Evac 910 Manual

EVAC 910 WALL TOILET

TECHNICAL INFORMATION

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved.

TECHNICAL DATA

Date: Doc.

VACUUM TOILET

1

6543418 EVAC 910, WALL MODEL, PRESTIGE SILENT, WHITE

6543419 EVAC 910, WALL MODEL, MOSAIK, WHITE

6547226 EVAC 910, WALL MODEL, PRESTIGE SOFT CLOSING, WHITE

09 Dec 2010 001991-3

* Prestige seat and cover fulll ANSI Z124.5 - 1997 [Plastic Toilet ( Water closet ) Seats] requirements.

** See available colours in document 002003-7

Materials Bowl: White vitreous china**

Seat; *Prestige and Prestige Soft Closing: UF-S**, Mosaik: PP**

Cover; *Prestige and Prestige Soft Closing: UF-S **, Mosaik: PP**

Pneumatic push button: White plastic, ABS

Discharge valve; plastic parts: PP, rubber parts: NR

Operating data Water pressure: 3 - 10 bar

Operating vacuum: -0.3 ... - 0.6 bar

Water consumption: ~1.2 ±0.15 litres/ush ( water pressure: 4 bar, vacuum: -0.4 bar )

Air consumption: ~60 ±10 litres/ush (normal atmospheric air)

Connections Water supply: 1/2” MPT, exible hose

Discharge: Discharge connection Ø50, connection sleeve includes two hose clamps

to O.D. 48 - 52mm pipes

Shipping data P/N 6543418 Evac 910, wall model, Prestige Silent and

P/N 6547226 Evac 910, wall model, Prestige Soft Closing:

Net weight: 20.8 kg

Shipping weight: 23.1 kg

Shipping volume: 0.168m3

P/N 6543419 Evac 910, wall model, Mosaik:

Net weight: 17.7 kg

Shipping weight: 19.7 kg

Shipping volume: 0.168m3

Water supply 1/2”

Shut-off valve

Vacuum breaker

P/N 6541458 Pneumatic push button, white

Max. 420

230

550

Max. 450

110

365

50 430

Seat and cover:

*Prestige, Mosaik or Prestige Soft Closing

Bowl

Connection sleeve

Discharge connection

250

400

Flexible water

connection hose

45

Edge strip

Ø50

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

TECHNICAL DATA

Date: Doc.

09 Nov 2010 1:01005G

6541458 PNEUMATIC PUSH BUTTON, WHITE

Materials Cover: ABS, white

Button: PBT, white

Bottom plate: POM, natural

Connections Hose nipple Ø4

Shipping data Net weight: 0.2kg

40

58

170

60

Ø 4.5

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved.

TECHNICAL DATA

Date: Doc.

VACUUM TOILET

1

09 Dec 2010 002003-7

STANDARD COLOURS, EVAC 910, WALL MODELS AND FLOOR MODELS

Product

no. Toilet name

Toilet bowl Seat and cover

Standard colour code Standard colour code Additional

colours*

min. 250

pcs / order

min. 1000

pcs / order

min. 1000

pcs / order

6543418 Wall model, Prestige Silent 01 white 01 white X

6543419 Wall model, Mosaik 01 white 01 white

6543420 Wall model USPH, Prestige Silent 01 white 01 white X

6543421 Wall model USPH, Mosaik 01 white 01 whitw

6544766 Wall model USPH, Open front 01 white 01 white

6544791 Wall model USPH, Prestige Silent, autoush 01 white 01 white X

6544792 Wall model USPH, Prestige Silent, autoush

10 Light grey 10 Light grey

X

30 Light green 30 Light green

68 Pregamon,

light beige

68 Pergamon,

light beige

6544793 Wall model, Prestige Silent

10 Light grey 10 Light grey

X

30 Light green 30 Light green

68 Pregamon,

light beige

68 Pergamon,

light beige

6544794 Wall model USPH, Prestige Silent

10 Light grey 10 Light grey

X

30 Light green 30 Light green

68 Pergamon,

light beige

68 Pergamon.

light beige

6545030 Wall model, B15, Prestige Silent 01 white 01 white X

6545031 Wall model USPH, B15, Prestige Silent 01 white 01 white X

6545818 Wall model USPH, Prestige Silent, autoush 01 white 01 white X

6546081 Wall model USPH, Prestige Silent, autoush

10 Light grey 10 Light green

X

30 Light green 30 Light green

68 Pergamon,

light beige

68 Pergamon,

light beige

6547226 Wall model, Prestige Soft Closing 01 white 01 white X

6547227 Wall model USPH, Prestige Soft Closing 01 white 01 white X

Product

no. Toilet name

Toilet bowl Seat and cover

Standard colour code Standard colour code Additional

colours*

min. 250

pcs / order

min. 1000

pcs / order

min. 1000

pcs / order

6545825 Floor model, Silent 01 white 01 white X

6545826 Floor model, Trevi 01 white 01 white

6545827 Floor model USPH, Silent 01 white 01 white X

6545828 Floor model USPH, Trevi 01 white 01 white

6545829 Floor model USPH, Open front 01 white 01 white

COLOURS FOR FLOOR MODEL TOILETS

COLOURS FOR WALL MODEL TOILETS

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved.

TECHNICAL DATA

Date: Doc.

VACUUM TOILET

2

09 Dec 2010 002003-7

STANDARD COLOURS, EVAC 910, WALL MODELS AND FLOOR MODELS

Bowl, seat and cover are available in white and in standard colours. Standard colours are shown in the standard

colour palette.

! NOTE: Evac 910 vacuum toilets with the Mosaik, Trevi or Open front seats and covers are available only in

white colour.

When you order a toilet in standard colour you must give the toilet’s part number, the name and the standard

colour code. Example: 6544794 Wall model USPH, Prestige Silent, 30 Light green.

* You can order the Prestige and the Silent seats and covers in additional colours only in large series. When you

order seat and cover in additional colours you must give an international colour code like the Muncell or RAL.

01 White 10 Light grey 68 Pergamon,

light beige

30 Light green

Standard colour palette

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

INSTALLATION

Date: Doc.

09 Dec 2010 001998-5

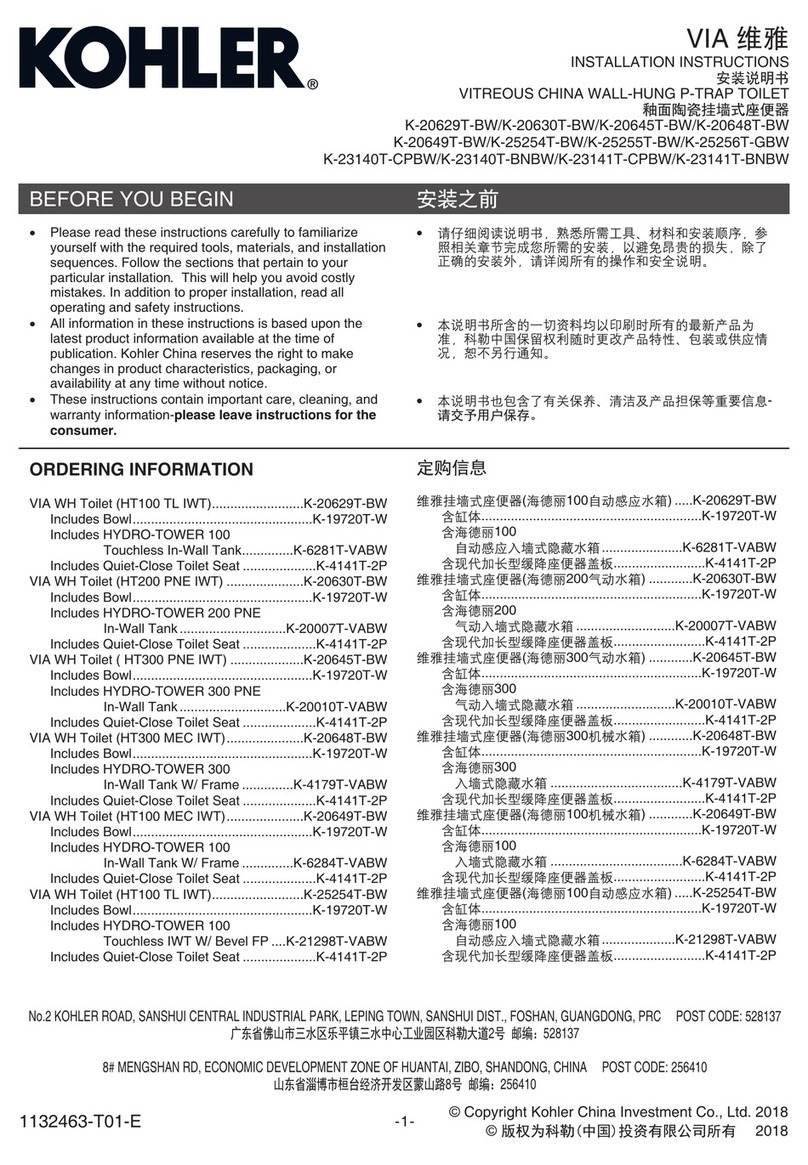

6543418 EVAC 910, WALL MODEL, PRESTIGE SILENT

6543419 EVAC 910, WALL MODEL, MOSAIK

6547226 EVAC 910, WALL MODEL, PRESTIGE SOFT CLOSING

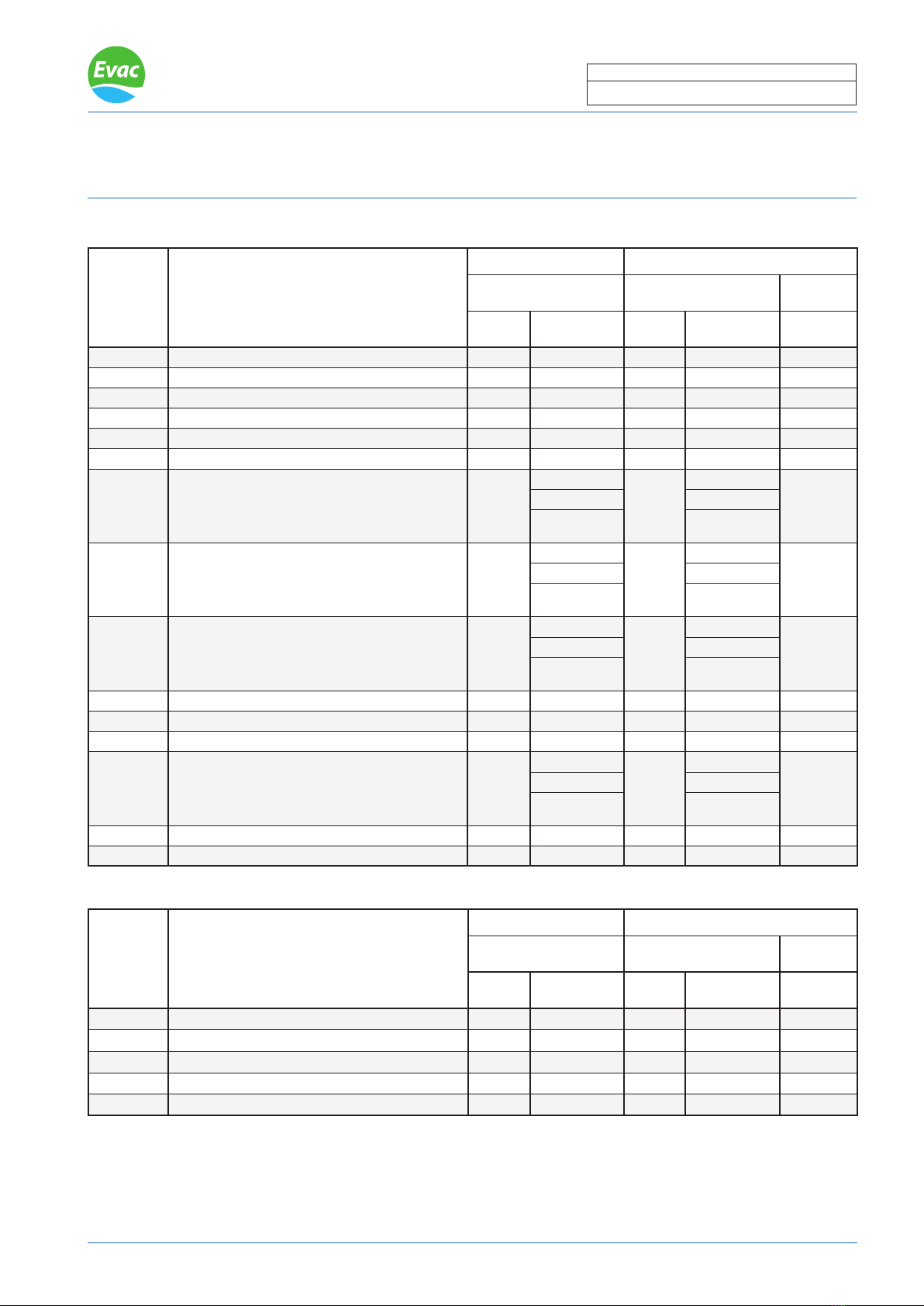

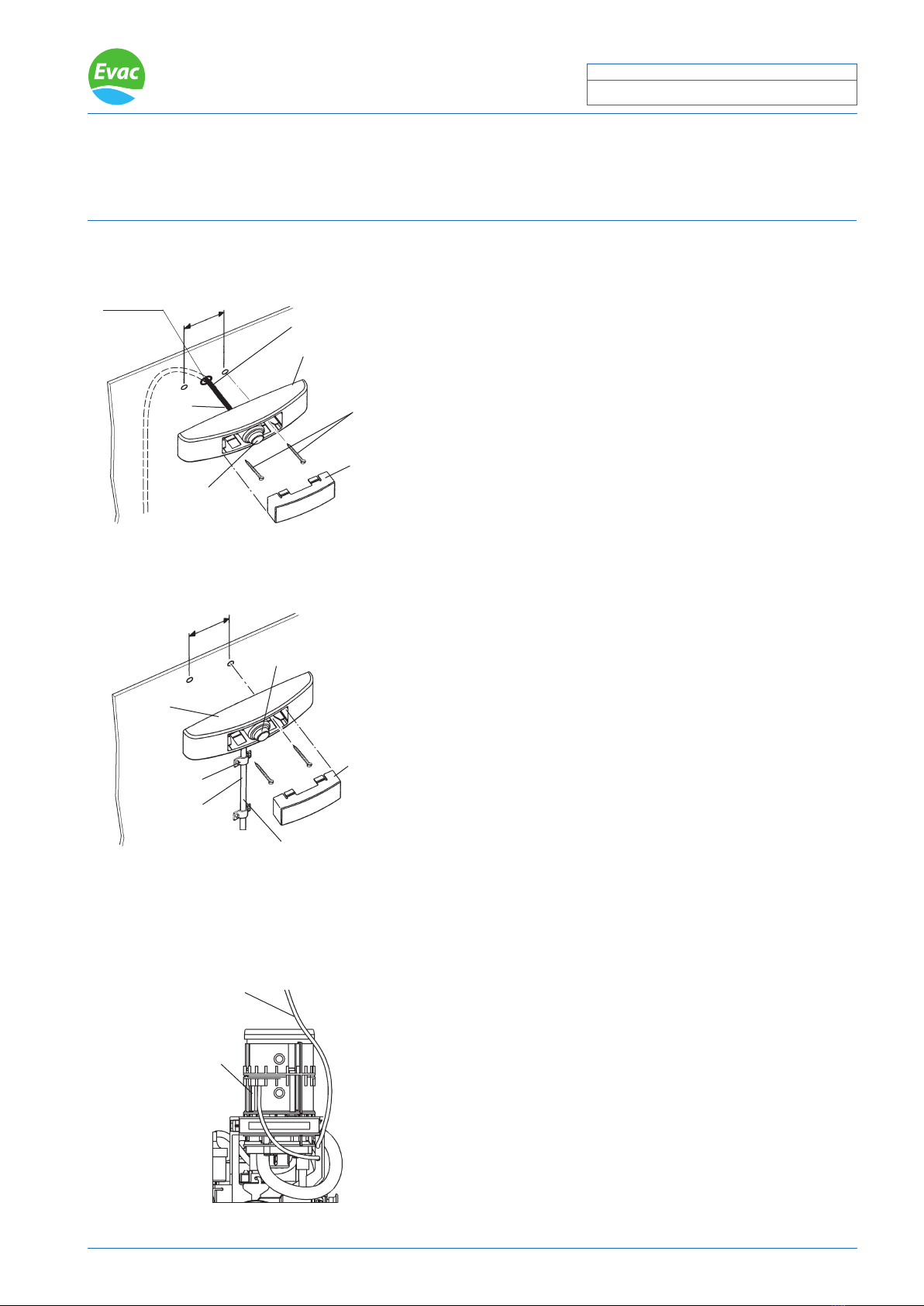

220 330

140160 220

*(Water supply hose)

! NOTE: Recommended place for the button.

If place is changed, consult EVAC.

A

A

U-beam

(Not included in EVAC supply)

Fasten the beam to a solid structure.

130

P/N 5433572

Straight connection hose

Pneumatic push button

50

Seat and cover:

Prestige or Mosaik or

Prestige Soft Closing

110

45

Ø50

Shut-off valve

1/2” MPT

Flexible water hose

Vacuum breaker

Discharge pipe

alignment

tolerance

to be ±3.0 mm

P/N 6544769

Rubber elbow 90°,

optional connection

* The vacuum breaker air inlet must be located at a minimum of

150mm (6”) above the overow point of the toilet.

*150

! NOTE: Overow point is inside the toilet bowl

Overow point

Vacuum breaker installation,

see doc. 002017-3

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 2

VACUUM TOILET

INSTALLATION

Date: Doc.

09 Dec 2010 001998-5

6543418 EVAC 910, WALL MODEL, PRESTIGE SILENT

6543419 EVAC 910, WALL MODEL, MOSAIK

6547226 EVAC 910, WALL MODEL, PRESTIGE SOFT CLOSING

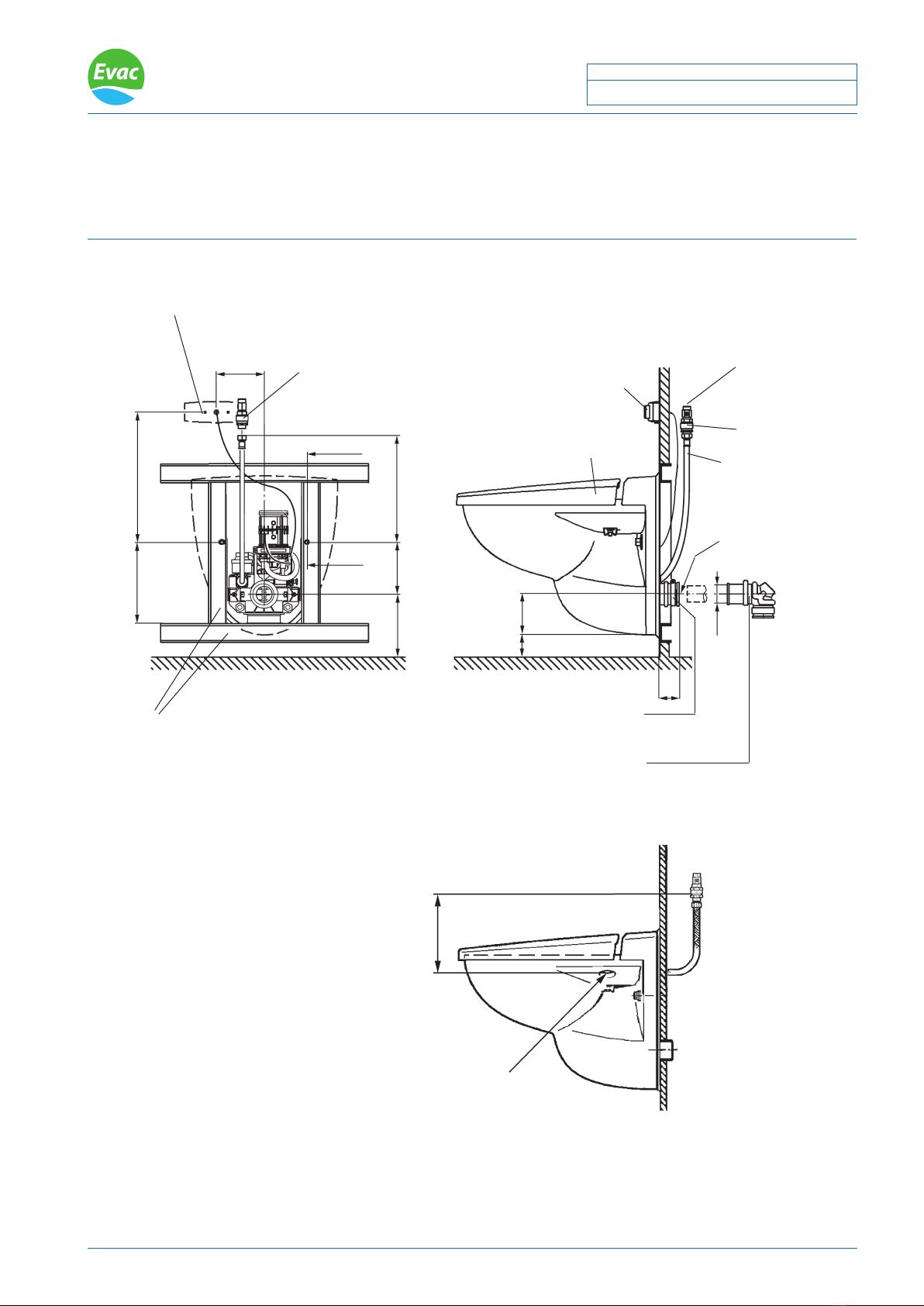

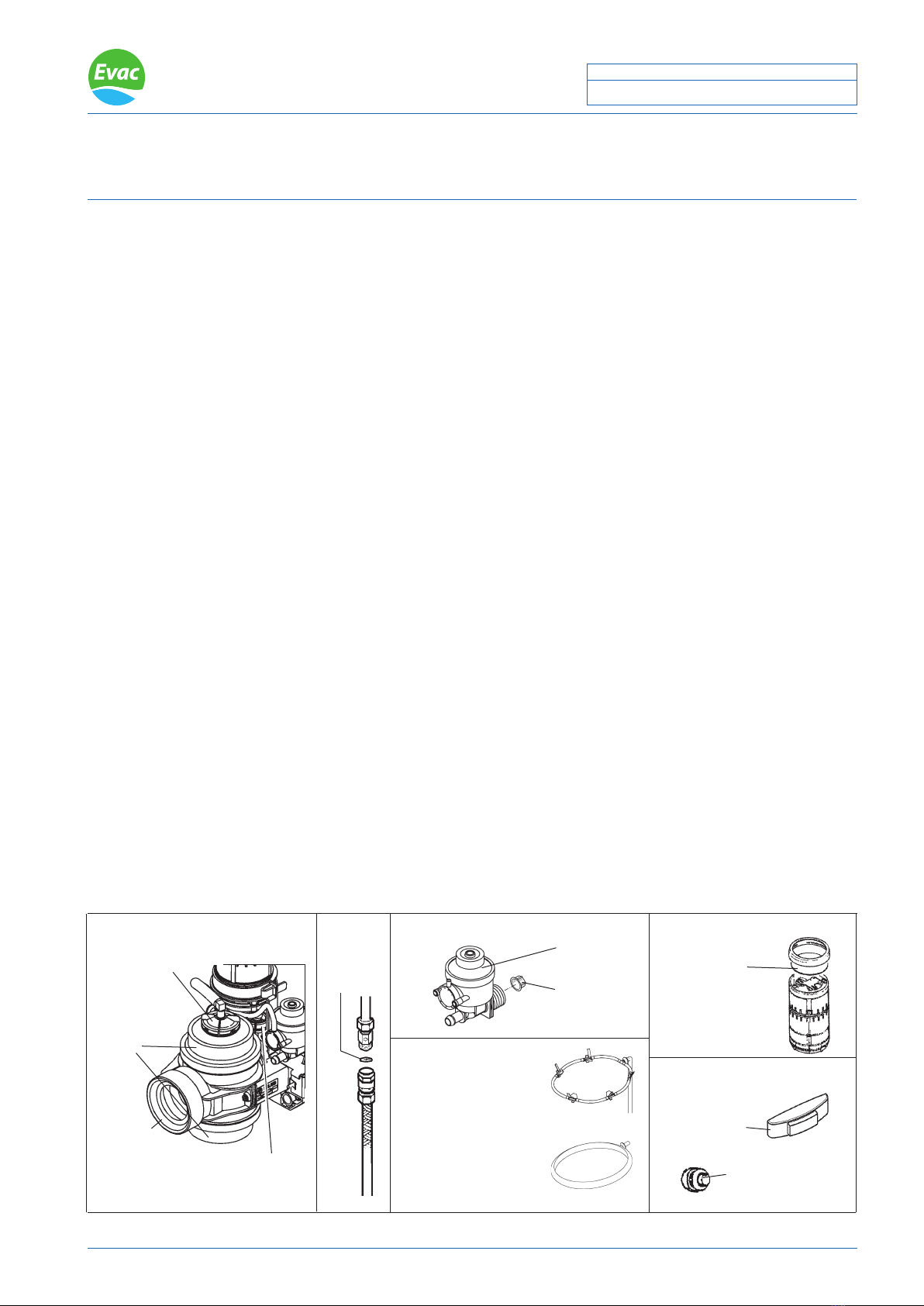

Installation kit 6540972 consists of:

Plastic nut M12 2 pcs

Guiding nut 2 pcs

Edge strip 1 pc

Mounting instruction 1 pc

Straight connection hose 1 pc

Hose clamp 2 pcs

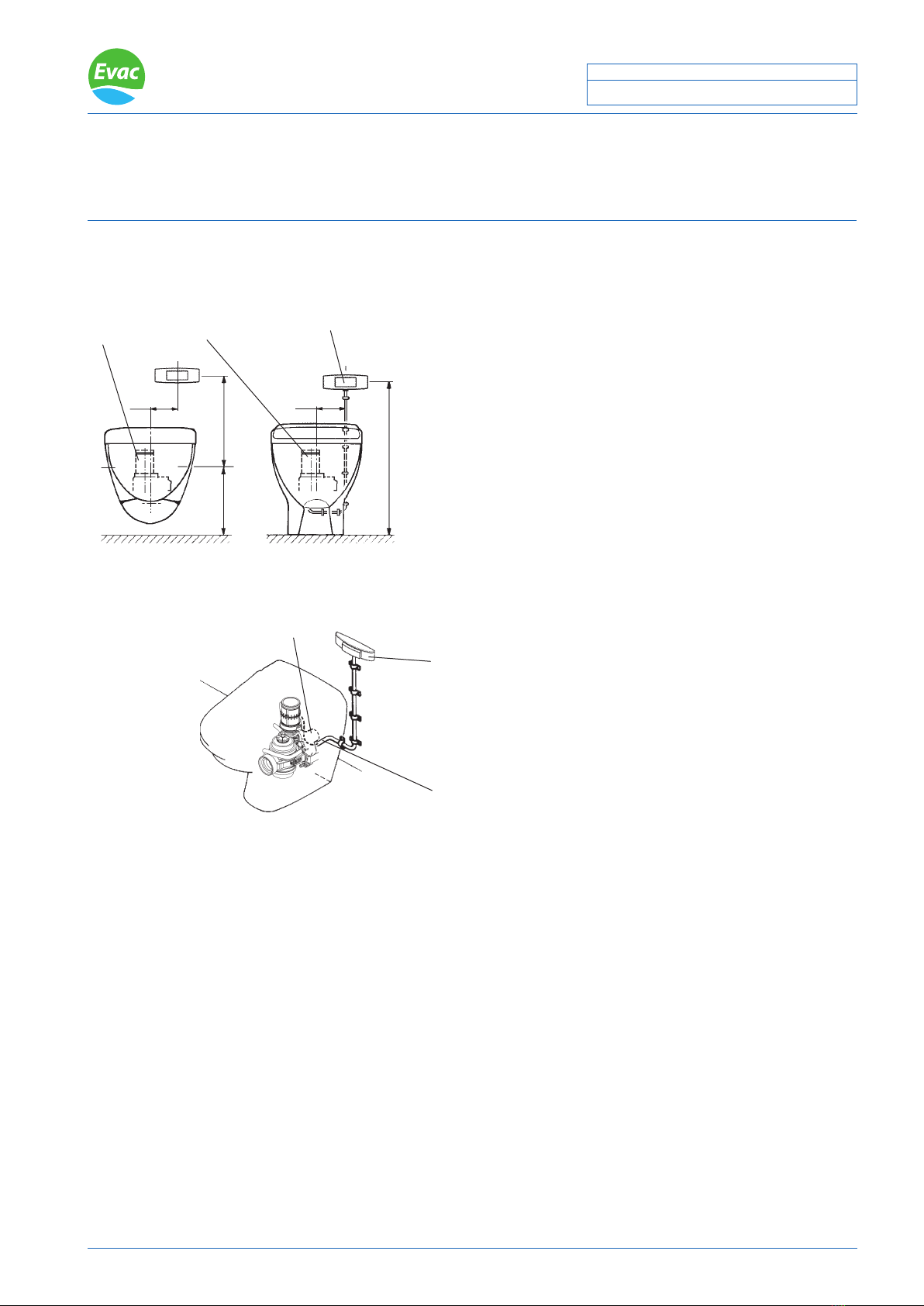

Toilet supporting beams for wall models

Cross section A - A

Edge strip

Total length of bolt = T + 65 ± 2

T65±2

Beam Toilet bowl

Bolt M12 (not EVAC supply) to be welded.

! NOTE: Thread on the bolt must be full length.

Ø13

230

Dimensions of toilet service opening through the wall

370

210

200

90

R20

Bolt M12 to be welded

(not EVAC supply)

Length according to

the space available

230

220

380

200

U-beam 50x30x2 (not EVAC supply)

09 Dec 2010 002017-3

6543418 EVAC 910, WALL MODEL, PRESTIGE SILENT

6543419 EVAC 910, WALL MODEL, MOSAIK

6547226 EVAC 910, WALL MODEL, PRESTIGE SOFT CLOSING

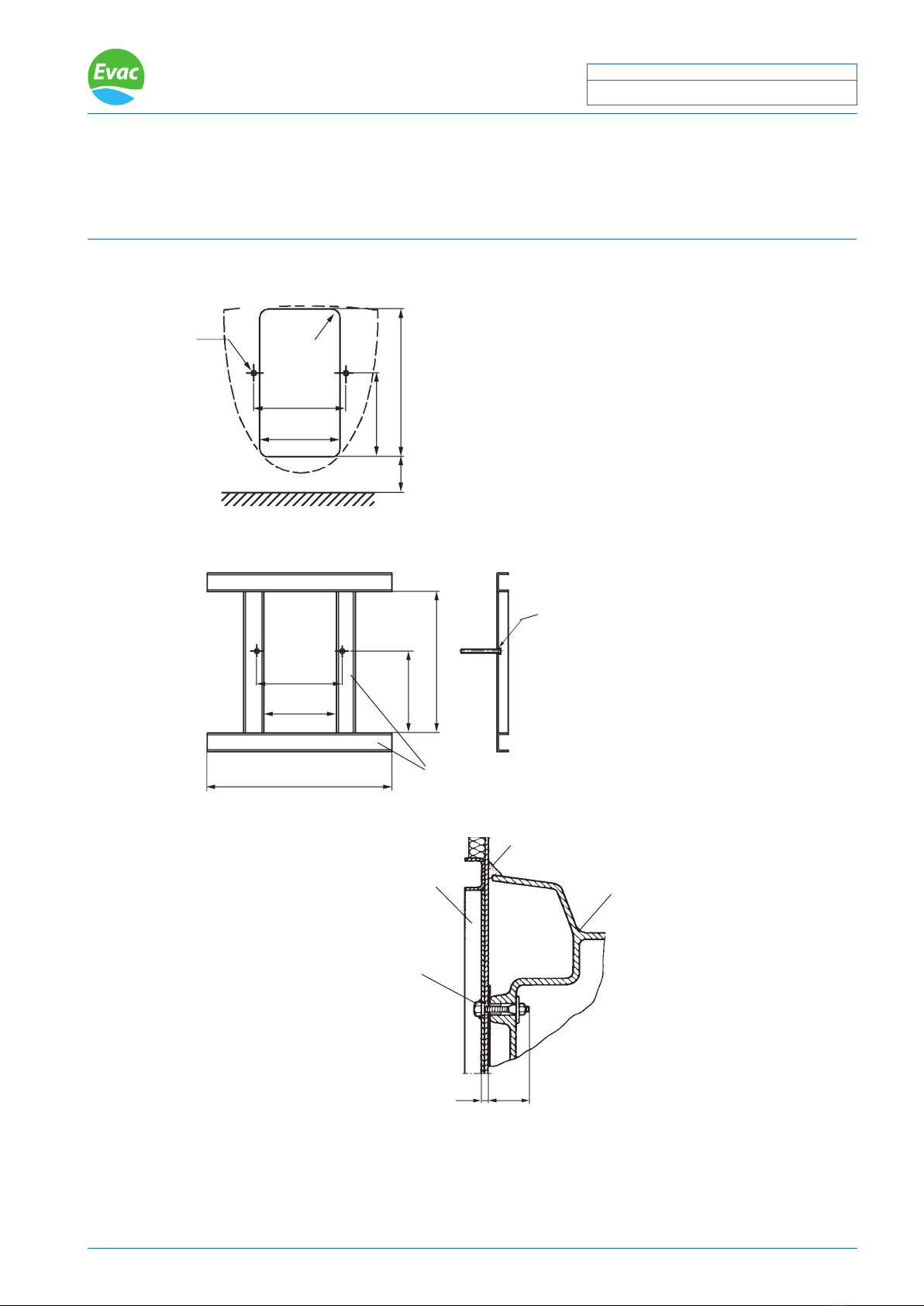

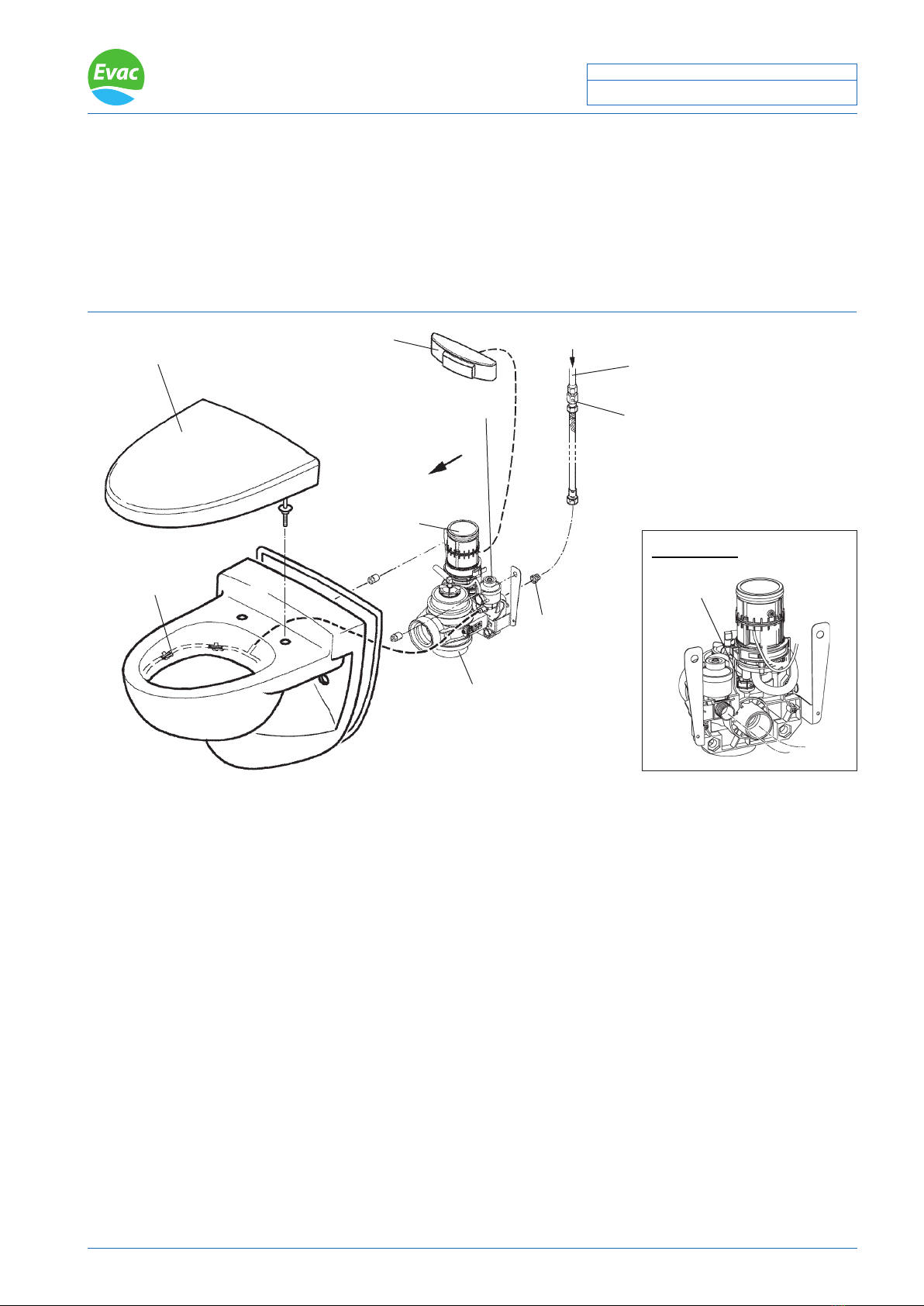

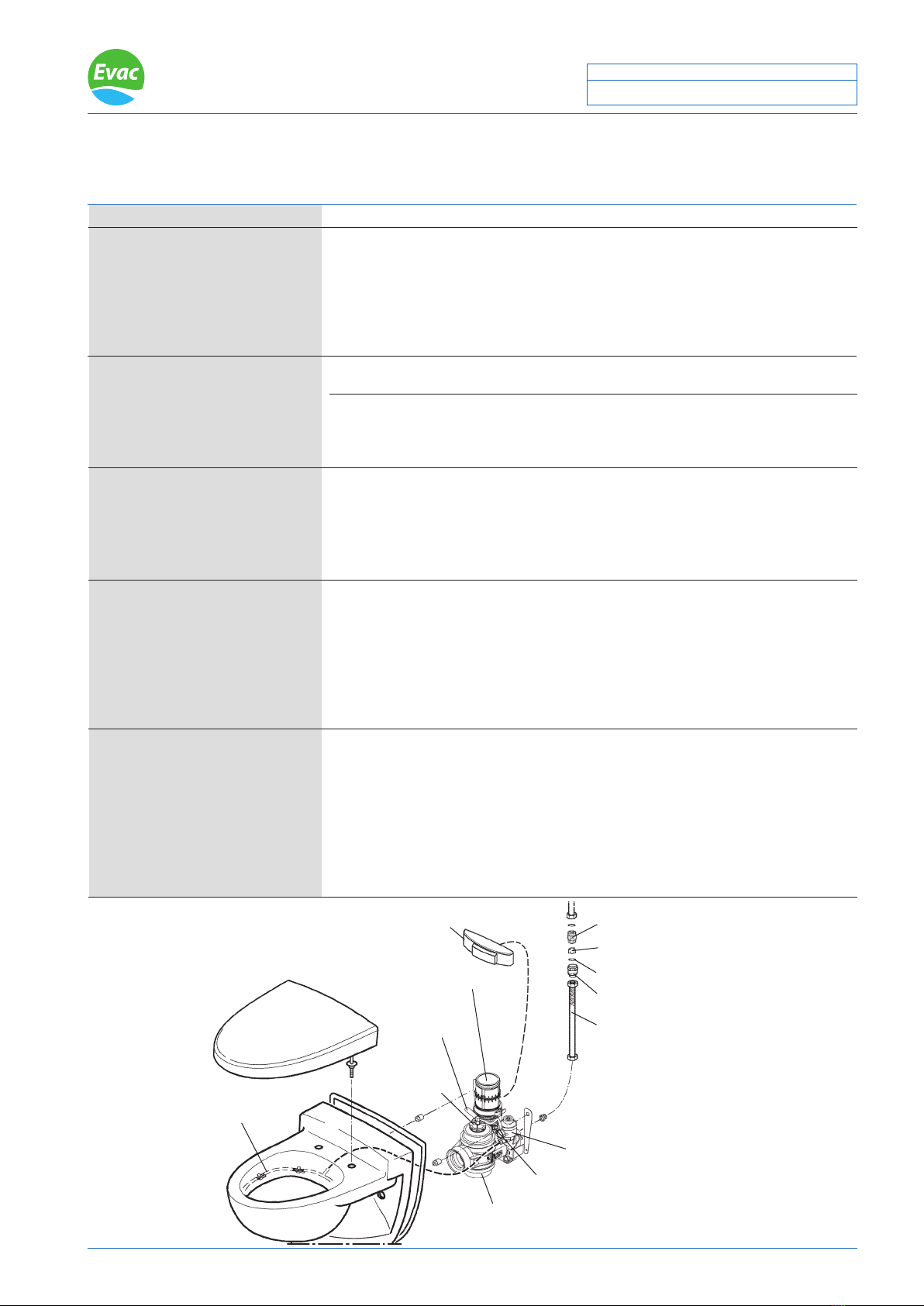

• Connect the water connection hose (A) to the water valve.

• Install the back plate assembly on the wall using the bowl fastening bolts (B) (M12, not included) and the

guiding nuts (C) (M12). The guiding nuts are necessary.

• Connect the hose (D) from the ushing ring to the water valve. Do not use any kind of grease during

installation! Secure with hose clamps. Tighten the hose clamps with pliers.

! NOTE: Install the hose (D) from the ushing ring in the toilet bowl to the right side of the discharge valve and

below all other hoses.

• Lift bowl onto the fastening bolts and tighten the securing nuts (E). Tightening torque is 15-20 Nm.

! NOTE: Check hoses through the toilet service opening in the wall that the hoses run smoothly. The hoses

shall not have any kinks.

• Fit the edge strip as shown in gure 1. Place the joint of the strip to the bottom side of the bowl.

• Install the seat and the cover. See the installation of the Prestige Soft Closing (document

002503-2).

• Connect the discharge connection. Secure with the hose clamps.

• Connect the shut-off valve/vacuum breaker assembly to the water supply. The shut-off valve must be installed

to the water supply piping’s side to ensure the correct ow direction in the vacuum breaker. Note the vacuum

breaker must be installed vertically as shown.

• Connect the water connection hose (A) to the shut-off valve/vacuum breaker assembly.

• Install the pneumatic push button (See document 002002-3).

E

Hose A (EPDM) L=400,

braid of stainless steel

wire

D

Water valve

B

Pneumatic push button

Edge strip

Mosaik

Prestige

Fig.1

C

Vacuum breaker

Shut-off valve,

1/2” MPT BSP

Shut-off valve /

vacuum breaker

assembly

Discharge valve (See notes!)

Hinge

Washer

Wing nut

Hingebody

or

Fresh water

connection

Back plate

assembly

Pipe Ø12

Washer

or

Prestige

Soft Closing

or

or

Nut Wing nut

Washer

Hinge

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved.

INSTALLATION

Date: Doc.

VACUUM TOILET

1

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

INSTALLATION

Date: Doc.

09 Dec 2010 002503-2

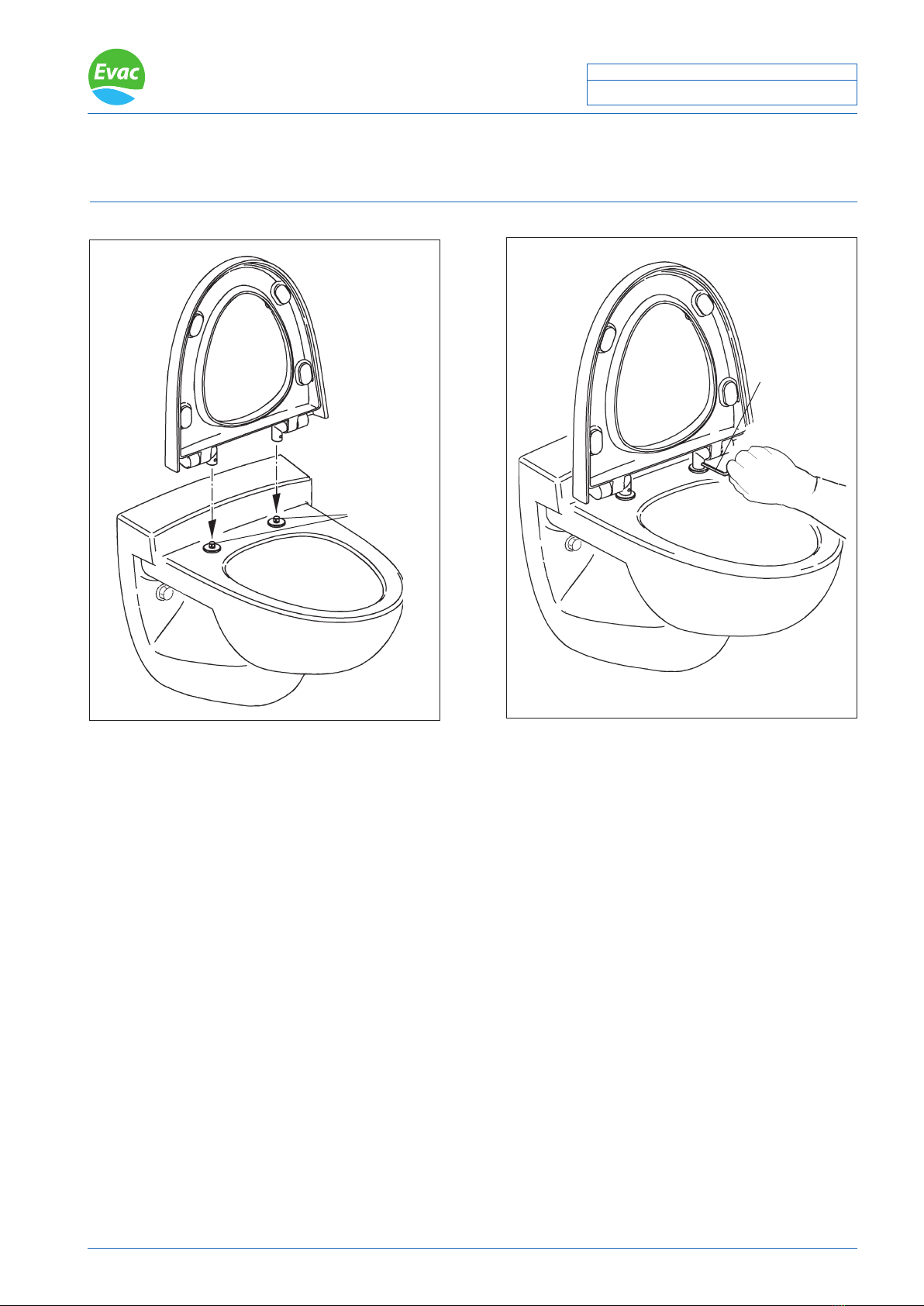

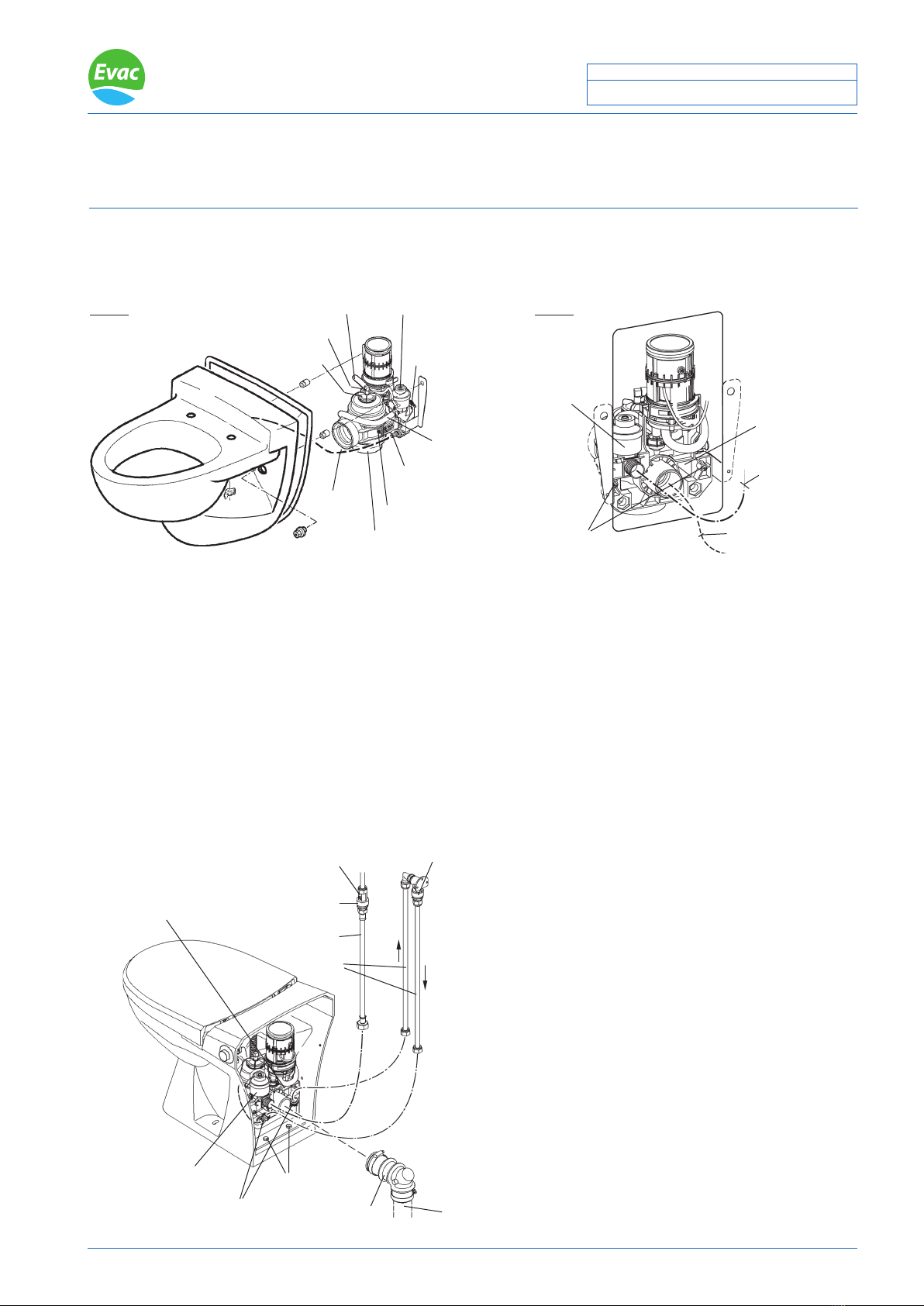

6546819 PRESTIGE SOFT CLOSING, SEAT AND COVER

002503-2

Screw

Washer (metal)

Bushing (plastic)

Washer

(metal and plastic)

Wing nut

Bowl

Hinge, left

(blue mark)

Hinge, right

(yellow mark)

Seat

Cover

2. Push the hinges into the hole of the seat and the cover.

1. Install the parts of the installation kit. Note the installation

order.

! NOTE: Do not open the seat (with the hinges

inserted) hinges before assembly. The opening angle

must not exceed 110°.

Installation

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 2

VACUUM TOILET

INSTALLATION

Date: Doc.

09 Dec 2010 002503-2

6546819 PRESTIGE SOFT CLOSING, SEAT AND COVER

3. Install the seat and the cover with the hinges on

the installation screws on the bowl.

Installation

screws

4. Tighten the retaining screws by the hex wrench.

(The installation kit includes two hex wrenches.)

Hex wrench

Maintenance

The seat is easy to clean, with just a few simple directions for you to observe.

• Use mild soap solution or biological cleaners.

• Rince the seat and cover and the hinges with water and dry with a soft cloth.

• Do not use abrasive scouring powders for the seat and cove and the hinges.

• Be careful with chemicals and cosmetics. Some of them may damage the seat at last.

• When you use abrasive, corrosive or chlorine based cleaners for the bowl, avoid contact with

the seat and cover and the hinges. Therefore, when you clean the bowl and ush cleaner

away, make sure that the seat and the cover are in an upright position.

! NOTE: Do not use too much force.

Do not use force when closing, this may cause

irreparable damage to the device.

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

INSTALLATION

Date: Doc.

28 Jan 2011 002002-3

6541458 PNEUMATIC PUSH BUTTON, EVAC 910, WALL MODELS

6541057 OPTIONAL PNEUMATIC PUSH BUTTON KIT, EVAC 910, FLOOR MODELS

E

Ø 6

AD

3.

C

From the control

mechanism

60

60

A

B

C

D

E

B

From the control

mechanism

Plastic hose to the

push button

Control

mechanism

Installing the push button on the wall, oor models with

the optional push button kit.

(Hose and protecting pipe on the surface of the wall)

1. Drill Ø6 mm hole for the hose (A).

2. Connect the plastic hose (A) from the control mechanism to

the bellows (B). Warm the end of the hose if needed to help

installation.

3. Install the body (C) of push button on the wall using screws

(D) (not included).

4. Snap the cover (E) of the push button its place.

! NOTE: Secure, that the hose (A) is not attened after

installation. Air impulse must always ow free.

1. Thread the hose from the control mechanism through the

protection pipe (A).

2. Install the protection pipe (A) on the wall using screws and

clamps (B).

3. Cut off the lm of the bushing for the plastic hose in the

bottom side of the push buttons cover.

4. Connect plastic hose from the control mechanism to the

bellows (C). Snap the plastic hose on the clip behind the

bottom plate.

5. Install the push button body (D) to the wall using screws

(not included).

6. Snap the cover of the push button (E) its place.

Control mechanism

Make sure, that the plastic hose does not get loose from

the control mechanism.

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 2

VACUUM TOILET

INSTALLATION

Date: Doc.

28 Jan 2011 002002-3

6541458 PNEUMATIC PUSH BUTTON, EVAC 910, WALL MODELS

6541057 OPTIONAL PNEUMATIC PUSH BUTTON KIT, EVAC 910, FLOOR MODELS

Control mechanism

~290 330*

130

~640*

110

Optional push button

(Floor models)

Discharge pipe

Recommended place for the button

! NOTE: Make sure, that cover does not hit the push button

when opened. (*In Aniara/Mosaik/Trevi models dimension

is 100mm smaller due to the exible cover.) If the place is

changed, consult EVAC.

Floor models

Optional pneumatic push button kit

Install the protecting pipe under the discharge pipe.

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

OPERATION AND MAINTENANCE

Date: Doc.

09 Dec 2010 002029-4

6543418 EVAC 910, WALL MODEL, PRESTIGE SILENT

6543419 EVAC 910, WALL MODEL, MOSAIK

6547226 EVAC 910, WALL MODEL, PRESTIGE SOFT CLOSING

6543420 EVAC 910, WALL MODEL USPH, PRESTIGE SILENT

6543421 EVAC 910, WALL MODEL USPH, MOSAIK

6544766 EVAC 910, WALL MODEL USPH, OPEN FRONT

6547227 EVAC 910, WALL MODEL USPH, PRESTIGE SOFT CLOSING

Start-up

• Clean the bottom of the toilet bowl.

• Check the mini-check valve and the discharge valve are clean and working correctly.

• Check the water supply hose and the lter of the water valve are not blocked up.

• Check sufcient vacuum (-0.3 bar) is available.

• Open the water supply valve in the water supply piping.

• Press the toilet push button. Pressing the button starts the ushing sequence. The discharge valve opens and

the contents of the bowl are extracted by vacuum. At the same time the bowl is rinsed by water.

• When the discharge valve has been closed water level is restored in the bowl by the closing time delay of the

water valve.

Monitoring the vacuum toilet in the normal operation

• Check the water valve provides the rinse water to the bowl at the same time as the discharge valve extracts

the bowl contents when the push button is pressed.

• Check the push button returns to it´s non-activated state.

• Check after the discharge valve closes, the water valve continues to provide water to the bowl. If the water

valve time delay is correctly adjusted, there should be a pool of water at the bottom of the bowl.

• Check there are no water or air leaks.

! NOTE: Water consumption is dependent on the water supply pressure and the vacuum level.

Preparation for a toilet not to be used for a long period

• Close the water supply valve.

• Run a ush cycle by pressing the push button.

• Close the toilet seat cover.

Water valve

Flushing ring

Discharge valve

Push button on the wall

(wall model toilets)

Control

mechanism

Mini-check

valve

Direction A

Seat and cover

Filter of the

water valve

Water supply piping

Water supply valve

A

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

OPERATION AND MAINTENANCE

Date: Doc.

09 Dec 2010 002028-4

6543418 EVAC 910, WALL MODEL, PRESTIGE SILENT, WHITE

6543419 EVAC 910, WALL MODEL, MOSAIK, WHITE

6547226 EVAC 910, WALL MODEL, PRESTIGE SOFT CLOSING

6543420 EVAC 910, WALL MODEL USPH, PRESTIGE SILENT, WHITE

6543421 EVAC 910, WALL MODEL USPH, MOSAIK, WHITE

6544766 EVAC 910, WALL MODEL USPH, OPEN FRONT, WHITE

6547227 EVAC 910, WALL MODEL USPH, PRESTIGE SOFT CLOSING

Operation

The toilet is ushed by pressing the push button. The pneumatic push button is connected to the control mechanism

with a control hose, which transports the air pulse from the push button to the control mechanism. The air pulse

starts the ushing sequence and the control mechanism connects vacuum to the control connections of the water

valve and the discharge valve. The water valve opens and lets rinsing water ow into the bowl through the ushing

ring. After a short delay vacuum acts in discharge valve housing and forces the rubber diaphragm in discharge

valve to open. Contents of the bowl is drained to the vacuum sewer by a pressure difference between the bowl

and vacuum sewer. The ushing cycle in the control mechanism starts the closing cycle. Vacuum enters to the

relief valve. The relief valve opens the port between athmospheric air and the discharge valve. Athmospheric air

enters to the discharge valve witch closes immediatelly. After a short delay the atmospheric air pulse reaches to the

water valve and the relief valve. The water valve closes and lets a certain level of water at the bottom in the bowl.

After the ushing cycle has stopped the push button and the system will be ready for the next ush.

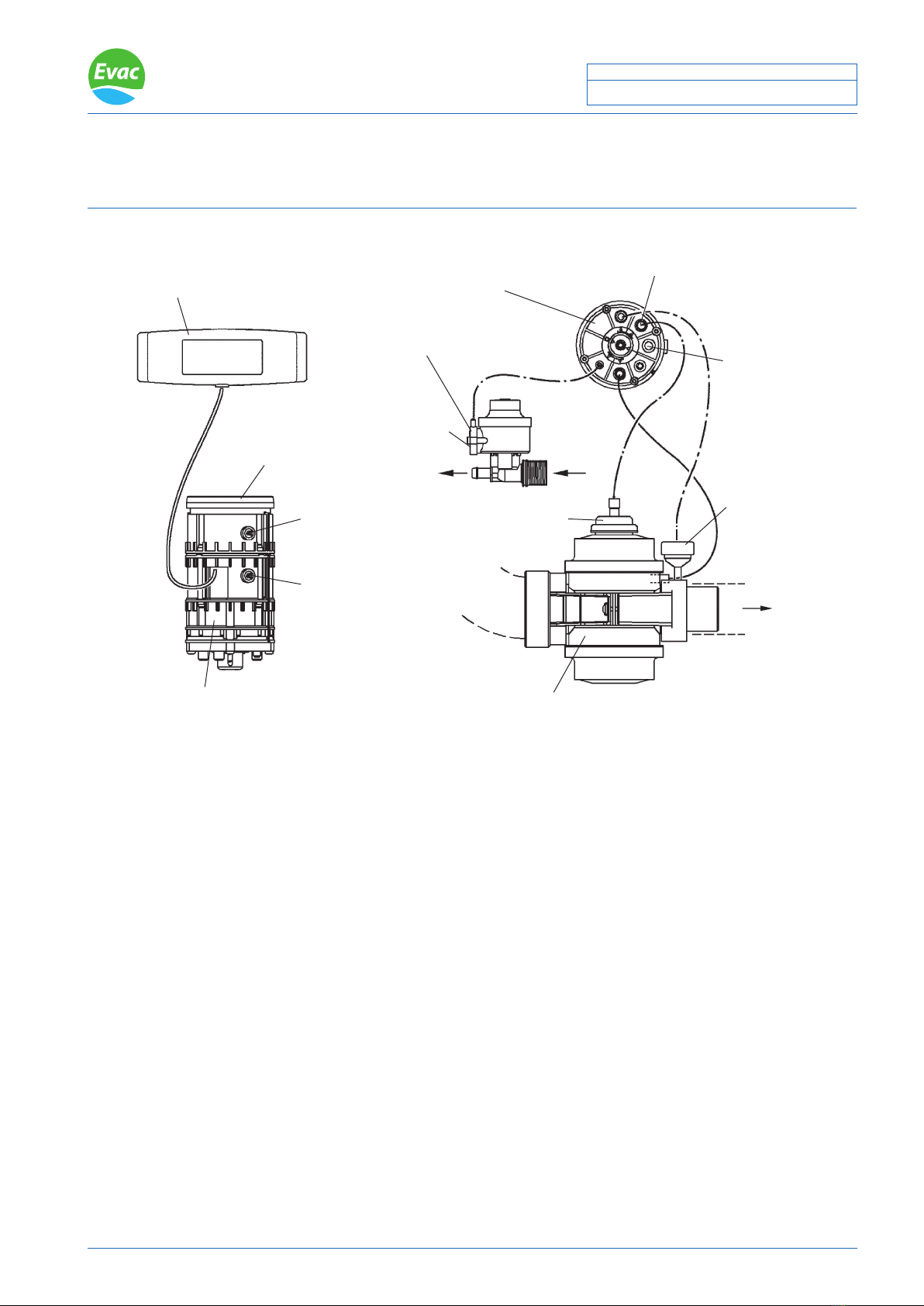

Discharge valve

Pneumatic push button

Flushing ring Water valve

Water supply

connection

Control

mechanism

Control hose

Bowl

Relief valve

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

OPERATION AND MAINTENANCE

Date: Doc.

09 Nov 2010 002030-2

5775500 CONTROL MECHANISM, EVAC 910, WALL MODELS AND FLOOR MODELS

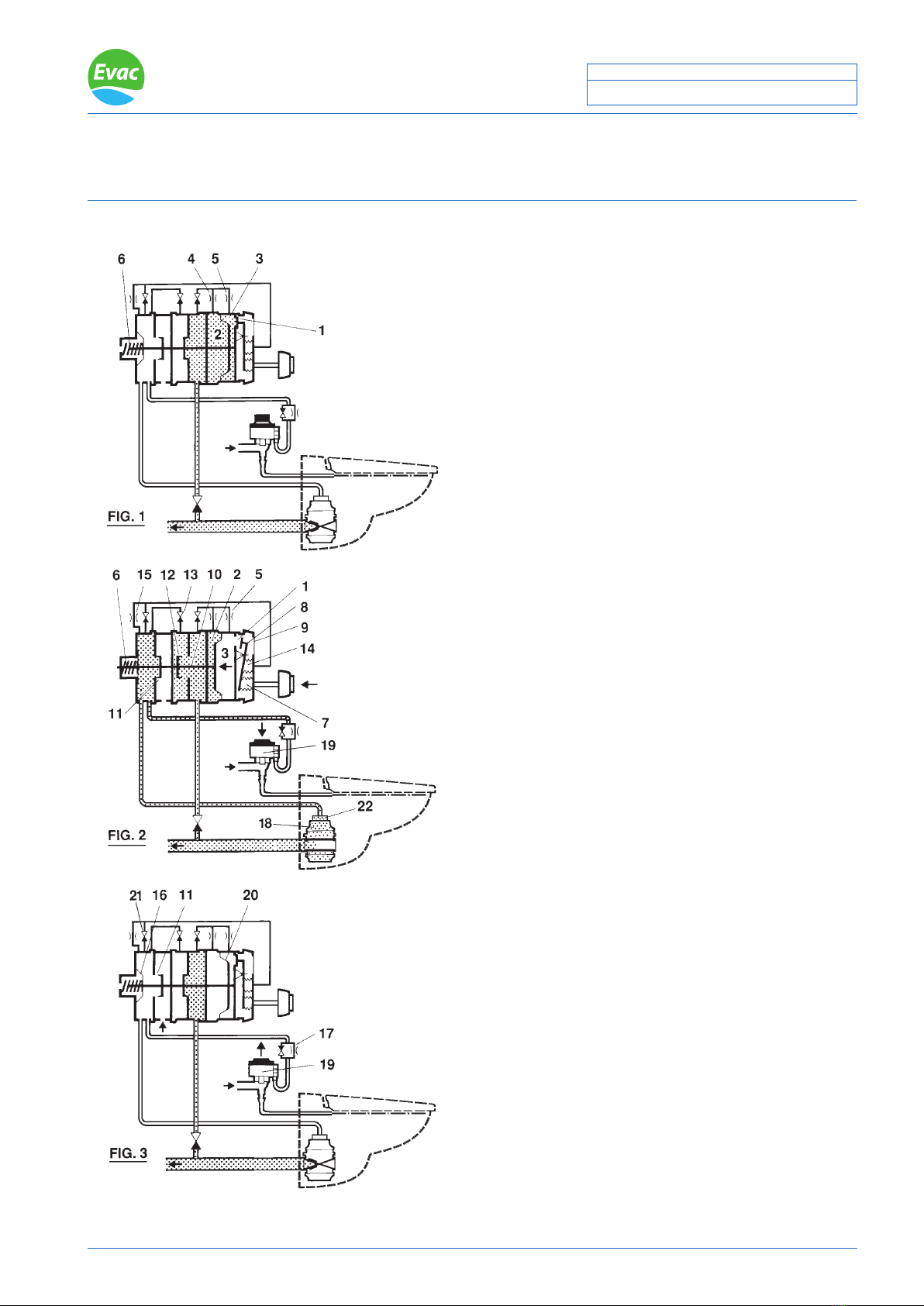

Description of the ushing sequence

In the standby position FIG.1

The control valve (1) is closed. Vacuum in the chambers

(2) and (3) is equalized by the jets (4) and (5). Force of the

spring (6) holds the mechanism in the non-activated position.

In the position immediately after the push button has

been pressed FIG.2

Air pressure applied from the ush button to the chamber

(7) has lifted the lever (8) and opened the control valve

(1). Atmospheric air has entered the chamber (3) through

the lter (9) and the valve (1). The force from the pressure

difference between (2) and (3) has moved the shaft (10) to

the left and the following sequence of events has occured:

The inlet valve (11) has closed. The vacuum valve (12) has

opened. Vacuum is distributed via the check valve (13) to

the discharge valve (18) and the water valve (19) which will

both open. The chamber (14) is also subjected to vacuum

through the check valve (21).

This vacuum will pull the lever (8) and the close valve (11)

and the timer function will start. The chamber (3) will be

evacuated through the jet (5) and the pressure difference

(2-3) equalizes. At the certain level, the counterforce from

the spring (6) will outweigh and the cycle will go in the

opposite direction:

The vacuum valve (12) will close. The air inlet valve (11)

will open and vacuum will enter the relief valve (22), the

athmospheric air enters the water valve, the discharge

valve and the chamber (14). The discharge valve (18) will

close and somewhat later (because of the jet (17)), the

water valve (19) closes when a suitable water level has been

reached at the bottom of the bowl. The relief valve closes.

Returning to the standby position FIG.3

The whole system goes to the standby position ready for

another VT-ush.

! NOTE: The diaphragm (16) has the same effective area as

the air inlet valve (11) to balance the vacuum forces. FIG.3

! NOTE: Check the valve (13) ensures that connected the

valves in the activated position are unaffected by changes

in the vacuum supply level.

! NOTE: If vacuum is too low or absent the function is

delayed. The control valve (1) stays open until the chamber

(14) is subject to vacuum.

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

OPERATION AND MAINTENANCE

Date: Doc.

09 Nov 2010 002032-2

5775500 CONTROL MECHANISM, EVAC 910 WALL MODELS AND FLOOR MODELS

Operation

The functioning of the vacuum toilet is entirely controlled by the control mechanism. The operation of the control

mechnism is based on vacuum in the sewage piping system.

Description of ushing sequence see document 002030-2.

Jet 1 (document 002030-2 pos. 5) controls the discharge valve opening time.

Jet 2 (document 002030-2 pos. 4) counters the effect of quick changes in the vacuum supply.

Jet 3 (document 002030-2 pos. 15) delays the vacuum changes in the chamber (14) (see document 002030-2).

This prevents a new ushing procedure to start before the previous procedure has stopped.

Maintenance

Check that the air lters (4) and (5) are not blocked.

Check hoses and pipe connections for leaks.

Toilet discharge time

Jet 1 Short discharge period Red jet 1.5 sec.

Normal discharge period Blue jet 2.0 sec.

Longer discharge period White jet 2.5 sec.

Less restriction shortens the time

Water valve opening time

Jet 6 Normal bowl water level White jet

Low bowl water level Blue jet

Push button

Filter 4

Jet 1

Jet 2

Control mechanism

Jet 6

(inside plastic cover)

Water valve

Discharge valve

Mini-check valve

Filter 5

(athmospheric air inlet for relief valve)

Jet 3

Control mechanism

Relief valve

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

OPERATION AND MAINTENANCE

Date: Doc.

09 Nov 2010 002033-4

6543002 DISCHARGE VALVE, EVAC 910, WALL MODELS, FLOOR MODELS AND

STAINLESS STEEL MODELS

Operation

Closed condition:

The control mechanism shuts off connection between the vacuum piping and the discharge valve housing. As the

valve housing is under atmospheric pressure the spring-loaded closing mechanism closes the rubber diaphragm

and isolates the bowl from the vacuum piping.

Open condition:

As the control valve opens the discharge valve housing is subjected to vacuum, thus forcing the closing mechanism

to open. This in turn allows the rubber diaphragm to open, and connects the bowl to the vacuum pipe line.

Closing sequence:

The vacuum pulse enters to the relief valve. The relief valve opens the port between athmospheric air and the

discharge valve. Athmospheric air enters to the discharge valve witch closes immediatelly. After a short delay the

atmospheric air pulse reaches to the water valve and the relief valve. The water valve closes and lets the certain

level of water at the bottom in the bowl.

Maintenance

See document 002034-6 for scheduled maintenance.

CLOSED

CONDITION

Closing

mechanism

Control mechanism

Bowl

side

Vacuum

piping

Vacuum hose

Connection

pipe

OPEN CONDITION CLOSING SEQUENCE

Rubber diaphragm

Rubber

sleeve

Rubber

sleeve

Relief valve

Discharge

valve

Discharge valve

Atmospheric air

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

MAINTENANCE

Date: Doc.

11 Nov 2010 002034-6

EVAC 910, WALL MODELS, FLOOR MODELS AND STAINLESS STEEL MODELS

Cleaning instruction for the seat

• The seat is easy to clean, with just a few simple directions for you to observe.

• Use a mild soap solution or biological cleaners.

• Seat and hinges should not be left damp, but be dried with a soft cloth.

• When using abrasive, corrosive or chlorine based cleaners for the bowl, avoid contact with the seat and

hinges. Therefore, when cleaning the bowl, make sure that seat and cover are in an upright position until all the

cleaner has been ushed away.

Scheduled maintenance program

Maintenance program is based on 20 toilet ushes per day and 20 years operation.

Every year:

• Change ap of Mini-check valve in every toilet.

• Check operation, push button, seat and cover, rinse pattern, discharge pattern.

• Check possible water and vacuum leakage.

• Clean Filter ( not in USPH models ) in water supply.

Every 5 years:

• Change Flap of mini-check valve in every toilet.

• Open and clean Water valve lter 5774150.

• Clean Control mechanism air lter 5778600.

• Check operation, push button, seat and cover, rinse pattern, discharge pattern.

• Check possible water and vacuum leakage.

• Check Flushing ring 6541025 (oor models), 6540968 (wall models) or 5433471 (Stainless steel models) and

ushing operation.

Every 10 years:

• Change Flap of mini-check valve in every toilet.

• Change Discharge valve rubbers: Rubber sleeve 6542990 (2pcs), Rubber diaphragm 6542989 and Diaphragm

6543134 in relief valve.

• Change Water valve diaphragm 5774400.

• Open and clean Water valve lter 5774150.

• Clean Control mechanism air lter 5778600.

• Check operation, push button, seat and cover, rinse pattern, discharge pattern.

• Check possible water and vacuum leakage.

• Check Flushing ring 6541025 (oor models), 6540968 (wall models) or 5433471 (Stainless steel models) and

ushing operation.

! NOTE: Use only genuine Evac spare parts.

Discharge valve Water

sypply

Control mechanism

Flushing ring

Floor models:

6541025 Flushing ring

Wall models:

6540968 Flushing ring

5778600

Air lter

Water valve 5774400

Diaphragm

5774150

Filter

6 5 4 1 4 5 8

Push button

Pneumatic push buttons

6542990

Rubber

sleeve

6542989

Rubber

diaphragm Mini-check

valve

Filter

Relief valve

6544996

Push button

Stainless steel toilet:

5433471 Flushing ring

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

TROUBLE SHOOTING

Date: Doc.

Filter ( not in USPH models )

11 Nov 2010 002031-3

EVAC 910, WALL MODELS

Push button

Water valve

Discharge valve

Vacuum

hose

Control mechanism

Mini-check valve

Flushing ring

Shut-off valve

Seal ( not in USPH models )

Vacuum breaker

Water supply hose

Trouble

Toilet is discharging continuously

(discharge valve open)

Bowl does not become empty

when ushed

No water or too little rinsing

water

Toilet is overowing

Toilet does not ush.

Cause

• Foreign object in bowl or

in discharge valve

• Blocked air relief tubing

• Quick relief valve malfunction

• Discharge valve blocked

• Leak in discharge valve housing

• Discharge pipe blocked

• Rubber sleeves leaking

• Water shut-off valve closed

• No water pressure

• Filter full or dirt in water valve

• Flush ring loose

• Flush ring clogged

• Filter blocked up in water supply

• Water valve jammed in open

position

• Bowl clogged or discharge valve

not operating

• Misuse (buckets of water thrown in

the bowl)

• Too low vacuum (less than 30%) to

ush

• No vacuum or low vacuum (less

than 30kPa)

• Clogged mini-check valve

• No impulse from push button

• Jammed control mechanism

• Jammed quick relief valve

Remedy

• Shut off the problematic branch line

valve

• Remove foreign object

• Change discharge valve

• Check and if necessary change

control mechanism

• Check relief valve operation

• Clear stoppage, if any, in discharge

valve

• Sharp tools may damage rubber

• Check that rubber sleeves are

undamaged and correctly tted

• Check relief valve operation

• Open valve

• Provide water pressure

• Clean lter

• Connect ushing ring

• Clean ushing ring

• Clean lter

• Close water shut-off valve

• Clean / change water valve nozzles,

springs, rubbers

• Discharge bowl, valve and piping

with normally ushing

• Check vacuum level, remove

blockage in piping

• Clean / change mini-check valve

• Check hoses and membrane of push

button

• Change control mechanism

• Check air lter condition. It should

be place.

• Check relief valve operation

Relief valve

EVAC reserves the right to make alterations to this specication without prior notice.

© Copyright Evac Oy. All rights reserved. 1

VACUUM TOILET

TROUBLE SHOOTING

Date: Doc.

11 Nov 2010 002262-2

6543002 DISCHARGE VALVE, EVAC 910, WALL MODELS AND FLOOR MODELS

Removal of the discharge valve (wall models)

1. Remove the bowl.

2. Disconnect the rubber hose A from the water

valve or from the connecting nipple (only in

USPH models).

3. Loose (only in USPH models) water valve from

the component plate.

4. Disconnect the hose C with the elbow from the

relief valve.

5. Unscrew two screws**.

Hose A

Water valve

Hose B

Elbow

Connecting

nipple

Relief valve

Hose C

Screw**

Fig. 1 Fig. 2

1. Disconnect the water supply hose from the water

valve and the discharge pipe from the backplate.

2. Unscrew two screws* (see g.2).

3. Disconnect the rubber hose A from the water valve

or from the hose nipple (only in USPH models).

4. Loose (only in USPH models) water valve from the

component plate.

5. Disconnect the hose from the relief valve.

6. Unscrew two screws** (see g.1).

From the cabin side: From the service space side:

Screws*

Water

valve

Discharge pipe

Water supply

hose

Back plate

Removal of the discharge valve (oor models)

Water supply

Water hose

Pipes

Rubber bend

Screws***

Water valve

Connection nipples

Vacuum breaker

(USPH models)

Back plate

Vacuum breaker

(not in USPH models)

Discharge piping

1. Close the water supply valve.

2. Disconnect the water hose from the water valve.

3. Disconnect the pipes of the vacuum breaker from

the connection nipples

4. Disconnect the toilet from the rubber bend.

5. Remove the toilet if needed.

6. Remove the screws***.

7. Disconnect the rubber hose A from the water

valve or the connecting nipple (only in the USPH

models).

8. Remove the back plate.

Component

plate

Discharge valve

Table of contents

Popular Toilet manuals by other brands

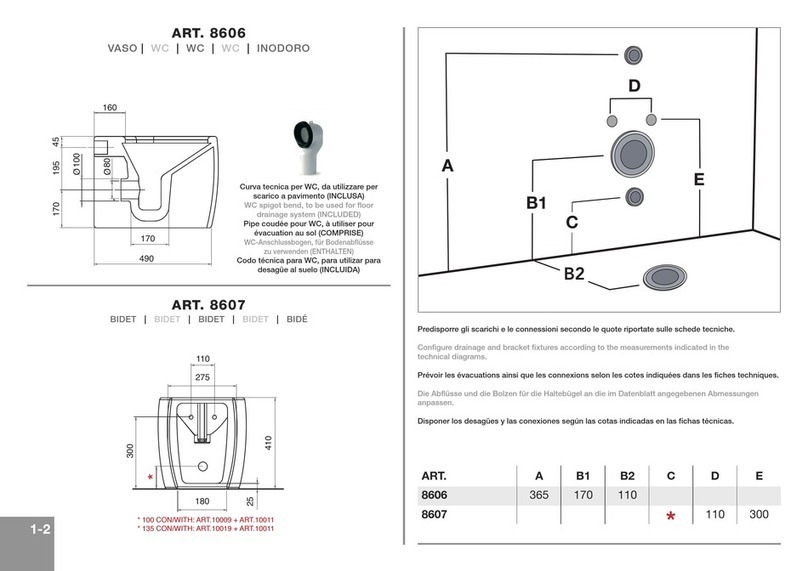

Scarabeo

Scarabeo Moai 8606 manual

Swiss Madison

Swiss Madison Sublime II SM-2T257 installation instructions

Kohler

Kohler C3-129 Homeowner's guide

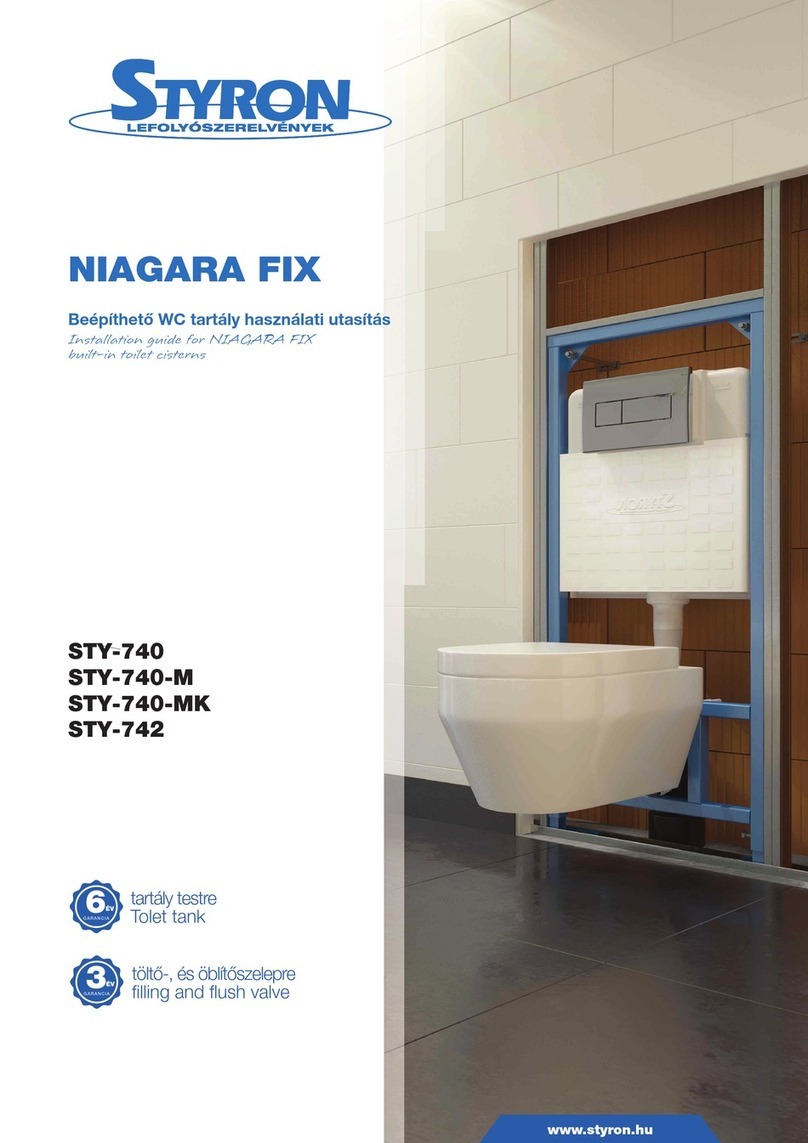

Styron

Styron NIAGARA FIX installation guide

Setma

Setma waterGenie Compact Installation and operating instructions

Kohler

Kohler STERLING 402040 Homeowner's guide