4

Operating Instructions

Position Switch NG…

Correct use

Position switches series NG are used for posi-

tioning and controlling machines and in industrial

installations.

The built-in switching element with snap-action

function has an NO and an NC contact with double

gap and electrically isolated switching bridge (direct

opening travel 2 x 0.6mm).

Correct use includes compliance with the relevant

requirements for installation and operation, in

particular

fEN60204-1

fENISO12100

Incorrect use

Position switches with switching element ES510

(snap-action switching contact not positively driven)

must not be used in safety circuits.

Mounting

Mounting must be performed only by authorized

personnel.

The position switches must not be used as a

mechanical end stop.

The actuator (arm) can be positively mounted to the

actuating shaft.

The square drives on the actuator and actuating

shaft must engage with each other (see Figure 2a).

Continuously adjustable fastening is possible (inter-

ference t, see Figure 2b).

To ensure correct operation, the trip dog must move

the actuator at least 1mm or 5° beyond the operat-

ing point (see Figure 5 Travel diagrams).

Position switches must be attached and, if nec-

essary, protected in such a way that predictable

damage can be avoided.

It must be ensured that position switches are acces-

sible for maintenance and function tests.

Important!

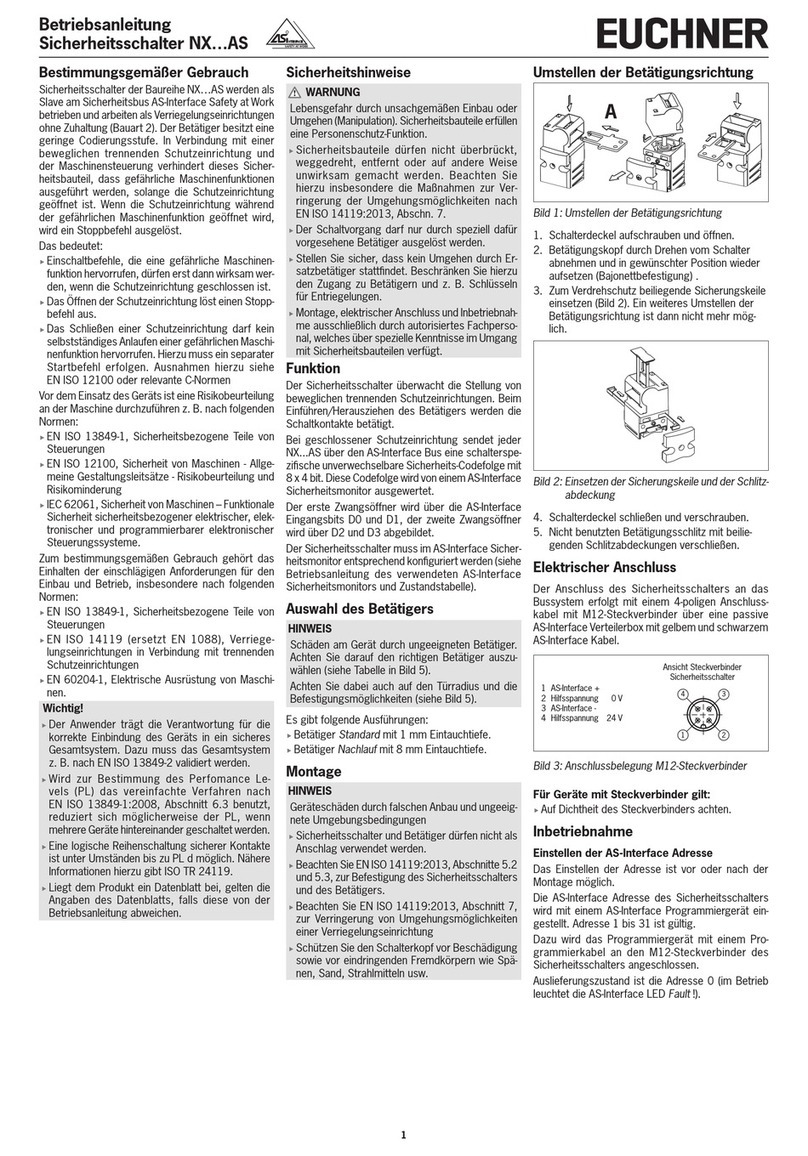

fTo prevent the actuating element from bouncing,

the dog must run out gradually (see Figure 1).

α

αα

Figure 1: Dog shape

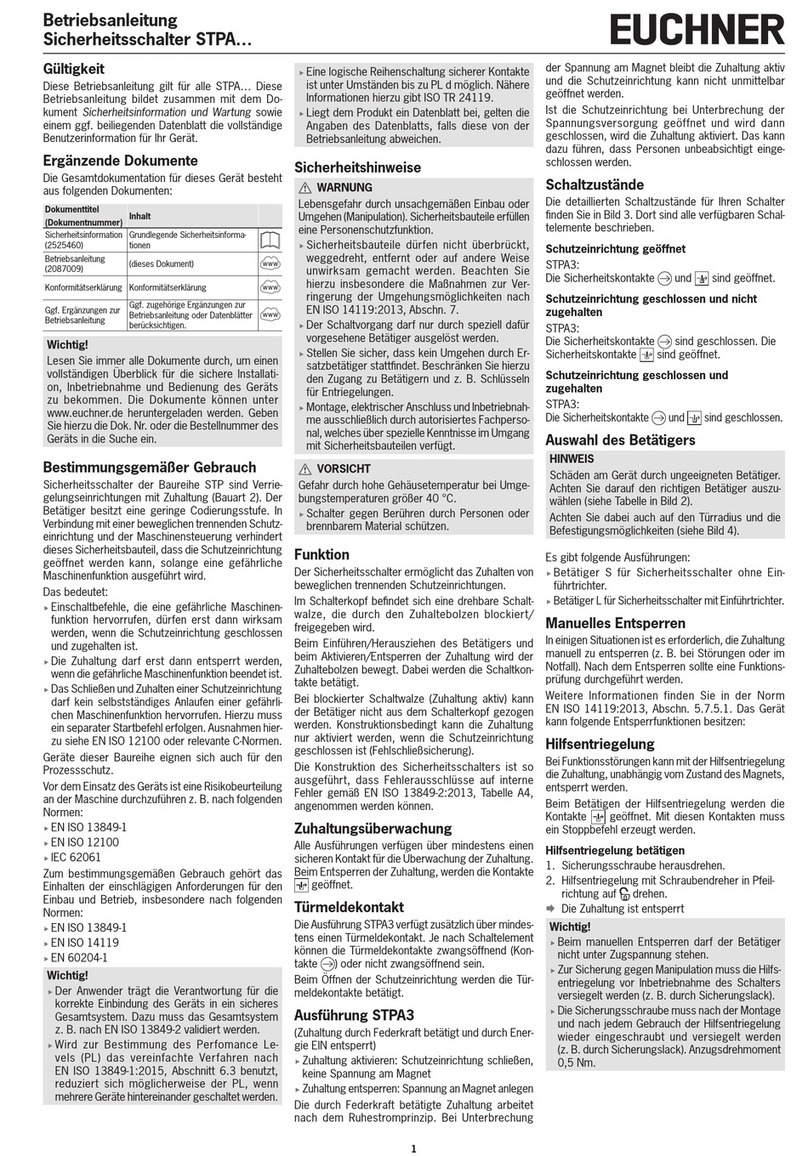

fAdjustment options

Vertical actuator adjustment

Figure 2: Vertical actuator adjustment

Horizontal adjustment 4 x 90°

Figure 3: Horizontal adjustment

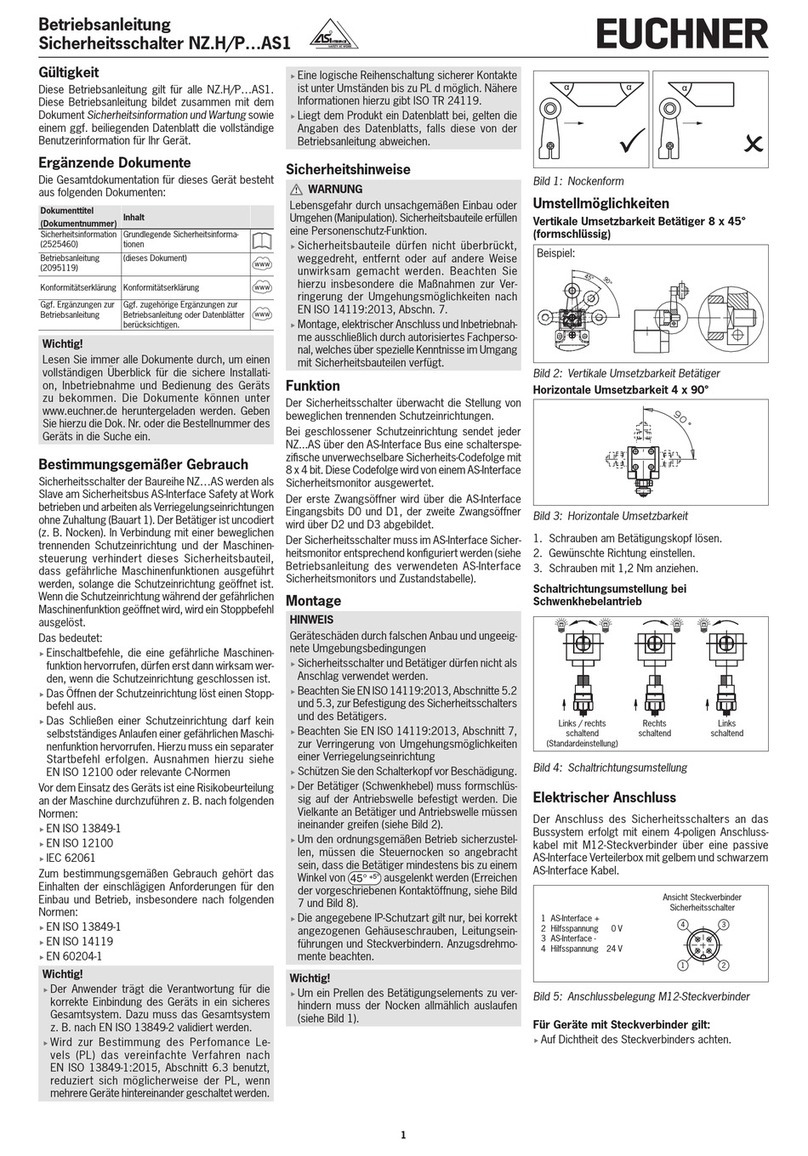

Changing the switching direction with lever

arm actuation

Figure 4: Changing the switching direction

Electrical connection

Electrical connection must be performed only

by authorized personnel.

When choosing the insulation material and

wire for the connections, pay attention to the

over-temperature in the housing (depending on

the operating conditions)!

fVersion NG1… (cable entry)

fFit cable gland M20x1.5 with appropriate degree

of protection.

fConductor cross-section 0.34 … 1.5mm².

fFor terminal assignment, see Figure 10.

fTighten screws for connections to the switching

elements to 1Nm.

fCheck that the cable entry is sealed.

fClose switch cover and tighten screws to 1.2Nm.

fVersion NG2… (plug connector SR6)

fConductor cross-section 0.5 … 1.5mm².

fFor connector assignment, see Figure 10a.

fVersion NG2…

(plug connector M12/SVM5)

fConductor cross-section 0.34mm².

fFor connector assignment, see Figure 10b.

Positive mounting 8 x 45°

Continuously adjustable interference t mounting

Figure 2a

45°

90°

Figure 2b

Setup

Function test

fActuate plunger or lever arm and check the

switching function.

Inspection and service

No servicing is required.

Inspection of the following is necessary to ensure

trouble-free long-term operation:

fcorrect switching function

fsecure mounting of all components

fdamage, heavy contamination, dirt and wear

fsealing of cable entry

floose cable connections or plug connectors.

Info: The year of manufacture can be seen in the

bottom, right corner of the type label.

Exclusion of liability and warranty

In case of failure to comply with the conditions for

correct use stated above, or if the safety regula-

tions are not followed, or if any servicing is not

performed as required, liability will be excluded and

the warranty void.

Notes about

For NG2:

For use and applications as per the requirements of

, a class2 power supply or a class2 transform-

er according to UL1310 or UL1585 must be used.

Connection cables for position switches installed at

the place of use must be separated from all moving

and permanently installed cables and un-insulated

active elements of other parts of the system that

operate at a voltage of over 150V. A constant

clearance of 50.8mm must be maintained. This

does not apply if the moving cables are equipped

with suitable insulation materials that possess an

identical or higher dielectric strength compared to

the other relevant parts of the system.

For NG1:

For use and applications as per the requirements

of , copper wire 60/75°C is to be used.

EU declaration of conformity

The declaration of conformity is part of the operating

instructions, and it is included as a separate sheet

with the unit.

The original EU declaration of conformity can also

be found at: www.euchner.com

Service

If servicing is required, please contact:

EUCHNER GmbH + Co. KG

Kohlhammerstraße 16

70771 Leinfelden-Echterdingen

Service telephone:

+49 711 7597-500

Fax:

+49 711 753316

E-mail:

support@euchner.de

Internet:

www.euchner.com

Left / right

switching

(default setting)

Right

switching

Left

switching