Evak E Series Instructions for use

2

3

Instruction Manual

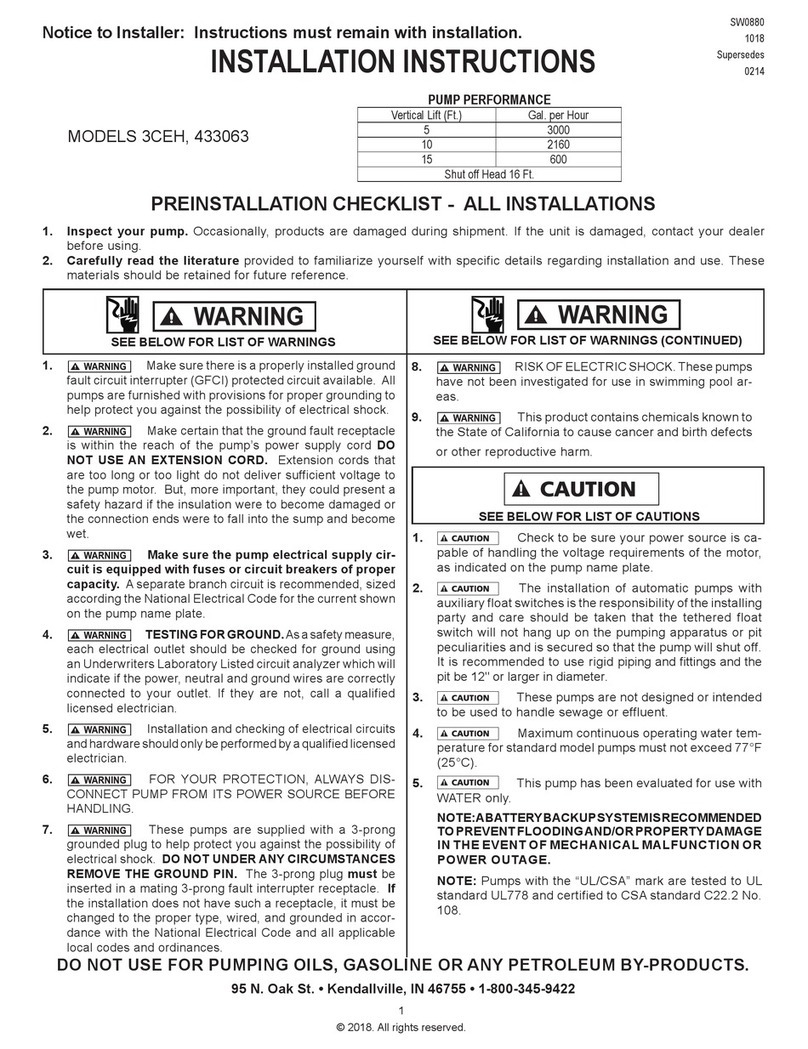

2.5" & 3" Full Free Passage Submersible Sewage Pump

HIPPO DN65/80 Series

Item Specifications

Liquid handled Type Sewage, waste water, miscellaneous drain water

Temperature Non-Automation 1.5~5.5 HP 0~40°C (32~104°F)

Automation 1.5~2 HP 0~40°C (32~104°F)

Materials Pump Casing EN-GJL-200

Impeller

Shaft AISI 410 stainless steel

Motor type Dry type submersible motor

Shaft seal lubrication oil Turbine No.32 ISO VG-32

Maximum water depth 10m (33ft)

EN-GJL-200

Introduction

Check the following points upon receipt of your pump:

> Is the pump exactly what you ordered? Check nameplate. It is especially important that you check

whether the pump is to be used with 50 or 60 Hz.

> Has any damage occurred during shipment? Are any bolts or nuts loose?

> Have all necessary accessories been supplied? (For a list of standard accessories see Construction.)

We recommend that you keep a spare pump on hand in case of emergencies.

Keep this instruction manual in a place for future reference.

Specifications

Check the nameplate for your pump’s head, discharge volume, speed (R.P.M), motor voltage

and current.

Other specifications are noted in the chart below.

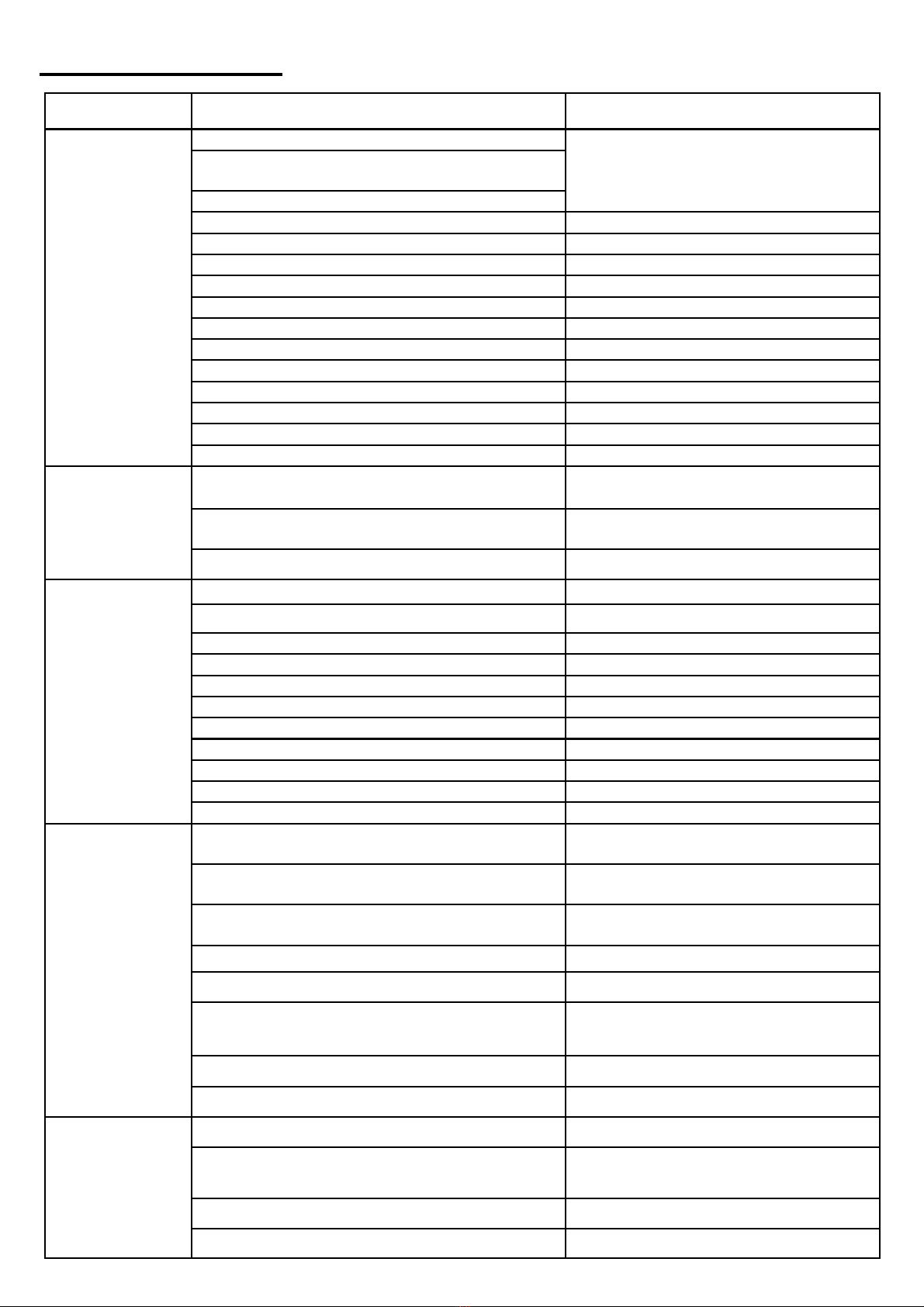

INDEX

Introduction……………...…………..PAGE. 3

Specifications………………….…….PAGE. 3

Installation……….…………………...PAGE. 4

Electrical wiring……………………...PAGE. 4

Operation………..………………...…PAGE. 5

Maintenance……………….…………PAGE. 5

Construction (HIPPO DN 1.5~2HP)…...…....PAGE. 6

Construction (HIPPO DN 3HP)……............PAGE. 8

Construction (HIPPO DN 4~5.5HP)……......PAGE. 10

Disassembly and Assembly…………….PAGE. 12

Nameplate format………………………..PAGE. 13

Troubleshooting…………………….……PAGE. 14

4

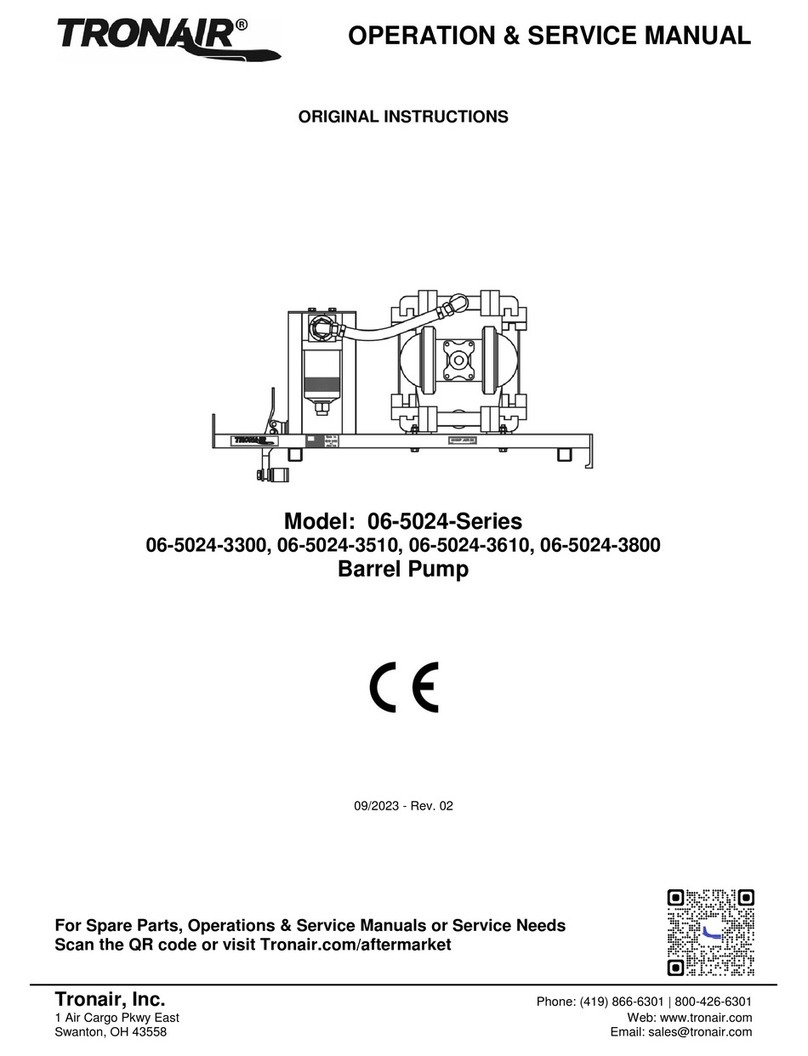

H2

H1

off

on

Installation

1. Check the following before beginning installation.

Insulation resistance measurement:

With the motor and cable (excluding the power supply cable) immersed in water, use a Megger to measure the insulation

resistance between ground and each phase of the motor, and again between each phase of the motor. The Megger should

indicate an insulation resistance of not less than 20mega ohms. While making the measurement, keep the power supply ca-

ble off the ground.

We recommend that an auxiliary pump be kept on hand in case of emergency.

2. Installation

Fig-1

Fig-2

Operating Water Level

Stop Water Level

H1: Lowest water level (Motor flange)

H2: Operating water level

This must be above the top of the motor

1.! WARNING : Under no circumstances should cable be

pulled while the pump is being transported or installed.

Attach a chain or rope to the grip and install the pump.

2.This pump must not be installed on its side or operated a dry

condition. Ensure that it is installed upright on a secure base.

3.Install the pump at a location in the tank where there is the least

turbulence.

4. If there is a flow of liquid inside the tank, support the piping

where appropriate.

5.Install piping so that air will not be entrapped. If piping must be

installed in such a way that air pockets are unavoidable, install

an air release valve wherever such air pockets are most likely to

develop.

6.Do not permit end of discharge piping to be submerged, as

backflow will result when the pump is shut down.

7..! WARNING : Non-automatic pumps do not have an automatic

operating system. Do not operate the pump for a long time with

the water level near the lowest water level(H1) as shown in

Fig.1, as the automatic cut-off switch incorporated inside the

motor will be activated.

8.To avoid dry operation, install an automatic operating system so

that this will not happen, as shown in Fig.2 and maintain a safe

operating water level.

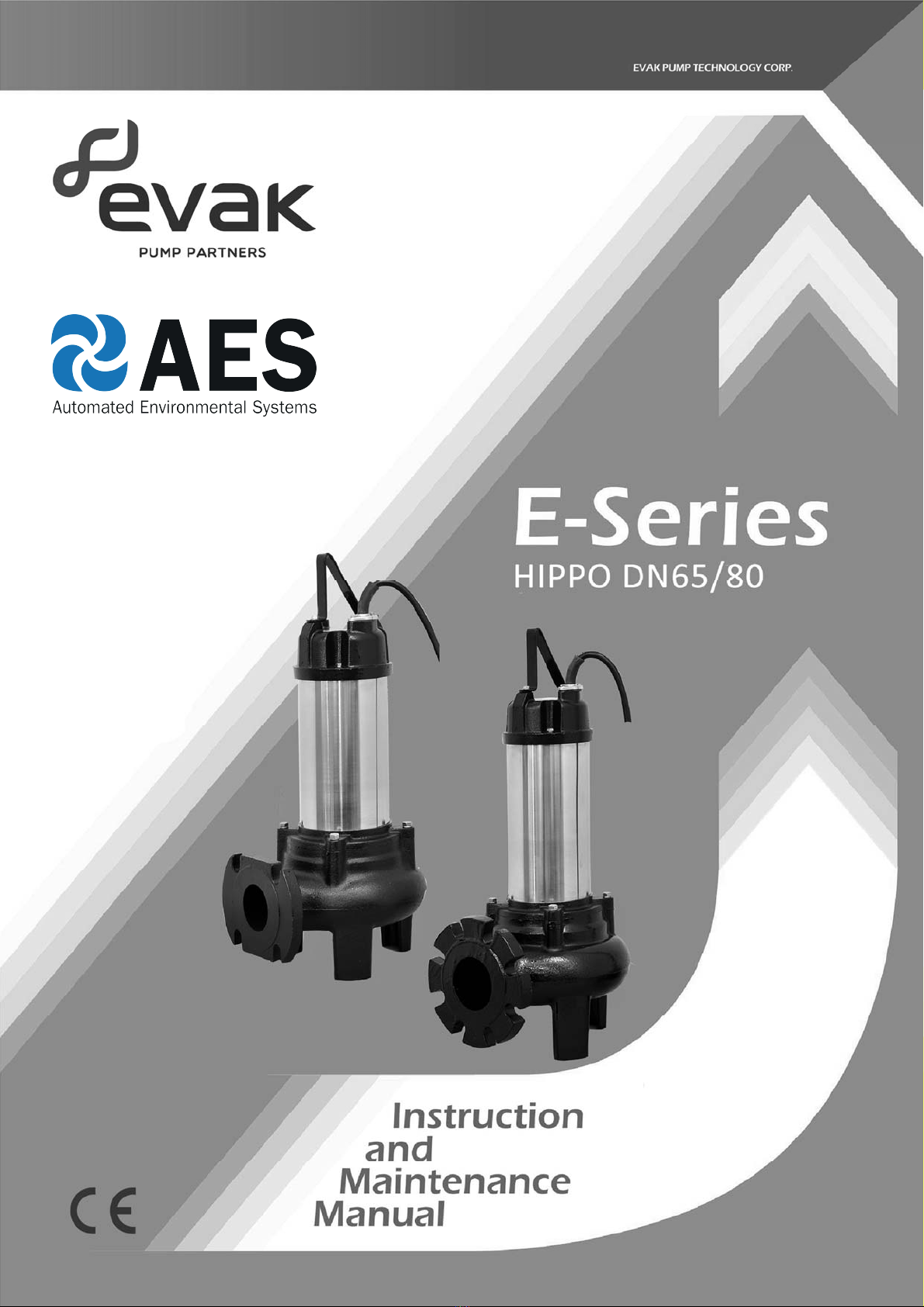

Electrical wiring

1.Wiring

A) Wire as indicated for the appropriate start system as shown in Fig-3 & 4 for singlephase version and Fig-5 for three phase.

B) Loose connections will stop the pump. Make sure all electrical connections secure.

C) For three phase motors - Operate the pump for a short time (1 or 2 seconds) to verify the rotation of direction of the impeller, if its recoil

is in counterclockwise direction, the direction of its rotation is correct. If not please switch two of the three power cords to correct the

rotation of direction of the impeller.

D) Make sure to check the pump’s direction of rotation with the pump exposed to the atmosphere. Operating the pump with reversed rota-

tion while in submerged condition under water will most likely to damage the pump, which may lead to leakage and electrical shock.

2.Cable

WARNING : Never let the end of the cable contact water.

A) If the cable is extended, do not immerse the splice in water.

B) Do not pull the cable.

C) Install the cable so that it will not overheat. Overheating is caused by coiling the cable and exposing it to direct sunlight.

3.Grounding

To ground the green (yellow/green) wire. Under no circumstances should the green (yellow/green) wire be connected to the power sup-

ply directly.

4. WARNING : Use short circuit breakers to prevent danger of electrical shock.

5. WARNING : Never start the pump while it is suspended, as thepump may jerk and cause serious accident involving injury.

Fig-3 Fig-4 Fig-5

Black

Green

White

Red

(Yellow/Green)

(Green/Yellow)

Frame grounding

Ground

Overload protector

R

S

T

PE

U

V

W

U2

W2

V2

Black

(Brown)

(Blue)

White

Green

(Yellow/Green)

Frame grounding

Ground (Green/Yellow)

Thermal

Protector

L

N

PE

Main

Auxiliary

(Yellow/Green)

Capacitor

Black

(Brown)

(Blue)

White

Green

Frame grounding

Ground (Green/Yellow)

Thermal

Protector

L

PE

Main

Auxiliary

N

Thermal

Protector

Black

(Brown)

(Blue)

White

Green

(Yellow/Green)

Ground (Green/Yellow)

Frame grounding

Main

Auxiliary

Capacitor

(Green/Yellow)

PE

Float Switch

5

Operation

Maintenance

Motor output 1.5HP 2HP 3HP 4HP 5.5HP

Mechanical seal 15Ø 20Ø

Lip seal 15Øx 24Øx7 t

Oil filler plug O-ring (Inner diameter) x (outer diameter) x (thickness) = 7.52Øx14.5Øx3.53 t

Lubricating oil

(turbine oil #32) 280 cc 500 cc

20Øx 38Øx7 t

Check pressure, output, voltage, current and other specifications. Unusual readings may indicate.

Refer to Troubleshooting and correct as soon as possible.

1. Daily inspections

Check current and ammeter fluctuation daily. If ammeter fluctuation is great, even though within the limits of pump

rating, foreign matter may be clogging the pump. If the quantity of liquid discharged falls suddenly, foreign matter

may be blocking the suction inlet.

2. Regular inspections

a. Monthly inspections

Measure the insulation resistance. The value should be more than 1M ohm. If resistance starts to fall rapidly even with

an initial indication of over 1M ohm, this nay be an indication of trouble and repair work is required.

b. Annual inspections

To prolong the service life of the mechanical seal by replacing the oil in the mechanical seal chamber once a year. Wa-

ter mixed the oil or cloudy textures are indications of a defective mechanical seal requiring replacement. When replac-

ing the oil, lay the pump on its side with filler plug on top. Inject suitable amount turbine oil No.32 (ISO VG-32) .

c. Inspections at 3-5year intervals

Conduct an overhaul of the pump. These intervals will preclude the possibility of future trouble.

3. Parts that will need to be replaced

Replace the appropriate part when the following conditions are apparent.

Replaceable part Mechanical seal Oil filler plug O-ring Lubricating oil O-ring

Replacement guide Whenever oil in

mechanical seal

chamber is clouded

Whenever oil is replaced

or inspected Whenever clouded or dirty Whenever pump is

overhauled

Frequency Annually A half yearly A half yearly Annually

Note: above replacement schedule is based on normal operating conditions.

1. Before starting the pump

a. After completing installation, measure the insulation resistance again as described in Installation.

b. Check water level.

If the pump is operated continuously for an extended period of time in a dry condition or at the lowest water

level, the motor protector will be activated. Constant repetition of this action will shorten pump service life. Do

not start the pump again in such a situation until after the motor has completely cooled.

2. Test operation….

Non-automatic pump

Automatic pump

a. Turn the operating switch on and off a couple of times to check for normal pump start.

Floating switch must be raised for the pump to start.

b. Next, check direction of rotation. If discharge volume is low or unusual sounds are heard when the pump is op-

erating, rotation has been reversed. When this happens, reverse two of the wires.

6

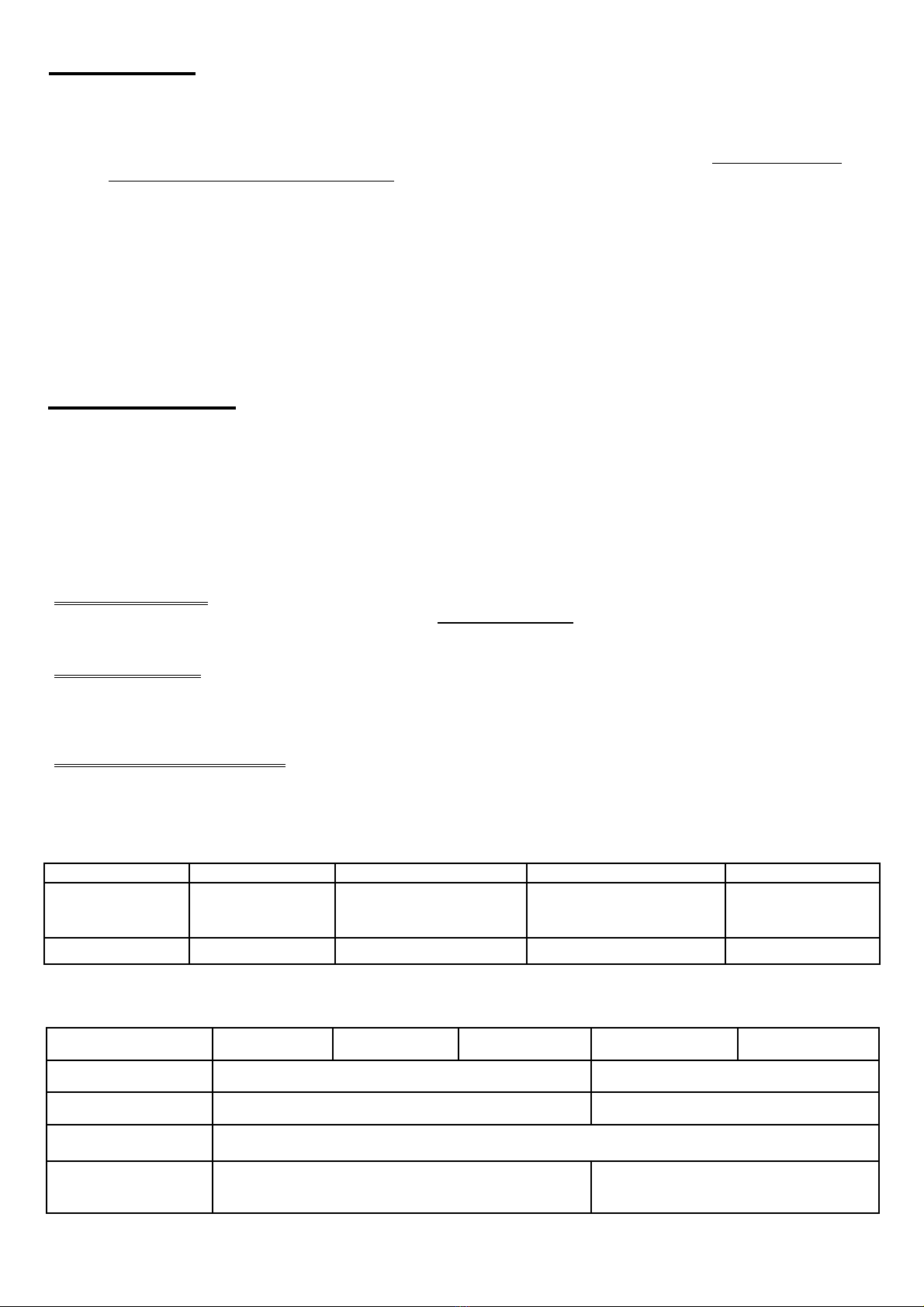

Construction

HIPPO DN 1.5~2HP

7

NO Part Material Photo NO Part Material Photo

2 Handle ASTM A36 12 Pump Casing

(DN65) EN-GJL-200

3 Motor

Cover EN-GJL-200 12 Pump Casing

(DN80) EN-GJL-200

4 Bracket EN-GJL-200 15-1

15-2 Upper Bearing

Lower Bearing NTN/TPI

5 Motor Housing

+Stator AISI 304

17-1

17-2 O-rings NBR

6 Shaft with Rotor AISI 410 18 Gasket NBR

7 Oil Chamber EN-GJL-200

18-1 Elbow Gasket

(DN65) NBR

8 Mechanical Seal CA/CE

+

SIC/SIC 18-1 Elbow Gasket

(DN80) NBR

9 Seal Housing EN-GJL-200 18-2 Flange Packing NBR

10 Lip Seal NBR

27 Flange

(DN65) EN-GJL-200

11 Impeller EN-GJL-200

28 Elbow EN-GJL-200

NO Part Material NO Part Material

19-2 Long Screw of motor Steel 21-9 Spring Washer AISI 304

19-3 Screw AISI 304 22 Oil Filler Plug AISI 304

19-4 Screw AISI 304 22-1 O-ring of Oil Filler Plug NBR

19-6 Screw AISI 304 24 Wire and Screw AISI 304

19-7 Screw AISI 304 31 Nut of impeller AISI 304

19-8 Screw AISI 304 31-1 Nut of Elbow AISI 304

19-9 Screw AISI 304 35 Key AISI 304

1 Cable H07RN-F/

SJTOW/STOW 20-5 Washer AISI 304

19-1 Screw AISI 304 21-6 Spring Washer AISI 304

14 Capacitor (1 Phase) - 21-1 Spring Washer AISI 304

13 Protector (3 Phase) KLIXON 20-7 Washer AISI 304

19 Screw AISI 304 21-4 Washer with O-ring AISI 304+NBR

TPI is a family brand of NTN group.

8

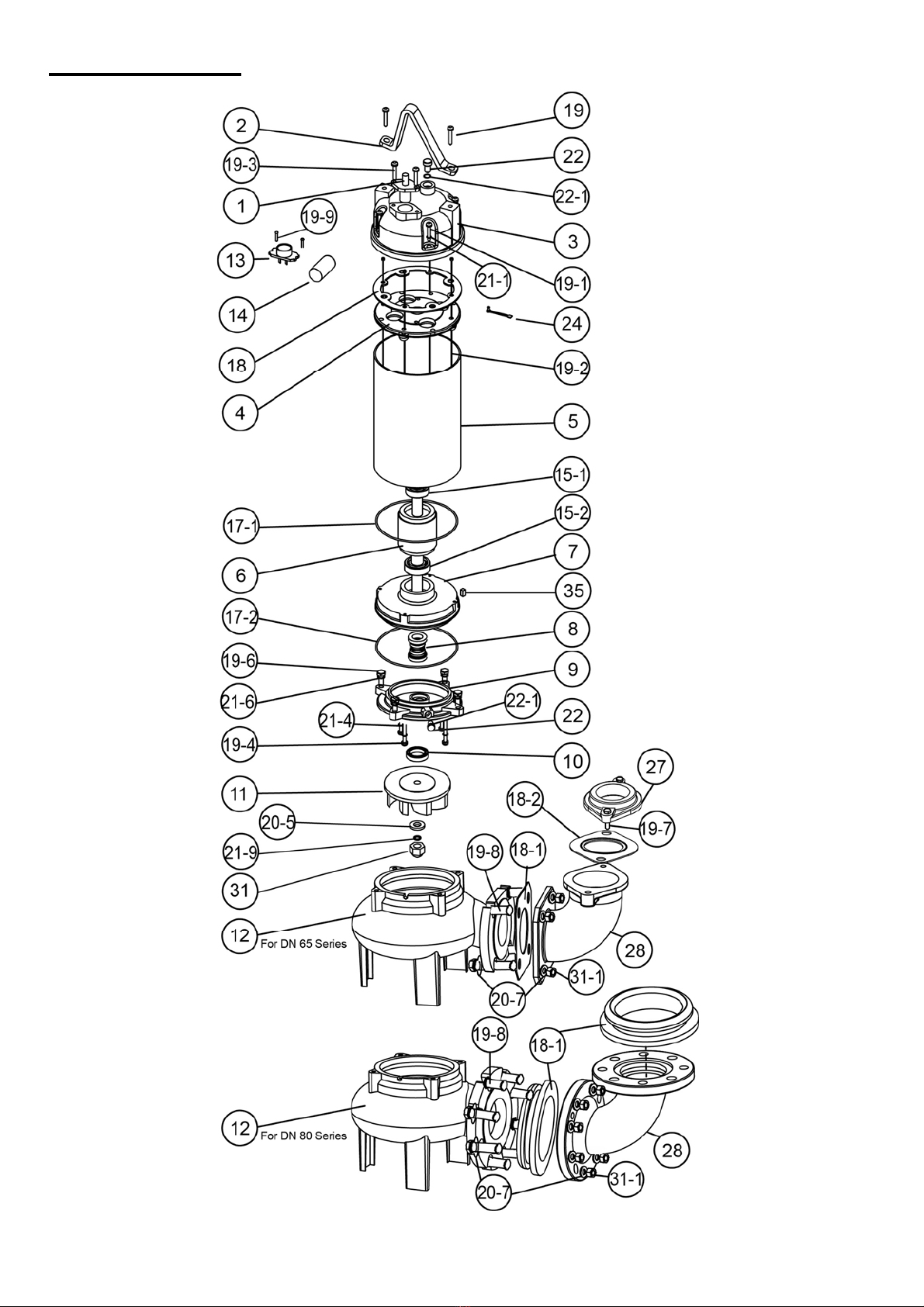

Construction

HIPPO DN 3HP

9

NO Part Material Photo NO Part Material Photo

2 Handle ASTM A36 12 Pump Casing

(DN65) EN-GJL-200

3 Motor

Cover EN-GJL-200 12 Pump Casing

(DN80) EN-GJL-200

4 Bracket EN-GJL-200 15-1

15-2 Upper Bearing

Lower Bearing NTN/TPI

5 Motor Housing

+Stator AISI 304

17-1

17-2 O-rings NBR

6 Shaft with Rotor AISI 410 18 Gasket NBR

7 Oil Chamber EN-GJL-200

18-1 Elbow Gasket

(DN65) NBR

8 Mechanical Seal CA/CE

+

SIC/SIC 18-1 Elbow Gasket

(DN80) NBR

9 Seal Housing EN-GJL-200 18-2 Flange Packing NBR

10 Lip Seal NBR

27 Flange

(DN65) EN-GJL-200

11 Impeller EN-GJL-200

28 Elbow EN-GJL-200

NO Part Material NO Part Material

19-2 Long Screw of motor Steel 21-9 Spring Washer AISI 304

19-3 Screw AISI 304 22 Oil Filler Plug AISI 304

19-4 Screw AISI 304 22-1 O-ring of Oil Filler Plug NBR

19-6 Screw AISI 304 24 Wire and Screw AISI 304

19-7 Screw AISI 304 31 Nut of impeller AISI 304

19-8 Screw AISI 304 31-1 Nut of Elbow AISI 304

19-9 Screw AISI 304 35 Key AISI 304

1 Cable H07RN-F/

SJTOW/STOW 20-5 Washer AISI 304

19-1 Screw AISI 304 21-6 Spring Washer AISI 304

14 Capacitor (1 Phase) - 21-1 Spring Washer AISI 304

13 Protector (3 Phase) KLIXON 20-7 Washer AISI 304

19 Screw AISI 304 21-4 Washer with O-ring AISI 304+NBR

TPI is a family brand of NTN group.

10

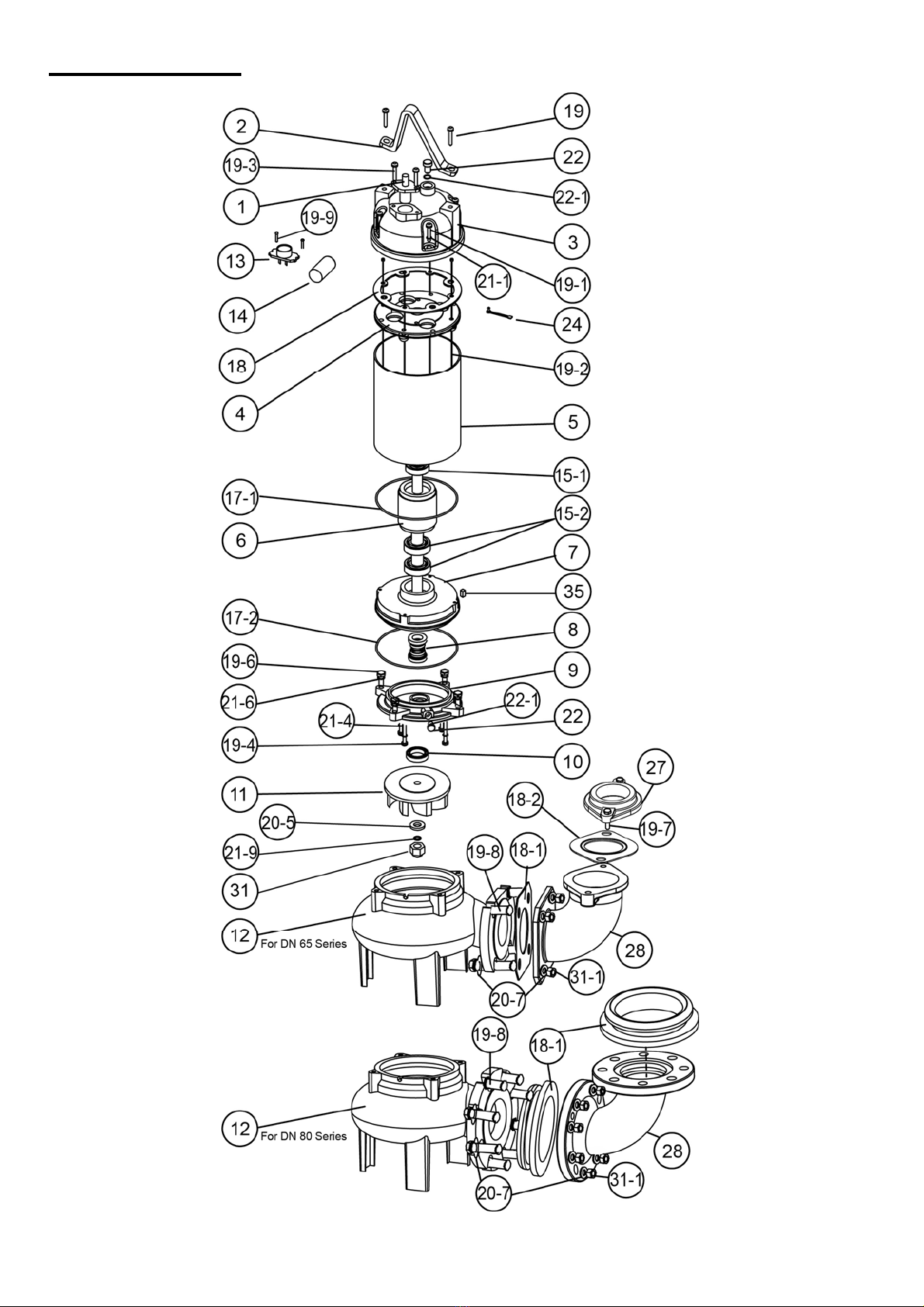

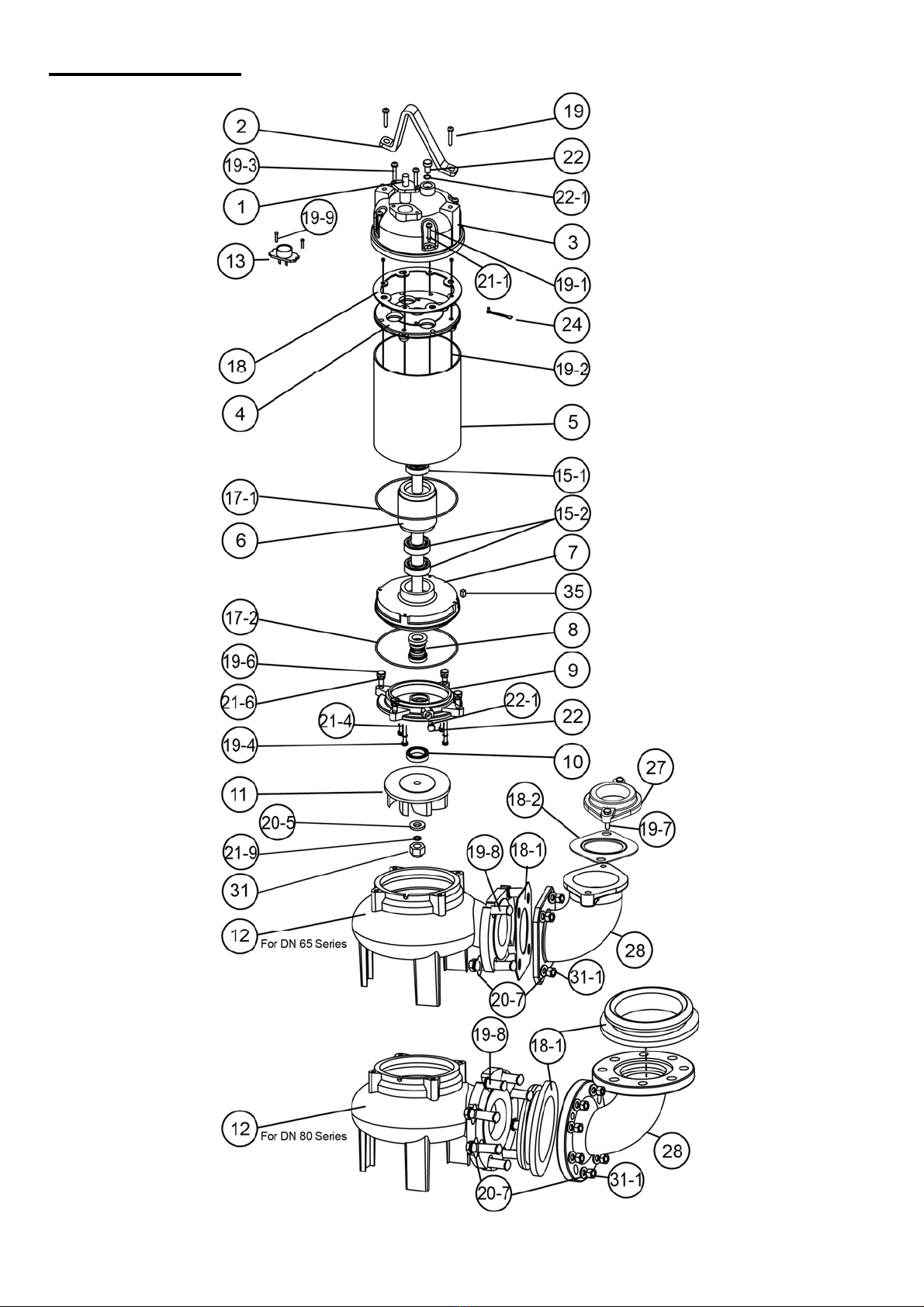

Construction

HIPPO DN 4~5.5HP

11

NO Part Material Photo NO Part Material Photo

2 Handle ASTM

A36 12 Pump Casing

(DN65) EN-GJL-200

3 Motor

Cover EN-GJL-200 12 Pump Casing

(DN80) EN-GJL-200

4 Bracket EN-GJL-200 15-1

15-2 Upper Bearing

Lower Bearing NTN/TPI

5 Motor Housing

+Stator AISI 304 17-1

17-2 O-rings NBR

6 Shaft with Rotor AISI 410 18 Gasket NBR

7 Oil

Chamber EN-GJL-200 18-1 Elbow Gasket

(DN65) NBR

8 Mechanical Seal CA/CE

+

SIC/SIC 18-1 Elbow Gasket

(DN80) NBR

9 Seal Housing EN-GJL-200 18-2 Flange Packing NBR

10 Lip Seal NBR 27 Flange

(DN65) EN-GJL-200

11 Impeller EN-GJL-200 28 Elbow EN-GJL-200

NO Part Material NO Part Material

19-3 Screw AISI 304 22 Oil Filler Plug AISI 304

19-4 Screw AISI 304 22-1 O-ring of Oil Filler Plug NBR

19-6 Screw AISI 304 24 Wire and Screw AISI 304

19-7 Screw AISI 304 31 Nut of impeller AISI 304

19-8 Screw AISI 304 31-1 Nut of Elbow AISI 304

19-9 Screw AISI 304 35 Key AISI 304

20-5 Washer AISI 304

1 Cable H07RN-F/

SJTOW/STOW 20-7 Washer AISI 304

19-2 Long Screw of motor Steel 21-9 Spring Washer AISI 304

19 Screw AISI 304 21-4 Washer with O-ring AISI 304+NBR

13 Protector (3 Phase) KLIXON 21-1 Spring Washer AISI 304

19-1 Screw AISI 304 21-6 Spring Washer AISI 304

TPI is a family brand of NTN group.

12

Disassembly and Assembly

1. Disassembly-

When disassembling pump, have a piece of cardboard or wooden board ready to

place the different parts on as you work. Do not pile parts on top of each other. They

should be laid out neatly in rows. The “O” ring and gasket cannot be used again

once they are removed. Have replacement parts ready. Disassemble in the following

order, referring to the sectional view.

Be sure to cut off power source before disassembly.

(1) Remove pump casing bolts, raise the motor section and remove pump casing.

(2) Remove shaft head bolt and impeller.

(3) Remove oil filler plug and drain lubricating oil.

(4) Remove intermediate casing bolts and oil chamber.

(Remember that any lubricating oil remaining in the mechanical seal chamber

will flow out.)

(5) Carefully remove mechanical seal, beware of not to scratch sliding surface of

motor shaft.

2. Assembly-

Re-assemble in reverse order of disassembly.

Be careful of the following points.

(a) During re-assembly, rotate the impeller by hand and check for smooth rotation.

If rotation is not smooth, perform steps-(3) through -(5) again.

(b) Upon completion of re-assembly step -(1) rotate the impeller by hand from the

suction inlet and check that it rotates smoothly without touching the suction cov-

er before operating the pump.

Please order “O” rings, packing, shaft seals and other parts from your dealer.

13

Nameplate format

14

Troubleshooting

Trouble Cause Remedy

Does not start.

Starts, but imme-

diately stops.

(1) Power failure (1)~(3) Contact electric power company and

devise counter-measures

(2) Large discrepancy between power source and

voltage

(3) Significant drop in voltage

(4) Motor phase malfunction (4) Inspect electric circuit

(5) Electric circuit connection faulty (5) Correct wiring

(6) Faulty connection of control circuit (6) Inspect connections and magnetic coil

(7) Fuses is blown (7) Check circuit then replace fuse

(8) Faulty magnetic switch (8) Replace with correct one

(9) Water is not at level indicated by Float (9) Raise water level

(10) Float is not in appropriate level (10) Adjust the position of float

(11) Float is not effective (11) Repair or replace

(12) Short circuit breaker is functioning (12) Repair location of short circuit

(13) Foreign matter clogging pump (13) Remove foreign matter

(14) Motor burned out (14) Repair or replace

(15) Motor bearing broken (15) Repair or replace

Operates, but

stops after a

while.

(1) Prolonged dry operation has activated motor pro-

tector and caused pump to stop (1) Raise water level to C.W.L

(2) High liquid temperature has activated motor pro-

tector and caused pump to stop (2) Lower liquid temperature

(3) Reverse rotation ! WARNING : (3) Correct rotation

Does not pump.

Inadequate vol-

ume.

(1) Reverse rotation (1) Correct rotation (see Operation)

(2) Significant drop in voltage (2) Contact electric power company

(3) Operating a 60Hz pump with 50Hz (3) Check nameplate

(4) Discharge head is high (4) Recalculate and adjust

(5) Large piping loss (5) Recalculate and adjust

(6) Low operating water level causes air suction (6) Raise water level or lower pump

(7) Leaking from discharge piping (7) Inspect, repair

(8) Clogging of discharge piping (8) Remove foreign matter

(9) Foreign matter in suction inlet (9) Remove foreign matter

(10) Foreign matter clogging pump (10) Remove foreign matter

(11) Worn impeller (11) Replace impeller

Over current (1) Unbalanced current and voltage (1) Contact electric power company

(2) Significant voltage drop (2) Contact electric power company and de-

vise counter-measure

(3) Motor phase malfunction (3) Inspect connections and magnetic switch

(4) Operating 50Hz pump on 60Hz (4) Check nameplate

(5) Reverse rotation ! WARNING : (5) Correct rotation

(6) Low head. Excessive volume of water (6) Replace pump with high head pump

(7) Foreign matter clogging pump (7) Remove foreign matter

(8) Motor bearing is worn out or damaged (8) Replace bearing

Pump vibrates;

excessive oper-

ating noise.

(1) Reverse rotation (1) Correct rotation

(2) Pump clogged with foreign matter

(2) Disassemble and remove foreign matter

(3) Piping resonates (3) Improve piping

(4) Strainer is closed too far (4) Open strainer

15

Note

16

Vol.PMHIPPODN-20051

Unit 1, 1 Wimbledon Avenue, Brandon, Suffolk, IP27 0NZ

01842 819130

This manual suits for next models

50

Table of contents

Popular Water Pump manuals by other brands

Makita

Makita EW1050H instruction manual

STIEBEL ELTRON

STIEBEL ELTRON PK 10 Operation and installation

Banjo

Banjo 300PI8PRO instruction manual

Flint & Walling

Flint & Walling 3CEH installation instructions

Federal Pump

Federal Pump BGP Series Installation, operation & maintenance manual

3P PRINZ

3P PRINZ Pompe 3P M Series Instruction & maintenance manual

MYERS

MYERS VRS10A-11 Installation and service manual

EasyPro

EasyPro EXP3200 Installation and service manual

Northern Industrial Tools

Northern Industrial Tools 1/2 HP SUMP PUMP owner's manual

Graco

Graco 257100 Operation

Grundfos

Grundfos Magna 32-120 Service instructions

Ozito

Ozito PSDW-350 instruction manual