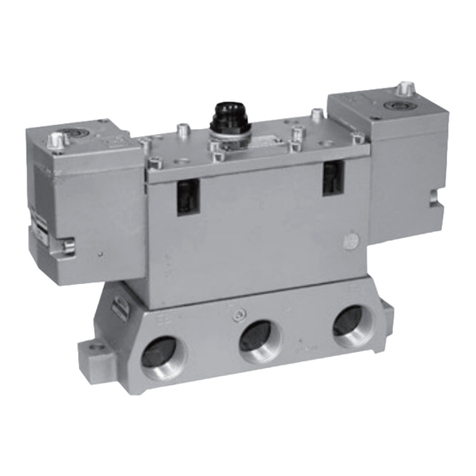

Proval A240 NAMUR Manual

Operation & Maintenance Manual of A240 NAMUR Solenoid Valves

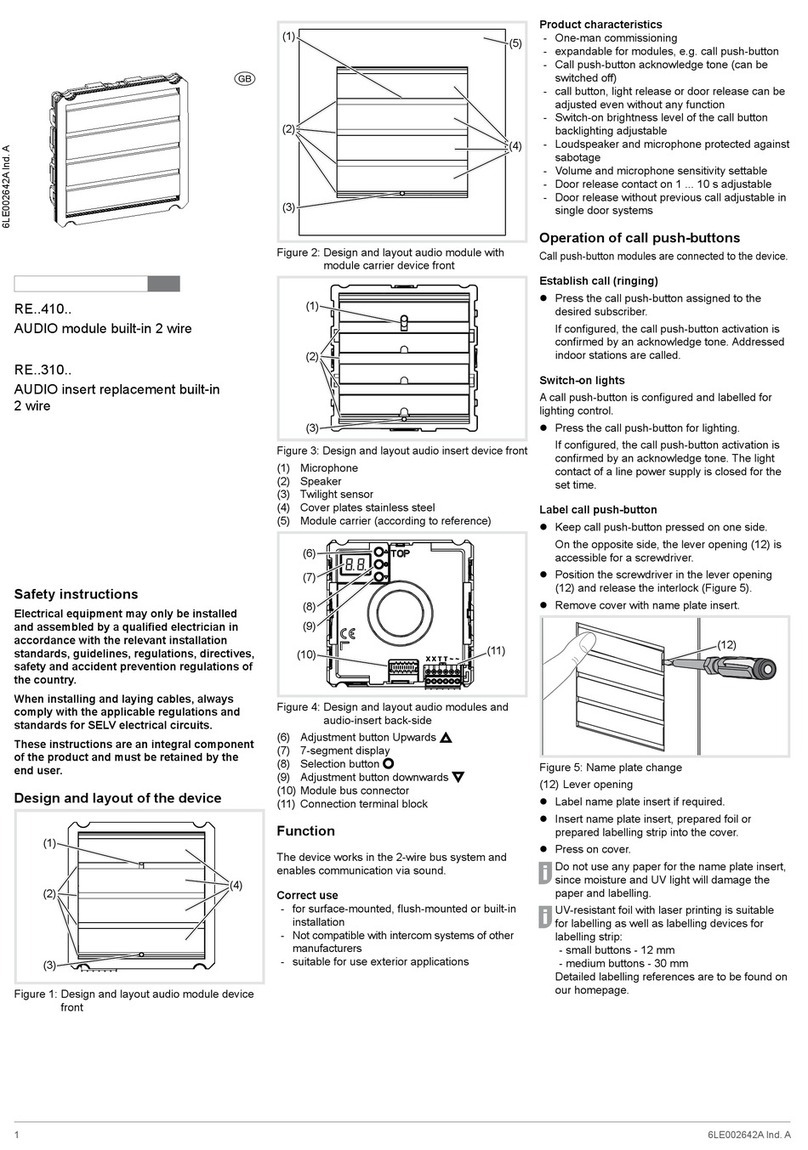

1. Description

PROVAL A240 NAMUR Type Solenoid valves are designed for use on double and single acting pneumatic valve actuators with

compressed air or non-corrosive and non flammable gases. Please keep this manual for your future reference and maintenance.

2. Areas of Application

PROVAL A240 NAMUR Solenoid valves can be used on Standard industrial applications

as well as in explosive atmospheres with gases or combustable dust of the category 2

Group II according to EN 13463-1 only if suitableexplosion proof coil (magnet) is used.

This manual only refers to valve body and does not cover the coil (magnet). Please refer

to coil (magnet) manufacturers application details. In case of use of explosion proof

coils, due to thickness of coil an extension adaptor plate is required to be used between

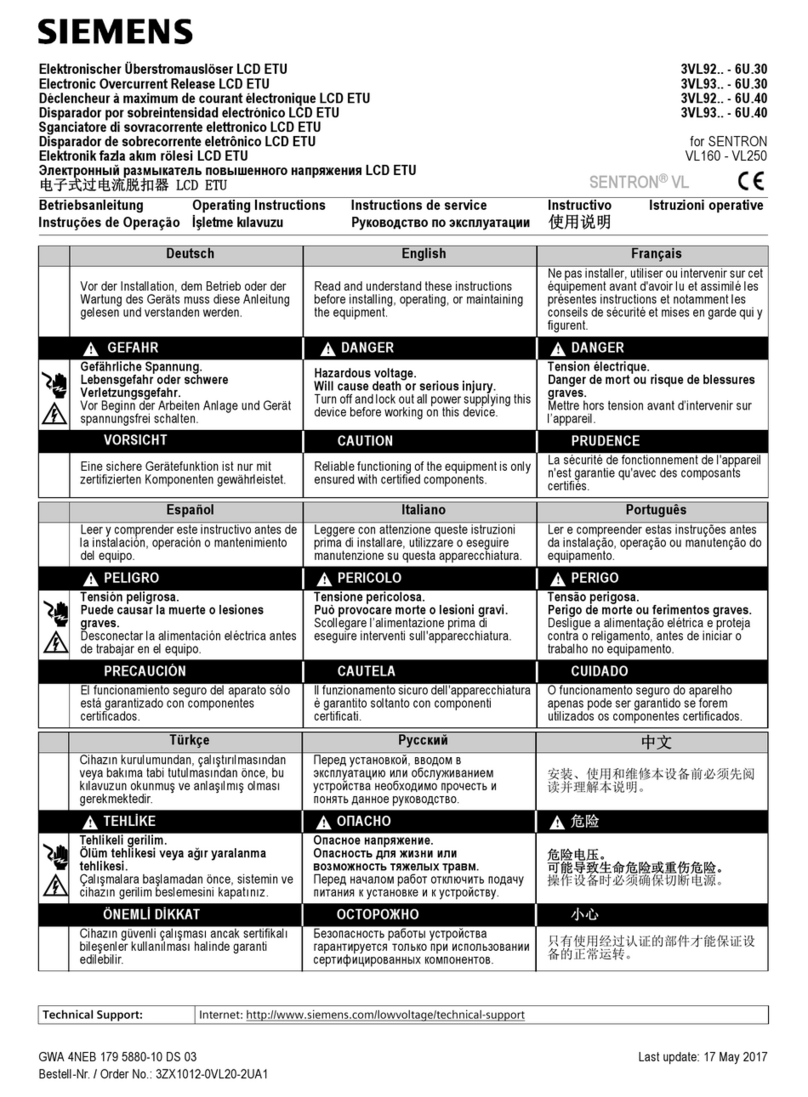

the valve and the actuator. Figure-1 : Label of Solenoid Valves

3. Main Parts & Dimensions

In order to avoid any failure, the solenoid valves must be

installed and initiated by skilled persons. Please read carefully

the below instructions and follow up the steps carefully.

• Verify that the valve is correctly chosen for your application

• Please take appropriate measures to avoid accidental activation

and improper external influence

• Consider the manual of the magnet coil manufacturer for the

electrical initiation

• Protect the equipment and cables from any damage

• Avoid static charging or peripheral devices

• Ensure that the equipment will be available for regular cleaning

• Avoid strong bending of air tubes

Coil

Nut

O-Ring

Coil With Connector

Explossion Proof

Coil (magnet)

Functional

Sealing

Valve

Body

1/4"

G/NPT

Main

Air

Inlet

(Port.1)

1/4"

G/NPT

Exhaust

Port

(Port.3)

1/4"

G/NPT

Exhaust

Port

(Port.5)

Manual

Override

All ports must remain open. The solenoid valve will not be able to operate if any unused ports are clsoed.

Use only suitable silencers / speed reducers to avoid dirt coming inside the valve.

During the functioning of the valve the magnet coil is heating-up. In order to avoid burning do not touch

the coils while operating.

Operation & Maintenance Manual of A240 NAMUR Solenoid Valves

4. Assembly of Solenoid Valves

PROVAL A240 NAMUR Type Solenoid valves are 3/2 Way (for single acting actuators) and 5/2 way (for double acting actuators)

convertible design. In order to change the valve from 3/2 way to 5/2 way just turn the functional sealing through 180° and place to

its position.

Please ensure that functional sealing is in correct position.

If functioanl seal is extending

upper side and shows the arrow

3/2, than valve functions as 3/2 way

If functioanl seal is extending

lower side and shows the arrow

5/2, than valve functions as 5/2 way

Front side view of 5/2 Valve

Back side view of 5/2 Valve

Front side view of 3/2 Valve

Back side view of 3/2 Valve

3/2 Way Valve 5/2 Way Valve

Correct Assembly

Way of Functional

Sealing

Wrong Assembly

Way of Functional

Sealing

When the solenoid valves are set for the right

position (function) they can be mount on

any NAMUR interface pneumatic actuators.

The mounting position is user defined but

preferably with an upterned coil (magnet)

position.

Operation & Maintenance Manual of A240 NAMUR Solenoid Valves

5. Disassembly of Solenoid Valves

Please consider the safety instructions given on Chapter-3.

5.1. Disconnect the supply voltage line and remove the pneumatic air supply tube

5.2. Disconnect all leads from the solenoid valve

5.3. Release the hexagon socket screws and remove the solenoid valve from the actuator

6. Air Supply Ports

Working pressure of PROVAL A240 Solenoid valves is between 3.0 to 8.0 bar compressed air or non flammable gases.

Please ensure that solenoid valves are feeded with filtered and dry air. Mulfunction, due to dirt inside of the solenoid

valve will not be the covered in warranty conditions.

Air is connected from Port Nr.1 (Main Air Inlet Line) and Ports Nr.3 and Nr.5 are for exhaust and must never be closed and allways to be

kept free for exhaust purposes during operation of solenoid valves.

1/4" Size silencers (Proval A145) can be used to avoid the dirt or dust coming into the solenoid valve or adjustable speed reducer with

silencer (Proval A146) can be used for regulating the speed of actuators to avoid water hammer in the process line because of the very

fast closing of the valves as well as reducing the noise of exhaust air as in A145 Silencers.

7. Operation

Operate the solenoid valves only with filtered (clean) and lubricated or non-lubricated compressed air with a quality level 5 according

to ISO8573-1. Corrosive and explosive gases are not allowed to use in any case. In areas with temperature with below 0°C it is highly

necessary to use dried air.

Please allways consider the indicated temperature class of the coil (magnet) which is marked on. The non-electric parts of the valve

will not heat up as the coils.

• Bending or torsion on operator of solenoid valve will cause damage and the valve will not operate properly

• Overpressure on operation will cause damages on the valves

• Avoid contacts with corrosive gases and liquids

8. Maintenance

Check the connections regularly for both electrical and pneumatic supply. In case the valve is not operating check if the air pressure is

in required range. Unless otherwise clearly specified, supplied valves are sized for actuators working in 5.6 bar standard industrial

pressure range. If the coil is not functioning it may be burned and will require to be replaced. If the valve is not operating properly

please remove the coil, and remove the valve from actuator and dismantle it completely, clean from any dirts, check for o-rings on

piston; clean it and re-assemble and test it for proper functioning.

If you require any further assistance please contact your local dealer or the factory at below details.

Before start up please ensure that the correct voltage coils are used. Operate the solenoid valves only with filtered (clean) and

lubricated or non-lubricated compressed air with a quality level 5 according to ISO8573-1. Corrosive and explosive gases are not

allowed to use in any case. In areas with temperature with below 0°C it is necessary to use dried air.

In order to avoid any mechanical damage please handle the valves properly. Bending or torsion on

operator of solenoid valves will cause damage and the valve will not operate properly

Popular Control Unit manuals by other brands

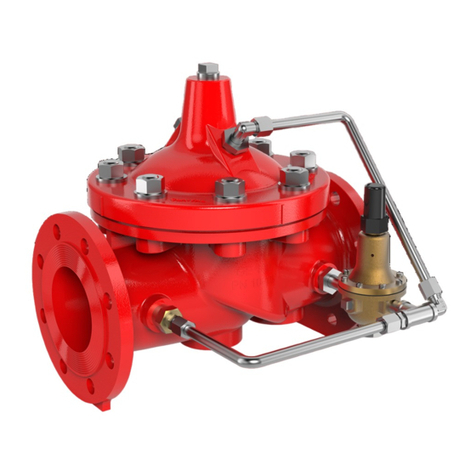

CLA-VAL

CLA-VAL 90G-21 UL Installation, operation & maintenance manual

thermital

thermital TBOX BASIC R Installation, operation and maintenance manual

Pari

Pari 041F05 Instructions for use

Immergas

Immergas MAGIS PRO 5 ERP Instruction and recommendation booklet

Laird

Laird BTM521 user manual

Watts

Watts AMES 979GD-20 Installation, operation and maintenance