etrailer e98988 Assembly instructions

e98988

e98988

etrailer.com ATV Utility 12 V

Electric Winch - 2500 Lb.

LIT-00114, Rev -

Page 2 e98988

Rated Single

Line Pull

2,500 lb. (1,134 kg.)

Application Utility/Shop/ATV

Motor 12VDC 1 HP Permanent Magnet

Power IN &

Power OUT Yes

Duty Cycle Rating 5% (45 sec at Max Rated Load;

14 min, 15 sec Rest)

Geartrain Single-stage Planetary

Gear Ratio 153:1

Freespool Yes

Brake Auto. Load Holding Dynamic

Drum (Dia. X L) 1.25″ X 2.8″ (32mm X 71mm)

Hook 1/4″ Eye Hook

Fairlead Hawse Fairlead

Wire Rope

Size / Type

Ø5/32″ x 50′ (Ø4mm X 15.2m)

Synthetic Rope

Battery 12VDC, Minimum 12 Ah

Battery Cables 10 gauge, 5.8′ (1.78m) long

Mounting Pattern 3.15″ (80mm)

Mounting Hardware Winch: 2x G8, M8-1.25 X 35mm

Fairlead:

2x G8, M8-1.25 X 19mm

Overload Protection In line Circuit Breaker

Sound Rating 85 dB

Overall Dimensions

(L X D X H)

11.25″ X 3.88″ X 4.25″

(286 X 99 X 108mm)

Weight 14.7 lb. (6.7 kg.)

IP Rating IP 65 - Winch and Controls

(resistant to water jets)

Layer Rated Line Pull Rope Capacity

12500 lb. (1134 kg.) 6′ (1.8m)

22045 lb. (928 kg.) 13.3′ (4.0m)

31731 lb. (785 kg.) 21.9′ (6.7m)

41500 lb. (680 kg.) 31.8′ (9.7m)

51324 lb. (600 kg.) 43.1′ (13.1m)

61184 lb. (537 kg.) 50′ (15.2m)

First Layer of Wire Rope Performance

1

Line Pull lb. (kg.) Line Speed fpm (mpm) Amp Draw (@ 12V)

0 (0) 13.3 (4.1) 10

1000 (454) 8.3 (2.5) 55

2000 (907) 4.1 (1.2) 106

2500 (1134) 2.7 (0.8) 132

Specifications

LIT-00114, Rev -

Page 3

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that

follow this symbol to avoid possible injury or death.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

Addresses practices not related to personal injury.

Symbol Property or Statement

Wear heavy-duty, cut- and

abrasion-resistant leather gloves.

Wear ANSI-approved safety glasses.

Cut or sever hazard.

Roller entanglement hazard.

Hot surface burn hazard.

Fire hazard.

Caustic chemical hazard

from battery acid.

Explosion hazard.

Do not loop the wire rope around

object and hook onto itself.

Do not place finger(s) through hook.

Fingers may be caught and get

pulled into fairlead or drum.

Pull hook using strap only.

Symbol Property or Statement

Do not use winch in

overwind orientation. (Wire rope

enters/exits at the top.)

Use winch only in underwind orientation.

(Wire rope enters/exits at the bottom.)

VDC Volts Direct Current

AAmperes

CCA Cold Cranking Amperes

HP Horsepower

fpm Feet Per Minute

mpm Meters Per Minute

RPM Revolutions Per Minute

IP

International Protection rating

Classifies the degrees of protection

provided against the intrusion of solid

objects, dust, accidental contact, and water.

G8 Grade 8

A fastener strength rating.

e98988

LIT-00114, Rev -

Page 4

Important Safety Information

WARNING! Read all instructions carefully.

Failure to follow listed instructions could result in accident, injury and/or DEATH.

The warnings and instructions listed in this manual cannot cover all possible hazardous

conditions. Operate with caution.

Installation Precautions

1. Do not wear loose fitting clothing or jewelry,

while installing, servicing, or operating winch.

2. Wear ANSI-approved safety goggles and heavy-duty

leather work gloves during installation.

3. Before installation confirm that drill area is clear

of all obstructions and equipment that could be

damaged during drilling.

4. Mounting location and hardware

must support winch and load.

5. Use supplied power cords and rope listed

in manual only.

6. Do not route electrical cables near sharp edges,

moving parts, or hot equipment.

7. Ventilate area well before and while working

on battery.

8. Only connect to a clean, corrosion free battery.

9. Do not come in contact with

battery while making connections.

10. Remove all metal jewelry before working near battery.

11. Connect red wire to positive battery terminal

and black wire to negative battery terminal.

12. Insulate all exposed wiring and

terminals after installation.

13. Install winch and fairlead in underwind orientation, so

that the winch rope enters and exits the

winch at the bottom of the drum.

e98988

LIT-00114, Rev -

Page 5

Operation Precautions

1. Do not exceed load capacity.

2. Do not maintain power to the winch if winch

motor stalls. Verify that load is within rated capacity

outlined on page 2.

3. Wear ANSI-approved safety goggles and

heavy-duty leather work gloves during operation.

4. Do not disengage clutch under load.

Engage clutch before starting.

5. Keep clear of fairlead when operating.

Do not try to guide winch rope.

6. Use included strap to hold hook. Placing hands /

fingers through hook could cause them to be pulled

into fairlead / drum.

7. Stay out of the direct line of the winch rope when in

operation. Line breakage could cause damage to

equipment, injury, and / or death.

8. Do not use winch for hoisting or moving people.

9. (If Applicable) Do not use the hand crank to assist

winch operation.

10. Do not use ATV / UTV / vehicle to aid in winch

operation. This could place undue stress on the

winch rope and lead to rope breakage.

11. Disconnect battery cables before performing any

maintenance on the winch.

12. Inspect winch, winch housing, mounting hardware,

winch rope, and electrical cables for damage before

use. Damaged or broken equipment can lead to

accident, injury, and / or death.

13. Keep all bystanders from work area when operating

winch.

14. Only connect winch to appropriate pulling points

during operation. Do not "choke" load with winch

rope.

15. Do not use a recovery strap for winching. Recovery

straps are designed to stretch and can cause

accident, injury, or death if used improperly.

16. Do not operate winch if less than 5 full turns of winch

rope are on drum.

17. Ensure that winch rope is taut before beginning

winching operation. Failure to do so can lead to

binding of the winch rope on the drum.

18. If winch rope begins to get tangled, stop winching,

release winch tension with switch, and realign load.

19. Only winch with vehicle transmission in neutral and

parking break applied.

20. Winch operation is restricted to +/- 15° vertical

variation and +/- 25° horizontal variation from winch

center line.

21. If load must be pulled at angles outside of the range

indicated above, use an appropriately sized, rated

pulley (sold separately).

22. Winch motor will be hot after use, use caution.

23. Do not power hook all the way in to the fairlead. This

could cause the winch motor to overload and damage

the winch.

SAVE THESE INSTRUCTIONS.

e98988

LIT-00114, Rev -

Page 6

Installation and Setup

Mounting the Winch

1. Winch mounting location must be rated to maximum

winch capacity.

2. Winch must be placed on the center line of the

vehicle, and fairlead must be perpendicular to vehicle

centerline.

2*Ø0.33 in. / 8.5mm

3.15 in.

/ 80mm

3.94 in. / 100mm

2 in. /

51mm

8.31 in. / 211mm

11.25 in. / 286mm

2.83 in.

/ 72mm

4.13 in. / 105mm

1.25 in.

/ 32mm

Figure D: Winch Dimensions

3. Verify backside of mounting locations are clear of

obstructions and equipment that can be damaged by drilling

the mounting holes.

4. Use winch mounting plate as a

template to mark and drill holes for

mounting hardware.

5. Install the winch with specified

hardware.

Mounting Winch Components

1. Mount solenoid box so that:

a. Wires between winch components can be routed

without contacting sharp edges, moving parts, or

hot equipment.

b. Normal operation of vehicle components are not

affected.

c. Backside of mounting holes are clear of

equipment and obstruction.

2. Use bolt pattern as template for drilling pilot

holes.

3. Secure in place with mounting screws.

e98988

LIT-00114, Rev -

Page 7

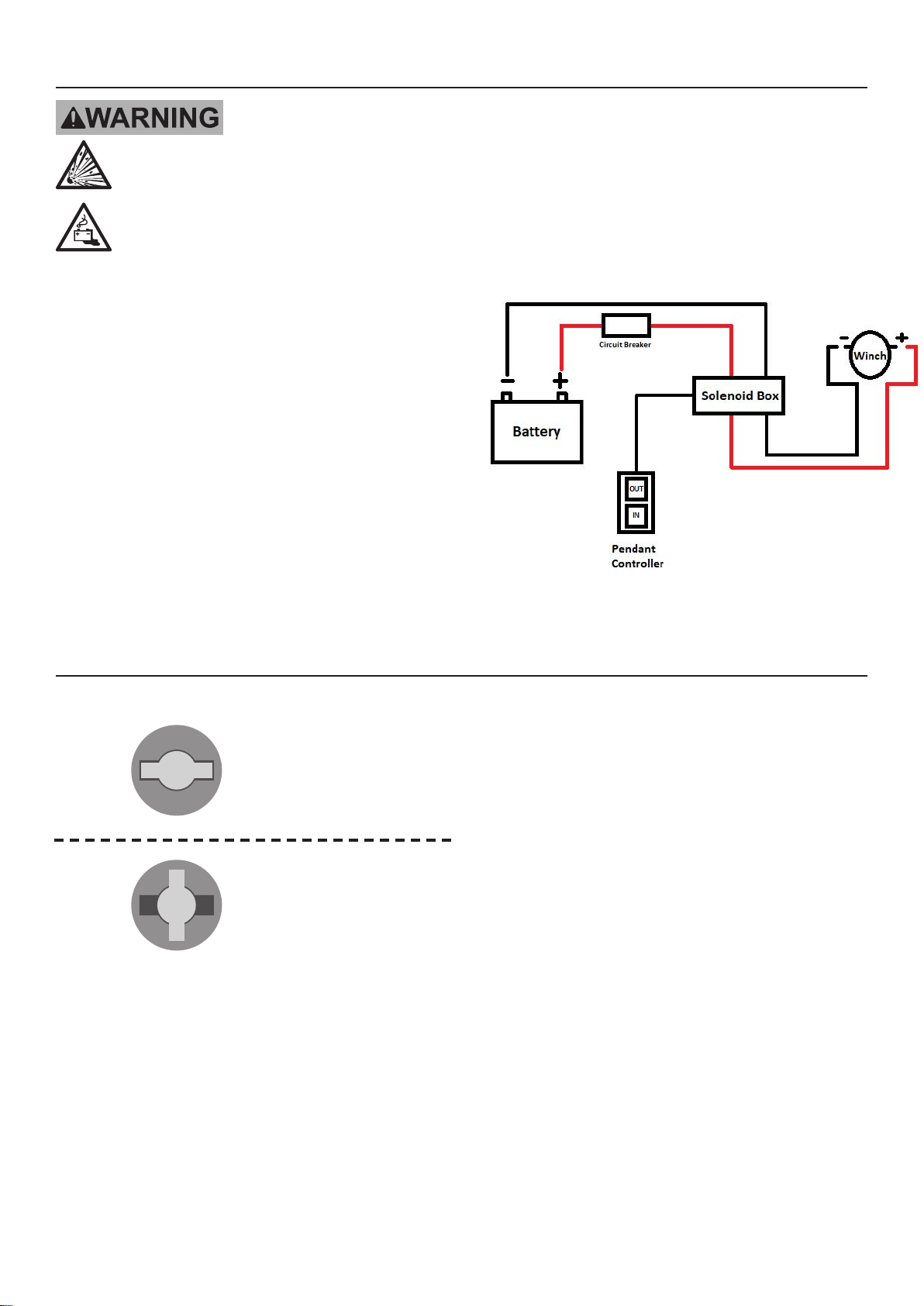

Wiring

Disconnect all battery cables before starting installation

Use only a 12 V automotive battery, in good condition, for power

source.

1. Wiring must be routed to avoid sharp edges, moving

components, hot equipment, and contact from the

ground or environment while vehicle is in operation.

2. When wiring must be routed through drilled holes,

install rubber grommets to prevent wire breakage and

wear.

3. Refer to Figure E for wiring diagram.

Figure E: Wiring Connections

e98988

Clutch Operation

Shaft

Pin

Drum

End

If the pin rests

in the groove in the drum

the clutch is engaged.

Shaft

Pin

Drum

End

If the pin rests

on top of the end of the

drum the clutch is released.

2. To change clutch position:

a. Pull clutch knob out.

b. Turn it 90° while it is pulled out, then release it.

LIT-00114, Rev -

Page 8

Troubleshooting

Problem Possible Causes Likely Solutions

Motor overheats. 1. Incorrect power cords.

2. Winch running time too long.

1. Use only supplied power cords.

2. Allow winch to cool down periodically.

Motor does

not turn on.

1. Remote battery dead.

2. Loose battery cable connections.

3. Vehicle battery needs charging.

4. Solenoid malfunctioning.

5. Defective motor.

6. Water has entered motor.

1. Replace Remote battery.

2. Tighten nuts on all cable connections.

3. Fully charge battery.

4. Tap solenoid to loosen contacts. Apply 12

volts to coil terminals directly. A clicking

indicates proper activation.

5. Check for voltage at armature port with

Switch pressed. If voltage is present,

replace motor.

6. Allow to drain and dry. Run in short bursts

without load until completely dry.

Motor runs but

winch rope drum

does not turn.

Clutch not engaged. Move the Clutch Handle to the Engaged position.

Motor runs

slowly or without

normal power.

1. Insufficient current or voltage.

2. Loose or corroded battery

cable connections.

3. Incorrect power cords.

1. Verify supply battery charge.

Recharge if necessary.

2. Clean, tighten, or replace.

3. Use only supplied power cords.

Motor runs in one

direction only.

1. Defective or stuck solenoid. 1. Tap solenoid to loosen contacts.

Follow all safety precautions whenever diagnosing or servicing

the tool. Disconnect power supply before service.

e98988

LIT-00114, Rev -

Table of contents

Popular Winch manuals by other brands

HyQuest Solutions

HyQuest Solutions BAROSSA DDT700 user manual

Tractel

Tractel Carol TR Series Operation and maintenance manual

Bush

Bush II Series quick start guide

C-Max

C-Max VIGO Installation & operation manual

DINAMIC OIL

DINAMIC OIL SE45 Manual of use and maintenance

TAUBENREUTHER

TAUBENREUTHER 16 -831 Installation instruction

Andersen

Andersen 46ST product manual

AEV

AEV Bison installation guide

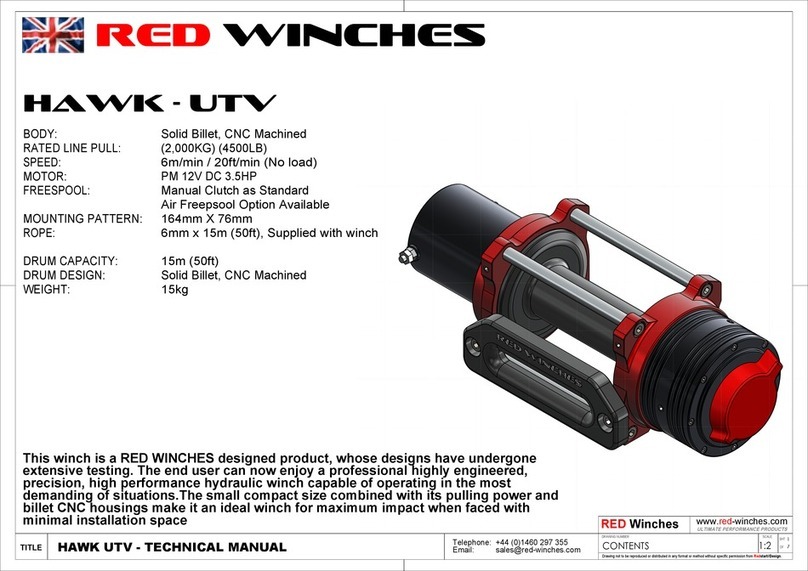

Red Winches

Red Winches HAWK - UTV Technical manual

Mile Marker

Mile Marker SEC8 Scout ES Installation & operator's manual

Huchez

Huchez MANIBOX VS Series instruction manual

Harken

Harken Radial Winch 70.2 ST Installation and maintenance manual