euro verbau EG PV 4000 User manual

TRENCH SHORING SYSTEMS FROM SHORING PROFESSIONALS

Trench shoring equipment

Production - Sales - Rental - Service

MANUAL

GmbH

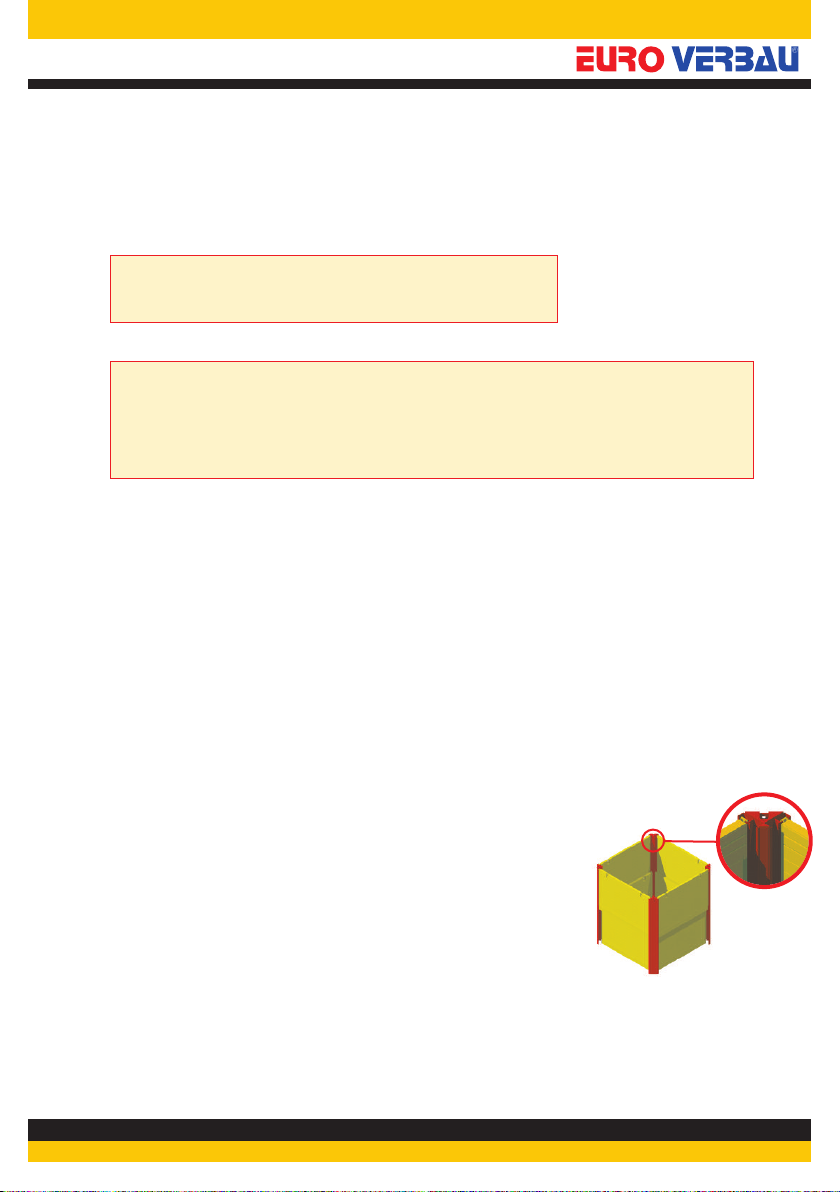

CORNER SLIDE RAIL SYSTEM

EG- / DG-CORNER

Hoc ks teiner Weg 30

Tel:

+49 21 66-3 98 63 60

Site:

www.euroverba u.de

D-41189 Mönchengladbach

Fax:

+49 2166-3 98 63 78

Mail:

info@euroverb au.de

MANUAL

CORNER SLIDE RAIL SYSTEM EG-CORNER / DG-CORNER

2

These instructions for use must be presented to the bui ding site personne .

1. Genera purpose of use

Shafts and excavations with head shoring.

2. Specifications EG PV 4000

Description Type Dimensions [mm] Weight [kg]

Single-corner slide rail EG corner L=3 00 189

Double-corner slide rail DG Corner L=4 00 469

Double-corner slide rail DG Corner L= 00 73

3. Safety regu ations

We refer to the fact that the above shoring system is only for the intended use and may only be

assembled, installed, dismantled and extracted in the sequence listed under the following points,

exclusively with the use of all relevant ”original construction elements”. The shoring plates used are

slide-rail plates of the KRA/KRI VS 100 type (plate thickness 10 mm) and KRA/KRI VS 120 (plate

thickness 12 mm).

Failure to obeserve these unser instructions make the manufacturer’s liability and warranty are invalid.

Observe the load-bearing capacity of the shoring elements.

Note:

All of the requirements of BG-Bau (the professional association) as well as DIN 4124 ”Excavations and

trenches, embankments, workroom widths, shoring” are applicable. In the event of conditions deviating

from the standard conditions, construction site statics must be prepared.

4. Shoring widths for sing e pits, EG (single slide ail) or DG (double slide ail) corner

Shoring widths for EG corner

Shoring plate bc b b

Inner plate [mm] Trench width [mm] Outer rail [mm]

Shoring widths for DG corner

Shoring plate bc b b

Inner plate [mm] Trench width [mm] Outer rail [mm]

WARNING

Trench shoring equipment

Production - Sales - Rental - Service

KRA

KR 8000 8185

KR 7000 7210

KR 6000 6210

KR 5000 5210

KR 4500 4710

KR 4000 4210

KR 3500 3710

KR 3000 3210

KR 2500 2710

KR 2000

KRI

8090

7106

6106

5106

4606

4106

3646

3146

2646

2146 2210

KRI KRA

8485

7460

6460

5460

4960

4460

3920

3420

2920

8390

7356

6356

5356

4856

4356

3856

3356

2856

2356 2420

8437

7433

6433

5433

4933

4433

3933

3433

2933

2433

KR 8000

KR 7000 7106 7210

KR 6000 6210

KR 5000 5210

KR 4500 4710

KR 4000 4210

KR 3500 3710

KR 3000 3210

KR 2500 2710

KR 2000

6106

5106

4606

4106

3646

3146

2646

2146 2210

KRI KRA

8090 Innenplatte

KRI KRA

8737

76567760 7733

66566760 6733

56565760 5733

51565260 5233

46564760 4733

41564220 4233

3656 3720 3733

31563220 3233

26562720 2733

8785 Außenplatte

Trench shoring equipment

Production - Sales - Rental - Service

MANUAL

CORNER SLIDE RAIL SYSTEM EG-CORNER / DG-CORNER

3

Excavation with outside walert and foot rest (lost)

5. Insta ation

a) Depending on the soil conditions, create an advance excavation for the pit. Set up one plate and se-

cure it against falling over or hold it in position with a second machine

b) Thread one corner slide rail at one end of the plate, into the outer guide, push in with the excavator

and secure it. Insert one plate at right angles to the first plate.

c) Thread the second corner slide rail into the outer guide, push in with the excavator to secure it.

d) Repeat steps C and D on the other side. Make sure that the two plates are at right angles to the head

plate. Insert 2 corner rails on the free plate ends and press them down.

e) Insert one plate into the outer guides of the corner rails. Align the pit system. Lower the plates and

corner rails gradually. At a depth of approx. 2.3 m, affix a support plate to the EG corner, secure it with

bolts and gradually lower it. Max. depth 3.7 m. If necessary, use protection rails and a protection anvil.

On the DG corner, the additional plates in the inner guide are built into the DG corner. At greater

depths, a top plate can also be used in the outer guide. The maximum depth is 6.1m. The plates should

lead ahead of the corner slide rails so that the guides of the slide rail remain free.

Image 2a Image 2b Image 2c

a)b)c)

d) e) e)

Trench shoring equipment

Production - Sales - Rental - Service

MANUAL

CORNER SLIDE RAIL SYSTEM EG-CORNER / DG-CORNER

4

f) If the plate head has reached the upper edge of the pit, in-

sert a second plate into the inner guide of the corner slide

rail if necessary, as far as the height of the blade of the first

plate. Press in the inner plate further, as described in e) If

necessary, slide support plates into the outer slide-rail guide

and connect them to the lower plate by means of locking

bolts and safety clips.

g) When the excavation is finished, the plate head should lie

approx. 10 cm above the base and serve as a scree pro-

tector.

6. Dismant ing

a) Insert the backfill material in layers (observing the compac-

tion level).

b) Pull out the plates and corner slide rails up to the filled

area. In doing so, start from the inner plate. The height of

the respective pullout is according to compaction level.

c) Compact the backfill material.

d) Restart at point 6.a, until the shoring iscompletely pulled

out of the earth.

7. Disassemb y

Before transporting away the shoring unit, it is disassembled

analogously to the assembly but in the reverse sequence.

8. Maintenance / Service

On each disassembly, the corner rails should be cleaned. The

entire shoring unit must be protected against corrosion cau-

sed by handling damage by the use of appropriate protective

measures.

9. Transport

When unloading, you should store the supplied wooden

blocks and the rubber plates appropriately. These parts must

always be re-used for the return transport. As the shipper, you

are co-responsible for the appropriate shipping of the return

transport.

©2012 EUROVERBAU • Die hie ve öffentlichten Inhalte sind u hebe echtlich geschützt. De Inhalt da f ohne sch iftliche Genehmigung de He ausgebe wede bea beitet, übe setzt, ve vielfältigt ode ve b eitet we den. 2012A

Manufacturer Certification in Compliance

with DIN EN 1090-2

f)f)g)

Table of contents