| 4

144XXXME4.00 - 06/2020 - EV3 Mix

IMPORTANT INFORMATION

Liability and residual risks

EVCO assumes no liability for any damage caused by the following (by way of example; this is not an exhaustive list):

• Installation/useforpurposesotherthanthosespeciedand,inparticular,notadheringtothesafetyprovisionssetout

by current regulations in the country in which the product is installed and/or contained in this manual;

• Useinappliancesthatdonotguaranteesufcientprotectionagainstelectricshocks,wateranddustwithinthe

installation conditions created;

• Useinappliancesthatallowaccesstohazardouspartswithouttheuseofakeyedortooledlockingmechanismwhen

accessing the instrument;

• Tampering and/or modifying the product;

• Installation/use in appliances which do not comply with current regulations in the country in which the product is installed.

The customer/manufacturer is responsible for ensuring their machine complies with these regulations.

EVCO’s responsibility is limited to the correct and professional use of the product in accordance with regulations and the

instructions contained in this manual and other product support documents.

TocomplywithEMCstandards,observealltheelectricalconnectioninstructions.Asitdependsonthewiringconfigurationas

wellastheloadandtheinstallationtype,compliancemustbeverifiedforthefinalmachineasspecifiedbytherelevantproduct

standard.

Disclaimer

This document is the exclusive property of EVCO. It contains a general description and/or a description of the technical

specifications for the services offered by the products listed herein. This document should not be used to determine the

suitability or reliability of these products in relation to specific user applications. Each user or integration specialist should

conducttheirowncompleteandappropriateriskanalysis,inadditiontocarryingoutaproductevaluationandtestinrelation

to its specific application or use. Users can send us comments and suggestions on how to improve or correct this publication.

Neither EVCO nor any of its associates or subsidiaries shall be held responsible or liable for improper use of the information

contained herein.

EVCOhasapolicyofcontinuousdevelopment.Therefore,EVCOreservestherighttomakechangesandimprovementstoany

product described in this document without prior notice.

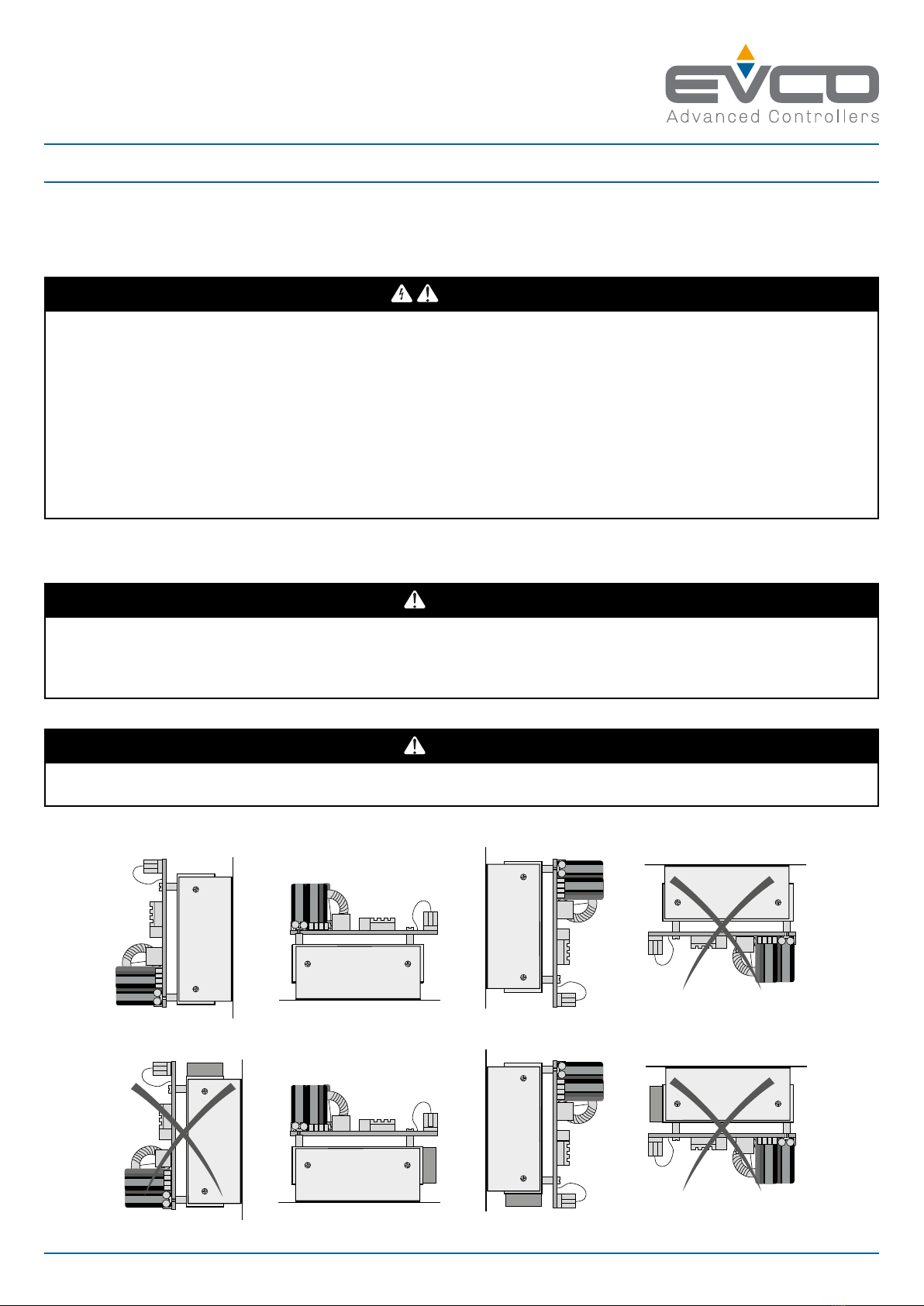

The images in this document and other documentation supplied with the product are provided for illustrative purposes only and

may differ from the product itself.

The technical data in this manual is subject to change without prior notice.

Terms and Conditions of use

Permitted use

Thedevicemustbeinstalledandusedinaccordancewiththeinstructionsprovidedand,inparticular,hazardousliveparts

must not be accessible under normal conditions.

The device must be suitably protected from water and dust with regard to its application and must also only be accessible with

the aid of a tool (with the exception of the front panel).

Only qualified personnel may install the product or perform technical support procedures on it.

The customer must only use the product as described in the documentation relating to that product.

Prohibited use

Anyuseotherthanthosedescribedinthe"Permitted use"sectionandintheproductsupportdocumentationisprohibited.

The product must be installed outside hazardous ATEX areas.

Disposal

The device must be disposed of in accordance with local regulations regarding the collection of electrical and

electronic appliances.

Consider the environment

Withaviewtorespectingtheenvironment,westrivetoadheretotheenvironmentalperformanceofthecompany,

whiletakingaccountofcustomerrequirements,technologicalinnovationsintermsofmaterialsandtheexpectations

ofthecommunitytowhichwebelong.EVCOplacesgreatimportanceonrespectingtheenvironment,encouragingall

associatestobecomeinvolvedwithcompanyvaluesandguaranteeingsafe,healthyandfunctionalworkingconditions

andworkplaces.

Please consider the environment before printing this document.