HyQuest Solutions Pty Ltd

WS200/WS300/WS500 Page 9of 28

© Copyright

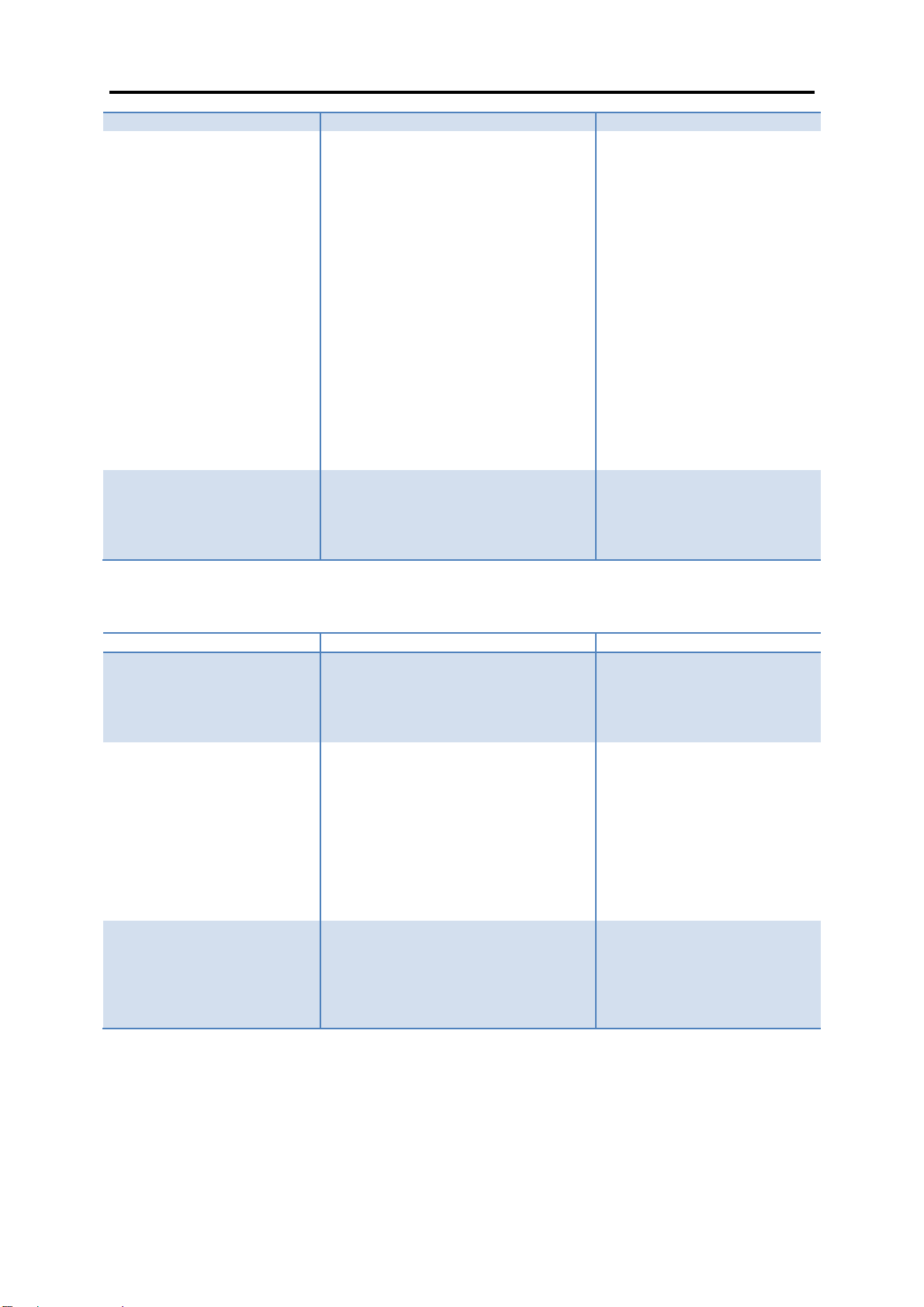

FAU LT FINDING

Mechanical

Fault Symptom Possible Cause Action

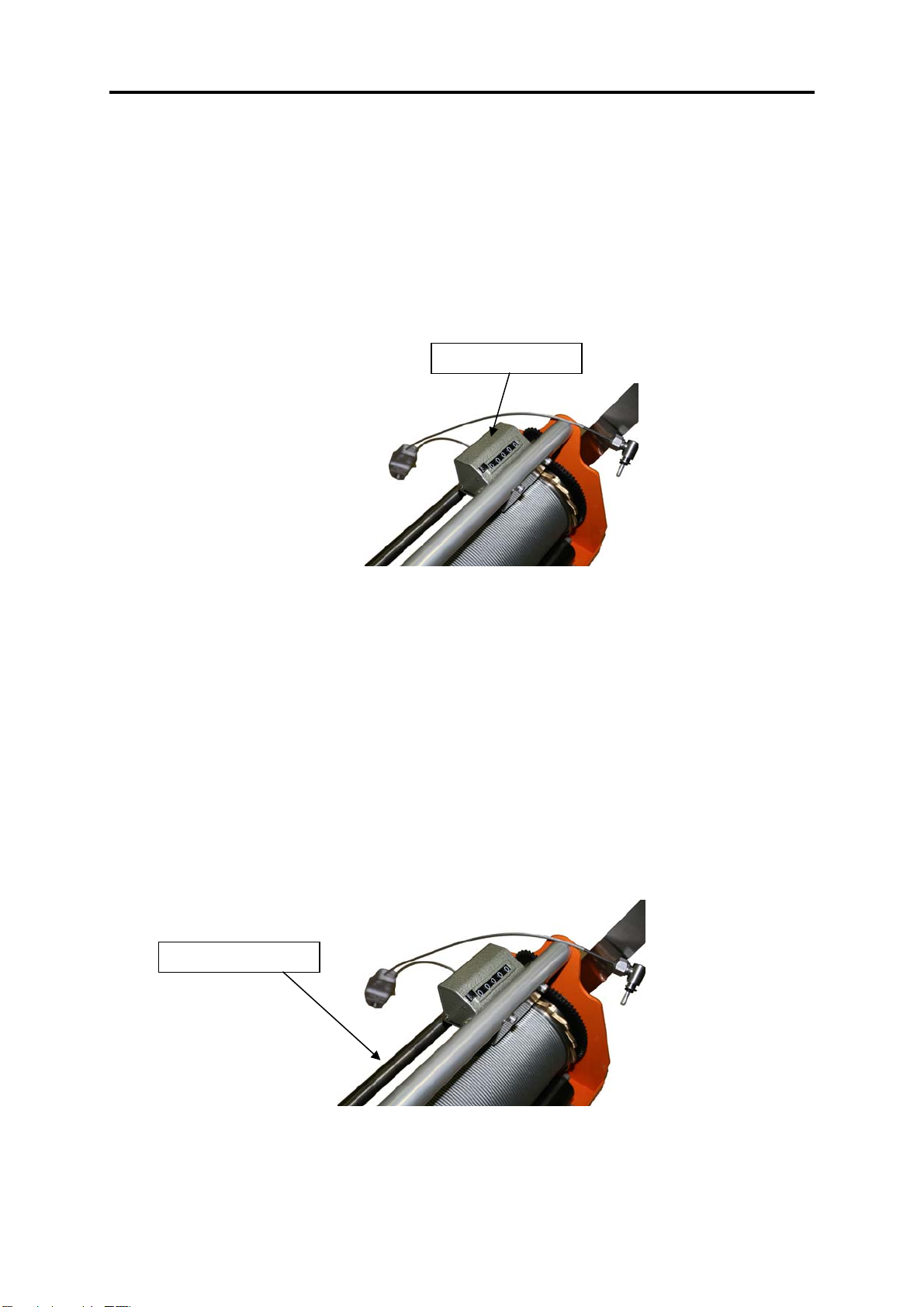

Counter not registering -Counter was reset while rotating

handle -Reset counter in a stop

position

-Counter gear loose on shaft - Tighten Grub Screw

Weston brake will not

disengage -Seizure due to prolonged period

without use-Attach heavy load to

cable and pull or hit the

handle sharply in the

lower direction (Anti-

Clockwise). Repeat

several time and if

unsuccessful; remove

brake assembly for

inspection.

Weston brake slips in “raise”

mode -Ratchet wheel, friction disc and

drum end surfaces not “bedded-

in”

-Attach light load to

cable and wind up and

down several times with

Weston brake engaged.

If no improvement,

dismantle and check for

grease on friction

surfaces.

Layer winding sheave not

freely running, emitting

“squealing” noise or lead

screw dry

-Shaft dirty - Remove from winch

and clean sheave and

shaft separately. Lightly

oil or grease after re-

installing

-Thread damaged -Repair damaged thread

with file. Lightly oil or

grease after re-installing

-ThreadDry -Lightly oil or grease

Electrical

Fault Symptom Possible Cause Action

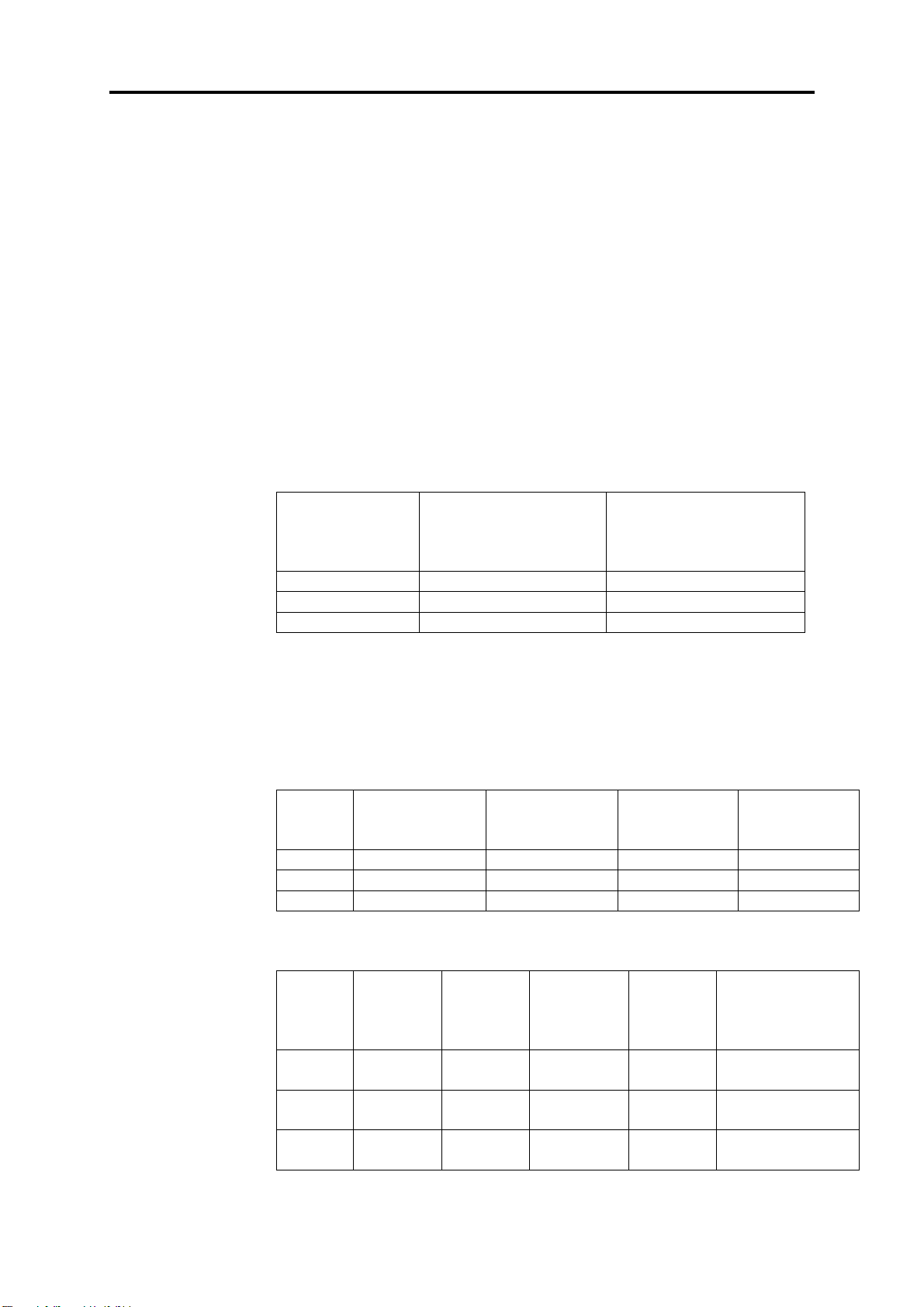

Current meter counter not

registering -Counter faulty -Bridge positive and

negative terminals on

counter. If no signal,

repair counter

-Lead damaged - Connect lead to counter

and bridge other end. If

no signal, lead faulty.

Replace or repair ends.

-Earth (Black) terminal is faulty -With lead connected to

winch, bridge red

terminal to frame. If no

signal terminal loose or

corroded.

ISSUE 3:11/6/19