9

2541786-01-10/20 (Translation of the original operating instructions)

Operating Instructions

Transponder-Coded Safety Switch CTM-CBI-BP

EN

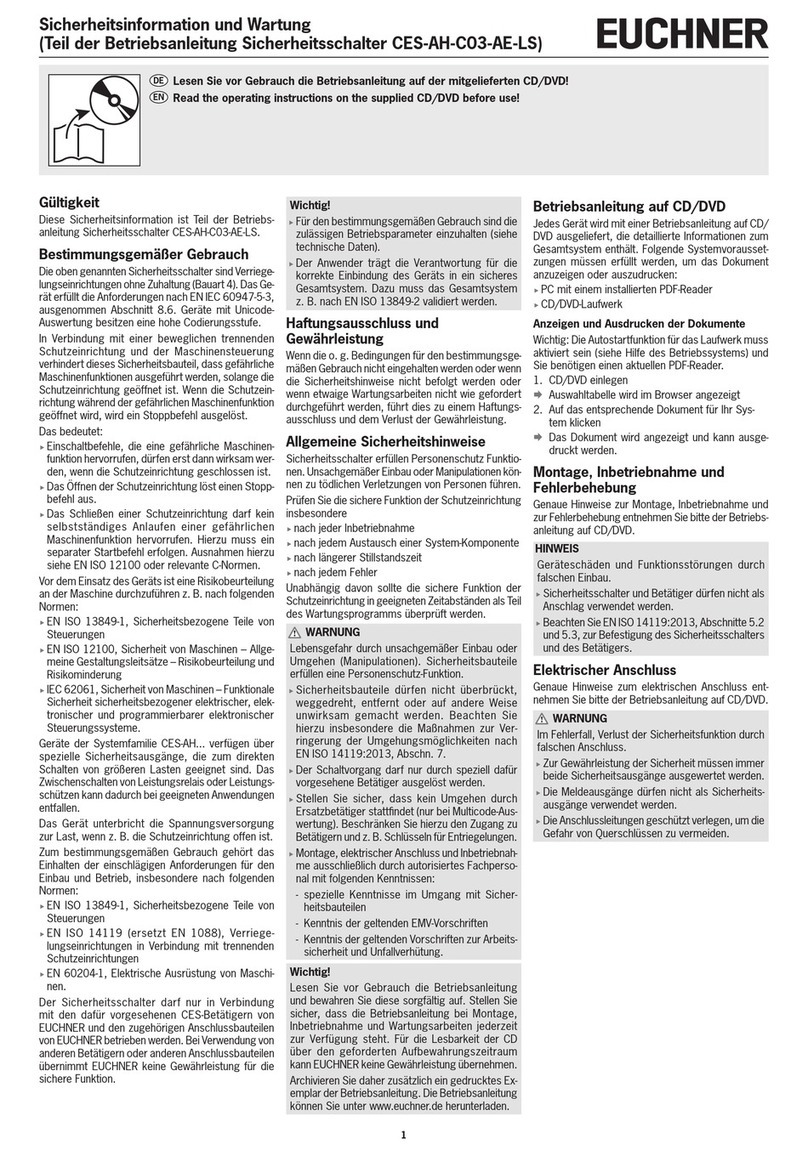

6. Function

The device permits the locking of movable guards.

The system consists of the following components: coded actuator (transponder) and switch.

Whether the device learns the complete actuator code (unicode) or not (multicode) depends

on the respective version.

ÌDevices with unicode evaluation: The actuator must be assigned to the safety switch

by a teach-in operation so that it is detected by the system. This unambiguous assign-

ment ensures a particularly high level of protection against tampering. The system thus

possesses a high coding level.

ÌDevices with multicode evaluation: Unlike systems with unique code detection, on

multicode devices a specic code is not requested but instead it is only checked wheth-

er the actuator is of a type that can be detected by the system (multicode detection).

There is no exact comparison of the actuator code with the taught-in code in the safety

switch (unique code detection). The system possesses a low coding level.

When the guard is closed, the actuator is moved into the safety switch. When the operating

distance is reached, power is supplied to the actuator by the switch and data are transferred.

Door position monitoring output/bit OD is set when a permissible code is detected. Guard

locking is activated automatically if no voltage is present at IMP. The following switch-on

conditions apply to the safety outputs FO1A and FO1B:

Conguration of guard lock monitoring Active (ON) Inactive (OFF)

No fault in the device TRUE (ON) TRUE (ON)

Guard closed TRUE (ON) TRUE (ON)

Guard locking active TRUE (ON) Not relevant

Guard lock monitoring output/bit OL is switched off when guard locking is released.

In the event of a fault in the safety switch, the safety outputs are switched off and the DIA LED illuminates red. The occurrence

of faults is detected at the latest on the next demand to close the safety outputs (e.g. on starting).

6.1. Bistable guard locking

Guard locking of the switch functions according to the bistable principle. This means that guard locking is kept in its last

position if the power supply is interrupted or when the machine is switched off for servicing, for example. As a result, the

safety door is either constantly locked or it can be closed and opened as required without activating the guard locking.

Guard locking is released via control input IMP. Also see chapter 6.10. Guard locking on version CTM-CBI on page 10.

6.2. Guard lock monitoring

(only with active guard lock monitoring)

All versions feature two safe outputs for monitoring guard locking. The safety outputs (FO1A and FO1B) are switched off

when guard locking is released.

6.3. Connection OD/C

The device has a connection that can be used either as a door monitoring output or as a communication connection to a

BR/IO-Link Gateway. During starting, the device automatically detects whether it is connected to an input on a BR/IO-Link

Gateway. In this case, connection OD/C operates as communication output C.

6.4. Door position monitoring output/bit OD

Door position monitoring output/bit OD is switched on as soon as the actuator is inserted into the switch (state: guard closed

and not locked). Door position monitoring output/bit OD also remains switched on when guard locking is active.

6.5. Communication connection C

The communication connection is used for information exchange with a BR/IO-Link Gateway. The switch delivers process

data determined cyclically. Acyclical data can also be sent by means of specically polling by the evaluation unit. You will

nd an overview of the communication data in chapter 9.10. Connection to a BR/IO-Link Gateway.

Transponder-coded

actuator

Safety switch