True Blue Power®5 Manual Number 9017680

a division of Mid-Continent Instrument Co., Inc. Revision C, January 2, 2015

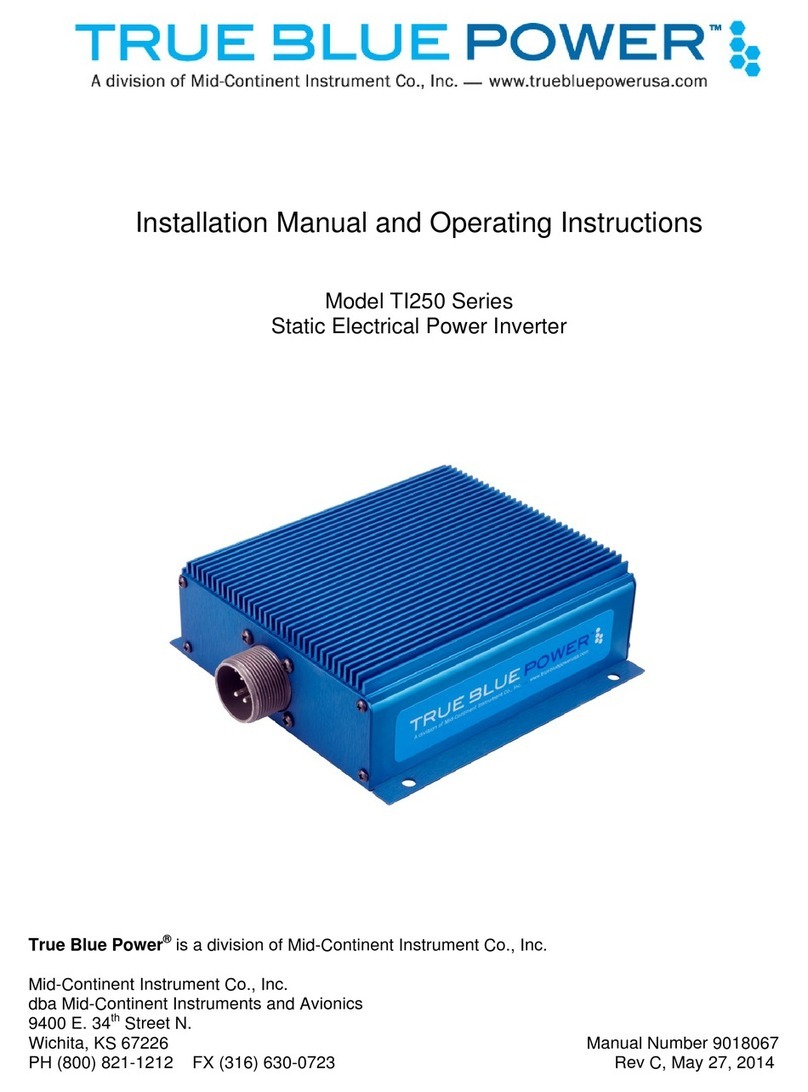

SECTION 1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The model TI1200 Series Static Electrical Power Inverter is a lightweight power converter that translates a

20 to 36 VDC input to two separate output options:

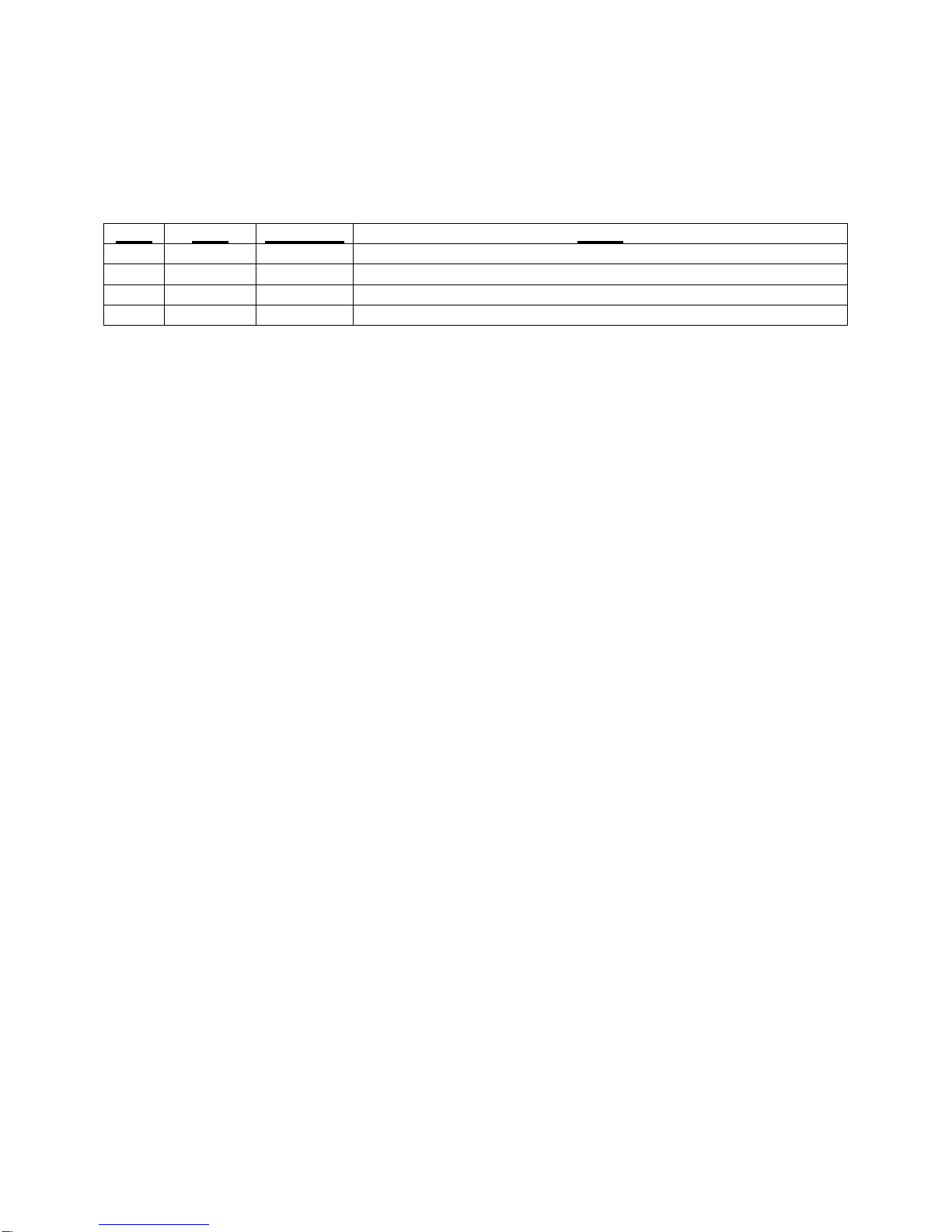

Model Part Number Output

TI1200 6431200-1 115 VAC, 60 Hz

TI1202 6431200-3 230 VAC, 50 Hz

Both configurations of the Model TI1200 Series provide 1200 watts (VA) of power. The alternating current

output is defined as a pure sine wave with less than 2.5% of total harmonic distortion for clean, noise-

free, harmonic-free power to supply loads of corresponding voltage, power and frequency. For the

TI1200, the 115VAC, 60 Hertz (Hz) is suitable for nearly any common commercial or consumer load rated

for a nominal input of 115VAC. The TI1202 is designed for a 230VAC output with an AC frequency of 50

Hz for common avionics and related equipment. The TI1200 Series Static Inverter is FAA certified to TSO

C73 and tested to rigorous environmental standards and levels of RTCA DO-160. The small size and light

weight in conjunction with its installation flexibility (inside or outside the pressure vessel) make it an ideal

choice for aircraft power needs while reducing the challenges associated with other similar products.

Highlighted features include short circuit protection, overload capability, low voltage shut-down,

temperature monitoring, a self-resettable over-temperature disable, and a remote on/off function. The

rugged extrusion that houses the unit is designed to help dissipate heat and provide mechanical strength

against vibration or other possibilities of damage. Two independent fans allow for a smaller unit and

provide a quieter operation while keeping the internal components cool and extending the life of the unit.

1.2 TECHNICAL SPECIFICATIONS

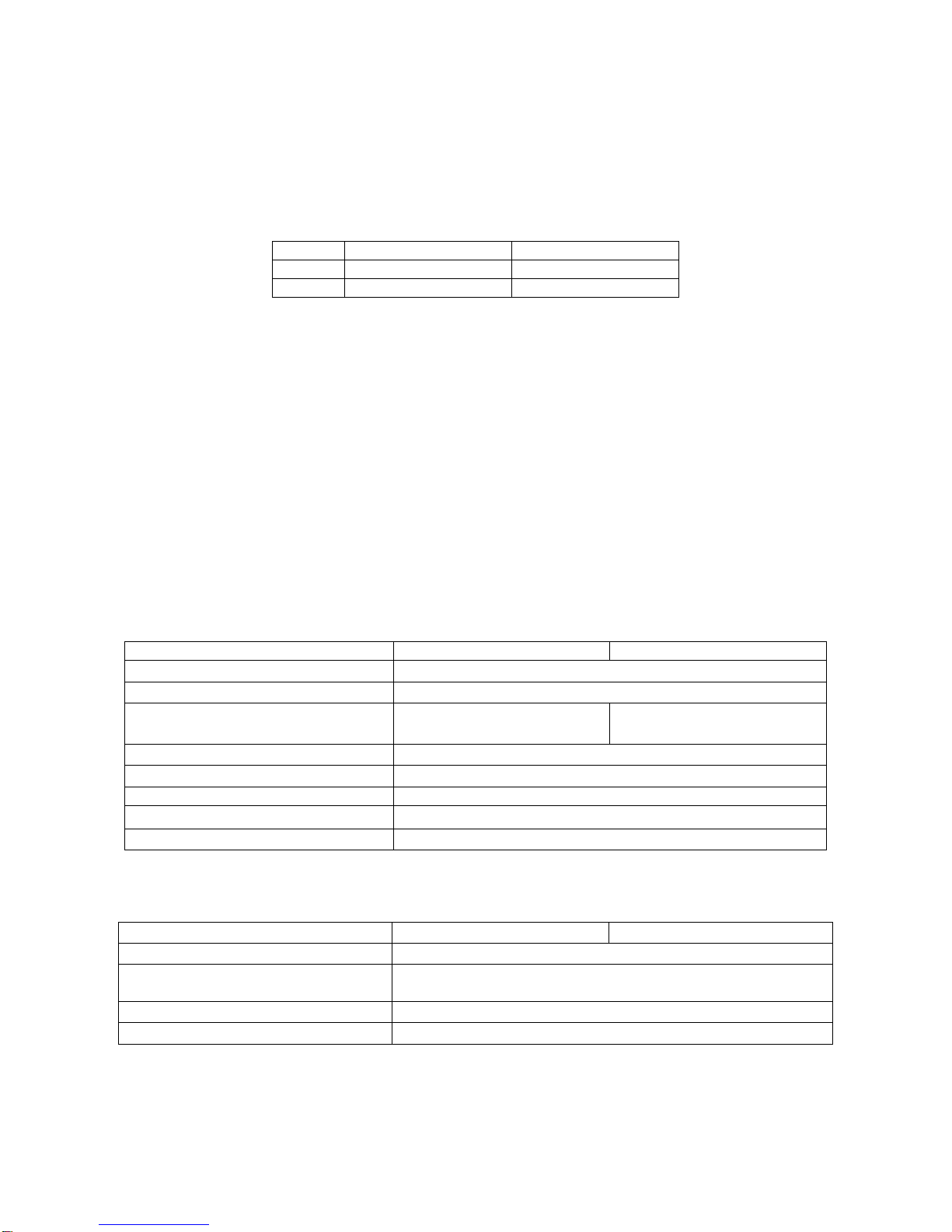

Electrical Attributes: Model TI1200 Model TI1202

Input Voltage: Rated 28VDC nominal; 20-36VDC certified; see figure 4.2

Input Power: 60 amps; 0.2A at no load

Output Voltage: 115VAC ±3% at 60 Hertz

±0.1% (single phase) 230VAC ±3% at 50 Hertz

±0.1% (single phase)

Output Power: 1200 watts (1200 VA at power factor = 1)

Output Waveform: Pure sine wave (less than 2.5% distortion)

Power Factor: -0.8 to +0.8

Efficiency: 88% nominal

Total Harmonic Distortion (THD): < 3%

Table 1.1

Physical Attributes: Model TI1200 Model TI1202

Weight: 7.25 pounds max

Dimensions:

(not including connector mate) 12.00 inches long x 6.32 inches wide x 3.45 inches high

Mating Connector (and cable clamp): MS3102A24-12S or equivalent (MCI P/N 9017235)

Mounting: Base mount – orientation not critical

Table 1.2