EUTHANEX SMARTBOX PRODIGY EA-3300TS User manual

AutoCO2System

PRODIGYEA‐3300TS

877‐559‐0159TollFreeE‐ZSystems/EuthanexCorp.

610‐882‐3800PhoneP.O.Box3544

610‐882‐3801FaxPalmer,PA18043

www.euthanex.com[email protected]

2

TABLE OF CONTENTS

Disclaimer____________________________________ 3

SystemOverview_______________________________ 4

Safety________________________________________ 5

SystemSetup__________________________________ 6

OperatingtheSystem___________________________9

AdministratorInstructions_______________________13

Troubleshooting_______________________________23

EMC / EMI.

This equipment has been tested and found to

comply with the limits for a Class A Equipment,

pursuant to part 15 of the FCC rules.

IEC 61326-1:2005 / EZ 61326-1:2006

3

DISCLAIMER:

THISMANUALMUSTBEREADBEFORESETTINGUPANDOPERATINGTHESMARTBOXAUTOCO2

SYSTEM.Theusershouldbethoroughlyfamiliarwiththecontentsofthismanualpriortousingthe

systemwithanimals.Onlytechniciansthatareproperlytrainedshouldoperatethesystem.

Theuser/ownerofthisequipmentshallhavethesoleresponsibilityforanydamageorinjuryresulting

fromoperationthatisnotinaccordancewiththeauthorizedinstructions.

Thisincludes,butisnotlimitedto,operatingtheequipmentoutsideofrecommendedsafetylevels,

variationfromspecifiedoperatinginstructions,andnotfollowingstandardlaboratorysafetyprocedures

whenworkingwithanestheticagentsandvolatilecompressedgases.

ThesystemanditscomponentsmustonlybemodifiedorrepairedbyEuthanex®authorizedservice

technicians.Impropermodificationorrepairmayresultindangertopersonnel,harmordeathto

animal,and/orequipmentdamage.Theuser/ownerofthisequipmentshallhavethesoleresponsibility

foranydamageorinjuryresultingfromimpropermaintenanceandrepairthatisnotdonebyauthorized

maintenanceandrepairpersonnel.

Partsthathavefailed,inwholeorinpart,exhibitexcessivewear,arecontaminatedorareotherwiseat

theendoftheirusefullife,shouldnotbeusedandshouldbereplacedwithpartssuppliedbyEuthanex

Corporation.Tamperingwiththemaincontrolunitbyunauthorizedpersonnelautomaticallyvoidsall

warrantiesandspecifications.Themanufacturerassumesnoresponsibilityforanymalfunctionorfailure

oftheunitiftamperingissuspected.

4

OVERVIEW:

TheSMARTBOX®Prodigyallowsadministratorstoprogramanunlimitednumberofcagesandsizes.The

administratoronlyneedstoselecttheflowratepercentage.TheEA‐33000TSwillautomaticallycalculate

therequiredflowrate.Anunlimitednumberofpassword‐protectedusersaddsevenmoreflexibility.

Eachusercanonlyseethecagesauthorizedbytheadministrator.Theusercanconnectupto3cagesat

onetime.TheTouchScreendisplayshowsthecycle,cycletime,andtotaltimeremaining.

Pleaserefertothe“FlowRate&PresetTimes”sectiontoderivetheAVMArecommendedflowrate.

POWER

SWITCH

DC

POWER

GASIN

GASOUTLETS

TOCAGES

T

h

s

y

i

n

u

n

pr

m

pe

1.

2.

3.

4.

5.

6.

7.

8.

9.

1

0

1

1

1

2

h

e lightning fla

s

y

mbol within an

n

tended to alert t

h

n

insulated "dan

g

r

oduct's enclosu

r

m

agnitude to con

s

e

rsons.

Read these i

n

Keep these i

n

Heed all wa

r

Follow all i

n

Do not use t

h

Do not clea

n

unit.

Do not bloc

k

Install in ac

c

instructions.

Do not insta

l

as radiators,

unit that pro

d

Do not defe

a

p

olarized or

p

olarized pl

u

wider than t

h

has two bla

d

p

rong. The

w

are provided

p

lug does n

o

electrician f

o

outlet.

0

.Protect the p

on or pinche

d

convenience

where they

e

1

.Unplug this

u

storms or w

h

time.

2

.Refer all ser

v

p

ersonnel. S

e

unit has bee

n

such as pow

e

damaged, li

q

have fallen i

n

unit has bee

n

moisture, do

e

b

een droppe

d

s

h with an arrow

equilateral tria

n

h

e user to the p

r

g

erous voltage"

w

r

e that may be o

f

s

titute a risk of

e

n

structions.

n

structions.

r

nings.

n

structions.

h

is unit near wa

t

n

by spraying liq

u

k

any ventilatio

n

c

ordance with th

e

l

l near any heat

s

heat registers, s

t

d

uce heat.

a

t the safety pur

p

grounding-type

u

g has two blad

e

h

e other. A grou

n

d

es and a third g

r

w

ide blade or th

e

for your safety.

o

t fit into your o

u

o

r replacement

o

ower cord from

d

particularly at

receptacles, an

d

e

xit from the uni

t

u

nit during ligh

t

h

en unused for l

o

v

icing to qualifi

e

e

rvicing is requ

i

n

damaged in an

y

er

-supply cord o

q

uid has been sp

i

n

to the unit, the

n

exposed to rai

n

e

s not operate n

o

d

.

hea

d

n

gle, is

r

esence of

w

ithin the

f

sufficient

e

lectric shock to

t

er.

u

id directly ont

o

n

openings.

e

manufacturer'

s

s

ources such

t

oves, or othe

r

p

ose of the

plug. A

e

s with one

n

ding type plug

r

ounding

e

third prong

If the provide

d

u

tlet, consult an

o

f the obsolete

being walke

d

plugs,

d

the point

t

.

t

ning

o

ng periods of

e

d service

i

red when the

y

way,

r plug is

i

lled or objects

n

o

r

o

rmally, or has

5

o

s

The

e

inten

d

oper

a

the li

t

War

n

Caut

Serv

i

Volt

a

Press

u

Tem

p

e

xclamation poi

n

d

ed to alert the

u

a

ting and mainte

n

t

erature accomp

a

n

ing!

To reduce

t

do not exp

o

moisture.

Use line co

Be advised

require the

cord and at

t

shipped wi

t

installation

contact us

f

This equip

m

socket outl

e

should be

e

Do not inst

Do not ope

n

inside.

ion: You are ca

u

modificati

o

manual co

u

this equip

m

i

ce

There are

n

All service

personnel.

a

ge 100-

2

selec

t

u

re 175

p

p

0to

con

d

n

t within an equ

i

u

ser to the prese

n

n

ance (servicin

g

a

nying the prod

u

t

he risk of fire o

r

o

se this unit to r

a

rd supplied wit

h

that different o

p

use of different

t

achment plugs.

t

h the requested

requirements c

h

f

or the correct p

l

m

ent should be

i

e

t and disconne

c

e

asily accessible

.

all in a confine

d

n

the unit - risk

u

tioned that any

o

ns not expressl

y

u

ld void your au

t

m

ent.

n

o use

r

-servicea

b

must be perfor

m

2

40 v ac 50-60h

z

t

)

p

si max to inlet

40

°

C<>10to

8

d

ensation)

i

lateral triangle

i

n

ce of importan

t

g

) instructions i

n

u

ct.

r

electric shock,

a

in o

r

h

the product.

p

erating voltage

s

types of line

The unit was

plug. If the

h

ange please

l

ug.

i

nstalled near th

e

c

tion of the devi

c

.

d

space.

of electric shoc

k

change o

r

y

approved in th

i

t

hority to operat

b

le parts inside.

m

ed by qualifie

d

z

5 amp Max (a

u

8

5%RH(no

i

s

t

n

s

e

c

e

k

i

s

e

d

u

to

SYS

T

Theunit

c

1.Theu

n

mounted

2.Conne

theProdi

g

3.Conne

c

valveon

t

WARNIN

G

closedan

thesafet

y

T

EM SE

T

c

omeprepro

g

n

itsitsonthe

tothewall

w

cttheextern

g

ylocatedo

n

c

tthesupplie

t

heEuthanex

GAS

W

G

‐Aminimu

m

dwillnotop

e

y

popoffvalv

T

U

P

:

g

ramwithba

s

tabletopor

c

w

iththeoptio

alCO

2

gaslin

n

theleftside

dcagehose

f

Lid.Theuni

t

W

ILLNOTFLO

m

ofonecag

e

e

nuntilconn

e

etoeruptor

s

esetting.A

d

c

anattachto

nalwallmou

efromtheP

S

.Checkthe

F

f

romtheout

p

t

willsuppor

t

WINTOLIDI

e

mustbeco

n

e

cted.Failur

internalhos

e

6

d

ditionalcha

ametalsurf

a

ntingbracke

t

S

Iregulator

o

F

lowRateGu

i

p

utofthePr

o

t

operationo

f

FTHECOUP

L

n

nected.All

q

etodosowi

e

stodisconn

ngescanbe

m

a

cewiththe

m

t

.

o

rin‐linePSI

r

i

detodeter

m

o

digy(locate

d

f

3cagesina

L

ERISNOTP

R

q

uickdiscon

n

llcauseover

ect.

m

ake.Ref.t

o

m

agneticfee

t

r

egulator,to

t

m

inethecorr

e

d

ontherigh

t

cycle.

R

OPERLYATT

A

n

ectfittings

a

pressurizati

o

o

Page12

t

,Itcanalso

b

t

hegasinput

e

ctPSIsettin

g

t

side)tothe

A

CHED.

a

renormally

o

nandmyre

s

b

e

of

g

s.

input

s

ultin

7

4.PlacetheEuthanexLidonthecage.Toproperlymaketheconnection,pullbackthecouplerandslide

itoverthemalestem.Thecouplerwillsnapbackintoplaceandsecuretheconnection.Thesystemis

readyforoperation.

Setfor20PSIout.

5.AttachtheheatedregulatortotheCO2tank.ItisrecommendedthatTeflontapebeusedontheCO2

tankthreadsbeforeattachingregulator.Useawrenchtotightenthemountedregulator.Setfor20

PSIout.

Werecommendsettingtheincomingpressureto20PSIbutdonotexceed35PSI.Theunitwill

workonlowincomingpressurebutmayresultintheinabilitytoachievehigheroutputflow

rates.

Note:TheEA‐550ElectricallyHeatedRegulatorisrecommendedtooperatethesystem.Usinganon‐

heatedregulatorwilllikelyresultinfrozenCO2lines.

Setupisnowcomplete.

Theimag e cann ot be disp layed. Yo ur comp uter may not hav e enou gh memory too pen the image, o r the image may h ave been co rrup ted. Restart yo ur comp uter, and then op en the file again . If the r ed x still app ears, y ou may hav e to d eleteth e image and then insert it again.

MountedHeatedRegulator

OPE

R

1)Press

foru

s

runni

2)Ensu

r

3)Open

gaug

e

4)Open

flow

o

Setther

e

WARNIN

G

closedan

thesafet

y

Werec

o

The

achi

e

PSIG

a

Gas

V

R

ATING

theOnswit

c

s

e.Ifthisist

h

nganycycle

s

r

ethelid(s)h

a

thegasflow

e

shouldber

e

thegasflow

o

fgastothe

c

e

gulatorto2

G

‐Aminimu

m

dwillnotop

e

y

popoffvalv

o

mmend

s

unitwill

w

e

vehighe

r

a

uge

V

alve

THE S

Y

c

hinthebac

k

h

efirsttime

u

s

(seeadmini

s

a

sbeenplac

e

fromtheCO

2

e

ading800‐

8

outofther

e

c

ontroller.

0PSI.

m

ofonecag

e

e

nuntilconn

e

etoeruptor

s

ettingthe

w

orkonlo

w

r

outputfl

o

Y

STE

M

:

k

oftheunit.

u

singthesys

t

s

tratorinstru

c

e

donthecag

2

tankbytur

n

8

50PSIifthe

t

e

gulatorbyt

u

e

mustbeco

n

e

cted.Failur

internalhos

e

incoming

w

incomin

g

o

wrates.

8

Theunitwill

t

emtheoper

a

c

tionspg13)

e(s)andhos

e

n

ingthetank

t

ankisfull,l

e

u

rningtheco

n

n

nected.All

q

etodosowi

e

stodisconn

pressure

t

g

pressure

bootandco

m

a

tingparam

e

.

e

sarecorrec

t

valveknobc

o

e

ssifitisnot

a

n

trolbarcou

n

q

uickdiscon

n

llcauseover

ect.

t

o20PSIb

butmayr

e

C

T

a

m

etotheho

m

e

tersmustbe

t

lyattachedt

o

unterclock

w

a

fulltank.

n

terclockwis

e

n

ectfittings

a

pressurizati

o

utdonot

e

e

sultinth

e

C

O

2

TankVal

v

a

nkPressure

G

m

escreenre

a

setupprior

t

otheunit.

w

ise.Thelar

g

e

.Thisbegin

s

a

renormally

o

nandmyre

s

e

xceed35

e

inability

t

v

e

G

auge

a

dy

t

o

g

ePSI

s

the

s

ultin

PSI.

t

o

9

5)FromtheHomeScreenpress"Start".

Ifpasswordsareactivatedthenextscreenwillbepasswordenter.

6)Selectthecagetypebytouchingthescreenonthecagedesired.Ifthereisalargeamountof

registeredcages,youwillneedtoscrollthroughalisttofindyourdesiredselection.Thenhitnext.

PowerShutdownButton

10

7)Nextyouwillneedtoconfirmthehoseconnectionmessage,thenselectthenumberofcagestobe

usedinthecycle.

NOTE:Thesystemsupportsupto13lpm@20PSI.Ifmultiplelargevolumecagesareselectedandthe

flowrateisexceeded,thesystemwillautomaticallyadjustthecagenumberfortheallowable

amountofconnectedcages.

8) Thesystemwillcyclethroughtwostages:

Stage1Charge:Gasflowstothecages,fullychargingthemwithCO2.

Stage2Dwell:GasflowstopsandthecagesremainsfullychargedwithCO2.

Option:Ifprogrammed,thesystemwillperformasecondCO2chargeanddwellcycle.

11

9)Theredemergency“STOP”iconmaybepressedatanytimetostoptheeuthanasiacycle.A

passwordmayberequiredtoengagethestop(adminsetting).Gasflowwillimmediatelycease.

NOTE:Ifthereisnogaspressureontheinletoftheunitduetothehosenotbeingconnectedorthe

supplyhasrunout,thebelowscreenwillappear.

12

ADMINISTRATOR INSTRUCTIONS:

Changing Operating Specifications

Default flow rates and times were chosen to comply with the latest guidelines of the AVMA

Panel on Euthanasia and through extensive testing performed by Euthanex. Flow rates and

times are programmable and may be changed by a designated administrator. Flow rates

and times are password protected for security.

The Charge stage delivers the CO2, humanely euthanizing the animals. After all gas has

been delivered, the Dwell stage allows the gas to remain in the chamber for a pre-set

amount of time, ensuring proper euthanasia.

CO2Time: This determines the amount of time “CO2” is to be delivered during the

euthanizing stage.

Dwell: After all gas has been delivered, the dwell stage allows the gas to remain in the

cage for a preset amount of time, ensuring proper euthanasia.

2nd CO2Time: This determines the amount of time “CO2” is to be delivered during the 2nd

Charge euthanizing stage.

2nd Dwell: After gas has been delivered for the 2nd Charge, the Dwell stage allows the gas

to remain in the cage for a preset amount of time, ensuring proper euthanasia.

Flow Rate: This is the calculate amount of gas to be delivered for the cage based on the fill

rate percentage. The gas flow rate is delivered in liters per minute (lpm).

13

1. FromtheHomeScreenpress"Admin".

2. EntertheAdministrator4digitpassword(defaultis7777andcanbechangedonceintheadmin

settingsscreen)andpressNext.

14

3. TheAdminOptionsScreenwillappear.

a. AddNewCage

i. UsethistoaddnewCagetypesforcycle.Thisincludessettingthecagesizeand

desiredflowratepercentage.

b. EditExistingCage(Willdisplaycurrentsettings)

i. Usetochangeoperatingparametersofdefinedcagesthatarealreadyinthe

system.

c. ChangeSystemParameters

i. Usetochangebasicsystemsettings.

d. AddNewUser

i. Setupnewusernameandpassword.

e. EditUser

i. Changeusernamesorpasswordsthatarealreadyinthesystem.

f. ChangeAdminPassword

g. Thedownarrowwilltakeyououtofthesoftwaretothedesktoptoallowforremote

serviceconnection.Pleasecontactsupport.

15

4. ToAddNewCage,selectfromadminscreen

a. Theaddnewcagescreenwillbedisplayed.

b.Typeinthelabelofthecagethatyouwanttoadd,thenhitnext.

c.Thecagedimensionsortotalvolumemustbeenteredonthisscreen.

Thesystemwillcalculateyourcagevolumebasedonthedimensionsspecified.

d.Wheninputiscompletepress"Next".

16

e.Thedesiredflowratepercentageneedstobesetforthenewcagetype.Usethe+/‐to

adjusttheflowpercentageyouwouldlike.Theunitcalculatesyourflowratebasedonthe

cagedimensionsthatwereenteredonthepreviousscreen.Press"Next"whenset.

f.Nowthetimesneedtobesetforthenewcage.Usethe+and–nexttothetimestobe

adjusted.

g.Ifasecondchargeisneeded,Usethe+and–nexttothetimestobeadjustedfor

secondchargeinputtimes.

h.Oncethesettingarecorrectpress"Save",anditwillreturntotheAdminscreen.

5. ToEditCage,selectfromAdminscreen

a. Selectthecagesthatyouwouldliketoeditfromthepop‐upmenu,thenhitok.

17

b. Thecurrentparametersfortheselectedcagewillbedisplayed.

c. Tomakechangesselect"Edit",andfollowtheinstructionsforaddinganewcage.

6. C

hangeSyste

m

a. Select

Setla

n

b. Scree

n

c. Elimin

d. Gasw

a

e. Ifyou

tocon

f. WIFIs

Select

g. Updat

h. Backu

p

these

t

asyo

u

i. When

A

m

Parameter

s

ifthesyste

m

n

guage,use

d

n

savertime

o

atesthegas

c

a

rningOn,th

needustoc

o

necttotheu

ettings.Use

d

thenetwork

e,usedtou

p

p

/Restore,

t

t

tingparame

u

areconnect

e

allchanges

a

s

,selectfrom

m

willrequire

d

tochoosed

e

o

utsetting.B

c

onnection

w

isadjuststh

e

o

nnecttoyo

u

nit.E

d

toconnect

t

andsecurity

p

datethePro

d

t

hesystemc

a

terswillbes

a

e

dtoWIFI.

a

remadesel

e

F

18

adminscree

apasswordf

e

siredinterf

a

w

arningoncy

c

e

timetoacti

v

u

runitforse

r

t

heunittoy

o

protocolthe

d

igysoftwar

e

a

nbebacked

a

ved.Youca

e

ctSave.

B

C

n

oruseroper

a

a

celanguage.

c

lerun.C

v

atethewar

n

r

vicesupport

,

o

urWIFInet

w

nenterthe

p

e

iftheuniti

s

uptoourse

r

nrestoreth

e

D

W

W

a

tion.AIfth

i

n

ingofnoga

s

,

thisistheI

D

w

ork.F

p

assword.Hi

t

s

connectedt

o

r

viceandsu

p

e

parameters

E

W

IFIisconn

e

W

IFIinNOT

c

i

sistunedof

f

s

flow.D

D

thatwewill

t

Save.

o

theinterne

p

portserver.

atanytimea

s

e

cted

c

onnected

f

then

need

t.

Allof

s

long

19

7. AddNewUser

a. Typeintheusernamethatyouwishtoadd.

b. Settheuserpassword.

i. SelectiftheuserwillhaveEmergencyStopbuttonduringthecycle.

ii. Selectifitwillrequireanadminpasswordtoengage.Ifyouselecttousesystem

password,thisopenstheoptionoflimitingthecagesthatausermayselector

operation

iii. OncecompletehitSave.

c. The"RequireAdminPasswordforemergencystop"flagifcheckedwillrequirethe

Administratorpasswordtobeenteredtostopacycle.Ifnocheckismadetheuserwill

beallowedtoinvokethestopwithnopasswordduringacycle.

NOTE:Ausercannotbesavedwithoutselectingcagesandcagequantitiesfortheuser.

20

d. Cagescanbeactivatedperuser,hitthe"Cages"icon.

e. Toactivateacage,placeachecknexttoallthecagesthattheuserwillhaveaccessto

whenloggedin.Hit"OK"tosave.

f. Thequantityofcagesthatcanbeselectedbythisusercanbelimitedbyselectingthe

g. "Quantity"button.

Table of contents

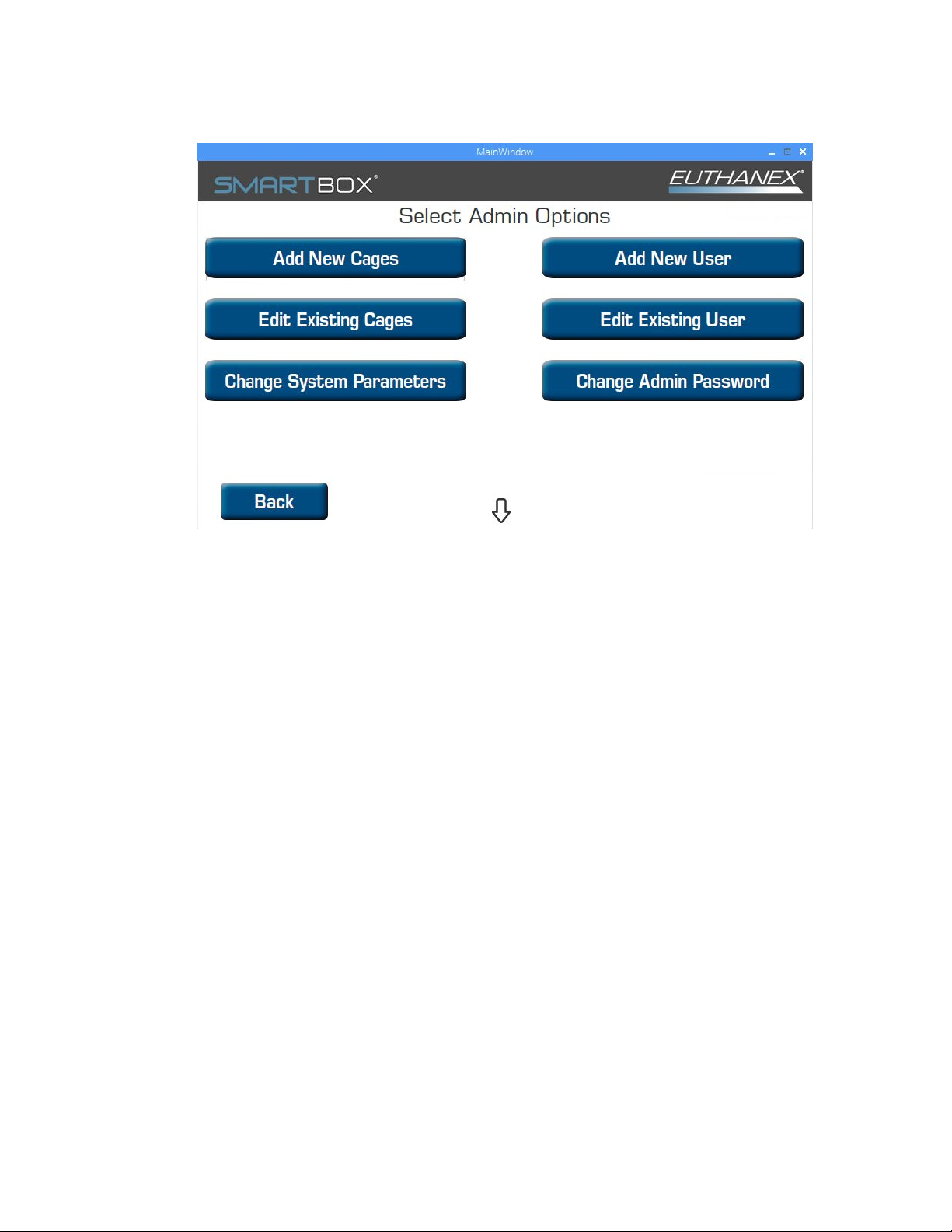

Other EUTHANEX Control Unit manuals