Eurolube 53408 User manual

English Manual for TCM-module 53408, R10, 181008

LUBE-MASTER R10

R10

TCM MANUAL

TANK CONTROL MODULE

53408

LUBE-MASTER R10

2(20)

Table of Contents

1. INTRODUCTION 3

2. MECHANICAL INSTALLATION 3

3. ELECTRIC INSTALLATION 3

4. CONFIGURATION 5

4.1. CHECK BEFORE CONFIGURATION 5

4.2. ADDRESSING THE TCM 5

4.3. SET-UP MODE 5

4.4. CHANGE ADDRESS [TCM//ADDRESS]5

4.5. RECOMMENDATION FOR SETTING ADDRESSES 6

5. CONFIGURE THE PORTS 6

5.1. CONNECT A TANK TO A PORT [TCM//PORTX/TANK]6

5.2. SET THE MASK [TCM//PORTX/MASK] 6

5.3. ANALOGUE SENSOR SETTINGS 7

5.3.1. Set the input signal filter time constant .............................................................................................7

5.3.2. Adjusting the offset ............................................................................................................................7

5.3.3. Adjusting the calibration ...................................................................................................................7

5.3.4. Set sensor full scale ...........................................................................................................................8

5.4. FLUID SPECIFICATION 8

5.4.1. Set fluid name....................................................................................................................................8

5.4.2. Set fluid part number.........................................................................................................................8

5.4.3. Set the fluid density............................................................................................................................9

5.5. TANK SPECIFICATION 9

5.5.1. Set tank capacity................................................................................................................................9

5.5.2. Set the tank reorder volume level ......................................................................................................9

5.5.1. Set the tank stop volume level..........................................................................................................10

5.5.2. Set tank bottom area........................................................................................................................10

5.5.3. To configure a TCM port for a tank that does not have a constant area.........................................10

5.6. DISPLAYING TANK CONTENT ON A LED DISPLAY 11

5.6.1. Set LED address ..............................................................................................................................11

5.6.2. Set LED update interval ..................................................................................................................11

5.7. SET THE TYPE OF TANK (PC SYSTEM). 12

6. MENU TREE 13

7. FAST MENU CODES 14

8. TECHNICAL SPECIFICATION 15

9. TO CONNECT DISCRETE LEVEL SENSORS 53132/138/171 AND SOLENOID VALVES 16

9.1. FRESH OIL TANK,53138 (2-LEVELS) 16

9.2. FRESH OIL TANK,53171/53183 (1-LEVEL) 16

9.3. WASTE OIL TANK,53132 (2-LEVELS) 16

9.4. ONE TCM PORT CONTROLS A NUMBER OF PUMPS 17

10. EX-BARRIER 53187 FOR DISCRETE LEVEL SENSORS. 17

10.1. CONNECTING A WASTE OIL TANK 53132 (2-LEVELS) 18

11. TO CONNECT AN ANALOGUE SENSOR 18

11.1. ANALOGUE SENSOR 53417 18

11.2. CONNECTING AN ANALOGUE SENSOR. 19

12. EX-BARRIER 53188 FOR ANALOGUE SENSORS. 19

12.1. CONNECTION 20

13. MPDM PCB MOUNTED IN A TCM BOX 20

LUBE-MASTER R10

3(20)

1. Introduction

The LUBE-Master TCM module, (Tank Control Module), is used to control pumps and/or measure levels in tanks

using floater based level switches. A TCM can be used both for fresh and waste oil tanks.

The TCM (53408) is eighter a MPDM (53400) with another software (early model the chip should be labeled TCM

1.xx.xx) or has the PCB 203 02 91 equipped with a chip marked TCM 2.xx.xx.. Because of this a lot of this manual is

similar to the manual of the MPDM.

NOTE! The LUBE-Master installation guide should be available when installing and configuring a TCM.

2. Mechanical installation

The TCM is delivered mounted in a metal box with power supply. It can also be delivered as a PCB with mounting kit.

Complete TCM in a box is mounted on a wall or other suitable place using the four-ø5 mm holes in the bottom corners

of the box.

If a PCB is used it is important that a power supply with enough performance is used.

3. Electric installation

The power supply should be connected to mains

230VAC in a proper way following valid rules.

Alentec & Orion AB recommends that the

connection be done through a 2-pole working

switch.

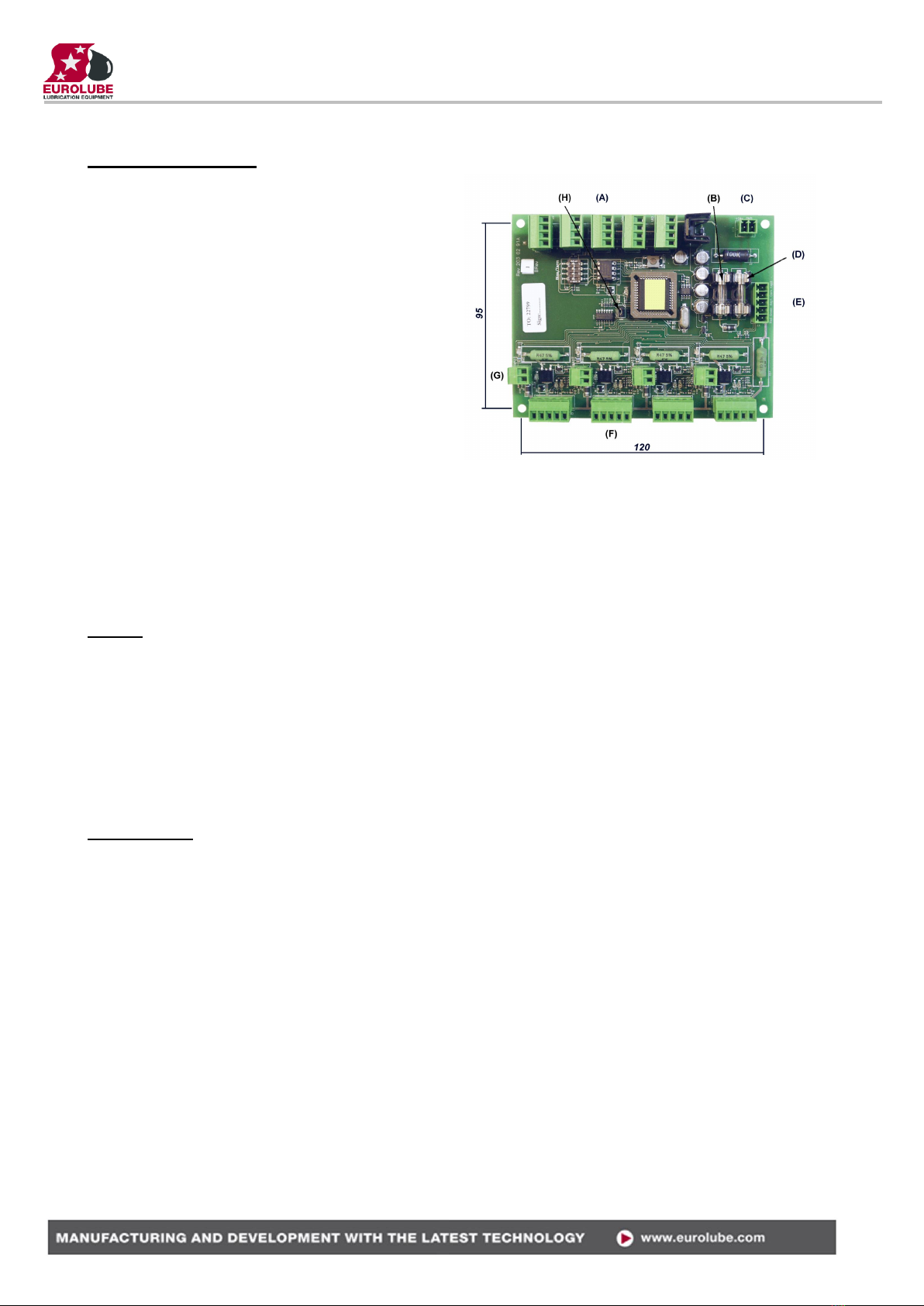

It has five connectors (A) for the LUBE-Master communication. Two of these connectors, MPDM IN and MPDM

OUT are not connected to +24V and are intended for a connection to another TCM, MPDM or other modules that

already have +24VDC. This is to prevent connecting +24VDC from two power supplies.

The other three connectors are used to connect external devices without a power source such as a Printer Module (PM),

a LED Module (LED) and/or a KeyPad (KP). These connectors can only supply power to a single device. For more

detailed information see the LUBE-Master Manual

NOTE! If the communication loop begin in one of these modules it must be connected to either MPDM IN or

MPDM OUT or +24V must not be connected.

The RESET-button (B) can be used to reset the module or reset the module address. Power supply is connected to the

connector (C).

NOTE! Check polarity, GND is closest to the hole!

The connector (D) is used when you install a chassis-mounted key switch and diode.

With the key switch you can set the status of the module to OFF-, NORMAL-, or

OVERRIDE-mode. The diodes indicate setting.

There are four connectors (E) market +24 V, OC, A, B and GND, one for

each pump/tank. Solenoid valves and level sensors are connected to these

connectors.

“A” of a TCM port is connected to “order oil/emptying” of the level

sensor.

“B” of a TCM port is connected to “Stop level” of the level sensor.

“GND” of a TCM port is connected to common of the level sensor.

“+24V” of a TCM port is connected to one of the terminals of a solenoid

valve and “Sol” is connected to the other.

TIP! If a TCM is used for a tank containing flammable liquid it could be necessary to use an EX

protection.

ALARM

Solenoid valve

STOP

+24 V

A

GND

B

Sol

LUBE-MASTER R10

4(20)

There are two diodes (F) for every port. These indicate the status of entry points A and B, the level in the tank.

One diode (G) on each port indicates if the solenoid valve is open or not.

If the diode (H) is flashing the module is operational and working properly. A steady light or completely off indicates a

problem.

DIL switches for termination and BIAS are located at (I). (J) Shows the position of the replaceable communication

driver. The SetupLock jumper at position (K) has no function for a TCM.

A LED (L) shows if an analogue sensor is detected or not, lit if detected. The analogue sensors are connected to the 2-

pole connectors marked (M). The polarity is marked on the PCB.

TCM100 PCB 203 02 62X with chip

TCM 1.xx.xx.

TCM200 PCB 203 02 91X with chip

TCM 2.xx.xx.

LUBE-MASTER R10

5(20)

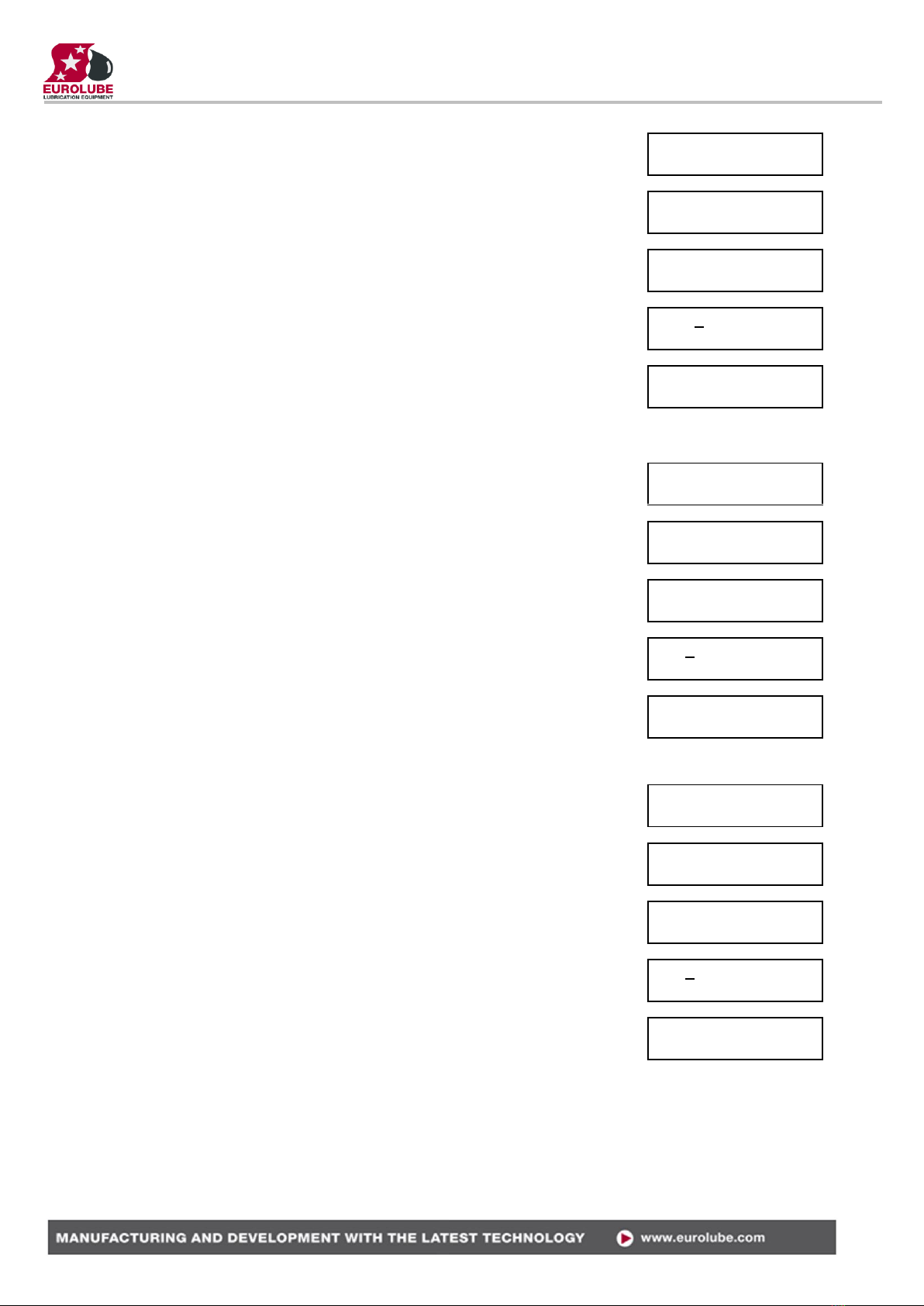

Reel:SETUP ‡

EXIT STOP CE ENT

PASS:_ ‡

Enter Password

Addr:8???_ ‡

Address[CODE]

TCM: ‡

TCM MainMenu

TCM: ‡

TCM MainMenu

Address:8XXX ‡

Ange Adress 8???

Address:8XXX ‡

Set Address 8???

4. Configuration

An LUBE-Master configuration sheet should always be filled or altered during the configuration.

NOTE! To obtain technical support a copy of the configuration sheet for the complete installation must be

sent to Alentec & Orion AB at

E-mail: lubemaster@alentec.se

Post: Alentec & Orion AB

LUBE-Master Support Team

Grustagsvägen 4

SE-138 40 Älta

SWEDEN

4.1. Check before configuration

Check that the TCM is working and communicating with the system according to the LUBE-Master Manual chapter

Testing modules.

NOTE! Do not forget to check and adjust the termination and BIAS according to LUBE-Master Manual.

4.2. Addressing the TCM

A new module has a default address when delivered such as MPDM 1000, PM 2000, KP 3000, LED 4000, TCM

8000 and so on. To set an address for a new TCM or a TCM with unknown address press and hold it’s RESET

button for 5 seconds to set a temporary address. Immediately enter set-up mode from a KP and type 0 and then

ENTER to get to the Main menu of the TCM, see below.

NOTE! Only one new module can be installed at a time. If you press the RESET-button on several

terminals simultaneously or in a sequence, only the most recently pressed will be active.

TIP! Follow preferably ”Recommendation for setting new addresses” when setting addresses.

4.3. Set-Up mode

Type the word ”SETUP” on a KeyPad and press ENTER.

Type the password and press ENTER.

Type the address for the TCM that is to be configured and press ENTER to access

its main menu. It is possible to add the 4-digit menu code to go directly to the

desired menu.

Scroll through the TCM sub menus by pressing or . When the desired menu is

shown press ENTER etc.

4.4. Change address [TCM//Address]

Enter menu [TCM//Address] by pressing ENTER.

Press ENTER to get the cursor.

Type in the desired address and acknowledge by pressing ENTER. When the

cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode.

NOTE! If two or more TCM’s have the same address the system will fail. The TCM’s has to be re-addressed.

TIP! Follow preferably ”Recommendation for setting addresses” when setting addresses.

LUBE-MASTER R10

6(20)

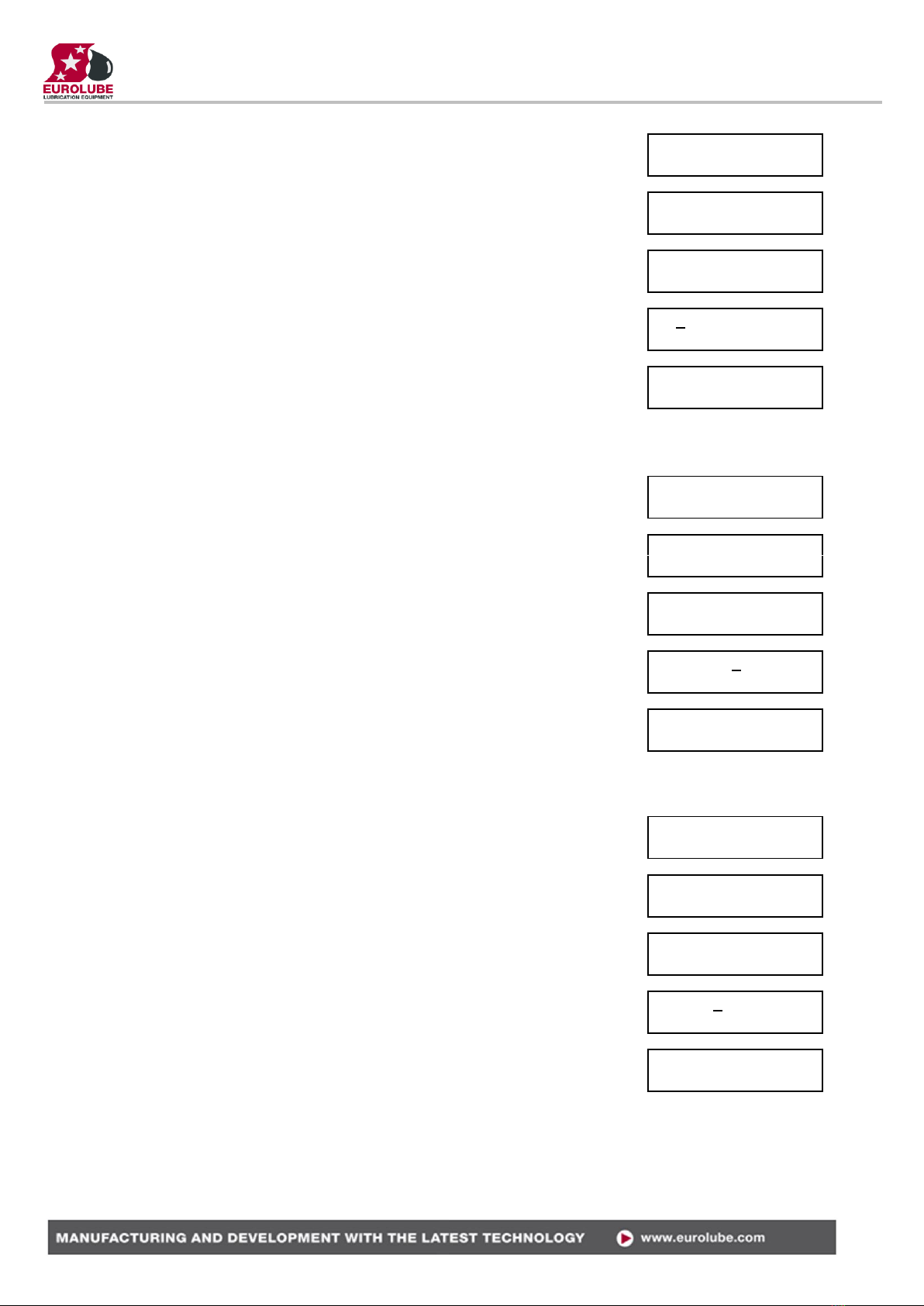

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

Mask:X ‡

Set Mask 0-15

Mask:X ‡

Set Mask 0-15

Mask:X ‡

Set Mask 0-15

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

Tank:X ‡

Set TankNo ???

Tank:X ‡

Set TankNo ???

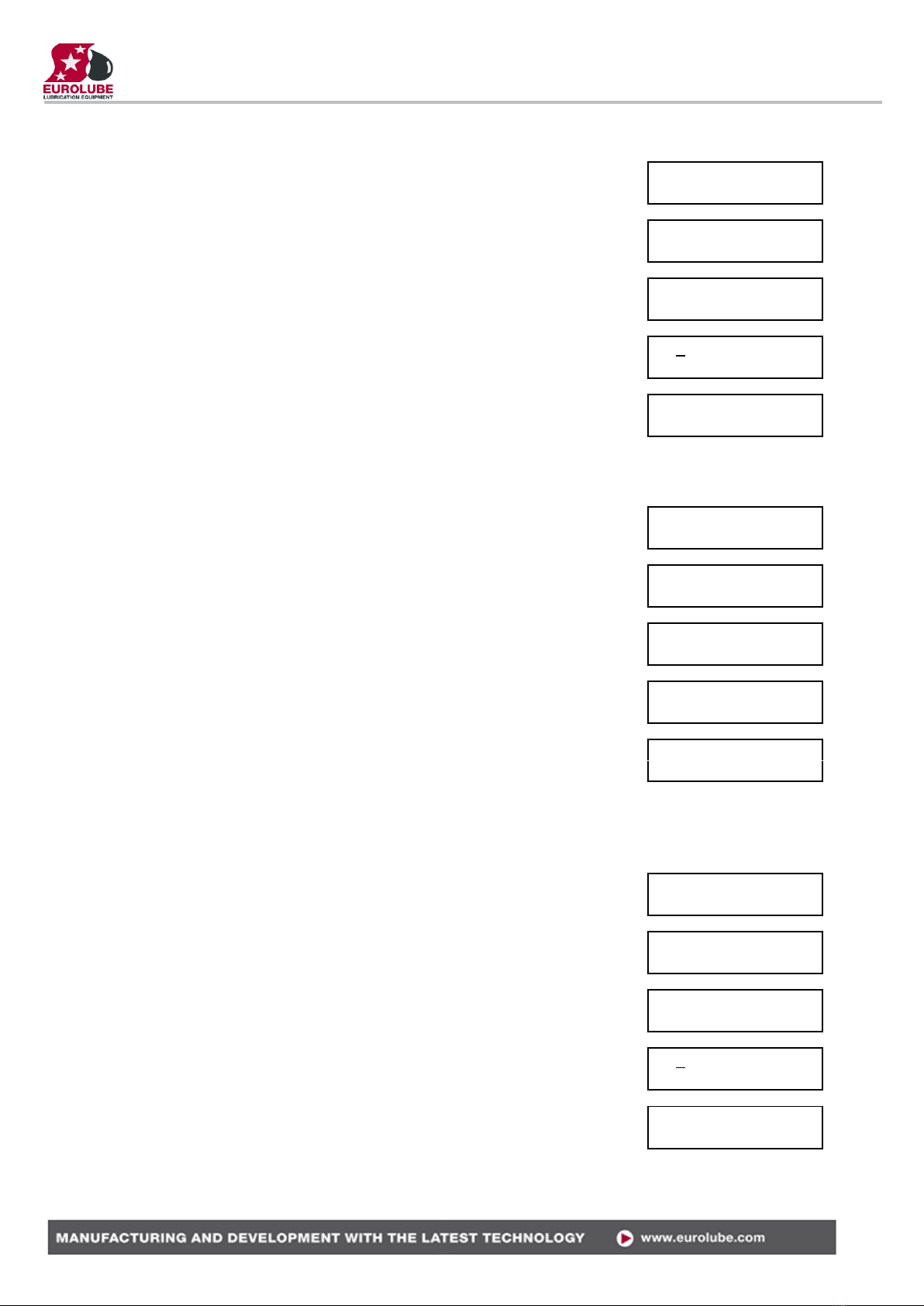

4.5. Recommendation for setting addresses

Each module demands a unique 16 bit hexadecimal address. There are

some forbidden and some reserved addresses but it is possible to use all

addresses between 0001 and 9999. To make it easier to upgrade and

support the system we recommend using the chart to the right.

This means that the first TCM should have the address 8001 and the next

one 8002 etc. It is a good idea not to use the default address 8000, it

makes it easier to add new Tam’s

NOTE! It is essential to add modules to the configuration sheet

continuously as they are configured to avoid collisions.

NOTE! Address 0000 is forbidden and addresses above 9999 are

reserved for the system.

5. Configure the ports

A TCM has four ports that are used to control four different pumps/tanks.

5.1. Connect a tank to a port [TCM//PortX/Tank]

This is only needed for systems using the service TCmS.dll (early versions).

A R6 or later system uses the WinDb Service (WinDB.dll) for this and then

TankNo is only for informational purpose. Use correct TankNo or set all to “0”.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Press ENTER to get the cursor.

Check the number of the tank that is connected to portX, type that number in and

press ENTER to acknowledge. When the cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode.

5.2. Set the Mask [TCM//PortX/Mask]

Using the Mask each tank function can be set. This is done by

adding the values for the desired functions, in the chart to the right.

EXAMPLE: Port 1 measures the level of a waste oil tank and

controls the air to a waste oil pump using an Eurolube 2-levels

sensor 53132. This is up done by calculating the value of the Mask 1+4+8=13. The Mask should be set to 13.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to Mask: using or .

Press ENTER to get the cursor.

Type the mask value and press ENTER to acknowledge. When the cursor

disappears it is finished.

Press EXIT two times to leave Set-Up mode.

Adress Module

0000 Forbidden

1000 –1xxx MPDM

2000 –2998 PM

2999 PC-database

3000 –3xxx KeyPad

4000 –4xxx LED-display

5000 –5xxx PLC-modules

6000 –6xxx Reserved

7000 –7xxx Reserved

8000 –8xxx TCM

9000 –9xxx Others

A000 –FFFF Forbidden

Function Value

Waste oil tank 1

Disable output 2

Invert B 4

Invert A 8

LUBE-MASTER R10

7(20)

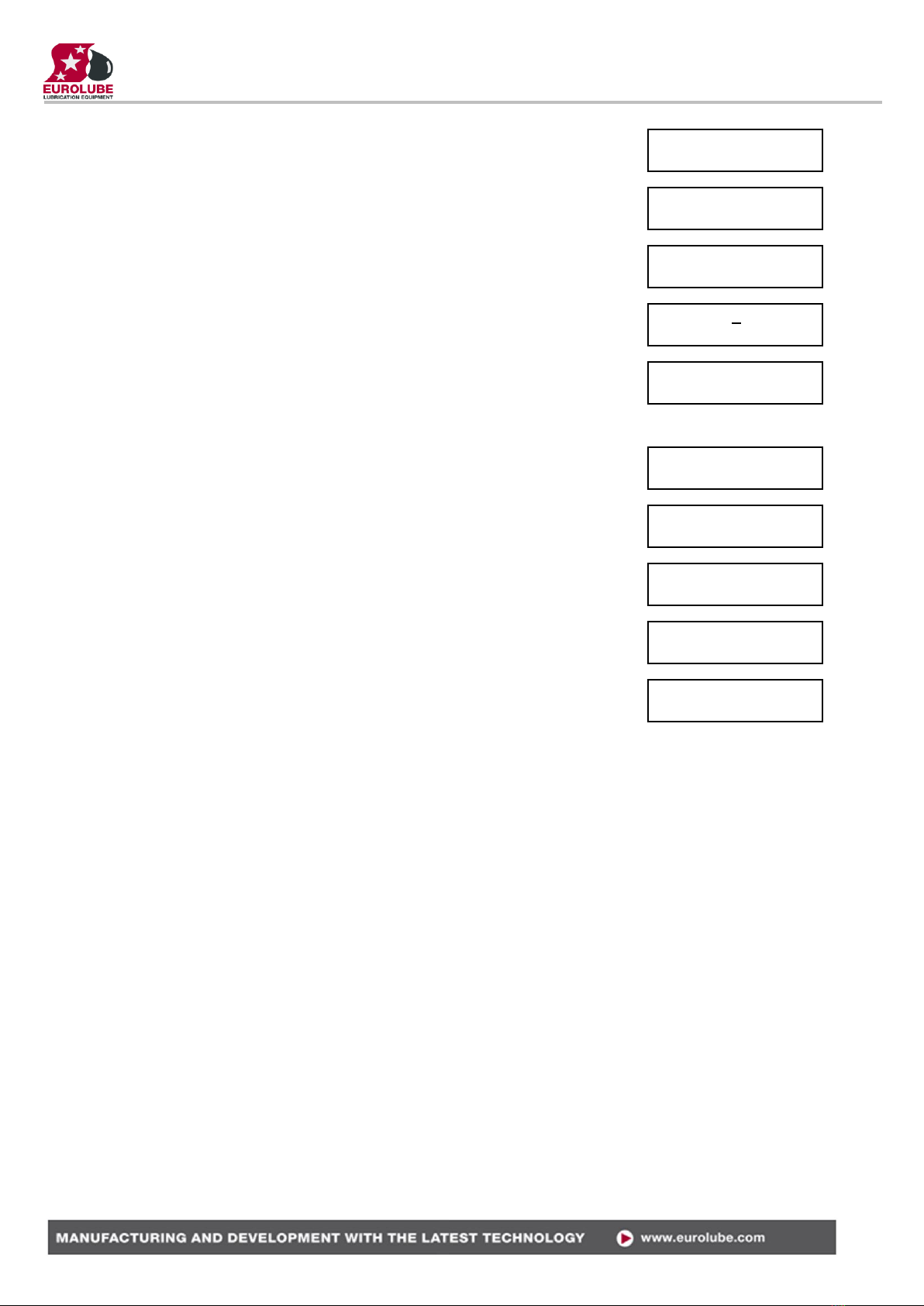

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

O:0.000 ‡

Zero adjust

O:-0.120_ ‡

Zero adjust

O:-0.120 ‡

Zero adjust

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

C:1.000 ‡

Calibration

C:1.000 ‡

Calibration

C:1.000 ‡

Calibration

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

T:6 ‡

Time constant

T:6 ‡

Time constant

T:6 ‡

Time constant

5.3. Analogue sensor settings

5.3.1. Set the input signal filter time constant

This time constant (Tau) is used to filter the sensor signal to create an

accurate tank level. “0” means no filter and a higher value gives slower

response but a more accurate value. The default value of “6” is in most cases

good. It means that for a step in the tank level the reading of the level is on

99,9 % after 30 seconds.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to T: using or .

Press ENTER to get the cursor.

Type the time constant and press ENTER to acknowledge. When the

cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode.

5.3.2. Adjusting the offset

Offset adjusting is used to obtain “0” volume when the tank is empty. If the

sensor 23 417 is used a normal value is –0.080. The “-“ sign is typed on the

keypad by first pressing down arrow (yellow) two times followed by the “?”

mark.

If the tank is empty, put the sensor in the tank at the bottom. If there is fluid

in the tank hold the sensor outside the tank at bottom level. Adjust the offset

value until the tank level shows “0”.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to O: using or .

Press ENTER to get the cursor.

Type the offset value and press ENTER to acknowledge. When the cursor

disappears it is finished.

Press EXIT two times to leave Set-Up mode.

5.3.3. Adjusting the calibration

The calibration factor should normally be set to “1.018” if all other values

are set properly. The intention with the calibration factor is to have a quick

way to make small adjustments.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to C: using or .

Press ENTER to get the cursor.

Type the calibration value and press ENTER to acknowledge. When the

cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode

LUBE-MASTER R10

8(20)

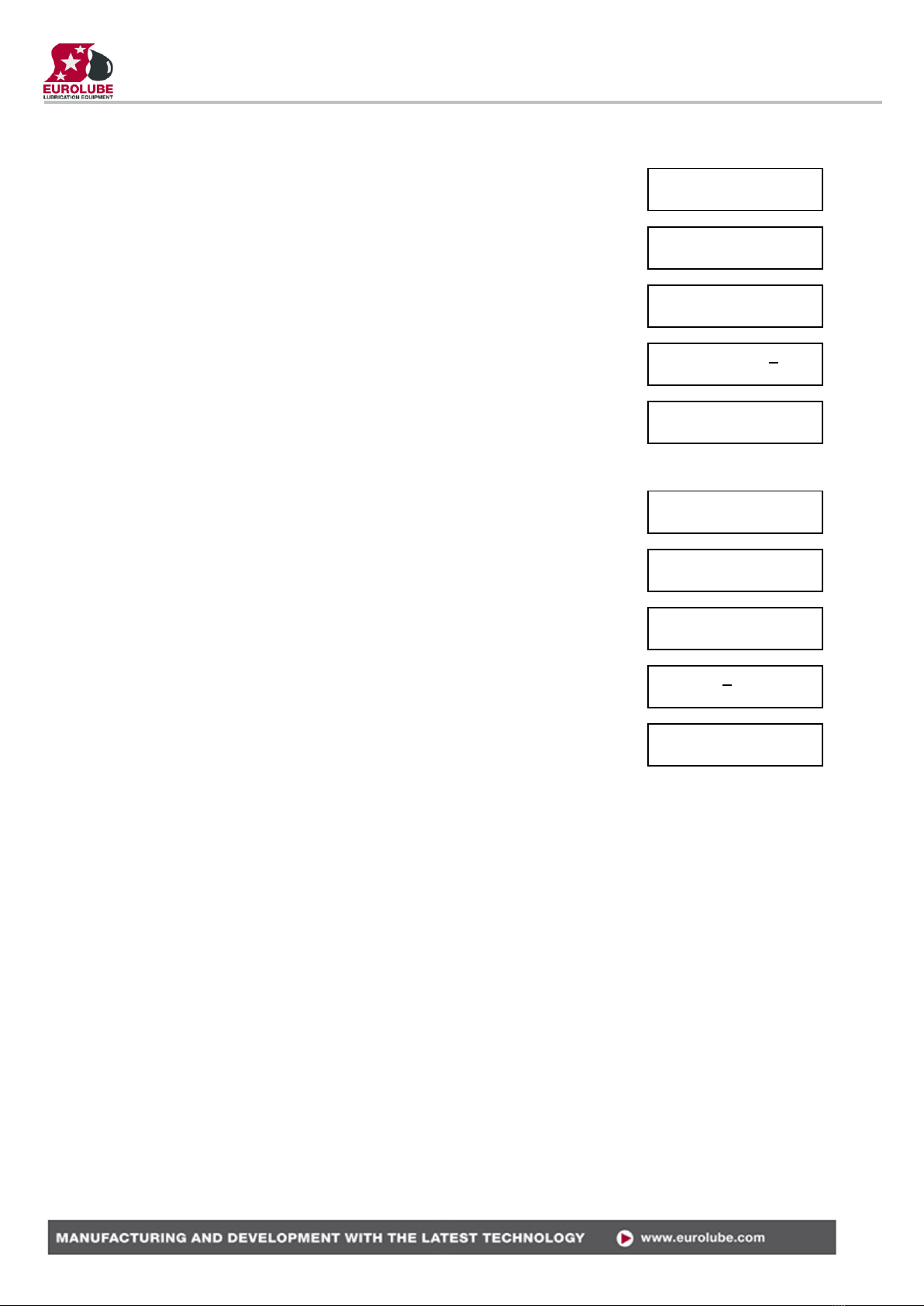

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

SFS:0.400 ‡

Full Scale [bar]

SFS:0.400 ‡

Full Scale [bar]

SFS:0.400 ‡

Full Scale [bar]

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

FN: ‡

Name (max 16 ch)

FN:_ ‡

Name (max 16 ch)

FN:Name ‡

Name (max 16 ch)

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

FP: ‡

Part number

FP:_ ‡

Part number

FP:XXXXXXXXX ‡

Part number

5.3.4. Set sensor full scale

The sensor full scale value is the pressure corresponding to 20 mA. If a

pressure sensor is used the value should be in [bar]. For sensor part number

23 417 the value should be as default “0.400”

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to SFS: using or .

Press ENTER to get the cursor.

Type the sensor full scale value and press ENTER to acknowledge. When

the cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode.

5.4. Fluid specification

5.4.1. Set fluid name

The fluid name set in the TCM makes it possible to show the fluid name in

the info box for the graphic representation of the analogue sensor. It should

be set to the same value as in the PC database.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to FN: using or .

Press ENTER to get the cursor.

Type the name of the fluid and press ENTER to acknowledge. When the

cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode

5.4.2. Set fluid part number

The fluid part number set in the TCM makes it possible to show the fluid

part number in the info box for the graphic representation of the analogue

sensor. It should be set to the same value as in the PC database.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to FP: using or .

Press ENTER to get the cursor.

Type the part number of the fluid and press ENTER to acknowledge.

When the cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode

LUBE-MASTER R10

9(20)

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

D:1.000 ‡

Density [kg/L]

D:1.000 ‡

Density [kg/L]

D:1.000 ‡

Density [kg/L]

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

TankVol:1000 ‡

Set max vol [L]

TankVol:1000 ‡

Set max vol [L]

TankVol:1000 ‡

Set max vol [L]

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

ReVol:1000 ‡

Reorder vol [L]

ReVol:1000 ‡

Reorder vol [L]

ReVol:1000 ‡

Reorder vol [L]

5.4.3. Set the fluid density

If a pressure sensor is used it is essential to set the true density of the fluid

because the pressure at the bottom of the tank depends on fluid level and

fluid density. The density is about 1 Kg/l and for water and 0.875 Kg/l for

mineral oil at 20°C.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to D: using or .

Press ENTER to get the cursor.

Type the Density and press ENTER to acknowledge. When the cursor

disappears it is finished.

Press EXIT two times to leave Set-Up mode

5.5. Tank specification

5.5.1. Set tank capacity

The tank capacity set in the TCM is used to create a true graphic

representation of the analogue sensor status. It should be set to the same

value as in the PC database.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to TankVol: using or .

Press ENTER to get the cursor.

Type the capacity of the tank and press ENTER to acknowledge. When the

cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode

5.5.2. Set the tank reorder volume level

The tank reorder volume set in the TCM is used to create a true graphic

representation of the analogue sensor status and start auto warning if that is

enabled. It should be set to the same value as in the PC database.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to ReVol: using or .

Press ENTER to get the cursor.

Type the reorder volume level of the tank and press ENTER to

acknowledge. When the cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode

LUBE-MASTER R10

10(20)

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

TBA: ‡

Bottom area [m2]

TBA:1.000_ ‡

Bottom area [m2]

TBA:1.000 ‡

Bottom area [m2]

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

StopVol:1000 ‡

Stop vol [L]

StopVol:1000 ‡

Stop vol [L]

StopVol:1000 ‡

Stop vol [L]

5.5.1.Set the tank stop volume level

The tank stop volume set in the TCM is used to create a true graphic

representation of the analogue sensor status and start auto warning if that is

enabled. It should be set to the same value as in the PC database.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to StopVol: using or .

Press ENTER to get the cursor.

Type the stopr volume level of the tank and press ENTER to

acknowledge. When the cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode

5.5.2. Set tank bottom area

Setting the tank bottom area is only usable for a tank with the same

projected area throughout the total tank height.

For other tank forms the profil has to be downloaded to the TCM from a PC.

The area should be in square meters. When the area is typed in and

<ENTER> is pressed the volume for each step on the scale is calculated and

stored in the TCM.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to SFS: using or .

Press ENTER to get the cursor.

Type the sensor full scale value and press ENTER to acknowledge. When

the cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode.

5.5.3. To configure a TCM port for a tank that does not have a constant area

Each TCM port can handle tanks of any shape buy using a tank shape file. To upload a tank shape file to the

TCM module it must be connected to a PC with LUBE-Master WinTools installed. After the tank shape file

has been uploaded the TCM can be disconnected from the PC. For detailed information see the LUBE-

Master WinTools manual.

LUBE-MASTER R10

11(20)

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

LED: ‡

LED Address 4???

TankVol:4XXX_‡

LED Address 4???

TankVol:4XXX ‡

LED Address 4???

TCM: ‡

TCM MainMenu

PortX: ‡

TCM MainMenu

LEDui: ‡

Update interval?

LEDui:1_ ‡

Update interval?

LEDui:1 ‡

Update interval?

5.6. Displaying tank content on a LED display

5.6.1. Set LED address

By specifying a LED address (4XXX) it is possible to show the content of

the tank in real time on a remote or local LED display. Observe that the

addressed LED will not be available for dispensing information.

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to LED: using or .

Press ENTER to get the cursor.

Type the LED address and press ENTER to acknowledge. When the cursor

disappears it is finished.

Press EXIT two times to leave Set-Up mode.

5.6.2. Set LED update interval

The default update interval is 1 second but since tanks seldom changes with

a speed that needs updating every second it good to increase the interval to

free up network for more important things. This is especially good in large

systems.

The interval is set in seconds. A setting of 5 will update the LED every 5

seconds

Enter menu [TCM//PortX] by scrolling with or .

At PortX: press ENTER.

Scroll to LEDui: using or .

Press ENTER to get the cursor.

Type the interval wanted and press ENTER to acknowledge. When the

cursor disappears it is finished.

Press EXIT two times to leave Set-Up mode.

LUBE-MASTER R10

12(20)

5.7. Set the type of tank (PC system).

To make it possible for the PC software to handle tank information, volumes, sensor inputs and valve output it is

necessary to define which TCM port to use, if it is a fresh oil tank or a waste oil tank, if there are any level sensors

connected and of which type if there are.

These settings is done from the PC using the LUBE-Master WinDB Manager software and is described in detail in

the LUBE-Master WinTools Manual. Below is only a short description.

To tell the system which hardware to use for each PC tank the TCM address and TCM port has to be set for all PC

tanks.

Each PC tank could share a TCM port if the same solenoid valve is used to control all pumps. This is not

recommended because of the loss of security and redundance.

The system must be told what hardware there is and how to use it properly. This is done through the Tank Type.

Tank type is set by a string of 0 and 1 were the first position sets if it is a fresh or waste oil tank. The second position

tells if there is a discrete level sensor present or not and the third position defines if there is an analogue sensor

present or not.

Tank type is “0??” for fresh oil and “1??” for waste oil.

Tank type is “?0?” for NO discrete sensor and “?1?” for discrete sensor connected.

Tank type is “??0” for NO analogue sensor and “??1” for an analogue sensor connected.

Example:

TankType = 000, a fresh oil tank without sensors.

TankType = 010, a fresh oil tank with a discrete level sensor.

TankType = 110, a waste oil tank with a discrete level sensor.

TankType = 001, a fresh oil tank with an analogue level sensor.

TankType = 101, a waste oil tank with an analogue level sensor.

TankType = 111, a waste oil tank with both a discrete and an analogue sensor.

LUBE-MASTER R10

13(20)

6. Menu tree

LUBE-MASTER R10

14(20)

7. Fast Menu codes

With a PC, the LUBE-Master WinTools software and a SIO, you can customize the quick menu that appear when you

press ”?” on a keypad. To do this, assign a name to the menu, a module address and then a code. Password is optional.

This code can also be used together with the address after you have typed SETUP followed by the password.

For a TCM-module it will look like this,

Set Mask 80000101 YYYYY where YYYYY=password

Part

Function

Address

Code

Comment

Main menu

Change address

0800

Ports

Change Tank No.

0X00

Where X is the port number

Change Mask.

0X01

Where X is the port number

Only for TCM with analogue sensor support (PCB 203 02 91 A and higher)

Change Time constant

0X02

Where X is the port number

Change Offset

0X03

Where X is the port number

Change Calibration

0X04

Where X is the port number

Change Density of fluid

0X05

Where X is the port number

Change Max volume of tank

0X06

Where X is the port number

Change LED Address

0X07

Where X is the port number

Change Name of Fluid

0X08

Where X is the port number

Change Part number of fluid

0X09

Where X is the port number

Change Sensor full scale

0X10

Where X is the port number

Generate Volume array

0X11

Where X is the port number

Change Reorder volume

0X11

Where X is the port number

Change Stop volume

0X12

Where X is the port number

Change LED update interval

0X13

Where X is the port number

Shows current volume [L]

0X60

Where X is the port number

Show sensor signal [%] &

[mA] (Observe! -Does not

always reflect the content of

tank because it refers to the

sensor max scale not the

max volume of the tank. )

0X61

Where X is the port number

Change Tank area

0X62

Where X is the port number

LUBE-MASTER R10

15(20)

8. Technical specification

Printed circuit board

Net ports: 5 LUBE-Master ports (A) for

data communication, 2 without

+24VDC.

Discrete level inputs: 4 (F), for one or two levels.

Switch or active signal max 50

V. Supports reorder and stop

set-up for both fresh and waste

oil.

Control outputs: 4 (F) for solenoid valve 24

VDC max 1,25 A. Closes after

about 30 s when short

circuited, this is logged in the

database.

Analogue level inputs:4 (G) 4 - 20mA, 24VDC with

10-bit A/D-converters.

Other: RISC-based microprocessor

EEPROM, 64 KB.

Connector (E) for 3-pos key switch. Connector (C) for 24 VDC 6.3A power supply.

SetupLock jumper (H), not used.

Fuses: T6.3A (D) and F1.6A (B)

Max current: 500 mA + 4x1.25 A for solenoid valves.

Casing

Power supply: Primary 230 VAC / 50Hz / 550mA.

Fuse T630mA

Casing: Strong black powder painted steel box

Outer measures: 303 x 228 x 65 mm.

Fitting: 4 x ø5mm

CC = 250 x 175 mm

Weight: 3,9 kg.

Environment

Use: Indoors.

Temperature 0 - +55°C

Humidity 90-95%, not condensing

Transport: Temperature –40 - +70°C

Humidity 90-95%, not condensing

Storage: Temperature –40 - +70°C

Humidity 90-95%, not condensing

LUBE-MASTER R10

16(20)

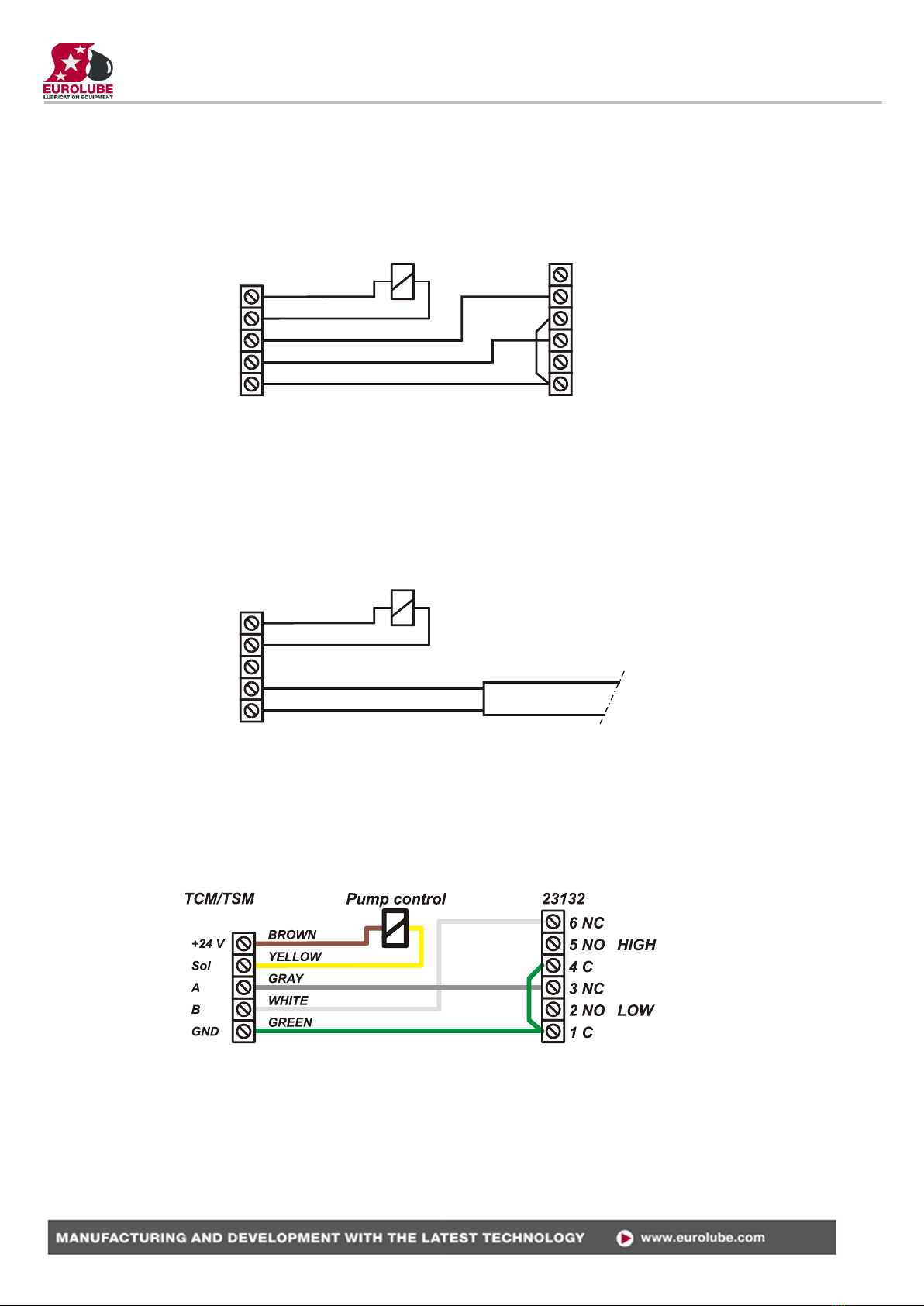

9. To connect discrete level sensors 53132/138/171 and solenoid valves

9.1. Fresh oil tank, 53138 (2-levels)

To achieve a proper function, that is the pump starts only if there are enough oil in the tank, a dispense point is open

and the sensor works properly, the following connection should be made.

The TCM port should be set to control the appropriate PC tank in relation to the physical tank. Correct TankType,

TCMAddress and TCMPort should be set using with WinDB Manager.

MASK =12, TankType = 01?

9.2. Fresh oil tank, 53171/53183 (1-level)

To achieve a proper function, that is the pump starts only if there are enough oil in the tank, a dispense point is open

and the sensor works properly, the following connection should be made.

The TCM port should be set to control the appropriate PC tank in relation to the physical tank. Correct TankType,

TCMAddress and TCMPort should be set using with WinDB Manager.

Mask = 4, TankType=01?

9.3. Waste oil tank, 53132 (2-levels)

To achieve a proper function, that is the pump stops if the physical tank is full or if the sensor is disconnected, the

following connection should be made. Colours are if you use control cable 53412.

The TCM port should be set to control the appropriate PC tank in relation to the physical tank. Correct TankType,

TCMAddress and TCMPort should be set using with WinDB Manager

MASK = 13, TankType = 11?

Solenoid valveTCM 23138

LOW

HIGH

1 C

2 NO

3 NC

4 C

5 NO

6 NC

+24 V

A

GND

B

Sol

Solenoid valveTCM

Blue

Brown 23171

+24 V

A

GND

B

Sol

LUBE-MASTER R10

17(20)

9.4. One TCM port controls a number of pumps

It is possible to control several pumps with only one solenoid valve, that is all pumps starts if one dispense point is

opened. To do this the solenoid valve is connected between +24V and Sol of a TCM port. The port is set to a tank

that does not exist in the PC database and the Mask is set to 0.

For all PC tanks that should be controlled by this solenoid valve the TCMAddress and TCMPort should be set to

this port. Using the WinDB Manager does this.

If this method is used of coarse no level sensor can be used.

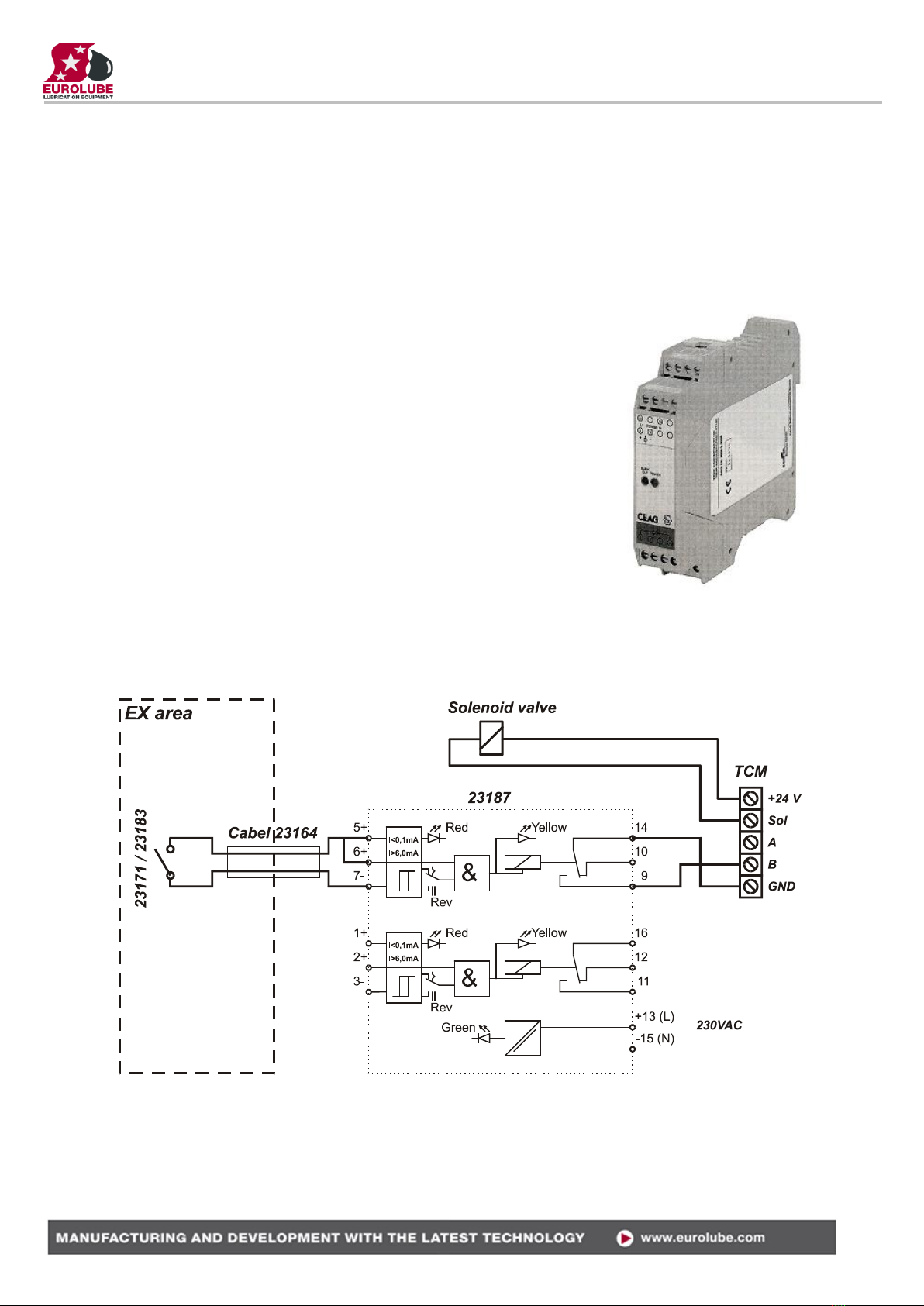

10. EX-barrier 53187 for discrete level sensors.

An EX-barrier is needed between the level sensor and the tank module if the

liquid is classed as flammable. For this purpose the EX-barrier 53178 and a

special EX approved cable 53164 can be used.

The EX-barrier, the solenoid valve that controls the air to the pump and the tank

module should be placed outside the EX-classed area. The EX approved cable

should be used to connect the level sensor on the tank inside the EX-classed area

with the EX-barrier outside the EX-classed area.

Connecting a fresh oil tank 53171/53183 (1-Level).

To achieve a proper function, that is the pump starts only if there are enough oil

in the tank, a dispense point is open and the sensor works properly, the

following connection should be made.

The TCM port should be set to control the appropriate PC tank in relation to the

physical tank.

Correct TankType, TCMAddress and TCMPort should be set using with

WinDB Manager

Mask = 4, TankType=01?

LUBE-MASTER R10

18(20)

10.1.Connecting a waste oil tank 53132 (2-Levels)

To achieve a proper function, that is the pump stops if the physical tank is full or if the sensor is disconnected, the

following connection should be made.

The TCM port should be set to control the appropriate PC tank in relation to the physical tank.

Correct TankType, TCMAddress and TCMPort should be set using with WinDB Manager

MASK = 13, TankType = 11?.

11. To connect an analogue sensor

The four analogue inputs on the TCM support any standard industrial 2-lead / 4-20mA / 24VDC sensors. To connect

sensors a 2-pole connector is used.

11.1.Analogue sensor 53417

The submerged pressure based level sensor 23

417 is a robust sensor that can be used with good

accuracy for tanks with a height of 1 –5 meters.

Max height depends on density of fluid. The

measuring resolution for a TCM with a 23 417

sensor is 4 mm for water and about 4.5 mm for

mineral oil.

Connect the red wire to +24VDC and the black

wire to Sense. +24VDC and Sense are printed on

the PCB.

If the sensor cable (6.5 m) is to short to reach the

TCM it can be lengthen using a standard 2-lead

wire with copper area of 0.5 mm2 for each lead.

For this purpose use the by-packed connection

box.

It is not necessary to use the shield to obtain a good signal because the signal is current based. The shield can be

used for protection grounding purposes if needed.

OBSERVE! It is important that the transparent tube is not blocked and that the humidity protection

filter is used. A blocked tube will cause measuring failure. Not using the humidity protection

could cause sensor malfunction due to corrosion caused by condensed water.

LUBE-MASTER R10

19(20)

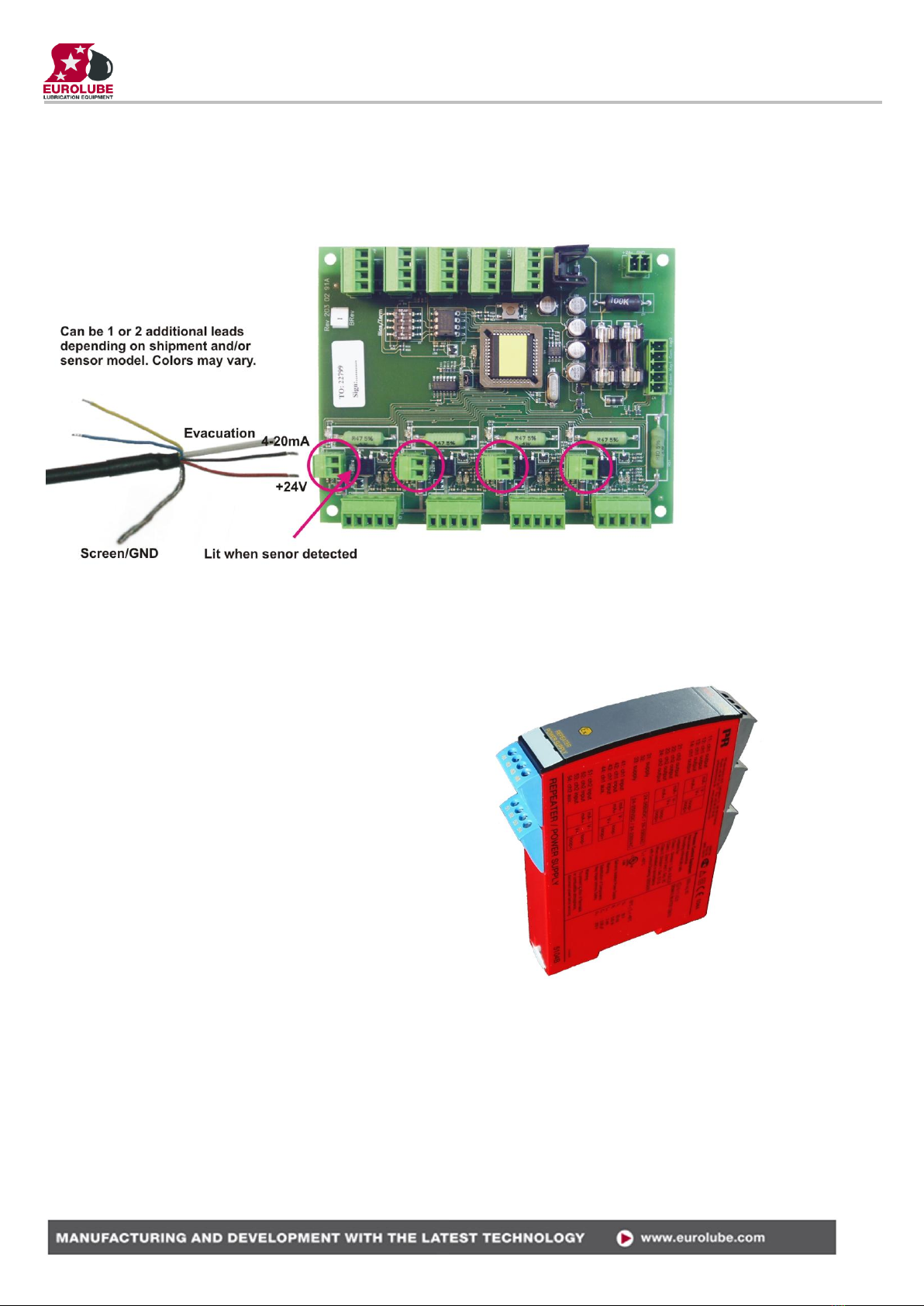

11.2.Connecting an analogue sensor.

The LUBE-Master TCM uses 2-lead 4-20mA 24VDC technique but there are several other techniques that uses

more leads. Because of this the sensor can have more than 2-leads but they are not used.

OBSERVE! Colors may vary between shipments and sensor types so check the sensor manual before

connecting it.

Correct TankType, TCMAddress and TCMPort should be set using with WinDB Manager

MASK = ??, TankType = ??1

12. EX-barrier 53188 for analogue

sensors.

An EX-barrier is needed between the level sensor and

the tank module if the liquid is classed as flammable.

For this purpose the EX-barrier 53188 and a special

EX approved cable p/n 53164 should be used.

The EX-barrier, the solenoid valve that controls the

air to the pump and the tank module should be placed

outside the EX-classed area.

The EX approved cable should be used to connect the

level sensor on the tank inside the EX-classed area

with the EX-barrier outside the EX-classed area.

LUBE-MASTER R10

20(20)

12.1.Connection

The analogue EX-barrier 53188 can handle 2 analogue sensors. Here is shown how to connect an analogue sensor

23 417 to a TCM port using channel 1 of the EX-barrier.

NOTE! The lead colours of the sensor may vary depending on the shipment and make but there are always +,

- and GND/Screen. Known variations are “+” is RED, “-“ is BLACK or BLUE and GND is

YELLOW or SCREEN.

In the connection sample picture the leads of the blue EX-Cable (53164) has for visibility been given

different colours, in the real cable they are black with figures.

13. MPDM PCB mounted in a TCM box

In a small system or at limited space it is possible to mount an additional module PCB in a TCM. In this example a

MPDM board is added. To do this the TCM PCB has to be moved and turned one quarter of a turn. See pictures below:

Make sure that the TCM is disconnected from the mains power supply and the LUBE-

Master network before any work is started. Use a voltmeter to make sure that there

is no power.

To the left is how the standard TCM looks like

inside.

Turn the TCM PCB a quarter of a turn and

place it at the top of the box. Move the plastic

distances to the holes which make it possible

to place the PCB as shown in the picture to the

right. Do not damage the cabling.

Fasten the short plastic distances so the new card can be placed closest to the bottom like

in the picture.

Table of contents

Other Eurolube Control Unit manuals