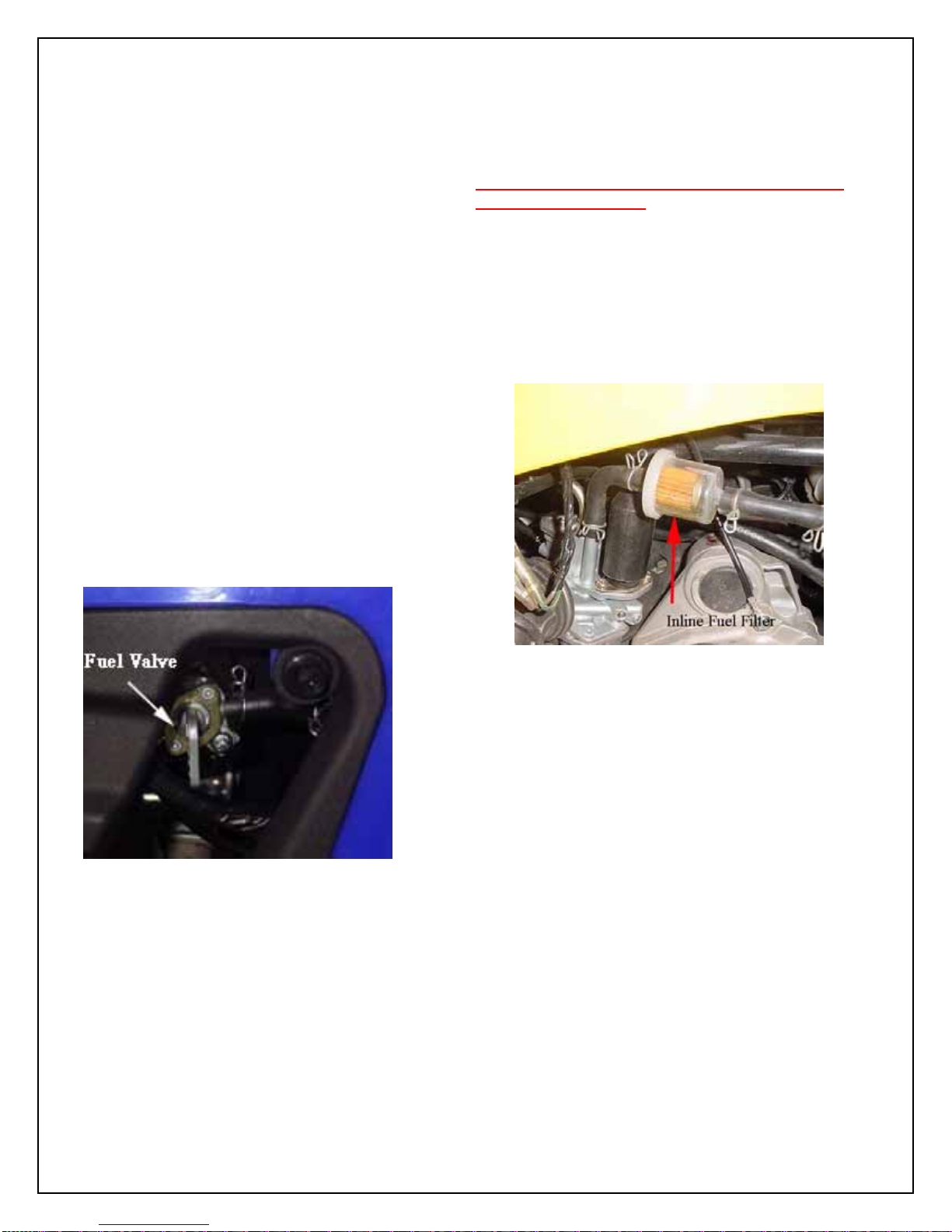

Fuel Tank

The fuel tank fill cap is located on top of the unit

just ahead of the seat. The cap contains a vent

to prevent a vacuum from forming in the tank as

fuel is used. The vent tube must be attached to

the cap and inserted in the vent tube holder hole

of the handle bar cover while operating the unit.

The fuel cap vent and vent tube must be clean

and clear of obstructions for the unit to operate

normally. You can check the vent and vent tube

by blowing air through the tube. If you can not

blow through the vent tube and cap you must

clean the vent and tube or replace them.

Every time you refuel your unit, check the rubber

seal inside the cap for cuts, tears and dirt. Clean

or replace the seal if it becomes worn or torn.

The seal must be in good condition to insure a

proper seal of the cap to the tank to prevent fuel

spills. DO NOT allow dirt or other debris to enter

the tank when refueling.

Replace the cap if damaged or if it will not seal

to the tank.