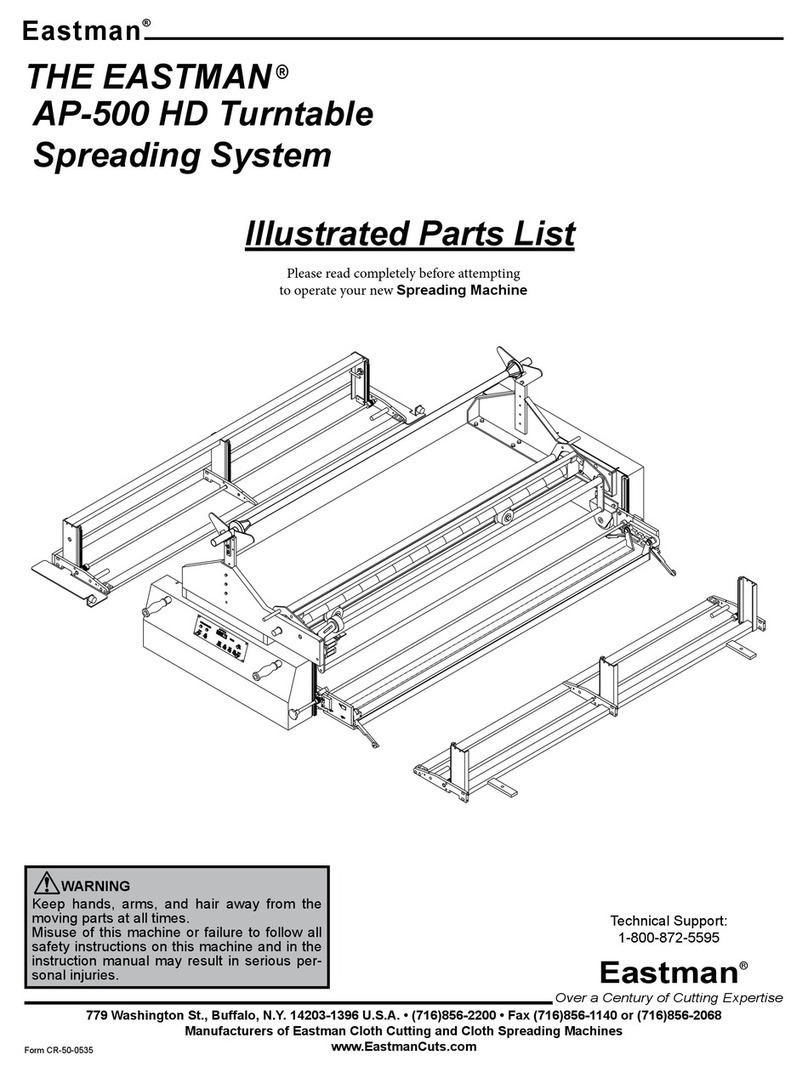

ETS-Lindgren 2187 User manual

M

od

el 2187

E

lec

t

ric

-

P

o

were

d

Tu

r

nt

a

b

le

2

-

M

e

t

er, 3

-M

e

t

er

U

s

e

r

M

anua

l

ii

|

E

T

S

-

L

i

ndg

r

en L.P.

r

e

s

e

r

v

e

s

the

ri

ght to

m

a

k

e

c

hange

s

to an

y

p

r

odu

c

t

s

he

r

e

i

n to

im

p

r

o

v

e

fun

c

t

i

on

i

ng o

r

de

s

i

gn. A

l

though the

i

nfo

rm

at

i

on

i

n th

i

s

do

c

u

m

ent ha

s

been

c

a

r

efu

ll

y

r

e

v

i

e

w

ed and

i

s

be

li

e

v

ed to be

r

e

li

ab

l

e, E

T

S

-

L

i

ndg

r

en doe

s

not a

ss

u

m

e an

y

li

ab

ili

t

y

a

ri

s

i

ng out of the

app

li

c

at

i

on o

r

u

s

e of an

y

p

r

odu

c

t o

r

c

ir

c

u

i

t de

sc

ri

bed he

r

e

i

n; no

r

doe

s

i

t

c

on

v

e

y

an

y

li

c

en

s

e unde

r

i

t

s

patent

ri

ght

s

no

r

the

ri

ght

s

of othe

r

s

. A

ll

t

r

ade

m

a

r

ks

a

r

e the p

r

ope

r

t

y

of the

ir

r

e

s

pe

c

t

i

v

e

o

w

ne

r

s

.

Cop

y

ri

gh

t

2007–2008

b

y

E

T

S

-

L

i

ndg

re

n

L

.P.

A

ll

R

i

gh

t

s

R

eserve

d

.

No

p

ar

t

o

f

t

h

is

do

c

u

me

n

t

may

b

e c

op

ie

d

b

y a

n

y mea

n

s wi

t

hou

t

wri

tt

e

n

p

ermissi

on

f

r

o

m

E

T

S

-

L

i

ndg

re

n

L

.P.

T

r

ade

m

a

r

ks

u

s

ed

i

n th

i

s

do

c

u

m

ent:

T

he

E

T

S

-

L

i

ndg

r

en

l

ogo

i

s

a t

r

ade

m

a

r

k

of E

T

S

-

L

i

ndg

r

en L.P.

R

evisi

on

R

ec

o

r

d

|

M

ANUAL

,2187

|

Par

t

#399789,

R

ev.

C

R

evisi

on

D

escri

p

t

i

on

D

a

t

e

A In

i

t

i

a

l

R

e

l

ea

s

e

J

une, 2007

B Added 3.0 tu

r

ntab

l

e

i

nfo

rm

at

i

on and d

r

a

w

i

ng

s

F

eb

r

ua

r

y

, 2008

C

R

eb

r

and

J

u

l

y

, 2008

|

iii

T

a

b

le

o

f

C

on

t

e

n

t

s

N

o

t

es,

C

a

u

t

i

on

s, a

nd

W

a

r

n

i

ng

s .........................................................................v

1.0 I

n

t

r

odu

c

t

i

on

...................................................................................................7

Standa

r

d

C

onf

i

gu

r

at

i

on....................................................................................................... 7

T

u

r

ntab

l

e A

ss

e

m

b

l

y

............................................................................................... 7

Sh

i

e

l

d

R

oo

m

F

eed

-

th

r

ough ................................................................................... 8

Opt

i

ona

l

Ite

m

s

..................................................................................................................... 8

Inf

r

a

r

ed

R

e

m

ote

C

ont

r

o

ll

e

r

.................................................................................... 8

S

li

p

R

i

ng ................................................................................................................ 8

E

UT

Po

w

e

r

Out

l

et

s

................................................................................................ 9

M

ounted L

i

ne I

m

pedan

c

e Stab

ili

z

at

i

on

N

et

w

o

r

k

................................................... 9

Add

i

t

i

ona

l

F

i

be

r

Opt

i

c

C

ab

l

e

s

................................................................................ 9

E

T

S

-

L

i

ndg

r

en P

r

odu

c

t Info

rm

at

i

on Bu

ll

et

i

n. ....................................................................... 9

2.0

M

ai

n

t

e

n

a

n

ce ................................................................................................11

R

e

c

o

mm

ended

M

a

i

ntenan

c

e S

c

hedu

l

e ........................................................................... 11

6

-M

onth Se

r

v

i

c

e .................................................................................................. 11

12

-M

onth Se

r

v

i

c

e ................................................................................................ 12

R

ep

l

a

c

e

m

ent and O pt

i

ona

l

Pa

r

t

s

...................................................................................... 12

Se

r

v

i

c

e P

r

o

c

edu

r

e

s

.......................................................................................................... 12

3.0

S

p

eci

f

ica

t

i

on

s..............................................................................................13

E

l

e

c

t

ri

c

a

l

Spe

c

i

f

i

c

at

i

on

s

.................................................................................................... 13

M

e

c

han

i

c

a

l

Spe

c

i

f

i

c

at

i

on

s

................................................................................................ 13

4.0

Tu

r

n

t

a

b

le I

n

s

t

alla

t

i

on

C

on

si

d

era

t

i

on

s.......................................................15

Befo

r

e You Beg

i

n

—

P

r

e

c

aut

i

on

s

....................................................................................... 15

Po

w

e

r

and S

i

gna

l

L

i

ne

s

.................................................................................................... 16

C

ondu

i

t ................................................................................................................ 16

E

l

e

c

t

ri

c

a

l

C

on

s

i

de

r

at

i

on

s

..................................................................................... 16

A

cc

e

ss

................................................................................................................. 16

Outdoo

r

In

s

ta

ll

at

i

on

s

......................................................................................................... 16

D

r

a

i

nage .............................................................................................................. 16

C

o

l

d

C

lim

ate

C

ond

i

t

i

on

i

ng................................................................................... 16

5.0 Elec

t

rical I

n

s

t

alla

t

i

on

..................................................................................17

iv

|

6.0

A

ssem

b

ly a

nd

I

n

s

t

alla

t

i

on

..........................................................................19

F

l

oo

r

F

l

ange In

s

ta

ll

at

i

on

i

n a Pane

l

ed

F

l

oo

r

..................................................................... 20

F

l

oo

r

F

l

ange In

s

ta

ll

at

i

on

i

n a

C

on

c

r

ete P

i

t ....................................................................... 22

I

R

R

epeate

r

In

s

ta

ll

at

i

on .................................................................................................... 23

In

s

ta

ll

at

i

on A

ss

e

m

b

l

y

C

o

m

ponent

s

..................................................................... 23

R

equ

ir

ed

T

oo

l

s

fo

r

In

s

ta

ll

at

i

on............................................................................. 23

In

s

ta

ll

at

i

on Step

s

................................................................................................. 23

7.0 O

p

era

t

i

on

.....................................................................................................25

A

pp

e

nd

ix

A:

L

is

t

o

f

A

ssem

b

ly

D

rawi

ng

s ........................................................27

A

pp

e

nd

ix

B:

W

arra

n

t

y ......................................................................................29

A

pp

e

nd

ix

C:

E

C

D

eclara

t

i

on

o

f

C

on

f

o

rmi

t

y....................................................31

|

v

N

o

t

es,

C

a

u

t

i

on

s, a

nd

W

ar

n

i

ng

s

No

t

e

:

D

enote

s

he

l

pfu

l

i

nfo

rm

at

i

on

i

ntended to p

r

o

v

i

de t

i

p

s

fo

r

bette

r

u

s

e of the p

r

odu

c

t.

C

a

u

t

i

on

:

D

e

no

t

es a

h

a

z

ar

d

.

F

ail

u

re

t

o

f

o

ll

o

w i

n

s

t

r

u

c

t

i

on

s

c

ou

l

d

res

u

l

t

i

n

mi

no

r

p

ers

on

al i

n

j

u

ry a

nd

/

o

r

p

r

op

er

t

y

d

ama

g

e. I

n

cl

ud

e

d

t

ex

t

g

ives

p

r

op

er

p

r

o

ce

du

res.

W

ar

n

i

ng

:

D

e

no

t

es a

h

a

z

ar

d

.

F

ail

u

re

t

o

f

o

ll

o

w i

n

s

t

r

u

c

t

i

on

s

c

ou

l

d

res

u

l

t

i

n

SEVE

R

E

p

ers

on

al i

n

j

u

ry a

nd

/

o

r

p

r

op

er

t

y

d

ama

g

e. I

n

cl

ud

e

d

t

ex

t

g

ives

p

r

op

er

p

r

o

ce

du

res.

See the E

T

S

-

L

i

ndg

r

en

P

r

odu

c

t Info

r

m

at

i

on Bu

ll

et

i

n

fo

r

s

afet

y

,

r

egu

l

ato

r

y

, and

othe

r

p

r

odu

c

t

m

a

r

k

i

ng

i

nfo

rm

at

i

on.

vi

|

T

h

i

s

page

i

ntent

i

ona

ll

y

l

eft b

l

an

k

.

I

n

t

r

odu

c

t

i

on

|

7

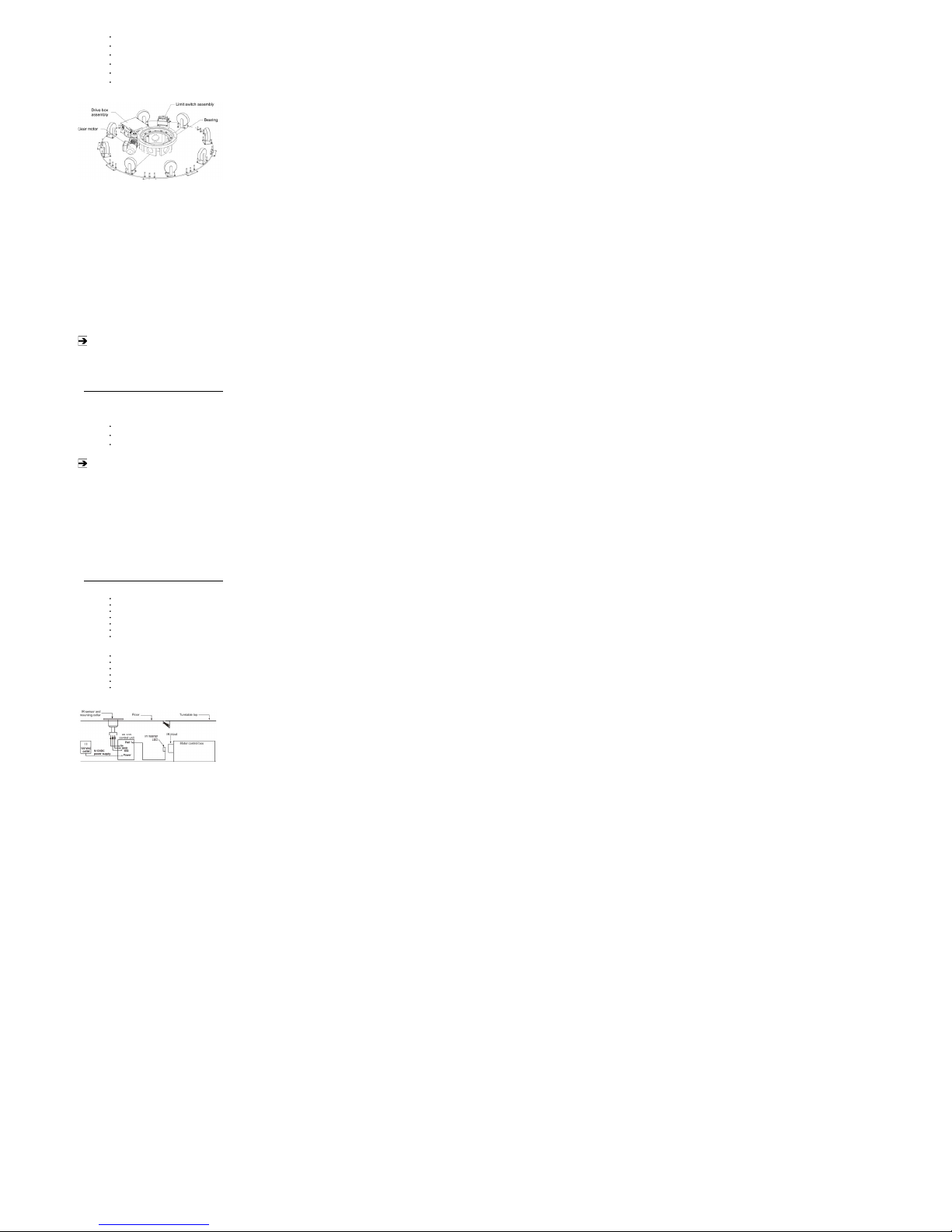

1.0 I

n

t

r

odu

c

t

i

on

T

he

E

T

S

-

L

i

ndg

re

n

M

od

el 2187

Tu

r

n

t

a

b

le

i

s

an e

l

e

c

t

ri

c

-

po

w

e

r

ed tu

r

ntab

l

e

p

l

atfo

rm

sys

te

m

de

s

i

gned fo

r

u

s

e

w

i

th the

M

ode

l

2090

M

u

l

t

i-

D

e

v

i

c

e

C

ont

r

o

ll

e

r

(

o

r

ne

x

t gene

r

at

i

on E

T

S

-

L

i

ndg

r

en

c

ont

r

o

ll

e

r

,

i

f app

li

c

ab

l

e

)

fo

r

E

M

I

c

o

m

p

li

an

c

e

te

s

t

i

ng.

T

he

M

ode

l

2187

i

s

a

v

a

il

ab

l

e

i

n 2.03

-m

ete

r

and 3.03

-m

ete

r

s

i

z

e

s

, both

de

s

i

gned fo

r

i

ndoo

r

o

r

outdoo

r

u

s

e.

T

he top of the tu

r

ntab

l

e

i

s

c

ondu

c

t

i

v

e

w

i

th a

c

ont

i

nuou

s

g

r

ound b

r

u

s

h to

e

l

e

c

t

ri

c

a

ll

y

c

oup

l

e

i

t to the g

r

ound p

l

ane.

T

he g

r

ound b

r

u

s

he

s

a

r

e atta

c

hed

d

ir

e

c

t

l

y

to the

c

ha

m

be

r

f

l

oo

r

b

y

the f

l

oo

r

f

l

ange, and a

r

e

i

n

c

ont

i

nuou

s

c

onta

c

t

w

i

th the tu

r

ntab

l

e top.

T

he b

r

u

s

he

s

po

i

nt do

w

n

w

a

r

d f

r

o

m

the f

l

oo

r

f

l

ange.

Both

m

ode

l

s

ut

ili

z

e a p

i

n

i

on and gea

r

d

ri

v

e

w

i

th a gea

r

r

edu

c

e

r

and e

l

e

c

t

ri

c

m

oto

r

l

o

c

ated beneath the p

l

atfo

rm

.

T

he bea

ri

ng on

w

h

i

c

h the tu

r

ntab

l

e

r

otate

s

ha

s

the

d

ri

v

e teeth

c

ut d

ir

e

c

t

l

y

on the out

s

i

de and

w

ill

ea

s

il

y

s

uppo

r

t

m

o

s

t Equ

i

p

m

ent

U

nde

r

T

e

s

t

(

E

UT

)

. Suppo

r

t fo

r

the tu

r

ntab

l

e

i

n

c

l

ude

s

c

a

s

te

r

s

that a

i

d

i

n the

s

uppo

r

t of

c

ant

il

e

v

e

r

ed

l

oad

s

on the out

s

i

de of the tu

r

ntab

l

e.

T

he tu

r

ntab

l

e top

i

s

s

e

c

t

i

ona

l

to p

r

o

v

i

de ea

sy

a

cc

e

ss

i

f

s

e

r

v

i

c

e

i

s

r

equ

ir

ed. On

s

tanda

r

d

m

ode

l

s

, a 15

-

c

m

ho

l

e

i

s

p

r

o

v

i

ded

i

n the

c

ente

r

of the tu

r

ntab

l

e to

a

cc

o

mm

odate

c

u

s

to

m

e

r

s

upp

li

ed

c

ab

li

ng to and f

r

o

m

the E

UT

.

T

o p

r

e

v

ent o

v

e

r-

t

r

a

v

e

l

of the tu

r

ntab

l

e

i

n e

i

the

r

d

ir

e

c

t

i

on of

m

o

v

e

m

ent, ha

r

d

limi

t

s

a

r

e p

r

o

v

i

ded

i

n the fo

rm

of p

i

n

s

that a

c

tuate

sw

i

t

c

he

s

l

o

c

ated be

l

o

w

the tab

l

etop.

T

he

s

e p

i

n

s

a

ll

o

w

limi

t

s

to be

s

et and a

ll

o

w

a

s

m

u

c

h a

s

t

w

o fu

ll

r

otat

i

on

s

.

R

otat

i

on

s

peed

c

an be

v

a

ri

ed f

r

o

m

a

c

ont

r

o

ll

e

r

(

not

i

n

c

l

uded

)

o

r

th

r

ough the IEEE

-

488

i

nte

r

fa

c

e bu

s

.

S

t

a

nd

ar

d

Con

f

i

gu

ra

t

i

on

TURNTABL

E

A

SSE

M

BL

Y

F

eatu

ri

ng

c

ont

i

nuou

s

o

r

non

-

c

ont

i

nuou

s

ope

r

at

i

on, the tu

r

ntab

l

e a

ss

e

m

b

l

y

i

n

c

l

ude

s

:

230 VA

C

e

l

e

c

t

ri

c

m

oto

r

un

i

t

C

on

v

en

i

ent

r

otat

i

ona

l

limi

t ad

j

u

s

t

sw

i

t

c

he

s

G

r

ound

ri

ng a

ss

e

m

b

l

y

w

i

th g

r

ound b

r

u

s

h and f

l

oo

r

f

l

ange

10

-m

ete

r

f

i

be

r

opt

i

c

c

ab

l

e

Add

i

t

i

ona

ll

y

, the tu

r

ntab

l

e

i

s

i

nf

r

a

r

ed

c

o

m

pat

i

b

l

e, and

c

an be u

s

ed

w

i

th an

opt

i

ona

l

E

T

S

-

L

i

ndg

r

en Inf

r

a

r

ed

R

e

m

ote

C

ont

r

o

ll

e

r

(

I

R

r

e

m

ote

)

.

F

o

r

m

o

r

e

i

nfo

rm

at

i

on on u

s

i

ng an I

R

r

e

m

ote,

s

ee

Inf

r

a

r

ed

R

e

m

ote

C

ont

r

o

ll

e

r

on page 8.

8

|

I

n

t

r

odu

c

t

i

on

S

H

IE

LD

R

OO

M

F

EE

D

-

THR

O

U

G

H

R

oute

s

the f

i

be

r

opt

i

c

c

ont

r

o

l

c

ab

l

e f

r

o

m

the

c

ont

r

o

l

r

oo

m

to the

s

h

i

e

l

d

r

oo

m

,

m

a

i

nta

i

n

i

ng

s

at

i

s

fa

c

to

r

y

s

h

i

e

l

d

i

ng attenuat

i

on.

T

he un

i

t

i

s

m

ade of b

r

a

ss

fo

r

c

ondu

c

t

i

v

i

t

y

and p

r

o

v

i

de

s

attenuat

i

on of g

r

eate

r

than 100 dB at 10 G

Hz

. A

s

i

ng

l

e

22.25

-mm

(

0.875

-i

n

)

ho

l

e

i

s

r

equ

ir

ed fo

r

m

ount

i

ng.

O

p

t

i

on

al I

t

ems

I

NFRAR

E

D

R

E

M

O

T

E

C

O

NTR

O

LL

E

R

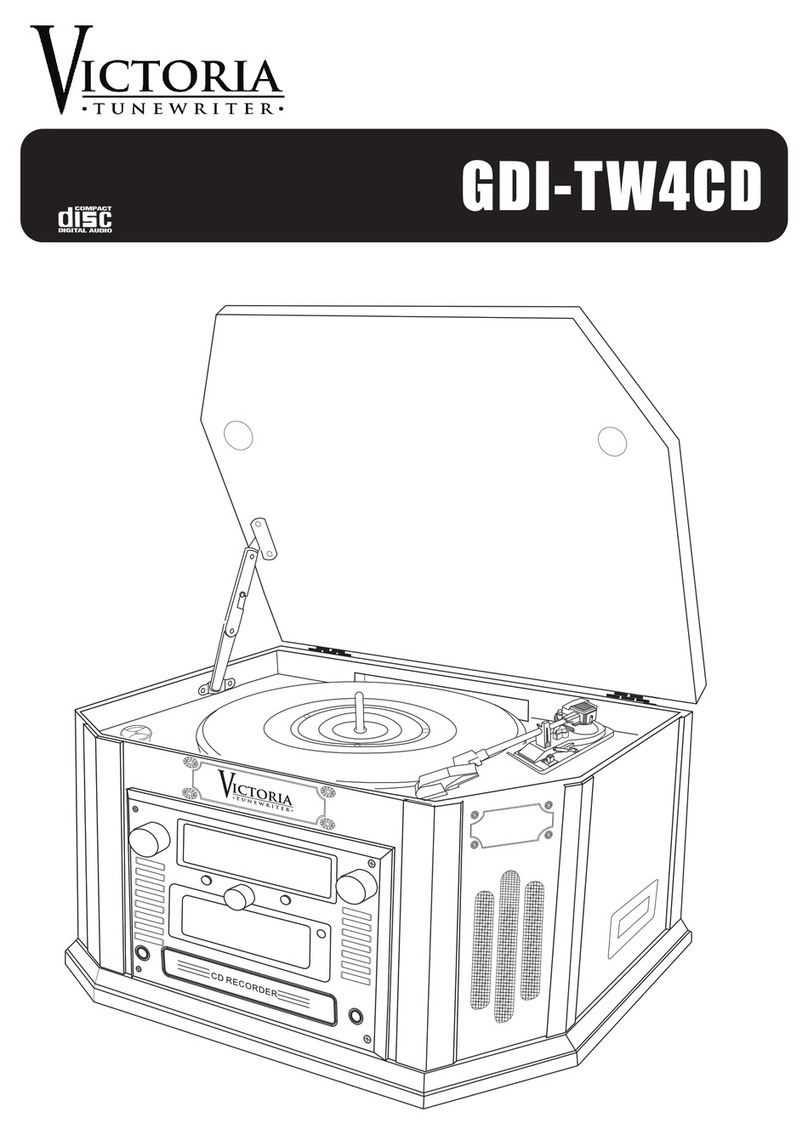

T

he

M

ode

l

2187

i

s

i

nf

r

a

r

ed

c

o

m

pat

i

b

l

e, and

c

an be u

s

ed

w

i

th a un

i

v

e

r

s

a

l

r

e

m

ote

c

ont

r

o

l

p

r

og

r

a

mm

ed to a

s

pe

c

i

f

i

c

p

r

oto

c

o

l

,

s

u

c

h a

s

the E

T

S

-

L

i

ndg

r

en Inf

r

a

r

ed

R

e

m

ote

C

ont

r

o

ll

e

r

(

I

R

r

e

m

ote

)

.

T

he I

R

r

e

m

ote

c

o

mm

un

i

c

ate

s

w

i

th an

i

nf

r

a

r

ed

r

e

c

e

i

v

e

r

i

n the

M

ode

l

2187

m

oto

r

ba

s

e th

r

ough an I

R

r

epeate

r

i

n

s

ta

ll

ed

i

n the f

l

oo

r

nea

r

the tu

r

ntab

l

e. See

I

R

R

epeate

r

In

s

ta

ll

at

i

on

on page 23 fo

r

i

n

s

t

r

u

c

t

i

on

s

on

i

n

s

ta

lli

ng an I

R

r

epeate

r

.

S

L

IP

R

I

N

G

A

ll

o

ws

c

ont

i

nuou

s

r

otat

i

on of the tu

r

ntab

l

e th

r

ough the

l

ate

s

t te

c

hno

l

og

y

i

n

m

e

r

c

u

r

y

s

li

p

ri

ng

s

, and e

i

the

r

S

c

hu

k

o o

r

N

E

M

A

c

onne

c

to

r

s

c

an be o

r

de

r

ed

w

i

th

the

s

li

p

ri

ng.

T

he

c

u

rr

ent

r

at

i

ng fo

r

the

s

tanda

r

d e

l

e

c

t

ri

c

a

l

a

ss

e

m

b

l

y

i

s

20 a

m

pe

r

e

s

.

C

onta

c

t E

T

S

-

L

i

ndg

r

en fo

r

c

u

s

to

m

r

equ

ir

e

m

ent

s

on

s

li

p

ri

ng

s

.

I

n

t

r

odu

c

t

i

on

|

9

E

U

T

P

O

W

E

R

O

UTL

E

T

S

R

e

c

epta

c

l

e

s

a

r

e u

s

ua

ll

y

m

ounted on the ba

s

e of the tu

r

ntab

l

e at the

c

ente

r

a

x

i

s

po

i

nt.

T

he

s

e

r

e

c

epta

c

l

e

s

c

an be

c

u

s

to

m

m

ounted, f

l

u

s

h

w

i

th the tab

l

etop on

s

o

m

e tu

r

ntab

l

e

s

.

C

onta

c

t E

T

S

-

L

i

ndg

r

en fo

r

i

nfo

rm

at

i

on.

M

O

UNT

E

D

L

I

N

E

I

M

PE

DANC

E

S

TAB

I

L

I

ZAT

IO

N

N

E

T

W

O

RK

A L

i

ne I

m

pedan

c

e Stab

ili

z

at

i

on

N

et

w

o

r

k

(

LIS

N

)

c

an be

m

ounted to the unde

r

s

i

de

of

s

o

m

e tu

r

ntab

l

e

s

.

T

h

i

s

opt

i

on

i

s

on

l

y

p

r

a

c

t

i

c

a

l

on

l

a

r

ge

r

tu

r

ntab

l

e

s

w

i

th

s

uff

i

c

i

ent

c

l

ea

r

an

c

e.

A

DD

I

T

IO

NAL

F

I

B

E

R

O

P

T

I

C

C

ABL

ES

Add

i

t

i

ona

l

l

ength

s

of f

i

be

r

opt

i

c

c

ab

l

e

m

a

y

be o

r

de

r

ed.

E

T

S

-

L

i

ndg

re

n

Pr

odu

c

t

I

n

f

o

rma

t

i

on

Bu

lle

t

i

n

See the E

T

S

-

L

i

ndg

r

en

P

r

odu

c

t Info

rm

at

i

on Bu

ll

et

i

n

i

n

c

l

uded

w

i

th

y

ou

r

s

h

i

p

m

ent

fo

r

the fo

ll

o

w

i

ng:

W

a

rr

ant

y

i

nfo

rm

at

i

on

Safet

y

,

r

egu

l

ato

r

y

, and othe

r

p

r

odu

c

t

m

a

r

k

i

ng

i

nfo

rm

at

i

on

Step

s

to

r

e

c

e

i

v

e

y

ou

r

s

h

i

p

m

ent

Step

s

to

r

etu

r

n a

c

o

m

ponent fo

r

s

e

r

v

i

c

e

E

T

S L

i

ndg

r

en

c

a

li

b

r

at

i

on

s

e

r

v

i

c

e

E

T

S L

i

ndg

r

en

c

onta

c

t

i

nfo

rm

at

i

on

10

|

I

n

t

r

odu

c

t

i

on

T

h

i

s

page

i

ntent

i

ona

ll

y

l

eft b

l

an

k

.

M

ai

n

t

e

n

a

n

ce

|

11

2.0

M

ai

n

t

e

n

a

n

ce

B

e

f

o

re

p

er

f

o

rmi

ng

a

n

y mai

n

t

e

n

a

n

ce,

f

o

ll

o

w

t

h

e sa

f

e

t

y

i

n

f

o

rma

t

i

on

i

n

t

h

e E

T

S

-

L

i

ndg

re

n

P

r

odu

c

t

I

n

f

o

rma

t

i

on

Bu

lle

t

i

n

i

n

cl

ud

e

d

wi

t

h

y

ou

r s

h

i

p

me

n

t

.

R

egu

l

a

rl

y

i

n

s

pe

c

t a

ll

equ

i

p

m

ent and

c

ondu

c

t

sc

hedu

l

ed

m

a

i

ntenan

c

e

i

n a

cc

o

r

dan

c

e

w

i

th the fa

c

to

r

y

r

e

c

o

mm

endat

i

on

s

p

r

o

v

i

ded.

WARRANTY

B

E

F

O

R

E SE

R

VI

C

I

N

G

:

C

O

NTACT

E

T

S

-

L

I

ND

G

R

E

N

(

+1.512.531.6400

)

—

Se

r

v

i

c

i

ng o

r

m

od

i

f

y

i

ng the un

i

t

w

i

thout

E

T

S

-

L

i

ndg

r

en autho

ri

z

at

i

on

m

a

y

v

o

i

d

y

ou

r

w

a

rr

ant

y

. If an

atte

m

pt to

s

e

r

v

i

c

e the un

i

t

m

u

s

t be

m

ade, d

i

sc

onne

c

t a

ll

e

l

e

c

t

ri

c

a

l

po

w

e

r

p

ri

o

r

to beg

i

nn

i

ng. Vo

l

tage

s

e

x

i

s

t at

m

an

y

po

i

nt

s

w

i

th

i

n the

i

n

s

t

r

u

m

ent that

c

ou

l

d,

i

f

c

onta

c

ted,

c

au

s

e pe

r

s

ona

l

i

n

j

u

r

y

. On

l

y

t

r

a

i

ned

s

e

r

v

i

c

e pe

r

s

onne

l

s

hou

l

d pe

r

fo

rm

ad

j

u

s

t

m

ent

s

and/o

r

s

e

r

v

i

c

e p

r

o

c

edu

r

e

s

upon th

i

s

i

n

s

t

r

u

m

ent.

C

apa

c

i

to

r

s

i

n

s

i

de th

i

s

i

n

s

t

r

u

m

ent

m

a

y

s

t

ill

be

c

ha

r

ged e

v

en

w

hen the

i

n

s

t

r

u

m

ent

i

s

d

i

sc

onne

c

ted f

r

o

m

the po

w

e

r

s

ou

r

c

e.

R

ec

o

mme

nd

e

d

M

ai

n

t

e

n

a

n

ce Sc

h

e

du

le

R

egu

l

a

r

m

a

i

ntenan

c

e

w

ill

p

r

o

l

ong the effe

c

t

i

v

e ope

r

at

i

on and

r

e

li

ab

ili

t

y

of

y

ou

r

tu

r

ntab

l

e.

F

o

ll

o

w

the

r

e

c

o

mm

ended

sc

hedu

l

e fo

r

6

-m

onth and 12

-m

onth

s

e

r

v

i

c

e.

Do

no

t

p

er

f

o

rm mai

n

t

e

n

a

n

ce w

h

ile

t

h

e

t

u

r

n

t

a

b

le is

op

era

t

i

ng

.

6

-M

O

NTH

S

E

R

VI

C

E

Lub

ri

c

ate the

c

a

s

te

r

s

w

i

th good qua

li

t

y

bea

ri

ng g

r

ea

s

e.

C

he

ck

the gea

r

bo

x

fo

r

f

l

u

i

d

l

ea

k

age. A

c

o

ll

e

c

t

i

on of

s

li

ght f

ilm

i

s

no

rm

a

l

, but

pudd

l

e

s

of f

l

u

i

d a

r

e not no

rm

a

l

.

T

he gea

r

bo

x

i

s

l

ub

ri

c

ated and

s

ea

l

ed at the

fa

c

to

r

y

.

U

nde

r

no

rm

a

l

c

ond

i

t

i

on

s

, the gea

r

bo

x

s

hou

l

d not

r

equ

ir

e

s

e

r

v

i

c

i

ng

du

ri

ng

i

t

s

li

fe.

12

|

M

ai

n

t

e

n

a

n

ce

12

-M

O

NTH

S

E

R

VI

C

E

Lub

ri

c

ate the

m

a

i

n bea

ri

ng

r

a

c

e

w

i

th a g

r

ea

s

e gun

c

onta

i

n

i

ng good qua

li

t

y

bea

ri

ng g

r

ea

s

e.

T

he g

r

ea

s

e f

i

tt

i

ng

s

a

r

e

l

o

c

ated

i

n

s

i

de the

r

a

c

e, 90 deg

r

ee

s

apa

r

t, beneath the top.

T

h

r

ee d

i

sc

ha

r

ge

s

f

r

o

m

the g

r

ea

s

e gun

i

n ea

c

h f

i

tt

i

ng

a

r

e adequate.

Lub

ri

c

ate the gea

r

teeth

w

i

th good qua

li

t

y

g

r

ea

s

e.

R

e

p

laceme

n

t

a

nd

O

p

t

i

on

al Par

t

s

F

o

ll

o

w

i

ng a

r

e the pa

r

t nu

m

be

r

s

fo

r

o

r

de

ri

ng

r

ep

l

a

c

e

m

ent o

r

opt

i

ona

l

pa

r

t

s

fo

r

the

M

ode

l

2187

T

u

r

ntab

l

e.

Par

t

D

escri

p

t

i

on

Par

t

Nu

m

b

er

T

u

r

ntab

l

e a

ss

e

m

b

l

y

F

o

r

a

li

s

t of a

ll

tu

r

ntab

l

e pa

r

t

s

,

s

ee the

d

r

a

w

i

ng

s

l

o

c

ated

i

n the ba

ck

of th

i

s

m

anua

l

.

I

R

R

e

m

ote

C

ont

r

o

ll

e

r

707030

N

E

M

A

c

onne

c

to

r

s

fo

r

s

li

p

ri

ng 103441

S

c

hu

k

o

c

onne

c

to

r

s

fo

r

s

li

p

ri

ng 103351

Service Pr

o

ce

du

res

F

o

r

the

s

tep

s

to

r

etu

r

n a

sys

te

m

o

r

sys

te

m

c

o

m

ponent to E

T

S

-

L

i

ndg

r

en fo

r

s

e

r

v

i

c

e,

s

ee the

P

r

odu

c

t Info

rm

at

i

on Bu

ll

et

i

n

i

n

c

l

uded

w

i

th

y

ou

r

s

h

i

p

m

ent.

S

p

eci

f

ica

t

i

on

s

|

13

3.0 S

p

eci

f

ica

t

i

on

s

Elec

t

rical S

p

eci

f

ica

t

i

on

s

D

rive S

p

ee

d

s

:

Va

ri

ab

l

e

No

mi

n

al

AC

V

o

l

t

a

g

e

:

208–230 VA

C

I

npu

t

F

re

qu

e

n

cy

:

50/60

Hz

Cu

rre

n

t

R

a

t

i

ng

:

15 a

m

p

s

e

r

v

i

c

e

Cu

rre

n

t

D

raw

:

< 10 a

m

p

s

R

P

M:

0.5–2.0

P

h

ase

:

S

i

ng

l

e

(

1

)

M

ec

h

a

n

ical S

p

eci

f

ica

t

i

on

s

D

iame

t

er

:

2.03

m

ete

r

s

3.03

m

ete

r

s

M

i

n

im

u

m

H

ei

gh

t:

27.63

c

m

10.88

i

n

27.63

c

m

10.88

i

n

M

axim

u

m

H

ei

gh

t:

31.57

c

m

12.43

i

n

31.57

c

m

12.43

i

n

R

e

qu

ire

d

Pi

t

D

iame

t

er

:

202.56

c

m

±

.63

c

m

79.75

i

n

±

.25

i

n

302.56

c

m

±

.63

c

m

119.12

i

n

±

.25

i

n

D

is

t

ri

bu

t

e

d

Lo

a

d

R

a

t

i

ng

:

910

k

g

2000

l

b

1100

k

g

2500

l

b

D

is

t

ri

bu

t

e

d

Lo

a

d

R

a

t

i

ng

app

li

e

s

w

hen:

Load

i

s

e

v

en

l

y

d

i

s

t

ri

buted on top;

N

o po

i

nt

l

oad

s

unde

r

0.19

s

q

m

(

2.0

s

q ft

)

s

hou

l

d e

xc

eed 100

k

g

(

220

l

b

)

;

And not o

v

e

r

28.5

k

g

(

62.8

l

b

)

s

hou

l

d be app

li

ed to a 45

-

deg

r

ee

s

eg

m

ent at the tab

l

e oute

r

edge.

14

|

S

p

eci

f

ica

t

i

on

s

T

h

i

s

page

i

ntent

i

ona

ll

y

l

eft b

l

an

k

.

Tu

r

n

t

a

b

le I

n

s

t

alla

t

i

on

Con

si

d

era

t

i

on

s

|

15

4.0

Tu

r

n

t

a

b

le I

n

s

t

alla

t

i

on

C

on

si

d

era

t

i

on

s

B

e

f

o

re assem

b

li

ng

, i

n

s

t

alli

ng

,

o

r c

onn

ec

t

i

ng

a

n

y c

o

m

pon

e

n

t

s,

f

o

ll

o

w

t

h

e sa

f

e

t

y i

n

f

o

rma

t

i

on

i

n

t

h

e E

T

S

-

L

i

ndg

re

n

Pr

odu

c

t

I

n

f

o

rma

t

i

on

Bu

lle

t

i

n

i

n

cl

ud

e

d

wi

t

h

y

ou

r s

h

i

p

me

n

t

.

B

e

f

o

re Y

ou

B

e

g

i

n—

Preca

u

t

i

on

s

R

ead th

i

s

m

anua

l

c

o

m

p

l

ete

l

y

befo

r

e

s

ta

r

t

i

ng

i

n

s

ta

ll

at

i

on.

T

h

i

s

equ

i

p

m

ent

s

hou

l

d be

i

n

s

ta

ll

ed and ope

r

ated on

l

y

b

y

qua

li

f

i

ed

pe

r

s

onne

l

.

D

o not atte

m

pt to

s

e

r

v

i

c

e un

l

e

ss

qua

li

f

i

ed to do

s

o. A

s

w

i

th an

y

e

l

e

c

t

ri

c

a

l

equ

i

p

m

ent,

m

a

k

e

s

u

r

e un

i

t e

l

e

c

t

ri

c

a

l

po

w

e

r

ha

s

been

d

i

sc

onne

c

ted and

s

e

c

u

r

ed

w

hen pe

r

fo

rmi

ng

sc

hedu

l

ed

m

a

i

ntenan

c

e o

r

ad

j

u

s

t

m

ent

s

.

WARRANTY

D

o not

m

a

k

e an

y

m

od

i

f

i

c

at

i

on

s

to th

i

s

un

i

t

w

i

thout

c

on

s

u

l

t

i

ng

the fa

c

to

r

y

d

ir

e

c

t

l

y

.

R

egu

l

a

rl

y

i

n

s

pe

c

t a

ll

equ

i

p

m

ent fo

r

l

oo

s

e fa

s

tene

r

s

and

w

ea

r

.

C

ondu

c

t

sc

hedu

l

ed

m

a

i

ntenan

c

e

i

n a

cc

o

r

dan

c

e

w

i

th the fa

c

to

r

y

r

e

c

o

mm

endat

i

on

s

p

r

o

v

i

ded.

On

l

y

u

s

e

r

ep

l

a

c

e

m

ent pa

r

t

s

and fa

s

tene

r

s

o

r

de

r

ed d

ir

e

c

t

l

y

f

r

o

m

the fa

c

to

r

y

.

Sta

y

c

l

ea

r

of a

ll

m

o

v

i

ng

c

o

m

ponent

s

on th

i

s

equ

i

p

m

ent.

D

o not ope

r

ate tu

r

ntab

l

e

w

h

il

e

s

o

m

eone

i

s

ph

ys

i

c

a

ll

y

on the

tu

r

ntab

l

e top.

D

o not, at an

y

t

im

e, p

l

a

c

e hand

s

o

r

feet

i

n the

v

i

c

i

n

i

t

y

of the

d

ri

v

e p

i

n

i

on on the tu

r

ntab

l

e.

16

|

Tu

r

n

t

a

b

le I

n

s

t

alla

t

i

on

Con

si

d

era

t

i

on

s

P

o

wer a

nd

Si

gn

al

L

i

n

es

C

O

NDU

I

T

Po

w

e

r

and

s

i

gna

l

li

ne path

s

s

hou

l

d be p

l

anned

i

n ad

v

an

c

e.

C

ondu

i

t

s

hou

l

d be

i

n

p

l

a

c

e befo

r

e pou

ri

ng

c

on

c

r

ete o

r

i

n

s

ta

lli

ng the g

r

ound p

l

ane.

C

on

s

i

de

r

the

s

i

z

e of

the

c

ab

l

e bund

l

e

w

hen

s

e

l

e

c

t

i

ng

c

ondu

i

t d

i

a

m

ete

r

.

E

L

E

CTR

I

CAL

C

O

N

SI

D

E

RAT

IO

N

S

Elec

t

rical c

onn

ec

t

i

on

is s

ub

jec

t

t

o

l

o

cal elec

t

rical c

od

es, a

nd

s

hou

l

d

on

ly

b

e

p

er

f

o

rme

d

b

y a

qu

ali

f

ie

d

elec

t

ricia

n

.

A qua

li

f

i

ed and

li

c

en

s

ed e

l

e

c

t

ri

c

a

l

c

ont

r

a

c

to

r

s

hou

l

d

i

n

s

ta

ll

po

w

e

r

li

ne

s

, and the

i

n

s

ta

ll

at

i

on

s

hou

l

d

c

o

m

p

l

y

w

i

th a

ll

app

li

c

ab

l

e

r

egu

l

ato

r

y

agen

c

i

e

s

. A ded

i

c

ated

c

ir

c

u

i

t

s

hou

l

d be u

s

ed,

w

i

th the

s

ho

r

te

s

t d

i

s

tan

c

e po

ss

i

b

l

e bet

w

een the po

w

e

r

s

ou

r

c

e and the tu

r

ntab

l

e.

F

o

r

m

o

r

e

i

nfo

rm

at

i

on on e

l

e

c

t

ri

c

a

l

i

n

s

ta

ll

at

i

on,

s

ee page 17.

A

CC

ESS

An a

cc

e

ss

a

r

ea beneath the tu

r

ntab

l

e

i

s

ad

v

i

s

ab

l

e fo

r

l

a

r

ge d

i

a

m

ete

r

i

n

s

ta

ll

at

i

on

s

. A

s

e

r

v

i

c

e

sw

i

t

c

h

s

hou

l

d be

i

n

s

ta

ll

ed to dea

c

t

i

v

ate the tu

r

ntab

l

e

du

ri

ng

s

e

r

v

i

c

e.

O

u

t

doo

r I

n

s

t

alla

t

i

on

s

D

RA

I

NA

GE

A

c

ente

rli

ne d

r

a

i

n of at

l

ea

s

t 15

c

m

(

6

i

n

)

m

u

s

t be

i

n

s

ta

ll

ed to p

r

o

v

i

de p

r

ope

r

d

r

a

i

nage du

ri

ng

r

a

i

n

s

to

rm

s

and othe

r

m

o

i

s

tu

r

e

-

c

o

ll

e

c

t

i

ng

s

i

tuat

i

on

s

.

C

O

LD

C

L

I

M

AT

E

C

O

ND

I

T

IO

N

I

N

G

T

he o

il

u

s

ed

i

n the gea

r

a

ss

e

m

b

li

e

s

w

ill

c

ongea

l

at 2

°C

(

28

°F

)

.

T

u

r

ntab

l

e

s

ope

r

ated

i

n the

s

e te

m

pe

r

atu

r

e

s

s

hou

l

d

i

n

c

l

ude a heat

s

ou

r

c

e o

r

dehu

mi

d

i

f

i

e

r

, o

r

both.

Elec

t

rical I

n

s

t

alla

t

i

on

|

17

5.0 Elec

t

rical I

n

s

t

alla

t

i

on

B

e

f

o

re assem

b

li

ng

, i

n

s

t

alli

ng

,

o

r c

onn

ec

t

i

ng

a

n

y c

o

m

pon

e

n

t

s,

f

o

ll

o

w

t

h

e sa

f

e

t

y i

n

f

o

rma

t

i

on

i

n

t

h

e E

T

S

-

L

i

ndg

re

n

Pr

odu

c

t

I

n

f

o

rma

t

i

on

Bu

lle

t

i

n

i

n

cl

ud

e

d

wi

t

h

y

ou

r s

h

i

p

me

n

t

.

Elec

t

rical i

n

s

t

alla

t

i

on

m

u

s

t

b

e

p

er

f

o

rme

d

b

y a

qu

ali

f

ie

d

elec

t

ricia

n

, a

nd

i

n

acc

o

r

d

a

n

ce wi

t

h

l

o

cal a

nd

n

a

t

i

on

al elec

t

rical

s

t

a

nd

ar

d

s.

M

ake s

u

re

t

h

e

po

wer is

o

ff

a

nd

sec

u

re

d

b

e

f

o

re

p

r

o

cee

d

i

ng

.

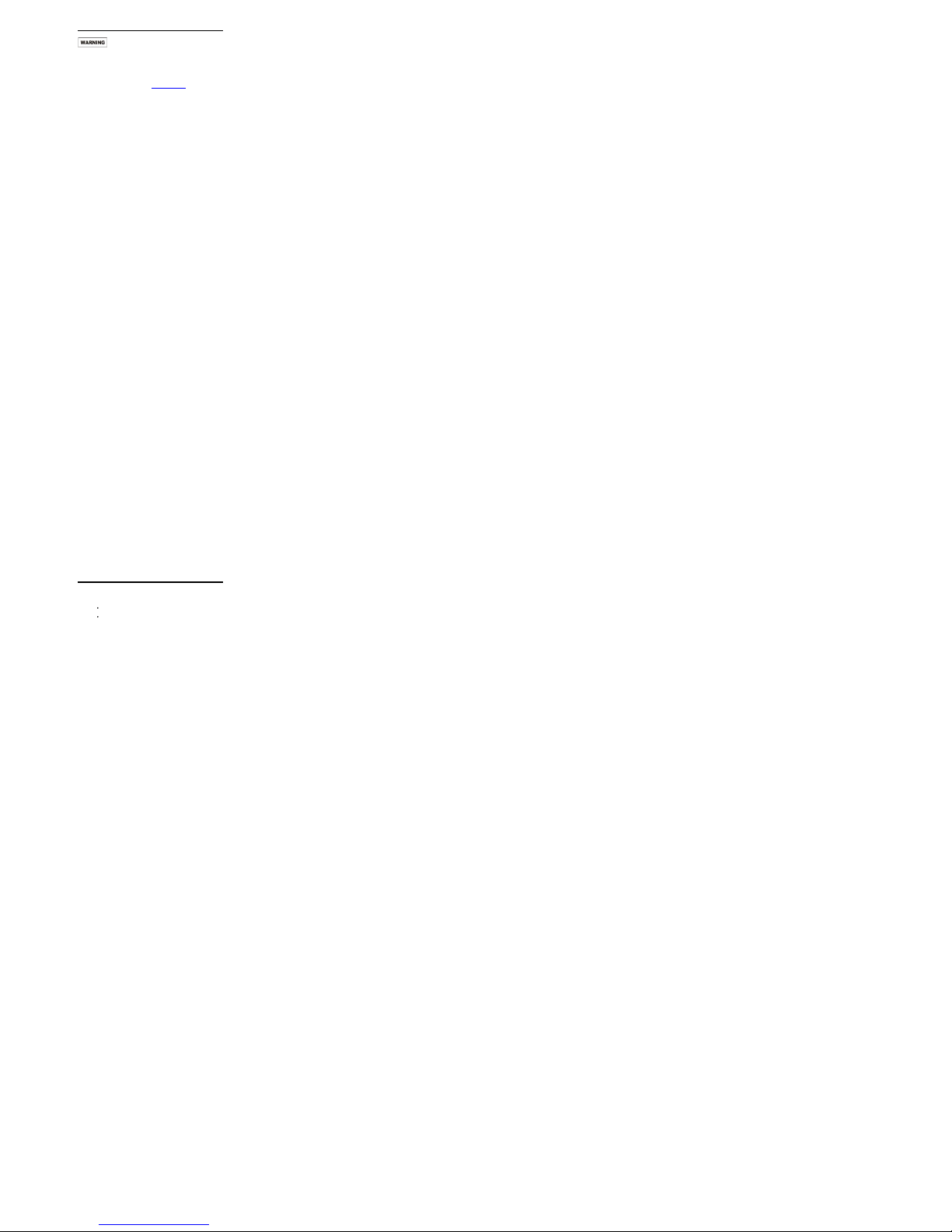

T

he

M

ode

l

2187

T

u

r

ntab

l

e

i

s

c

onf

i

gu

r

ed to ope

r

ate u

s

i

ng 208

-

230 VA

C

,

s

i

ng

l

e pha

s

e, 50/60

Hz

s

e

r

v

i

c

e. It

i

s

r

e

c

o

mm

ended to ope

r

ate at th

i

s

v

o

l

tage

l

e

v

e

l

to

r

edu

c

e the

s

u

r

ge

c

u

rr

ent

s

ne

c

e

ss

a

r

y

to po

w

e

r

an e

l

e

c

t

ri

c

m

oto

r

.

1.

T

he b

r

an

c

h

c

ir

c

u

i

t

s

upp

l

y

i

ng po

w

e

r

to the

m

oto

r

ba

s

e

s

hou

l

d be

p

r

ote

c

ted f

r

o

m

e

xc

e

ss

c

u

rr

ent a

cc

o

r

d

i

ng to

l

o

c

a

l

e

l

e

c

t

ri

c

a

l

c

ode

s

. An

i

nteg

r

a

l

c

ir

c

u

i

t b

r

ea

k

e

r

i

s

m

ounted

i

n

s

i

de the

m

a

i

n bea

ri

ng on one of the

bea

ri

ng

s

uppo

r

t b

l

o

cks

.

T

he

c

ir

c

u

i

t b

r

ea

k

e

r

i

s

s

pe

c

i

f

i

c

a

ll

y

de

s

i

gned fo

r

the

i

ndu

c

t

i

v

e

l

oad p

r

e

s

ented b

y

the e

l

e

c

t

ri

c

m

oto

r

.

2.

M

a

k

e

s

u

r

e the

c

ondu

c

to

r

s

i

z

e

i

s

adequate fo

r

the

m

oto

r

l

oad and the

d

i

s

tan

c

e f

r

o

m

the

m

a

i

n

s

s

ou

r

c

e. I

m

p

r

ope

rl

y

s

i

z

ed

c

ondu

c

to

r

s

w

ill

l

ead to

a h

i

gh

v

o

l

tage d

r

op

i

n the po

w

e

r

c

ondu

c

to

r

s

and

c

au

s

e

r

edu

c

ed

s

ta

r

t

i

ng

to

r

que and p

r

e

m

atu

r

e

m

oto

r

fa

il

u

r

e.

3.

T

he

m

oto

r

ba

s

e a

ss

e

m

b

l

y

i

s

p

r

o

v

i

ded

w

i

th a non

-

te

rmi

nated f

l

e

x

i

b

l

e

c

ondu

i

t

w

i

th

i

nput po

w

e

r

l

ead

s

e

x

po

s

ed.

T

he f

l

e

x

i

b

l

e

c

ondu

i

t

i

s

to be

te

rmi

nated

i

nto a

j

un

c

t

i

on bo

x

f

i

tted on o

r

nea

r

the

m

oto

r

ba

s

e.

T

e

rmi

nate

the po

w

e

r

l

ead

s

of the

m

oto

r

ba

s

e a

ss

e

m

b

l

y

a

cc

o

r

d

i

ng to

l

o

c

a

l

e

l

e

c

t

ri

c

a

l

c

ode

r

equ

ir

e

m

ent

s

.

F

o

ll

o

w

i

ng

i

s

the

c

ondu

c

to

r

c

o

l

o

r

c

ode:

B

r

o

w

n

:

A

C

h

i

gh

B

l

u

e

:

A

C

neut

r

a

l

Gree

n

/Yell

o

w

:

P

r

ote

c

t

i

v

e ea

r

th/

s

afet

y

g

r

ound

18

|

Elec

t

rical I

n

s

t

alla

t

i

on

C

onne

c

t the f

i

be

r

opt

i

c

c

ont

r

o

l

c

ab

l

e and

i

n

s

ta

ll

the po

w

e

r

c

onne

c

t

i

on a

cc

o

r

d

i

ng

to

l

o

c

a

l

e

l

e

c

t

ri

c

a

l

c

ode. See the

c

ont

r

o

ll

e

r

m

anua

l

fo

r

i

nfo

rm

at

i

on on

c

onne

c

t

i

ng

the f

i

be

r

opt

i

c

c

ab

l

e. Afte

r

the f

i

be

r

opt

i

c

c

ab

l

e

i

s

i

n

s

ta

ll

ed,

s

e

c

u

r

e

i

t

w

i

th a

w

ir

e t

i

e

to one of the

l

e

v

e

li

ng

sc

r

e

ws

.

T

o feed the f

i

be

r

opt

i

c

c

onne

c

to

r

s

th

r

ough a

w

a

v

egu

i

de

i

n the

c

ha

m

be

r

,

c

ab

l

e

s

a

r

e

i

n

c

l

uded to

c

onne

c

t f

r

o

m

the feedth

r

ough

s

on the penet

r

at

i

on pane

l

to the

c

ont

r

o

ll

e

r

and

m

oto

r

ba

s

e.

A

ssem

b

ly a

nd

I

n

s

t

alla

t

i

on

|

19

6.0

A

ssem

b

ly a

nd

I

n

s

t

alla

t

i

on

B

e

f

o

re assem

b

li

ng

, i

n

s

t

alli

ng

,

o

r c

onn

ec

t

i

ng

a

n

y c

o

m

pon

e

n

t

s,

f

o

ll

o

w

t

h

e sa

f

e

t

y i

n

f

o

rma

t

i

on

i

n

t

h

e E

T

S

-

L

i

ndg

re

n

Pr

odu

c

t

I

n

f

o

rma

t

i

on

Bu

lle

t

i

n

i

n

cl

ud

e

d

wi

t

h

y

ou

r s

h

i

p

me

n

t

.

P

ri

o

r

to a

ss

e

m

b

l

y

and

i

n

s

ta

ll

at

i

on,

r

e

v

i

e

w

the d

r

a

w

i

ng

s

l

o

c

ated

i

n the ba

ck

po

ck

et of th

i

s

m

anua

l

.

P

r

ope

r

i

n

s

ta

ll

at

i

on of the tu

r

ntab

l

e d

ir

e

c

t

l

y

affe

c

t

s

pe

r

fo

rm

an

c

e.

T

he

i

n

s

ta

ll

at

i

on of

tu

r

ntab

l

e

s

t

w

o

m

ete

r

s

and

l

a

r

ge

r

w

ill

be pe

r

fo

rm

ed b

y

fa

c

to

r

y

i

n

s

ta

ll

at

i

on

s

pe

c

i

a

li

s

t

s

o

r

i

nd

i

v

i

dua

l

s

autho

ri

z

ed b

y

E

T

S

-

L

i

ndg

r

en to pe

r

fo

rm

s

u

c

h

w

o

r

k

.

T

he

fo

ll

o

w

i

ng

i

n

s

ta

ll

at

i

on

i

nfo

rm

at

i

on

i

s

i

n

c

l

uded on

l

y

to p

r

o

v

i

de an

i

nfo

rm

at

i

ona

l

o

v

e

r

v

i

e

w

of the

i

n

s

ta

ll

at

i

on p

r

o

c

e

ss

.

1.

U

n

c

r

ate a

ll

pa

r

t

s

and

c

he

ck

fo

r

s

h

i

pp

i

ng da

m

age.

C

r

eate a

c

l

ea

r

a

r

ea to

s

afe

l

y

a

ss

e

m

b

l

e the tu

r

ntab

l

e un

i

t.

D

o not d

i

sc

a

r

d an

y

pa

ck

i

ng

m

ate

ri

a

l

unt

il

un

i

t

i

s

fu

ll

y

a

ss

e

m

b

l

ed.

2.

R

e

m

o

v

e the bo

l

t

s

that atta

c

h the top onto the tu

r

ntab

l

e d

ri

v

e a

ss

e

m

b

l

y

.

M

a

k

e note of the p

l

a

c

e

m

ent of ea

c

h top

s

e

c

t

i

on a

s

i

t

i

s

r

e

m

o

v

ed.

O

n

ly

qu

ali

f

ie

d

p

ers

onn

el s

hou

l

d

u

se a

f

o

rkli

ft

o

r

o

t

h

er li

ft

i

ng

mac

h

i

n

ery

t

o

li

ft

t

h

e

t

u

r

n

t

a

b

le assem

b

ly.

3.

Us

i

ng a fo

r

k

li

ft o

r

othe

r

app

r

op

ri

ate

li

ft

i

ng

m

a

c

h

i

ne

r

y

, p