EUTHANEX SMARTBOX EA-32000 User manual

1

Auto CO2Lab Control Unit

Model – EA-32000

1-877-559-0159 Toll Free Euthanex Corp. / E-Z Systems

1-610-882-3801 Fax P.O. Box 3544

www.ezsystemsinc.com Palmer, PA 18043

2

Table of Contents

Disclaimer and Lab Control Unit

Overview …………………………………………………………………………….3

Safety Instructions……………………………………………………………………4

System Set-Up..………………………………………………………………………5

Operating the System…………………………………………………………………8

Changing System Presets…..…………………………………………………………9

Flow Rate & Preset Times …………..………………………………………………11

EMC / EMI.

This equipment has been tested and found to

comply with the limits for a Class A Equipment,

pursuant to part 15 of the FCC rules.

IEC 61326-1:2005 / EZ 61326-1:2006

For the customers in Canada:

This Class A Equipment complies with

Canadian ICES-003:2012.

Cet appareil numérique de la classe A est

conforme à la norme NMB-003:2012 du Canada.

3

THIS MANUAL MUST BE READ BEFORE SETTING UP AND OPERATING

THE SMARTBOX AUTO CO2SYSTEM. The user should be thoroughly familiar with

the contents of this manual prior to using the system with animals. Only technicians that

are properly certified should operate the system.

The user/owner of this equipment shall have the sole responsibility for any damage or

injury resulting from operation that is not in accordance with the authorized instructions.

This includes, but is not limited to, operating the equipment outside of recommended

safety levels, variation from specified operating instructions, and not following standard

laboratory safety procedures when working with anesthetic agents and volatile

compressed gases.

The system and its components must only be modified or repaired by Euthanex

authorized service technicians. Improper modification or repair may result in danger to

personnel, harm or death to animal, and/or equipment damage. The user/owner of this

equipment shall have the sole responsibility for any damage or injury resulting from

improper maintenance and repair that is not done by authorized maintenance and repair

personnel.

Parts that have failed, in whole or in part, exhibit excessive wear, are contaminated or are

otherwise at the end of their useful life, should not be used and should be replaced with

parts supplied by Euthanex Corporation. Tampering with the main control unit by

unauthorized personnel automatically voids all warranties and specifications. The

manufacturer assumes no responsibility for any malfunction or failure of the unit if

tampering is suspected.

Overview:

The Lab Control Unit utilizes a programmable logic controller (PLC) that delivers a set

volume of CO2into an individual animal cage through the Euthanex Lid. The controller

unit operates at a fixed flow rate that is set at your external CO2source. Gas flows from

the external source into the Lab Control Unit. A solenoid valve opens to output gas to the

Euthanex Lid. After the euthanasia cycle is completed, the Lab Control Unit

automatically shuts the gas off.

The EA-31000 model treats a single cage or chamber.

The Lab Control Unit comes with one preset gas delivery timing. The EA-31000 offers a

single programmable timing. It is highly recommended that only designated, trained

personnel make adjustments to the timings, to ensure safe and effective settings.

Please refer to the “Flow Rate & Preset Times” section to derive the AVMA

recommended flow rate.

4

The lightning flash with an arrowhead

symbol within an equilateral triangle, is

intended to alert the user to the presence of

uninsulated "dangerous voltage" within the

product's enclosure that may be of sufficient

magnitude to constitute a risk of electric shock to

persons.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this unit near water.

6. Do not clean by spraying liquid directly onto

unit.

7. Do not block any ventilation openings.

Install in accordance with the manufacturer's

instructions.

8. Do not install near any heat sources such

as radiators, heat registers, stoves, or other

unit that produce heat.

9. Do not defeat the safety purpose of the

polarized or grounding-type plug. A

polarized plug has two blades with one

wider than the other. A grounding type plug

has two blades and a third grounding

prong. The wide blade or the third prong

are provided for your safety. If the provided

plug does not fit into your outlet, consult an

electrician for replacement of the obsolete

outlet.

10. Protect the power cord from being walked

on or pinched particularly at plugs,

convenience receptacles, and the point

where they exit from the unit.

11. Unplug this unit during lightning

storms or when unused for long periods of

time.

12. Refer all servicing to qualified service

personnel. Servicing is required when the

unit has been damaged in any way,

such as power-supply cord or plug is

damaged, liquid has been spilled or objects

have fallen into the unit, the

unit has been exposed to rain or

moisture, does not operate normally, or has

been dropped.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in

the literature accompanying the product.

Warning!

To reduce the risk of fire or electric shock,

do not expose this unit to rain or

moisture.

Use line cord supplied with the product.

Be advised that different operating voltages

require the use of different types of line

cord and attachment plugs. The unit was

shipped with the requested plug. If the

installation requirements change please

contact us for the correct plug.

This equipment should be installed near the

socket outlet and disconnection of the device

should be easily accessible.

Do not install in a confined space.

Do not open the unit - risk of electric shock

inside.

Caution: You are cautioned that any change or

modifications not expressly approved in this

manual could void your authority to operate

this equipment.

Service

There are no user-serviceable parts inside.

All service must be performed by qualified

personnel.

Voltage 100-240 v ac 50-60hz 1 amp Max (auto

select)

Pressure 75 psi max to inlet

Temp 0 to 40°C <> 10 to 85% RH (no

condensation)

5

System Set-Up:

1. Four mounting brackets are utilized to secure the controller unit to the wall. These are

on the controller when shipped.

2. Using a Phillips head screwdriver, loosen the screws and move the mount tabs outward

as pictured below. Tighten the screws once appropriate position is achieved.

6

3. With the mounting brackets moved, position the unit in the appropriate location on the

wall and mark the four holes. Remove unit from wall and drill the holes. Secure the unit

to the wall with appropriate screws. (Wall screws are not included.)

4. Connect the external CO2gas line from the regulator or flow meter, to the gas input of

the Lab Control Unit. Check the Flow Rate Guide to determine the correct LPM settings.

7

5. Connect the supplied cage hose from the output of the Lab Control Unit to the input

valve on the Euthanex Lid. To properly make the connection, pull back the coupler and

slide it over the male stem. The coupler will snap back into place and secure the

connection.

GAS WILL NOT FLOW INTO LID IF THE COUPLER IS NOT PROPERLY

ATTACHED.

6. Place the Euthanex Lid on the cage, and the system is ready for operation.

8

Operating the Lab Control Unit:

1. Be sure CO2source is open, and the regulator/flow-meter is set to the correct flow rate.

2. Move the rocker on/off button located on the bottom of the unit to the “On” position.

The green “Ready” light will turn on.

3. The EA-32000 offers two distinct timing choices. Select the desired timing cycle by

moving the toggle switch either up or down.

4. To begin the euthanasia cycle, press the toggle toward the desired species.

The red “Run” light will turn on, indicating that the cycle is operating.

When the cycle is complete, the red light will shut off and the gas flow will stop.

The green “Ready” light will turn on, indicating the cycle is complete and the

system is ready to run the next cycle.

Start

Toggle

9

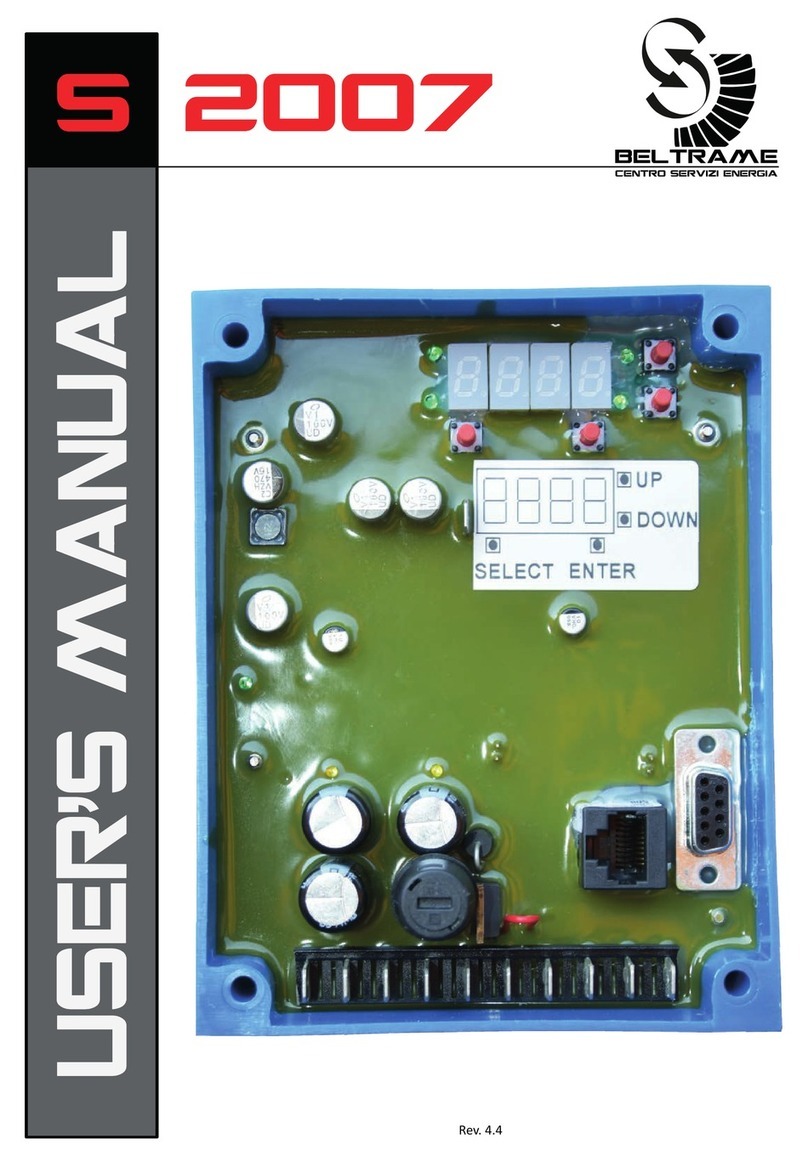

Changing the System Presets:

Before any service is done that would require opening the unit it must be

disconnected from the power source. If your location has lockout-

tagout protocols please follow them.

Preset times were determined based on extensive testing done by Euthanex Corp. and

designed to comply with the latest guidelines of the AVMA Panel on Euthanasia. Refer

to the Flow Rate to determine AVMA compliant flow rates and the timing presets. The

following is the procedure for changing the preset times:

1. Release the two latches to open the controller door.

2. The start-up screen will appear on the PLC.

3. To change the preset cycle times, press “ESC”. The option screen will appear.

4. Press the down button to move the arrow to: “> Set Param”. Press “OK”.

10

5. “Timer 1” screen will appear.

Press “OK” and the first number will begin to flash.

Use the Up/Down keys to increase or decrease the value.

Use the Right/Left keys to move the cursor to the number you would like to

change.

After the proper time is set, press “OK”.

Note: Only the T = 00:00m will be set. The Ta = 00:00 is not a programmable function.

6. The EA-32000 offers two programmable timer settings. Press the Up/Down keys to

navigate the timer choices. When the desired timer appears, repeat step five to change the

time.

7. After settings the timers, press the “ESC” button twice to return to the opening screen.

The Lab Control Unit is now ready to operate. Close and latch the door.

11

F series IDEC or Siemens:

1. Release the two latches to open the controller door.

2. The clock screen is on the PLC.

3. To change the preset cycle times, press ESC, then OK. The option screen will appear.

4. Press the down button , to move the arrow to: “> Program”. Press OK.

5. Press the down button , to move the arrow to: “> Set Parameter”. Press OK.

6. The password screen appears. Use the up/dw and Rt/Lt arrow to input password

"CLUTCH" then hit OK

12

6. Timer select screen appears. This screen is maybe different that the picture based on

the program loaded.

* Use the up/down keys to move to the value to change.

* Press “OK” and the screen will change. Press the right arrow until s large box

will be over the timer.

* Press “OK” and the box will become small and over the first value of the timer.

* Use the right/left keys to move the cursor to the number you would like to

change.

* Use the up/down keys to increase or decrease the value.

* Use the right/left keys to move the cursor to the number you would like to

change.

* After the proper time is set, press OK. The box will change back to large.

Note: only the T = 00:00m will be set. The Ta = 00:00 is not a programmable function.

13

6. After setting the timers, press the “ESC” button to return to the main screen.

Use the up key to move to start, hit "OK" button, use left arrow to move to Yes, Hit "OK"

button.

The Lab Control Unit is now ready to operate. Close and latch the door.

Flow Rate & Preset Times:

Default times were chosen to comply with the latest guidelines of the AVMA Panel

on Euthanasia and through extensive testing performed by Euthanex Corp. Times are

customizable to facility needs. The programmable times may be changed by a

designated administrator.

Preset Times: The units are pre-programed for Adult and Neonates unless

otherwise request at time of order.

Position 1 (Adult) = 5 minutes

Dwell = 5 minutes

Position 2 (Neonate) = 7 minutes

Dwell = 60 minutes

How to derive AVMA compliant flow rate from chamber size (for a single chamber):

Height(in) x Width(in) x Length(in)= Liters x 20% = flow rate

61

The 2013 AVMA Euthanasia Guidelines recommend 10 – 30% fill rate.

Other EUTHANEX Control Unit manuals

Popular Control Unit manuals by other brands

Nice

Nice IBT4ZWAVE Instructions and warnings for installation and use

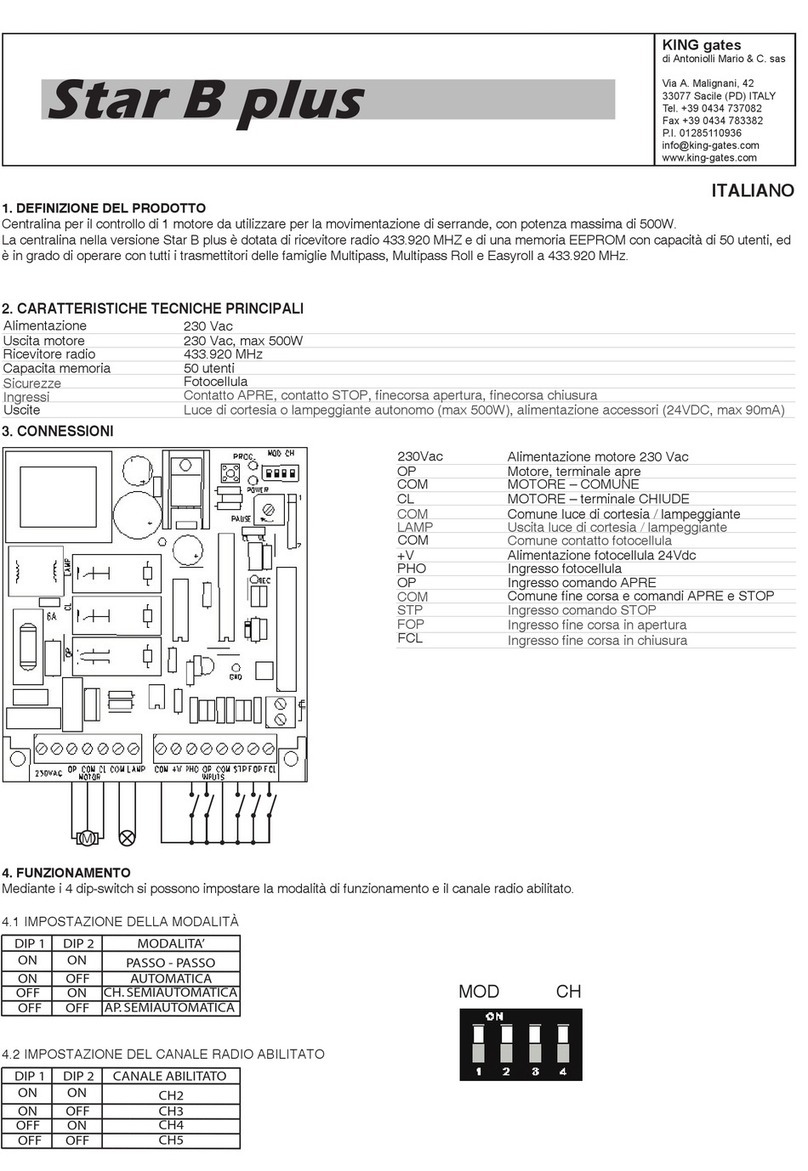

King gates

King gates Star B plus quick start guide

Samson

Samson 41-23 Series Mounting and operating instructions

Dormakaba

Dormakaba UNIQUIN Mounting instructions

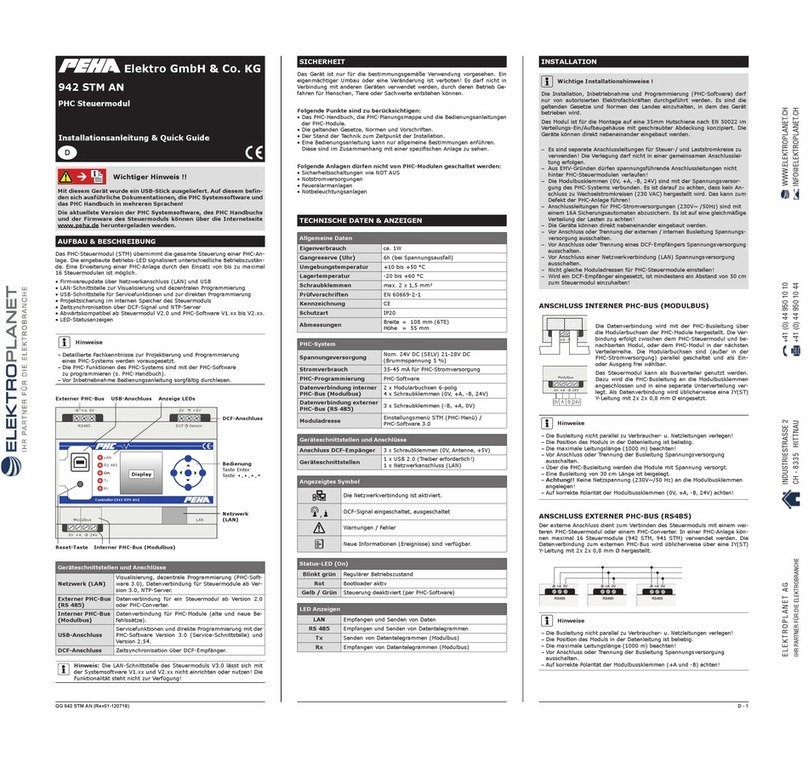

PEHA

PEHA 942 STM AN Installation Instructions and Quick Guide

BENDIX

BENDIX R-6 RELAY VALVE manual

DM Engineering

DM Engineering Mic Pro user guide

L&L

L&L TLR04M-350-700 installation instructions

QTS

QTS Level-Trac LT-310 Installation, operation and instruction manual

Akerstroms

Akerstroms Trux 700 user manual

Kintech Engineering

Kintech Engineering BGAN Installation & antenna orientation

Allen-Bradley

Allen-Bradley 1794-VHSC user manual