2) Product data / Product naming convention

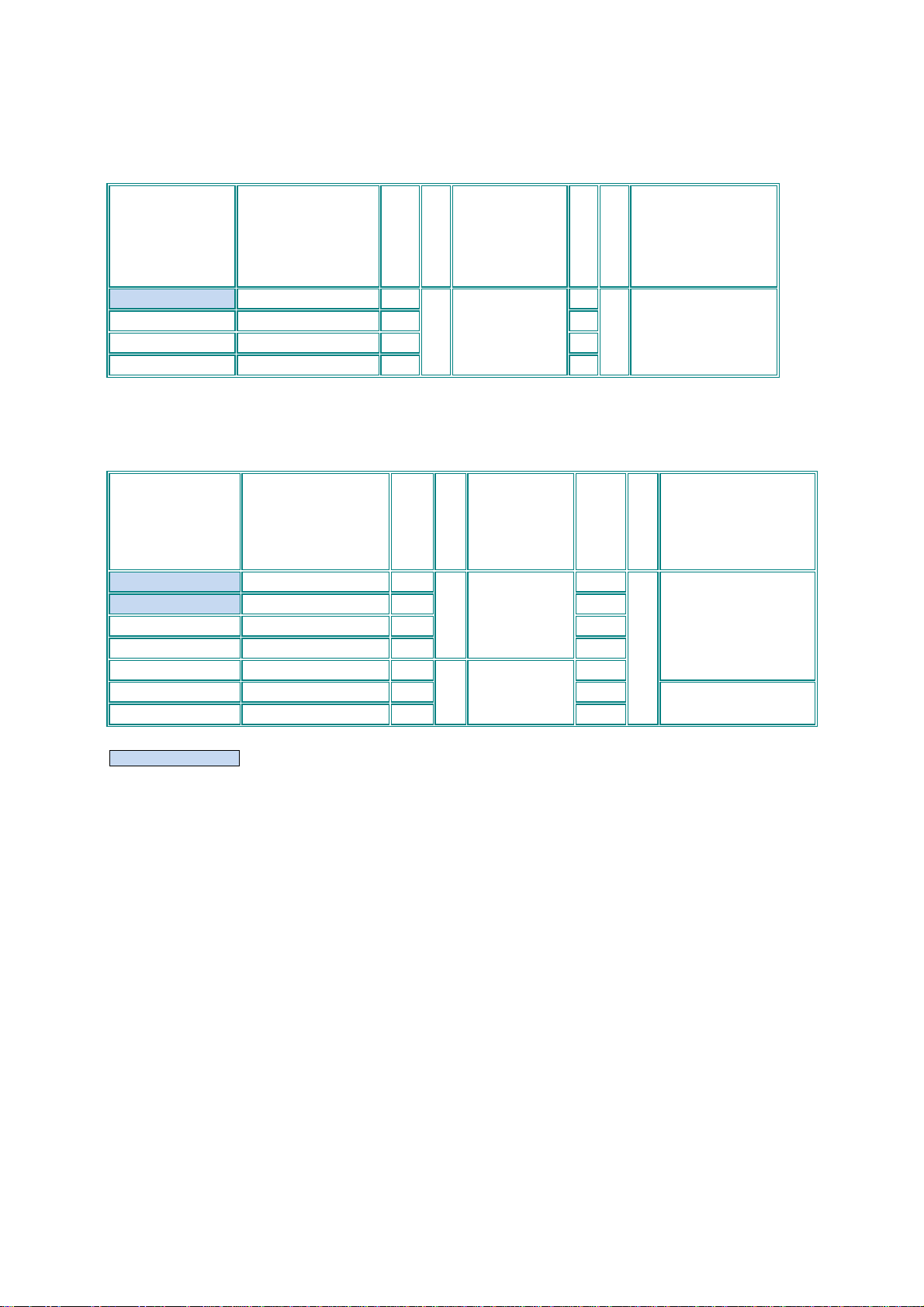

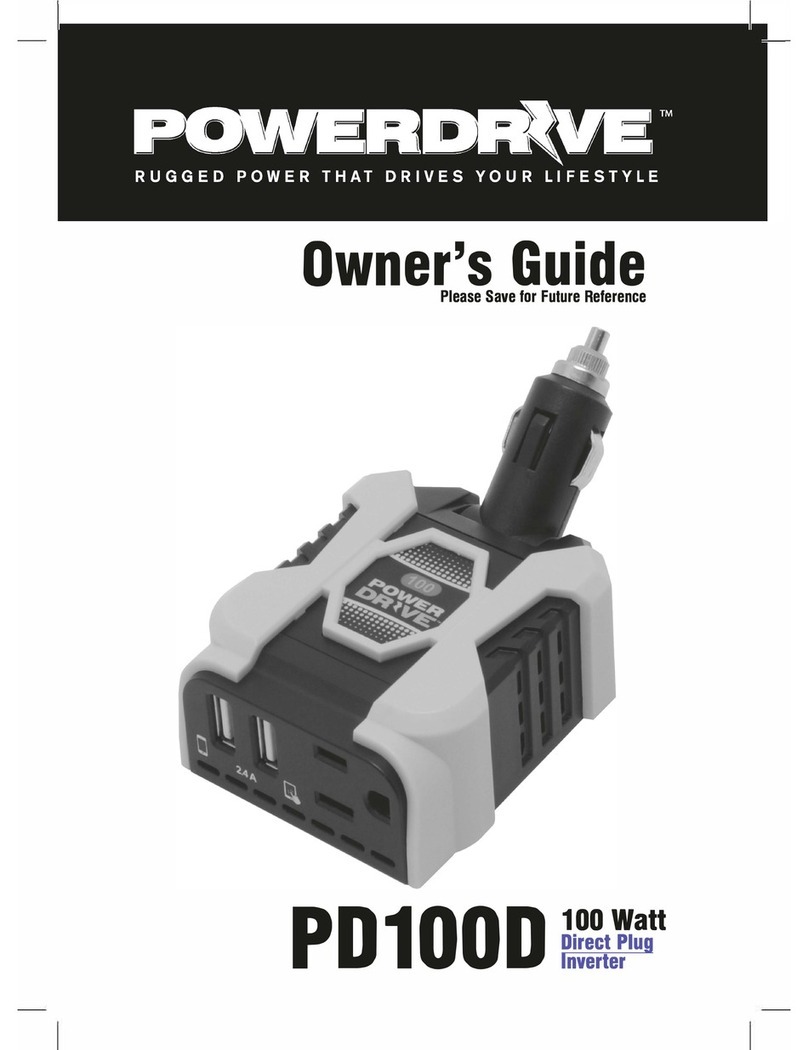

Technical data - inverter series E30

Power supply Rated voltage 3-phase 380…460V +/- 15% - 1phase 230V +/- 15%

Input frequency 44….67 Hz

EMC filter Integrated for 2. environment - optional for 1st environment

Output

Output voltage 0……...U-input

Output frequency 0……...650 Hz

Resolution of output frequency 0,01 Hz

Overload capability 150% - 60 sec. / 10 Min

Control mode

PWM control-modes V/Hz - Mode

SENSORLESS VECTOR (SLV) – Speed / torque control

Permanentmagnet Synchronus Motor PMM control

PWM frequency 0,8.....16 kHz

V/Hz characteristic Linear, quadratic, and user-programmable curve – independent output

voltage via setpoint

Starting torque 150% rated torque at 0,5 Hz (in SLV mode)

Torque boost Automatic / manual

Motor data input Manual input / intelligent AUTOTUNING function

Speed range 1:100 in SLV mode

Speed precision +/- 0,5% (SLV)

Torque precision +/- 5% (SLV)

DC-Brake Freq. threshold, duration and intensity programmable – DC injection

Brake chopper Integrated chopper transistor (Brake resistors – see product table)

Display 4 line LCD character display For programming and visualization of different operating parameters

I/O Channels,

control functions

Inverter control - Start/Stop To configure: terminals / keypad/ serial link

Digital control inputs 6 digital inputs (HIGH/LOW configurable), pulse input

Speed / torque reference signal Potentiometer/analogue input (terminals), via keypad, pulse input, serial link

Analogue setpoint input 2 Analogue channels 0…10V, 0..(4)20 mA (with programmable offset and

gain – to concatenate mathematically each other)

Analogue outputs 2 analogue output channels, both programmable in gain, different functions

to assign (0…10V, 0..20 mA)

Digitale outputs 1 digital output (different functions to assign)

Relays output 2 switchover contact 5 A 230 V (programmable for different functions)

Interface Serial link (MODBUS – ASCI/RTU)

Special function - control options

Jog mode, 12V / 50 mA auxiliary power supply on terminals

PI-control / Pump control, Master/Slave control, multipump control

Fixed frequency control, programmable cycling frequency sequence

"Catch on the fly function", AUTORESET/RESTART function

Protections with

fault memory Electrical protections Overvoltage, undervoltage

Overcurrent, overload, motor overload short circuit

Phaseloss, moptor phase imbalance

Thermal protections Ovetemperature, motor I2xt, motor PTC/KLIXON protection

Optionals

Operating panel Remote keypad / programming tool

Brake resistors High power resistors for heavy duty operation

Filter / chokes PFC chokes – dv/dt limiting output filter - sinusfilter

Parameter copy stick USB Stick with parameter dublication function – USB/RS485 converter

PC-Link Software (via MODBUS) Special tool for programming, control and diagnostic (parameter set memory)

Environmental

conditions

Protection IP66

Operating temperature -10……+50 °C

Humidity Max. 90 % not condensing, no corrosion

Elavation 1000 m - 1% derating / 100m above

Vibration Max. 4 g

Power range Size J1 - J2 0,4……7,5 kW

Standards EMC EN61800-3(2004)

Safety EN61800-5-1 2003

EM30 – Rev.03 - EN- SOFT Rev. 1.1x

© 2017-06-KPP-EURADRIVES EUROPE GmbH - 12 -