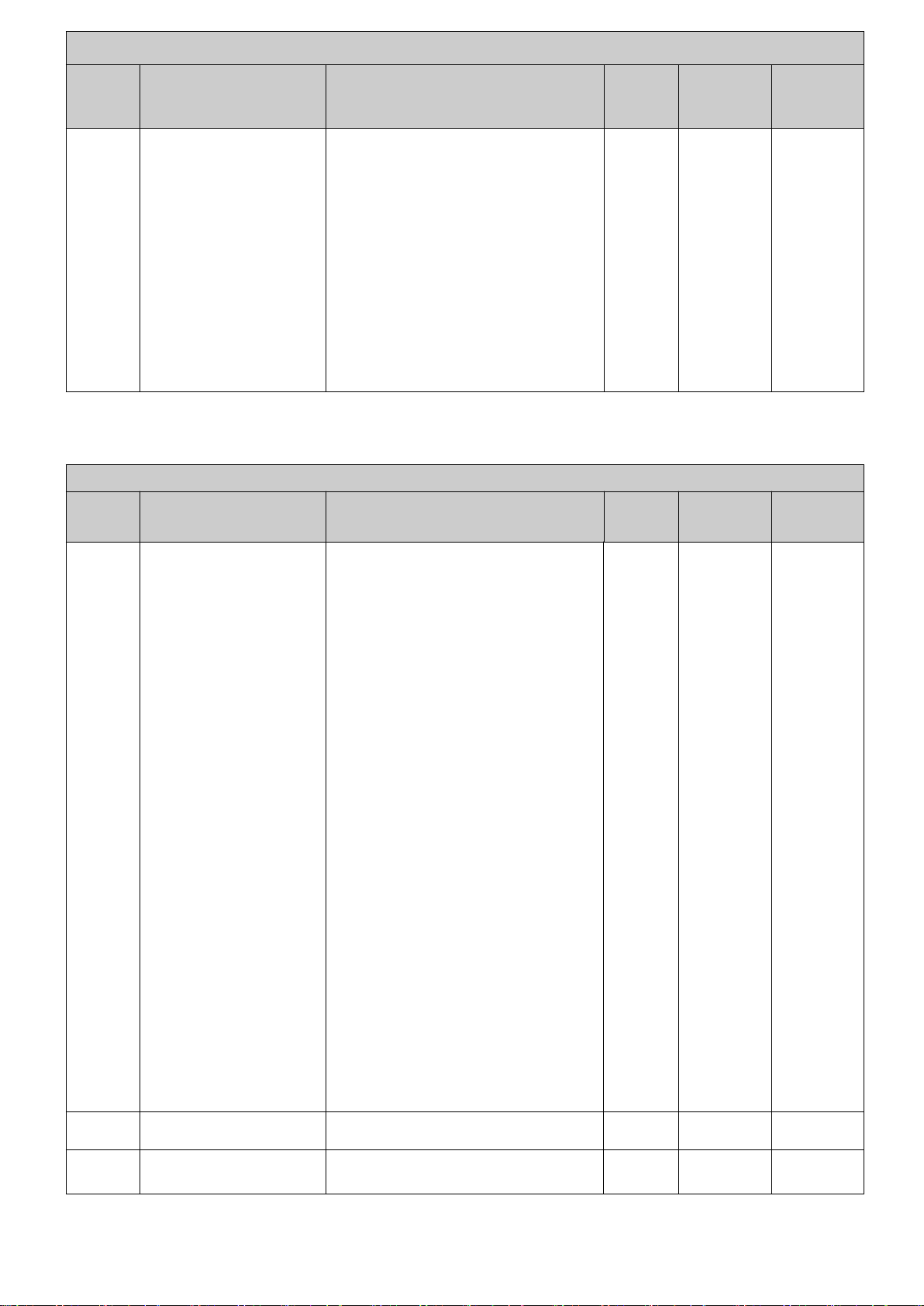

LED unit’s digit:

0: All parameters are allowed to be

modiFied.

1: All parameters are not allowed to

be

modiFied except this parameter

itself.

2: All parameters are not allowed to

be

modiFied except P0.02 parameter

and

this parameter itself

LED ten’s digit:

0:Inaction

1:Factory default reset

2:Clear history fault record

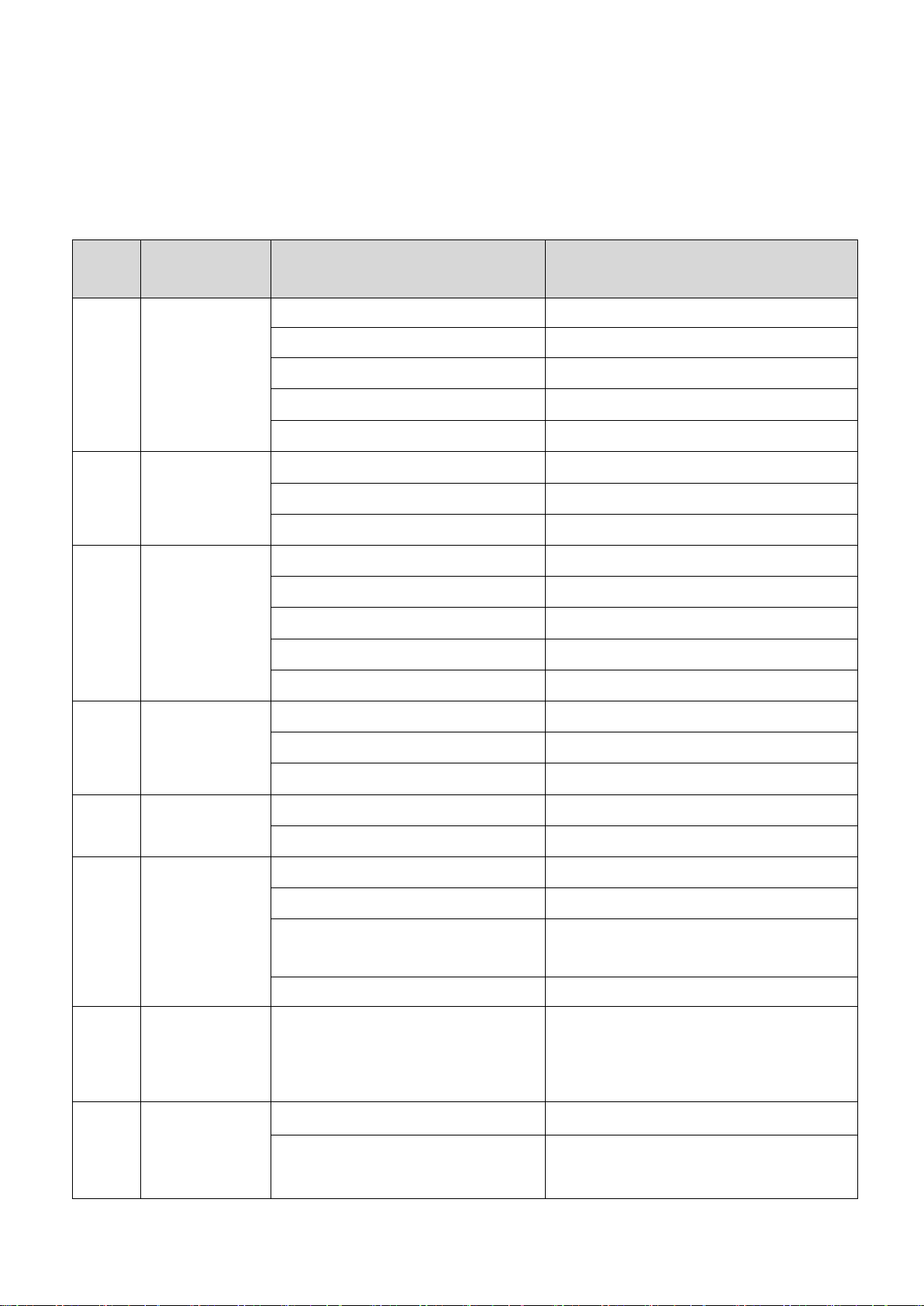

0:Idle terminal

1:Multi-stage speed control terminal 1

2:Multi-stage speed control terminal 2

3:Multi-stage speed control terminal 3

4:External FWD JOG control input

5:External REV JOG control input

6:Acc/Dec time terminal 1

7:Acc/Dec time terminal 2

8:Acc/Dec time terminal 3

9:3-wire control

10:Free stop input (FRS)

11:External stop command

12 :Stopping DC brake input command

DB

13:Inverter running prohibited

14:Freq. increase command(UP)

15:Freq. decrease command(DOWN)

16:Acc/Dec prohibited command

17:External reset input (clear fault)

18 :Peripheral equipment fault input

(normally open)

19:Freq. control channel selection 1

20:Freq. control channel selection 2

21:Freq. control channel selection 3

22:Command switched to terminal

23 :Running command control mode

selection 1

24 :Running command control mode

selection 2

25:Swing frequency selection

26:Swing frequency running reset

27:Close loop invalid

28:Simple PLC pause running command

29:PLC invalid

30:PLC Reset in stopping state

31:Freq. switch to CI

32:Counter trig signal input

33:Counter clear input

34:External interrupt input

35:Pulse freq. input (only valid for X6)

36: fire mode