ETT DESHU Owner's manual

Énergie Transfert Thermique

Technical instructions

for Operation & Maintenance

A different climate

Environmental control solutions

July 2016

Double ow dehumidier

DESHU

2

Energie

Transfert

Thermique

Contents

A. Equipment performance................................................................................................................................ 3

B. Maintenance intervals....................................................................................................................................... 3

C. Regulatory requirements................................................................................................................................. 5

D. Specic maintenance recommendations................................................................................ 7

E. Starting/Stopping the unit.............................................................................................................................. 9

F. Controller operation.......................................................................................................................................... 10

G. Diagnostics and troubleshooting support ............................................................................... 13

Information contained in this document has been prepared by qualied ETT specialists.

We are doing our best to ensure its completeness and accuracy but it does not constitute a guarantee.

This information is given in good faith, any use of the equipment not in accordance with the instructions

and warnings is done at the user's own risk.

3

MARK-NOT_01.00-EN

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

A. Equipment performance

• The validity of the guarantee is conditional upon strict compliance with instructions presented in this

document.

• Proper operation and maintenance:

>maintains units performance;

>extends equipment service life;

>reduces the risk of unit failure;

>allows energy costs management;

>ensures regulatory compliance (compulsory checks based on local regulations).

ETT Services is here to help you get the most out of your installation.

+33 (0)2 98 48 02 22

Contact your local ETT Services adviser.

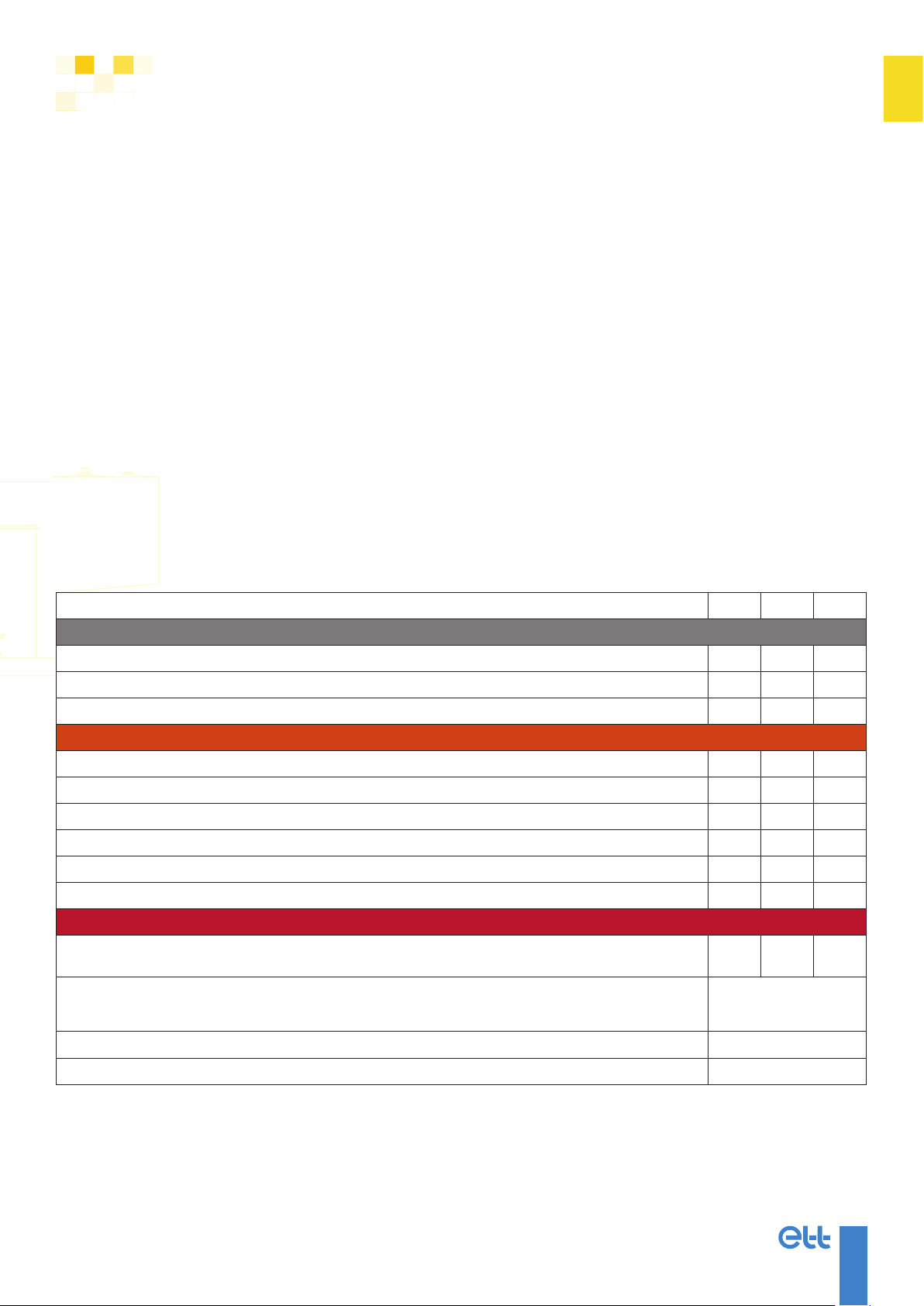

B. Maintenance intervals

Maintenance intervals: Q (Quarterly), S (Semi-annually), A (Annually)

Operations Q S A

General control

Check casing X

Clean siphons and condensate drain X

Operating time report X

Electricity / Control

Check controller X

Set clock and operating schedule X

Check setpoints X

Tighten electrical connections X

Check temperature probes X

Replace humidity probes sensor element (if applicable) X

Consumables

Clean or replace lters (1) 48 mm

X

98 mm

X

Replace smoke detector head

Nota: Maintenance intervals are given as indication only. Replacement may be needed more frequently in polluted

atmospheres.

Every 2 years

Replacement of the smoke detection box battery Every 2 years

Replace humidity probe and/or sensor element (if applicable) Every 2 years

4

MARK-NOT_13.00-EN ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

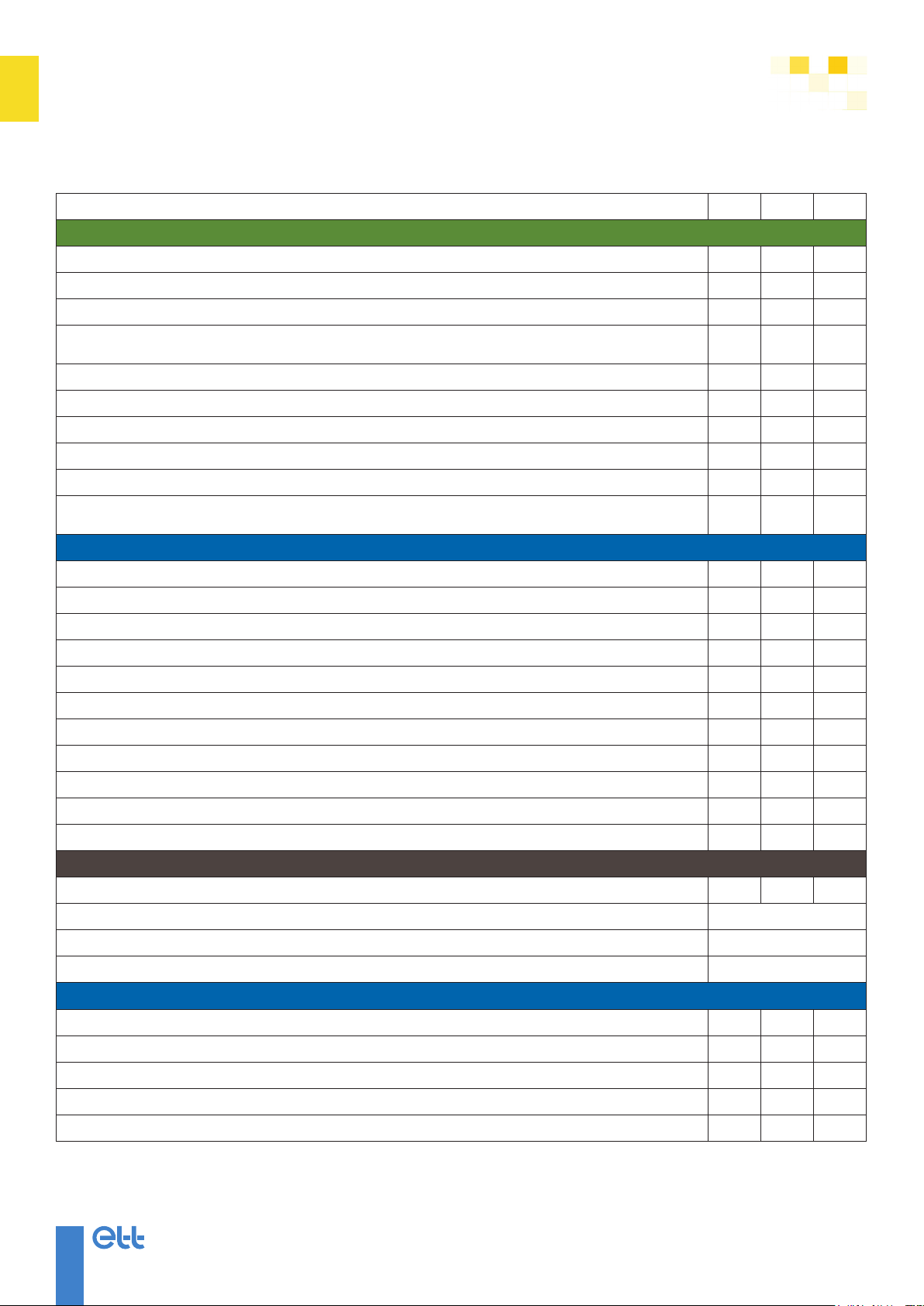

Maintenance intervals: Q (Quarterly), S (Semi-annually), A (Annually)

Operations Q S A

Ventilation

Servomotors and dampers control X

Control and cleaning of fans turbines X

Grease fans bearings or replace fan bearings grease cartridges X

Fans rotation speed and air ow rates control

Nota: In case of insufcient ow rate, apply recommendations described in “Specic maintenance recommendations”, p. 7

X

Check air ducting (cleanliness, cones, valves, etc.) X

Ventilation motors control X

Control of belts and their tension (if unit with belts) X

Change of belts (if unit with belts) X

Fans motors intensities report X

Check ventilation safety devices (ow rate, lters fouling, re contact, smoke detector,

post-ventilation, etc.) (1) X

Refrigeration circuits

Check oil level, adjust if necessary X

Compressor(s) intensities control X

Check pressures: HP and LP X

Control superheat and subcooling X

Check and clean refrigerant-to-air exchangers (1) X

Check expansion valve, adjust if necessary X

Electronic expansion valves: check parameters X

4-way valve(s) control X

Check refrigeration safety devices (HP & LP pressure switches, thermostats, etc.) X

Auxiliary condenser: check and adjust water ow rate X

Tighten refrigeration pipe clamps: adjust or replace if necessary X

Regulatory controls

Leakage checking (based on unit t CO2e) (2) >500 >50 >5

Pressure equipment inspection (2) Every 40 months

Pressure equipment certication (2) Every 10 years

Inspection of air-conditioning systems and heat pumps (2) Every 5 years

Heating (if applicable)

Check hot water coil (cleanliness, tightness) X

Check water quality in hot water coil X

Check 3-way valve operation X (3)

Check electric heaters X(3)

Check hot water coils (1)

5

MARK-NOT_01.00-EN

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

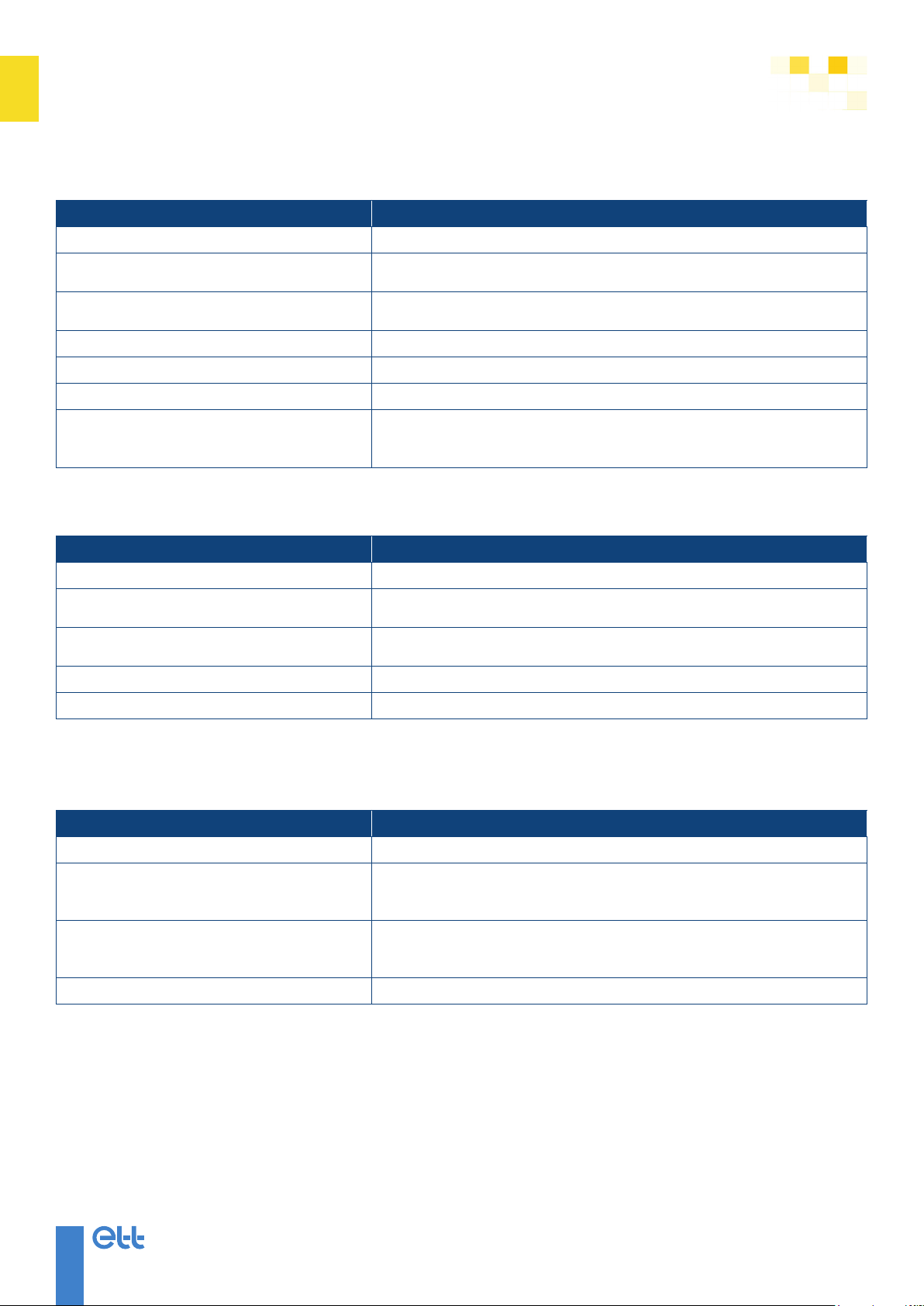

Maintenance intervals: Q (Quarterly), S (Semi-annually), A (Annually)

Operations Q S A

Heat pipe (if applicable) (1)

Check heat pipe efciency by measuring temperatures X

Check heat pipe jack operation (if applicable) X

Clean heat pipe X

Rotary exchanger (if applicable) (1)

Check heat exchanger efciency by measuring temperatures X

Control brushes / gaskets tightness X

Check heat exchanger drive motor (1) X

Check heat exchanger belt and belt tension X

Check bearing greasing (if not life-time lubricated) X

Thalassotherapy centres: corrosive/saline atmospheres (1)

Check and clean aluminium drift eliminator (which retains potential large salt or sand particles

from outside) X

Clean or replace G4 lters or washable lters PRP3 X

Clean or replace ne F7 lters or F9 polypropylene lters (also called coalescer lter), do not hold

the breglass media The lter can be cleaned at least twice (desalinate in a tray and dry) X

Cleaning procedure described in “Filtration”, p. 7

Check and clean refrigerant-to-air exchangers (SAKAPHEN coating) - clean with high pressure water

X

Grease fan bearings and shaft (whatever the type). X

Check and clean fans monthly. X

Clean heat exchangers with clear water monthly. X

(1) See “Specic maintenance recommendations”, p. 7.

(2) See “Regulatory requirements”, p. 5.

(3) In Heating mode.

C. Regulatory requirements

1/ Refrigerating system log book (EN 378-2)

Each system having a refrigerant charge, with a CO2 equivalent of 5 tonnes or above, requires its own separate

log book to be maintained.

The logbook shall be prepared by the installer during installation. It shall be updated after every maintenance

operation, as indicated in EN 378-4 standard.

Log books shall include the following information:

>detailed report of each maintenance or repair operation;

>quantity and nature (new, reused, recycled) of refrigerant added during the operation;

>quantity of refrigerant transferred during the operation (see also EN 378-4 standard);

>results of reused refrigerant analysis (if such analysis was performed);

>origin of reused refrigerant;

>system components replaced or modied;

>routine or periodic tests results;

>signicant non-use periods.

6

MARK-NOT_13.00-EN ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

2/ Check tightness

In application of EU regulations, the French decree of 29 February 2016 on certain refrigerants containing

uorinated greenhouse gases states that equipment containing such refrigerants must be periodically

checked for leakage (see table hereafter) by certied personnel and a tightness control certicate must be

issued.

Leak check intervals

Checking frequency Once a year Twice a year 4 times a year

Metric tonnes of CO2equivalent 5 to 50 50 to 500 >500

Fluid

R134a Refrigerant charge (kg) 3.5 to 35 kg 35 to 349.7 kg >349.7 kg

R407c Refrigerant charge (kg) 2.82 to 28.2 kg 28.2 to 281.8 kg > 281.8 kg

R410a Refrigerant charge (kg) 2.39 to 23.9 kg 23.9 to 239.5 kg > 239.5 kg

A label must be attached to the equipment:

• Blue label if the equipment complies with the requirements:

>The operator who performed the inspection must specify his qualification certificate number in the text

area provided at the centre of the label.

>The label indicates the expiry date of the control certificate.

• Red label if a leak is detected and the operator cannot stop it.

>The equipment shall not be charged with refrigerant until proper repairs have been carried out.

3/ Refrigerant handling

Refrigerant handling must comply with French Decree no. 2007-737 and European legislation:

>Technicians must be trained and must hold the relevant F-gasqualication.

>The company employing the operator must hold an F-gasCompanyCerticate authorising its personnel

to handle refrigerant.

>Refrigerant leaks must be handled and declared according to the installation refrigerant charge.

7

MARK-NOT_01.00-EN

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

4/ Pressure Equipment Directive

Although refrigeration installations fall within the pressure equipment category, they are a special case in

terms of in-service monitoring. In 2014, the French safety ofce of industrial equipment (BSEI) validated a

Technical Guidebook (CTP USNEF - Available on-line in French), which authorises waivers from the French

decree of 15 March 2000 (amended).

>Refrigeration installations shall be inspected at least every 40 months. Periodic inspection shall be

performed by an authorised person, under the responsibility of the operator.

>Refrigeration installations shall be requaliedevery10years. Periodic requalication shall be performed

by an authorised body which shall issue a requalicationcerticate. To avoid damage to the installation,

the hydraulic test is not required.

5/ Inspection of reversible heat pumps and air-conditioning systems

Decree 2010-349 of 31 March 2010

The inspection shall include documentary controls and an assessment of system efciency and sizing

compared with the cooling requirements of the building.

The inspection shall be performed:

>by an authorised person;

>at the owner’s initiative;

>at least every 5 years.

In case of replacement, the new equipment shall be inspected in the calendar year following replacement.

D. Specicmaintenancerecommendations

1/ Heat exchangers cleaning

Clean them using a bristle scrub brush, a vacuum or a compressed air jet if necessary. Rinse with cold and low

pressure water, avoiding spatters on the fan motor. Clean in counter ow of the air ow way.

2/ Filtration

Poor ltration or signicant fouling can affect unit efciency and damage the refrigeration circuit.

Nota:

Filters cannot be cleaned more than 2 or 3 times. Otherwise, ltration performance is

dramatically reduced. If a lter cannot be regenerated, replace it.

3/ Airowratescontrol

Insufcientairowratescanhaveseveralconsequences:

>The compressor operates out of the permitted operating range.

ÜRisk of compressor breakage

>Heat from auxiliary heaters is not evacuated.

ÜRisk of re alarm

>The setpoints are not reached.

ÜLower heating capacity

Incaseofinsufcientairowrates:

>Check supply air dampers operation;

>Check lters for fouling;

>Check exchangers for fouling;

>Check air ducts (re dampers, fouling in ducts, cone connectors).

8

MARK-NOT_13.00-EN ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

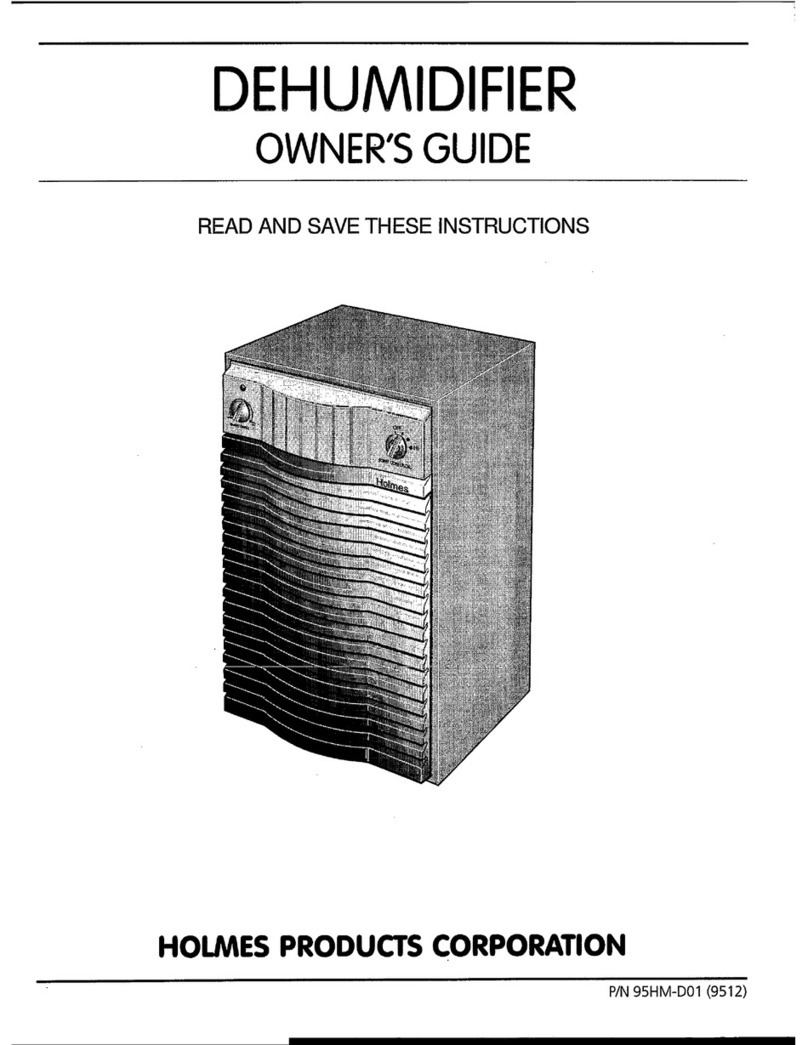

4/ Heatpipeorrotaryheatexchangerefciencycontrol

4.1/ Necessary conditions

>Stop compressors and auxiliaries. Only ventilation shall be activated.

>Outside temperature must differ from return air temperature in order to identify energy recovery through

the heat pipe or rotary heat exchanger.

4.2/ Control procedure

>Check fresh air and supply air temperatures on the controller.

>If fresh air and supply air temperatures are the same, the heat pipe or rotary heat exchanger failed to

transfer energy. Heat transfer efciency has diminished.

4.3/ Corrective measure

>Clean the heat pipe or rotary heat exchanger.

>On heat pipes, cleaning does not improve efciency. Check tightness.

4.4/ Heat pipe/Rotary heat exchanger operating principle

Example: Heating mode

5/ Cleaningprocedure:HPEpolypropylenelters(F7-F9)

!Caution:

When cleaning lters, always wear appropriate protective equipment: glasses, gloves and mask.

5.1/ Cleaning with water

>Lay the lter horizontally on the oor.

>Clean with non-pressurised water using a at jet nozzle. Hold the nozzle 20 cm (6”) from the lter to avoid

damage.

>Spray water in the direction of the pleats and rinse thoroughly the brous material.

>Clean the whole surface of the lter during approximately 1 minute.

>Turn the lter over and repeat the procedure on the other side.

>Detergent may be used for better cleaning.

>Drying time will vary based on ambient temperature and humidity conditions.

Nota:

Be sure the lter is completely dry before replacing it into the unit. A lter can be cleaned

twice without affecting ltration efciency.

5.2/ Cleaning with air

>Lay the lter horizontally on the oor.

>Use a compressed air gun.

>Hold the nozzle 15 cm (6”) from the lter to avoid damage.

>Spray air on the whole surface, in the direction of the pleats during approximately 45 seconds.

>Turn the lter over and repeat the procedure on the other side.

+

_

Air rejeté

Air soufflé

Air entrant

Air repris

Fresh air Supply air

Return airExhaust air

9

MARK-NOT_01.00-EN

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

6/ Actuating detector control

Operation must be controlled periodically, according to regulations applicable to the building. For type 1

detectors (S6), the secondary source must be controlled monthly by holding the "secondary source test"

button for at least 5 seconds. The "power" indicator must remain switched on.

Perform a functional test using an aerosol smoke detector tester. Follow manufacturer's instructions.

E. Starting/Stopping the unit

1/ Unit temporary shutdown

>Stop the unit.

>Do not shut off power to the evaporator crankcase heater (air-to-water, water-to-water heat pump) or

to the line heaters if the unit is installed in an area where the temperature is likely to fall below 0°C. This

operation is not handled automatically.

2/ Start-up after temporary shutdown

No special precautions are required. To start the unit, reverse the procedure outlined in “Unit temporary

shutdown”, p. 9.

3/ Unit seasonal shutdown

>If the heat pump includes water circuits, drain them. Also drain the connection lines if the unit is installed

in an area where the temperature is likely to fall below 0°C.

>Open the main power switch. Remove the fuse block or lock the main switch in opened position.

>If the heat pump is installed in an area subject to condensation, it is recommended to spray oil on

mechanical parts which are likely to rust (fan bearings, pulleys, etc.).

4/ Seasonal start-up

>Perform annual maintenance operations according to “Maintenance intervals”, p. 3.

>Fill the water circuits and bleed the air out as necessary.

>Fully open the compressor discharge valve.

>Open the liquid line stop valve (if applicable).

>Control refrigeration circuit tightness.

>Switch on the main power switch.

>Acknowledge faults on the detection station (if applicable).

>Allow the compressor crankcase heaters to preheat (12 hours).

>Start the system.

>Check operation of all interconnected devices.

>Check oil level and operating pressures after 15 to 20 minutes of operation.

>Make sure that refrigerant ows in a steady stream with no bubbles.

5/ Generating set - EJP (peak load reduction)

Equipment powered by a generating set must be correctly stopped. Refer to the procedure detailed in “Unit

temporary shutdown”, p. 9.

This can be managed manually or by programming the BMS according to feedback from your energy supplier

if you have a peak load reduction agreement.

Failure to take this precaution could result major damage to the unit or cause components to break (electrical

components, compressors). In such circumstances, components are not covered by ETT guarantee.

10

MARK-NOT_13.00-EN ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

F. Controller operation

1/ Main screen

Key Name Description

ALARM

- Press to access current alarms and faults.

- Press and hold to acknowledge alarms.

Nota: Correct the fault on the corresponding component (reset smoke

detector, re thermostat or frost protection, thermal protection, etc.).

PRG

- Press once to access setpoints.

- Press twice to access operating schedule settings.

- Press three times to access clock settings.

ESC - Go back to previous screen.

UP - Press to increase the selected value.

- From main screen: change display.

DOWN - Press to decrease the selected value.

- From main screen: change display.

ENTER - Press to conrm setting.

- Press and hold to start/stop the unit.

UP + DOWN - Press and hold together to access the Controller menu (password

protected).

11

MARK-NOT_01.00-EN

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

2/ Access to level 0 - User settings

Access to: - Setpoints

- Operating schedule

- Clock setting

+ Hold the UP and DOWN arrow keys simultaneously for 2 seconds.

Password = 0

Use the UP and DOWN arrow keys to scroll through menus.

Press the ENTER key to enter the selected menu.

Use the UP and DOWN arrow keys to scroll through screens.

Press the ENTER key to access screen setpoints.

Use the UP and DOWN arrow keys to select the setpoint to edit.

Press the ENTER key to access the setpoint.

Use the UP and DOWN arrow keys to adjust the setpoint.

Press the ESC key to return to the main screen.

12

MARK-NOT_13.00-EN ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

3/ Access to level 1 - Maintenance

Access to: - Maintenance

- Communication

- Alarms history

- Energy meter

- Inputs / Outputs

- Meter reset

+ Hold the UP and DOWN arrow keys simultaneously for 2 seconds.

Password = 1

Use the UP and DOWN arrow keys to scroll through menus.

Press the ENTER key to enter the selected menu.

Use the UP and DOWN arrow keys to scroll through screens.

Press the ENTER key to access screen setpoints.

Use the UP and DOWN arrow keys to select the setpoint to edit.

Press the ENTER key to access the setpoint.

Use the UP and DOWN arrow keys to adjust the setpoint.

Press the ESC key to return to the main screen.

13

MARK-NOT_01.00-EN

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

G. Diagnostics and troubleshooting support

1/ Smoke fault

Possible reasons Corrective actions

Smoke detection

- Check for smoke or dust

- Clean detector head

- Replace detector head

- Acknowledge the fault (See “Main screen”, p. 10)

Fouled detector head

- Check for smoke or dust

- Clean detector head

- Replace detector head

- Acknowledge the fault (See “Main screen”, p. 10)

Backup battery out of service - Replace battery

2/ Filter fault

Possible reasons Corrective actions

Fouled lters - Clean lters

- Replace lters

Fouled exchangers - Clean exchangers according to the recommendations

3/ Airowfault

Possible reasons Corrective actions

Fouled lters - Clean lters

- Replace lters

Leakage on air network - Repair air distribution network

Fouled air network - Clean air distribution network

4/ Fire fault

Possible reasons Corrective actions

Lack of air ow rate - Check lters

- Check fan and fan motor

Faulty thermostat - Check thermostat

5/ Antifreeze fault

Possible reasons Corrective actions

Lack of air ow rate - Check lters

- Check fan and fan motor

Faulty thermostat - Check thermostat

Faulty thermostat - Faulty thermostat

14

MARK-NOT_13.00-EN ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

6/ Low pressure fault

Possible reasons Corrective actions

Poor air ow - See “Air ow fault”, p. 13

Fouled lters - Clean lters

- Replace lters

Low pressure switch malfunction - Check pressure switch operation

- Check pressure switch connections

Expansion valve malfunction - Check expansion valve (status, settings, operation).

Refrigerant charge problem - Check tightness

Fouled evaporator - Clean exchangers according to the recommendations

Inefcient defrosting

- Check refrigeration circuit probes

- Check 3-way valve in external box

- Check defrost settings

7/ High pressure fault

Possible reasons Corrective actions

Wrong water ow rate - See “Air ow fault”, p. 13

High pressure switch malfunction - Check pressure switch operation

- Check pressure switch connections

Fouled lters - Clean lters

- Replace lters

Outside T° out of application range - No action

Poor air distribution - Check air distribution network

8/ Refrigeration circuit fault

8.1/ The compressor does not start.

Possible reasons Corrective actions

Electrical protection faults - Check protections

Control security

- Check control parameters

- Check securities

- Reset controller if authorised

Abnormal supply voltage

- Check phases

- Check voltage drop at unit start-up

- Check power supply chain (wire, connections, contactors, etc.)

Ventilation fault - Check external box and internal fan

15

MARK-NOT_01.00-EN

ETT may change equipment’s data & design without prior notice.

Specications given in this document are for information only and are not contractual.

Technical instructions

for Operation & Maintenance

8.2/ The compressor stops.

Possible reasons Corrective actions

Low pressure fault - See “Low pressure fault”, p. 14

High pressure fault - See “High pressure fault”, p. 14

Ipsotherm fault

- Check compressor cooling

- Check ipsotherm probe

- Check lters for fouling

Thermal fault - Check compressor's absorbed current

- Check voltage drop at start-up

Power supply chain interruption

- Check power supply chain (wire, connections, contactors, etc.).

Ventilation fault - Check external box and internal fan

8.3/ The compressor is noisy.

Possible reasons Corrective actions

Knocks - Check compressor suction pressure

Slugging

- Check charge (subcooling)

- Check superheat

- Check expansion valve bulb xation

Grunts

- Check supply voltage

- Check phases

- Galling → broken part

8.4/ The compressor does not stop.

Possible reasons Corrective actions

Stuck contactor - Check contactor

8.5/ Lack of capacity.

Possible reasons Corrective actions

Whistling expansion valve - Check expansion valve settings

- Check charge

Severe overheating - Check expansion valve settings

- Check charge

Pre-expansion - Check drier lter

Wrong ow rates - Check ow rates in air streams

www.ett.fr

Reference: MARK-NOT_13.00-EN

56 Route de Brest - BP26 - 29830 PLOUDALMEZEAU - France

Tel: +33 (0)2 98 48 14 22 - Fax : +33 (0)2 98 48 09 12

Export Contact: +33 (0)2 98 48 00 70 - ETT Services: +33 (0)2 98 48 02 22

Design: ETT - Document printed by an environmentally friendly printer using vegetable based ink on PEFC paper created from sustainably-managed forest.

A different climate

Environmental control solutions

Énergie Transfert Thermique

Table of contents