DINAMIC OIL SE45 Instruction manual

1/28

Manual of use and maintenance

SE45

Original instrucitions in english

Winch code: 93 45 00 10 0M

Edition: 01/2013

Manual code: M100

rev0 del 01/10/2012

2/28

Index

1 –GENERAL INFORMATIONS ......................................................................................................................................4

1.1 –Manufacturer’s identification data ........................................................................................................................4

1.2 –Winch identification data......................................................................................................................................4

1.3 –Using this instruction manual...............................................................................................................................4

1.4 –Exclusion of responsibility....................................................................................................................................4

1.5 –Instructions for technical assistance ....................................................................................................................5

1.6 –Receiving..............................................................................................................................................................5

1.7 –Warranty...............................................................................................................................................................5

1.8 –Standards and applied laws.................................................................................................................................5

1.9 –Safety symbols used in this manual.....................................................................................................................5

2 –TECNICAL INFORMATIONS......................................................................................................................................6

2.1 –Main parts and general winch description............................................................................................................6

2.2 –Description of machine functions.........................................................................................................................6

2.3 –Permitted use.......................................................................................................................................................6

2.4 –Uses not permitted...............................................................................................................................................6

2.5 –Environmental conditions.....................................................................................................................................6

2.6 –Safety devices......................................................................................................................................................6

2.7 –Residual risks.......................................................................................................................................................6

2.8 –Noise....................................................................................................................................................................6

2.9 –Electro-magnetic field...........................................................................................................................................6

2.10 –Overall dimensions.................................................................................................................................................7

2.11 –Technical data....................................................................................................................................................8

3 –SAFETY ......................................................................................................................................................................9

3.1 –General safety instructions...................................................................................................................................9

4 –TRANSPORTING, HANDLING AND INSTALLATION .............................................................................................10

4.1 –Packing the machine..........................................................................................................................................10

4.2 –Handling - Storage .............................................................................................................................................10

4.3 –Winch movement ...............................................................................................................................................11

4.4 –Assembly on base plate.....................................................................................................................................11

4.5 –Installation..........................................................................................................................................................12

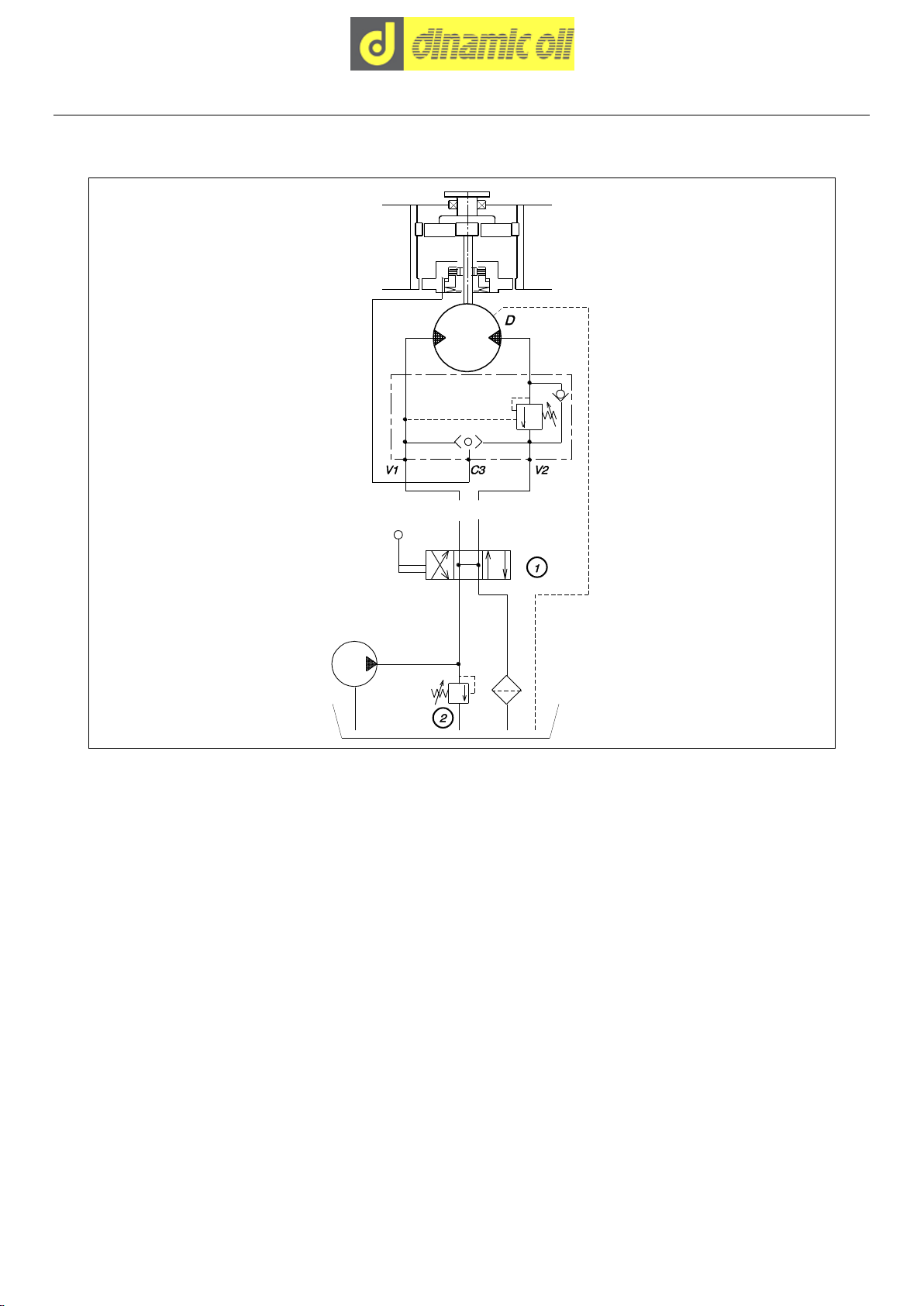

4.6 –Hydraulic diagram ..............................................................................................................................................13

4.7 –Checks ...............................................................................................................................................................16

4.8 –Cable mounting..................................................................................................................................................17

4.9 –Pulleys................................................................................................................................................................18

5 –INFORMATION ABOUT ADJUSTMENTS................................................................................................................19

5.1 –Adjustments .......................................................................................................................................................19

6 –START UP INFORMATION......................................................................................................................................20

6.1 –Start up...............................................................................................................................................................20

7 –MAINTENANCE INFORMATION..............................................................................................................................21

7.1 –Warning..............................................................................................................................................................21

3/28

7.2 –Maintenance schedule.......................................................................................................................................21

7.3 –Cable..................................................................................................................................................................21

7.4 –Lubrication..........................................................................................................................................................22

7.5 –Cleaning operations ...........................................................................................................................................24

7.6 –Scrapping and disposal......................................................................................................................................24

8 –PROBLEMS AND SOLUTIONS................................................................................................................................25

8.1 –Troubleshooting .................................................................................................................................................25

9 –PARTS REPLACEMENT..........................................................................................................................................26

9.1 –Cable replacement.............................................................................................................................................26

10 –ANALYSIS OF THE RESIDUAL RISKS .................................................................................................................27

11 –NOTES....................................................................................................................................................................28

4/28

1 –GENERAL INFORMATIONS

1.1 –Manufacturer’s identification data

DINAMIC OIL S.p.a.

Via Togliatti, 15

41030 Bomporto (Mo) - Italy

telefono 059/812611 - telefax: 059/812606

e-mail: dinam[email protected]

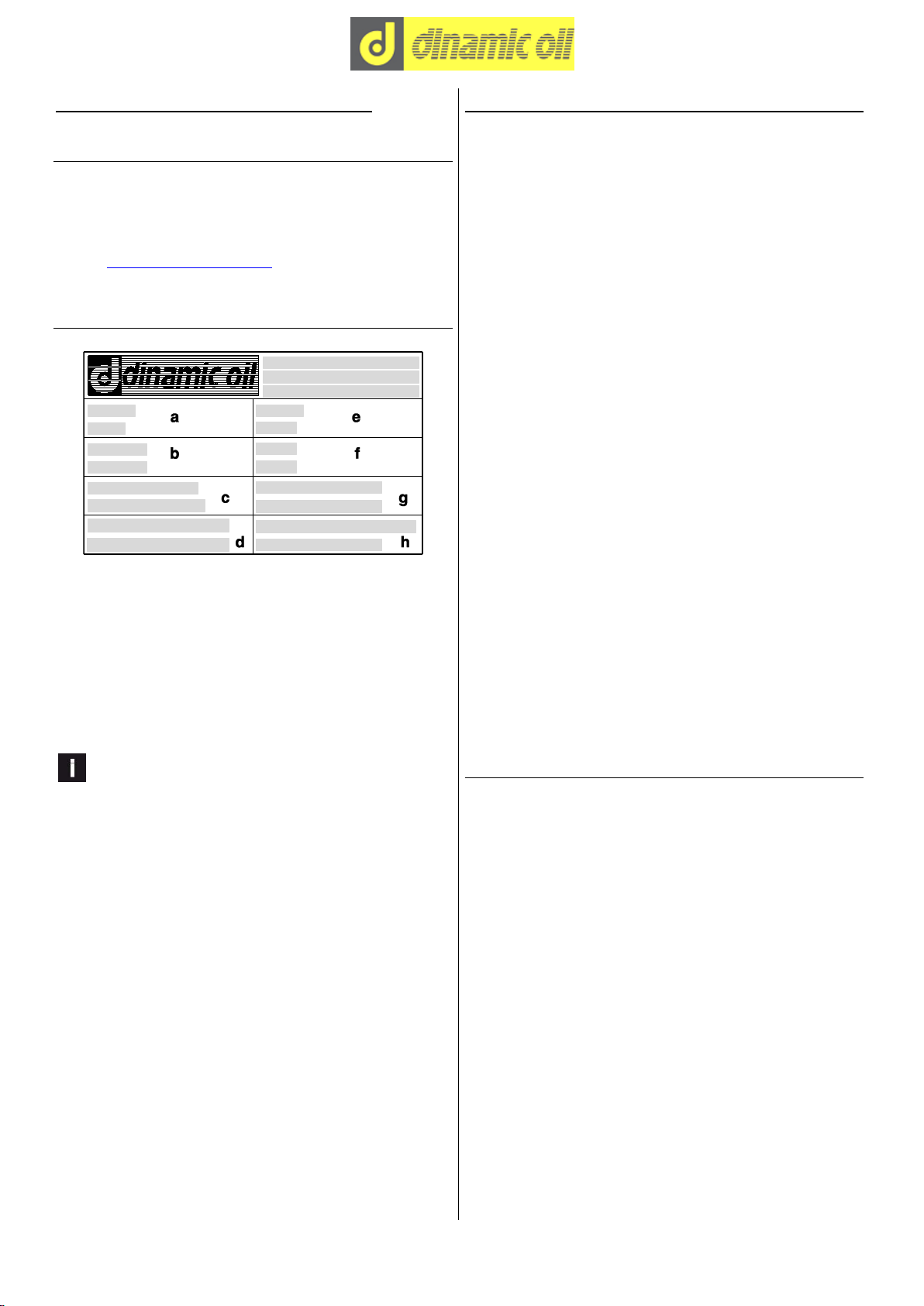

1.2 –Winch identification data

- Plate details

a = Model

b = Serial nr.

c = Max delivery

d = Max pull

e = Code

f = Year

g = Max speed

h = Hoisting pressure

Information

Under no circumstances must the data shown on the

identification plate be altered.

1.3 –Using this instruction manual

This manual contains the necessary information enabling

the operator to familiarize and correctly use the winch

(also simply described as “the machine”, although ac-

cording to Directive 2006/42/CE, the winch has been

classified as partly completed machine).

The information contained is intended for skilled op-

erators (1).

The original instructions are supplied by the manu-

facturer in English.

To fulfil legal or commercial requirements, the original in-

structions may be supplied by the manufacturer in other

languages.

If there are any doubts, whatsoever, concerning the cor-

rect interpretation of the instructions contained in this

manual, immediately contact the manufacturer for any

necessary clarifications.

To facilitate the consultation of the manual, it has been

divided into chapters of major concepts.

For quick searches please consult the index.

Reproduction or publication, in part or in whole, of the in-

formation contained in this manual is prohibited without

written authorization given by the manufacturer.

Using this instruction manual, for purposes other than

those described, without written authorization given by

the Manufacturer, is prohibited.

Any violation will be prosecuted according to the law.

(1) Only experienced people having the proper tech-

nical ability and knowledge of regulations and laws

will be able to carry out the necessary operations

and to identify and avoid possible damages during

handling, installation, operation and maintenance of

the machine.

1.4 –Exclusion of responsibility

The manufacturer is released from any responsibility for

damages deriving from:

- incorrect installation or which is not in accordance with

applicable laws;

- use of the machine by unauthorized and/or untrained

personnel;

- total or partial instruction disregarding;

- lack of maintenance;

- unauthorized modifications or repairs;

- non-designated uses;

- use of non-original spare parts and/or parts that are not

specific to the model;

- environmental circumstances beyond the manu-

facturer's control.

5/28

1.5 –Instructions for technical assistance

In case of machine malfunction or failure, for which spe-

cial technical assistance is required and for all spare

parts requests, contact directly the manufacturer or the

Reseller by phone or fax.

1.6 –Receiving

If any damages, faults or missing pieces are noted, con-

tact Dinamic Oil S.p.a. - Sales Office, immediately -

Winch Department - by phone 059/812611 or by fax

059/812606.

1.7 –Warranty

- Dinamic Oil S.p.a. warrants that its products are free

from all defects in materials or workmanship during the

warranty period indicated on the order confirmation Di-

namic Oil at the moment of purchase.

- During the warranty period Dinamic Oil S.p.a. will re-

pair or replace all parts or components that are unservi-

ceable due to ascertained defects in materials or work-

manship.

Under this warranty, any defective pieces must be sent to

Dinamic Oil S.p.a. which will examine them so as to de-

termine their cause.

- This warranty is strictly limited to the repair or re-

placement of products. Under no circumstances will the

manufacturer accept claims from customer demanding

reimbursement for direct or indirect damages of any na-

ture.

The merchandise may be returned only when previously

authorized by Dinamic Oil S.p.a.

- This warranty does not extend to “O” rings or gaskets in

general.

- This warranty does not cover any costs associated with

the installation or removal of defective parts from the

purchaser’s equipment.

- This warranty does not extend to any products that

have been repaired, modified or simply disassembled,

even partially.

- This warranty does not extend to any products that

have been subject to misuse or abuse, incorrect or care-

less assembly and tapering.

- This warranty recognized by Dinamic Oil S.p.a.

through its authorized sellers, disclaims all other warran-

ties of any nature whatsoever.

1.8 –Standards and applied laws

The machine was designed and constructed under cur-

rent directives 2006/42/CE and the following normes:

ISO 4301/01;

FEM 1.001 3rd edition (point 2,3,4,5,8).

1.9 –Safety symbols used in this manual

The following symbols will also appear throughout this

instruction manual. For safety purposes, these symbols

aim to highlight the operations which are considered

safety hazards. Therefore, it is absolutely indispensable

that the instructions highlighted by these symbols be res-

pected.

DANGER !!!

The information and procedures indicated by this symbol

which are not strictly respected will result in immediate

death or serious personal injuries.

ATTENTION !!!

The information and procedures indicated by this symbol

which are not strictly respected may result in death or

severe personal injuries.

CAUTION !!!

The information and procedures indicated by this symbol

which are not strictly respected may result in minor per-

sonal injuries or damages to the machine.

Information

Indicates important procedures and instructions.

6/28

2 –TECNICAL INFORMATIONS

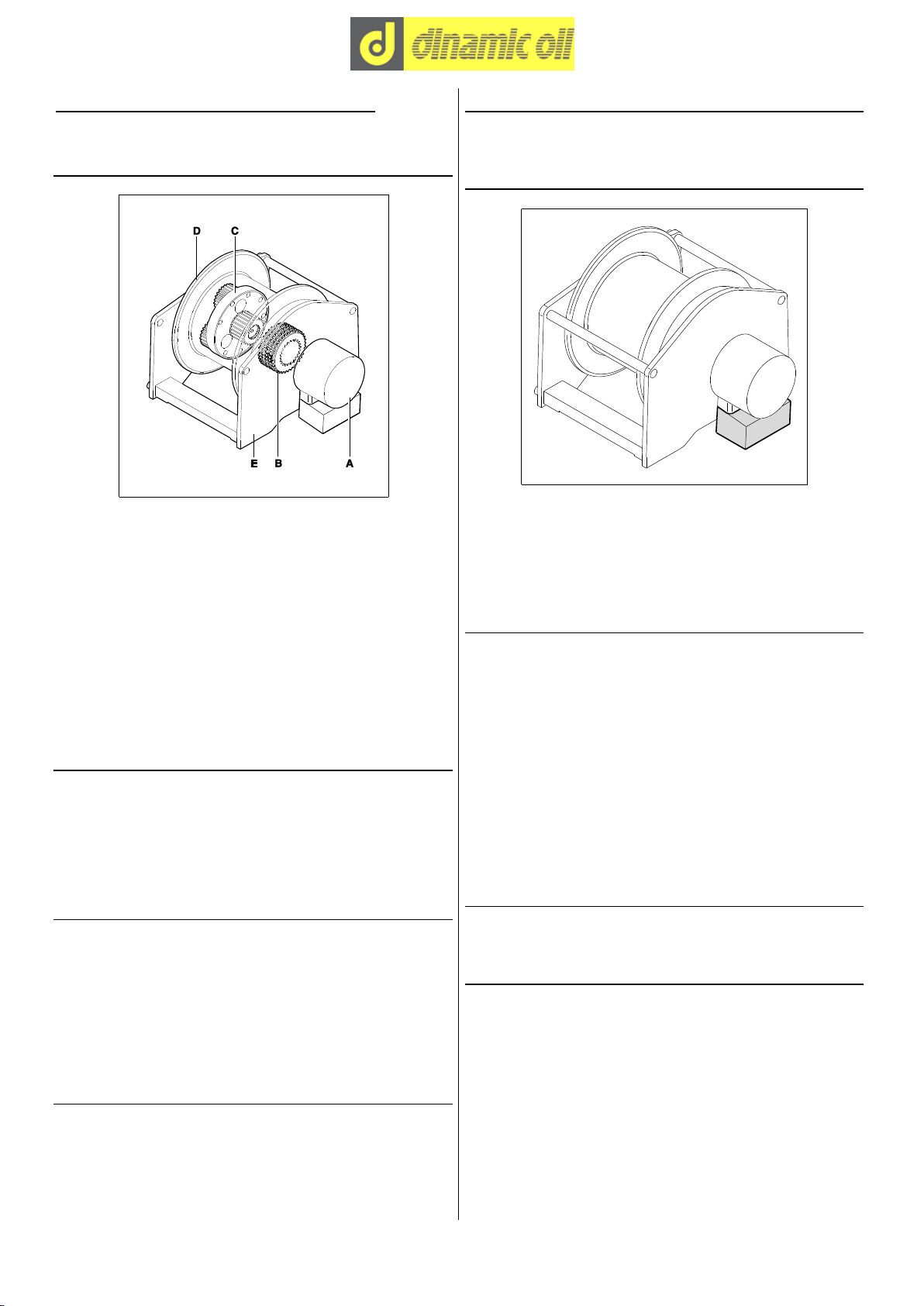

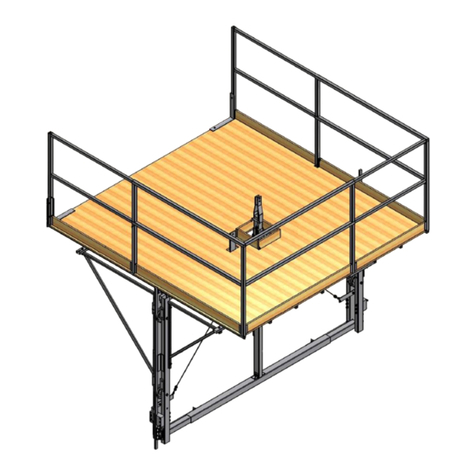

2.1 –Main parts and general winch descrip-

tion

- Legend

A = Hydraulic motor

B = Negative parking brake

C = Planetary reduction gear

D = Drum

E = Support structure

The winch is composed of a drum (in which an planetary

reduction gear and a negative parking brake are in-

serted) driven by a hydraulic motor, around which the

rope for load hoisting is wound: the whole unit is installed

on a support frame.

2.2 –Description of machine functions

The winch is commanded by the distributor of the opera-

tive machine on which it is installed. The rotation of the

drum winds and unwinds the rope to which the load is

applied. The brake is released when the motor is started

and is activated when the motor is stopped.

2.3 –Permitted use

The winch is designed to raise and lower loads by

winding and unwinding the cable around the drum. The

use of the winch with superior values to those listed in

the technical data is considered "improper use" and

therefore "not admitted"; insofar the builder declines

every responsibility in relation to the damages eventually

provoked to people or to things and cancels the warranty.

2.4 –Uses not permitted

Never use the winch to lift and transport people. It is for-

bidden to use the winch before machine on which it is

mounted has been declared compliant to the dispositions

of the Directive 2006/42/CE.

2.5 –Environmental conditions

Room temperature for a proper use: - 10°C; + 40°C.

2.6 –Safety devices

Valve for stopping and controlling the lowering

Fluid controlled, mounted directly on the hydraulic motor,

this part is essential for the safe functioning of the winch.

It prevents the load slipping out of the motor’s control

during lowering.

2.7 –Residual risks

Despite the observance of all safety norms and the em-

ployment according to the rules described in the manual,

there can still be some residual risks among which the

most recurrent are:

- friction;

- crushing between rope and drum;

- inverse rotation of the drum by human error;

- ejection of fluids due to the spillage of the oil in pres-

sure.

Keep in mind that the use of an any machine implicates

some risks. Face every type of operation with the maxi-

mum attention and concentration.

2.8 –Noise

The level of noise emissions detected is not relevant.

2.9 –Electro-magnetic field

The electro-magnetic discharges of the winch with cable

press - limit switch and load limiter are not significant.

7/28

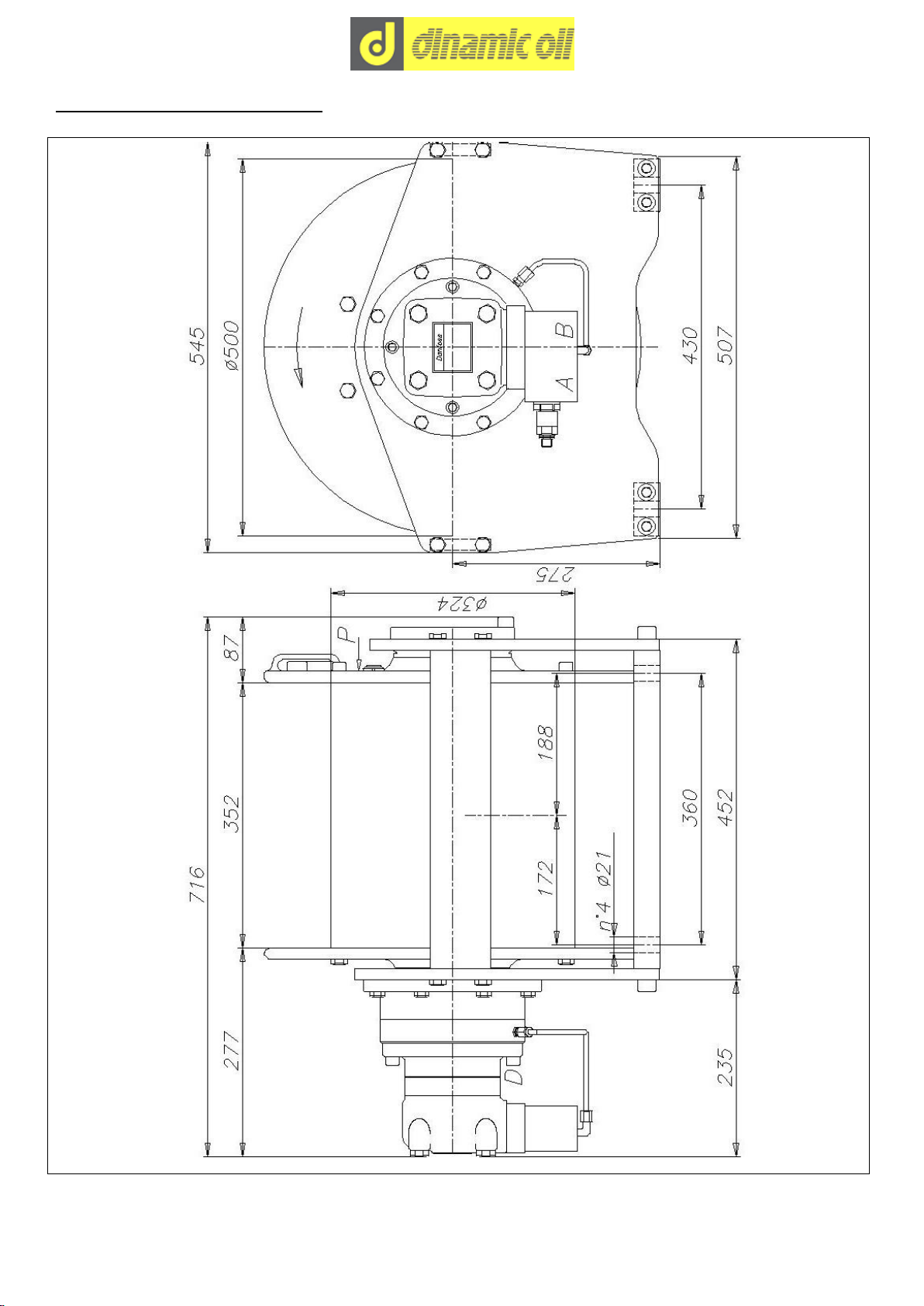

2.10 –Overall dimensions

V2 (A) = Hoisting line:

3/4” BSP

D = Drain line:

1/4” BSP

V1 (B) = Lowering line:

3/4” BSP

P = Lubrication oil plug:

1/2” BSP

8/28

2.11 –Technical data

Hydraulic motor:

SAUER DANFOSS OMTS

Motor displacement:

200 cm³

Maximum and minimun oil flow:

100/15 L/1’

Maximum counterpressure on the return line:

5 bar

Hoisting pressure:

230 bar

Negative brake:

static torque of 120 daNm

(with back pressure of 1 bar)

Minimun brake release pressure:

25 bar

Secondary safety brake:

not present

Planetary reduction:

ratio 1:18

Drum rotation direction(hoisting):

counterclockwise

Reduction lubrication oil:

HLP ISO VG 46 - 10 L

Fixing screws:

M20 –10.9 class (see “Tightening torques” chart)

Total weight of winch complete with lubricant:

265 kg

Recommended rope diameter:

16 mm

The winch is classified according to UNI ISO 4301/1 norm.

Rope layer

n°

1

2

3

4

5

6

Total line pull

daNm

5700

5200

4800

4500

Rope speed with capacity 100 L/1’

m/1’

28

30,5

33

35,5

Smooth drum rope capacity

m

23

47

73

102

Grooved drum rope capacity

m

- Tightening torques

Values for driving torques (Nm)

8.8 class

10.9 class

12.9 class

M10

50

73

86

M12

86

127

148

M14

137

201

235

M16

214

314

368

M18

306

435

509

M20

432

615

719

M22

592

843

987

M24

744

1060

1240

M27

1100

1570

1840

M30

1500

2130

2500

9/28

3 –SAFETY

3.1 –General safety instructions

- Read this manual carefully before attempting installation, use and maintenance operations.

- The user must be familiar with applicable safety rules and use modes of both the operating machine and the winch

installed, as he is responsible for his own safety as well as for any other person present near the machine working

area.

- All the operators must be suitably trained to use, adjust and operate of both the operating machine and the winch in-

stalled.

- Do not allow unauthorized personnel to use this machine.

- Do not start the machine, if it is faulty.

- Do not search for hydraulic leakage with bare hands, use a piece of paper or wood instead.

- A fluid coming from a very small hole might be almost invisible, and yet sufficient to penetrate the skin.

- If the fluid comes in contact with the skin, seek medical assistance immediately, for there might be risk of infection or

skin disease.

- Before removing any caps, plugs, or flexible tubes, make sure that there is no pressure in the hydraulic circuit.

10/28

4 –TRANSPORTING, HANDLING AND INSTALLATION

4.1 –Packing the machine

The packing of the machine is done according to the

agreements made with the Customer, taking into account

the distance and type of transport chosen.

In general the winches are packed in wooden boxes with

wood joists to facilitate harnessing and lifting.

Packing varies in relation to the quantity and type of

product.

The weight and dimensions are indicated in the transport

documents or on the package itself.

ATTENTION !!!

Do not tilt or turn the package upside down while lifting or

during transport.

4.2 –Handling - Storage

Use suitable means of transport to hoist and move the

packed unit, taking into account the type of packing.

If the package is moved with a fork-lift truck, make sure

the weight is balanced on the forks.

If the packages are moved with a hoist and, in any case,

with a hook, make sure that the load is balanced in the

sling.

Use lifting accessories that are suitable and legally certi-

fied.

While hoisting the unit and positioning it, take care not to

let it swing too much to prevent it hitting something.

The storage area must not be excessively damp or dusty.

The ambient temperature must be between - 20 °C and +

70 °C with a maximum humidity level of 90%, with no

condensation.

11/28

4.3 –Winch movement

For the hoisting procedures, strap the winch using two belts, which must be wrapped around the ends of the drum (fig.

A), or hook it on at the indicated points (fig. B) if present.

4.4 –Assembly on base plate

- Make sure that the surface the winch will be fastened to

is rigid enough and even.

- Place the winch on the surface and check that the fas-

tening plates lie perfectly flat on the fastening surface.

- If one of the 4 weight bearing points of application is

raised, insert a shim "A" to balance the unit and avoid

causing the unit undue tension during screw tightening.

- Tighten the screws with the correct tightening torque,

see section "2.11-Technical data".

12/28

4.5 –Installation

4.5.1 –Warnings

ATTENTION !!!

Winch installation and post-installation checks must be

carried out according to the applicable rules in the coun-

try where the machine is used.

Before assembly, make sure the winding direction of the

rope corresponds to the one indicated by the arrow ap-

plied on the winch (fig. 4.5.1).

Winches which rotate in the opposite direction to the

standard ones can be supplied on request (counter-

clockwise).

The winch can be mounted with the fastening surfaces

facing downwards, upwards or in any other position be-

tween the two.

4.5.2 –Hydraulic system

The distributor, therefore, must have an open centre (fig.

4.5.2) with an "H" configuration.

If the distributor presents a plurality of elements, connect

the winch to the last element closest to the outfeed side.

Connect the delivery opening of the element to the winch

motor in position “V2”.

The hydraulic system must meet the applicable rules and

realised with proper hoses, filters and valves.

13/28

4.6 –Hydraulic diagram

- Hydraulic diagram for winch without accessories

V1

= Lowering line

1

= Open centre valve

V2

= Hoisting line

2

= Relief valve

C3

= Connection to brake

D

= Connection of drainage unit

14/28

- Hydraulic diagram for winch with limit switch-electrical cable press (if present)

V1

= Lowering line

3

= Discharge activation solenoid valve n.o

V2

= Hoisting line

4

= Resetting microswitch

C3

= Connection to brake

5

= Upwards stroke limit micro-switch

D

= Connection of drainage unit

6

= Downwards stroke limit microswitch

1

= Open centre valve

7

= Fuse

2

= Relief valve

8

= Limit switch activation key

15/28

- Hydraulic diagram for winch with cable press - hydraulic limit switch (if present)

V1

= Lowering line

1

= Open centre valve

V2

= Hoisting line

2

= Relief valve

C3

= Connection to brake

3

= Lower stroke limit hydraulic valve

D

= Connection of drainage unit

16/28

4.7 –Checks

- Check the pressure in the return line of the circuit

This measurement should be made by disconnecting the

two tubes from the valve and connecting them with a “T”

connection that may be linked to a pressure gauge with a

maximum scale of 60 bar.

Information

This counterpressure must be between 5 and 1 bar.

CAUTION !!!

Counter-pressure values higher than 5 bar dangerously

limit the braking torque, and values lower than 1 bar

could cause an insufficient motor power supply.

D = Distributor

M = Motor

V = Valve

m = Pressure gauge

P = Pump

R = “T” connection

- Make sure the control distributor has the gate open

D = Distributor

M = Motor

V = Valve

P = Pump

If you do not have sure indications you may proceed as

follows:

- disconnect the tubes from the valve and place their

ends in a container with a sufficiently large capacity; start

the pump while keeping the distributor in the center.

- If the two tubes do not release oil into the container the

distributor has the gate closed; if instead the two tubes

release oil, the gate is open.

CAUTION !!!

Make sure the oil flow does not cause the container

to overflow and as a consequence waste oil as well as

releasing polluting substances into the environment: if

there is a risk of this occurring, interrupt the test imme-

diately and resume it only after having replaced the con-

tainer with a larger one.

Informazione

Non disperdere l’olio esausto nell’ambiente, ma racco-

glierlo e inviarlo per lo smaltimento agli enti autorizzati.

17/28

4.8 –Cable mounting

- Installing cable with thimble

ATTENTION !!!

The winding direction of the rope must correspond to the

drum rotation direction indicated by the arrow.

Make sure that the emergency switch is working and that

a skilled operator is on hand and ready to stop the hoist

in the event of entangling or other irregularities that may

cause harm to the operator who is in the vicinity of the

cable.

If the cable is not sufficiently compact during the initial

assembly phase, when it is loaded it may become caught

up in the turns below and damaged.

1) Introduce the rope end into slot positioned on the drum

and then in the poket “A”.

2) Fold the rope around the thimble “B”. Then secure the

rope and thimble in the slot by pulling firmly.

- Installing cable with clamps

ATTENTION !!!

The winding direction of the rope must correspond to the

drum rotation direction indicated by the arrow.

Make sure that the emergency switch is working and that

a skilled operator is on hand and ready to stop the hoist

in the event of entangling or other irregularities that may

cause harm to the operator who is in the vicinity of the

cable.

If the cable is not sufficiently compact during the initial

assembly phase, when it is loaded it may become caught

up in the turns below and damaged.

1) Place the end of the cable in the slot on the edge of

the drum and then in the clamps "A".

Minimum protrusion “B” from the last clamp equal to 2

times the Ø of the cable.

2) Tighten the clamps screws.

For a correct winding, it is necessary to have a minimum preload of 5% of the breaking force of the rope. The breaking

force of the rope depends on the diameter and of the type of the rope and it has to be indicated in the rope certificate.

18/28

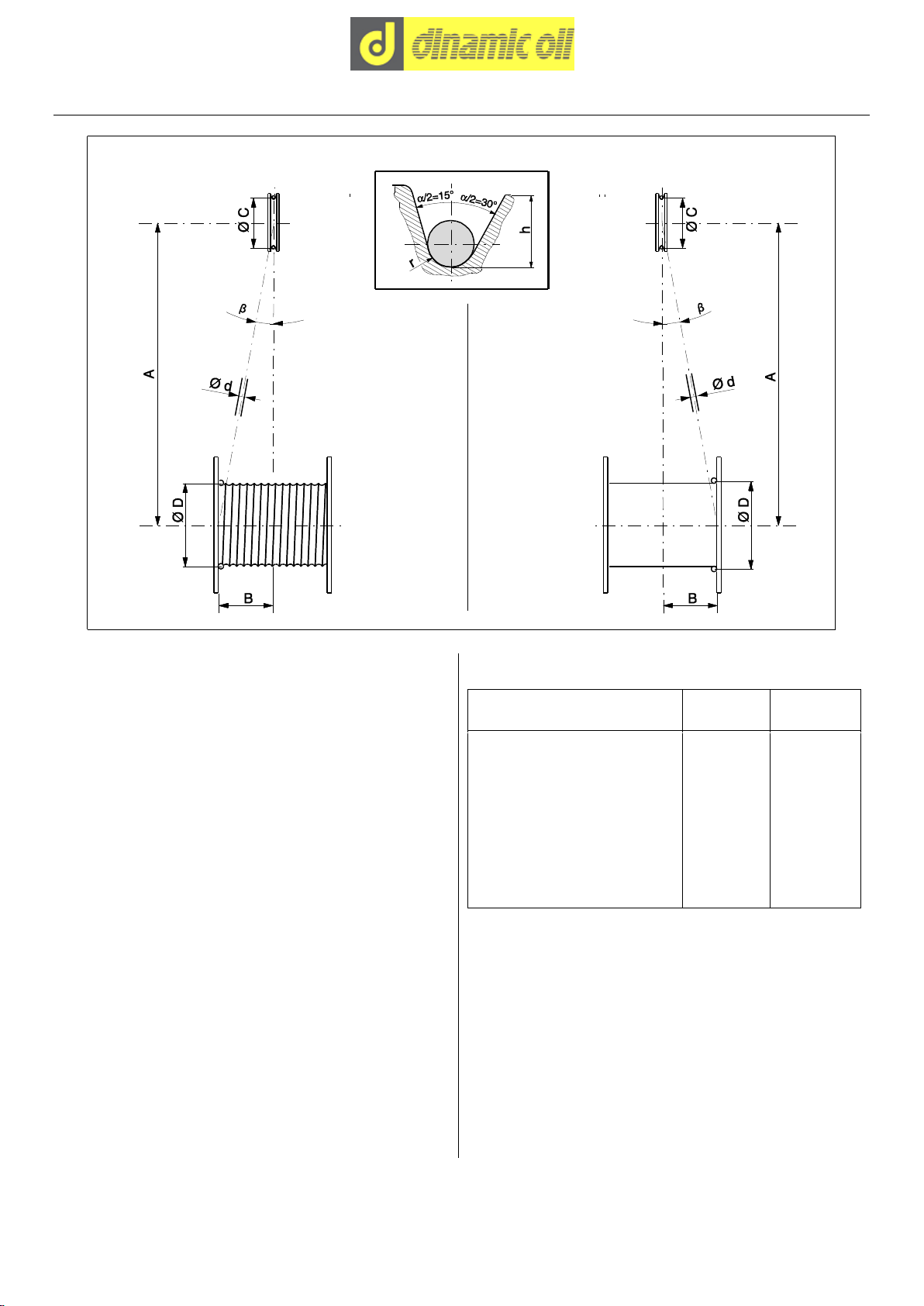

4.9 –Pulleys

- Legend

H

= Depth of the sheave groove

a

= Angle between sides of the sheave

d

= Nominal diameter of the rope

1

= Maximum angle “b”:

smooth drum = 1°30 (tg b= B/A)

threaded drum = 2° (tg b= B/A)

2

= Groove radius “r” = 0,5375 x d

3

= Groove minimum height “h” = 2 x d

4

= Angle between the pulley groove “a” = between

30° and 60°.

- Diameter choice according to gear class

Classification of mechanism

Drums

h1= D/d

Pulleys

h2= C/d

M1

11,2

12,5

M2

12,5

14,0

M3

14,0

16,0

M4

16,0

18,0

M5

18,0

20,0

M6

20,0

22,4

M7

22,4

25,0

M8

25,0

28,0

The size of the return pulley pitch diameter must comply

with the standard ISO 4308-1, according to the mechan-

ism classification.

Example:

for mechanism classification M5, the ratio between the

pulley pitch diameter and the diameter of the cable must

be no lower than 20.

19/28

5 –INFORMATION ABOUT ADJUSTMENTS

5.1 –Adjustments

- Calibrating the cable press limit switch (if present)

Information

Carry out the operation with the rope completely unwound.

1) Insert a shim “A” with the same diameter of the rope under the roller end.

2) Loosen screw “B”.

3) Turn lever “C” until screw “D” excites microswitch “E”.

4) Tighten screw “B”.

20/28

6 –START UP INFORMATION

6.1 –Start up

- Safety instructions

DANGER !!!

Before the intervention it is necessary to warn, with signs or other suitable means, that it is forbidden to get close and

stay in the danger zone due to the presence of suspended loads.

A danger warning plate, notifying the danger constituted by running cables that wrap around pulleys and drum, must

be placed on the machine. This prohibit anyone from approaching to the moving parts. This plate has to be reported in

the user manual of the crane or of the machinery on which it is mounted.

- Check hoisting part conditions (rope, hook, etc.) before using the winch.

- During start up operations, the operator and any member of the team shall keep a safety distance from the rope, to

prevent personal injuries in case of its breakage.

- It is standard practice to carry out the first few operations hoisting a modest load to no more than 1 metre from the

ground, in order to check that the lowering operation is controlled.

- Carry out manoeuvres gradually; avoid sudden jerking and load swivelling.

Other manuals for SE45

1

Table of contents

Other DINAMIC OIL Winch manuals

Popular Winch manuals by other brands

Harken

Harken 46.2 PTBBB Installation and maintenance manual

TORSO WINCH

TORSO WINCH CW02V12 Installation and operating instructions

Harken

Harken Performa Winch 20 STP Installation and maintenance manual

Tulsa

Tulsa RUFNEK 30 Service manual

EIVA

EIVA Ocean Enviro 10.4 user manual

Superwinch

Superwinch H25PRO owner's manual

ADFINIS

ADFINIS SKYLOCK user manual

Champion Power Equipment

Champion Power Equipment EWD8000 Assembly & operating instructions

Super Handy

Super Handy GUO076 Operator's manual

Dover

Dover Pull MASTER R5-12-70-1M Instructions and parts manual

Ronstan

Ronstan Andersen 12ST product manual

Runva

Runva 9.5 XS Installation & operation