Evergreen EG-1003 User manual

Instruction Manual

Multi-Function

Cleaning Gun

EG - 1003

Clean engines, wheels, tires, vents, trunks, door jams, etc.. Pressurized cleaning

brush easily breaks down stubborn dirt and grease. Green solution-10L/hour water

consumption.Please use the Multi-Function Cleaning Gun in a safe and secure

environment.Read the Direction For Use carefully before using the Multi-Function

Cleaning Gun.

During operation, please ensure that the equipment has not been damaged.Use of

controls, adjustments, or performance of procedures other than those specified in

instruction manual might result in poor performance, or damage the equipment.

Warning

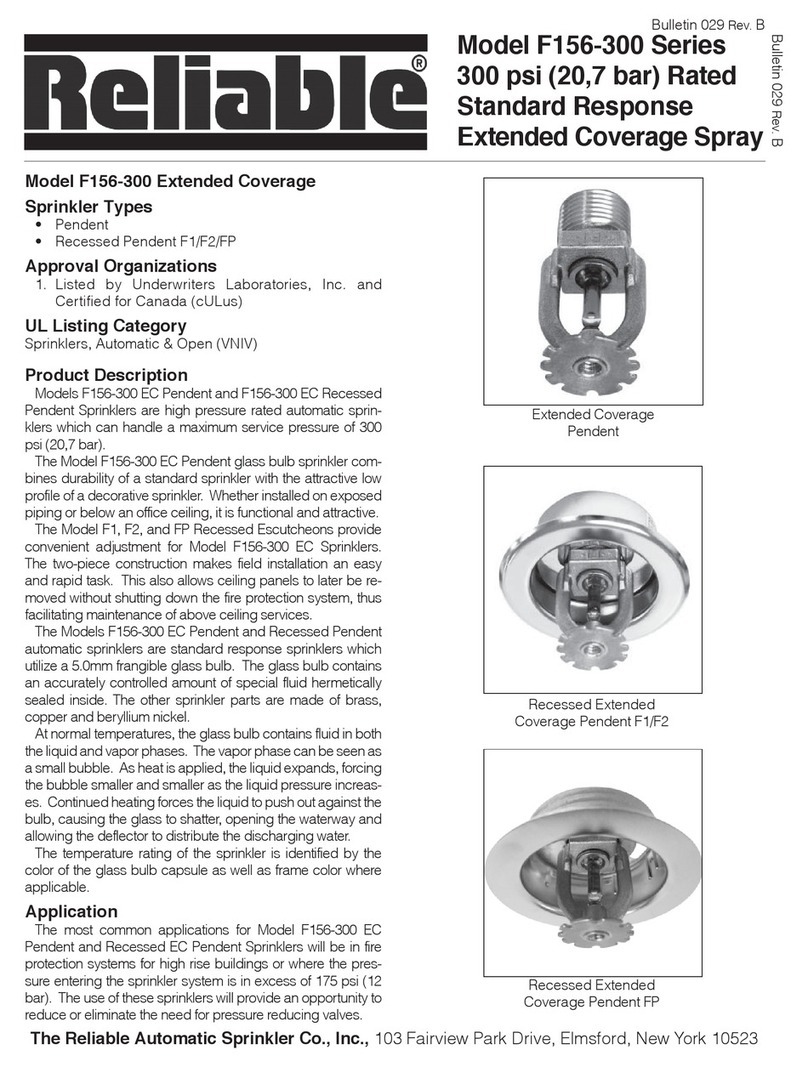

Trigger/Handle

Hold it, spray the liquid;

Release it, stop spraying the liquid

Air Tube (short)

Infusion Tube(long)

Air Reverse Switch

Switch between Air/Liquid

Air Adjusting Valve

Adjust air pressure.

Bursh

Air Plug (for air tube)

Clicking sound means the tube is

connected correctly.

Liquid Absorbing Tube:

Absorbs liquid. Connect the tube

to water or other solutions.

Liquid Adjusting Valve /

Fixed Valve (See Page 2)

Upper valve is Fixed Valve, please

tight up the valve, then use lower

liquid adjusting valve to control the

liquid flow.

Infusion Port

Port to connect the infusion tube

(See Page 2 for installation)

Air Tube Port

Port to connect the air tube

(See Page 2 for installation)

1

Maintenance Methods / Tips

Environmental Friendly

First, Turn on the air reverse switch and release pressure by pulling trigger of

the gun, until the brush is totally wet.

Next, completely turn off the air reverse switch, and release pressure by

triggering the gun, letting the reminding water and dust come out from the gun.

If the cleaning brush is still dirty, please repeat step 1 and 2. (Notice: Use an

empty container to clean the gun which would prevent the dirty water and dust

spreading all over the place.)

NANOSKIN CAR CARE PRODUCTS

Division of Total Import Solutions, Inc.

La Habra, CA 90631

Made in USA

www.nanoskinusa.com

For Chemical Emergency: PERS – Day or Night

NORTH AMERICA :1-800-633-8253

INTERNATIONAL :1-801-629-0667

2

EG-1003

W50 D290 H180

0.6

75~115

200 @72Psi

10

Neutral

10~50

1/4”

Model No.

Dimension (mm)

Weight (kg)

Air Pressure (Psi)

Air Consumption (L/min)

Max. Spraying Volume (L/min)

Detergent

Working Temperature ( oC)

Air Inlet

SPECIFICATION

Annotation

Read and observe the safety notes in the Operating Instructions and the safety labels

located on the system. Failure to observe the safety notes may lead to serious injuries

and to significant damages to the Equipment. Warning instructions in this manual point

out particular dangers to users and equipment and state measures for avoiding the

hazard.

Higher pressure may cause damages to

the guns, and cause danger.

Please set knob from o and below 4.

Please refer the right graph for using 1- 2MPa.

Grip

Outlet

Adjust Air Compressor Knob

■The pressure must be set below 115 Psi.

Higher than 115 Psi may cause damage to the equipment and create the dangerous events.

■ONLY use guns and nozzle for cleaning work.

It could cause body injuries or create danger.

■NEVER point the cleaning guns in the direction of human body, face or eyes.

Wear safety goggles and respirator during operation.

■Use ONLY neutral liquid / solutions.

Specially note that organic solvent even in neutral feature cannot be used, because it contains

enormous factors might cause deterioration

■DO NOT use unoriginal accessories or special consumables, or repair

your own parts for replacement.

■DO NOT disassemble or change the cleaning guns.

These warning instructions fall into the following categories:

In case of any abnormity or damage of equipment during the use process, please terminate the

operation immediately.

TISI shall not be responsible for device damage caused by application of unoriginal accessories and

special consumables, or your own repair, parts replacement, and disassembly of the device.

In such case, warranty will be void.

Possible danger. Non-observance can result in death, serious injury and

serious damages of equipments.

The content under this label must be strictly abided by. Improper operation

and use may cause serious damages to the devices and minor injuries.

Provide information on particular characteristics and how to proceed.

Warning

Notice

Caution

Warning

Warning

3

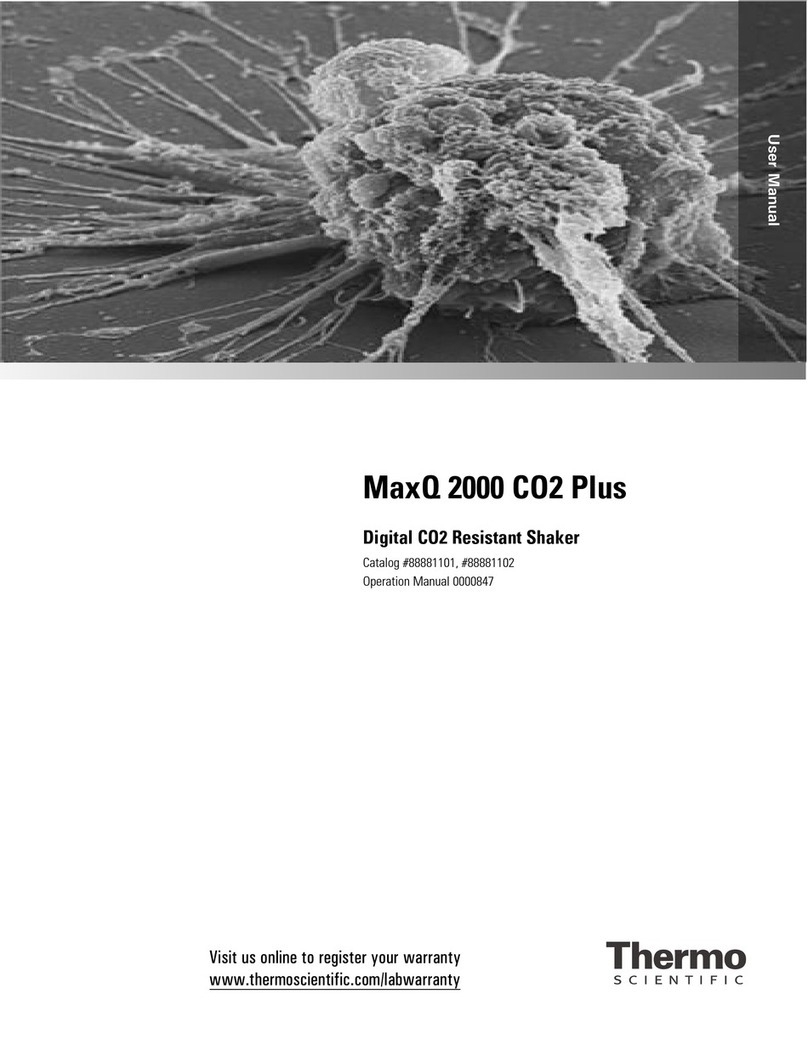

Adjustment of Liquid Adjusting Valve/

Fixed Valve

Caution

Notice

Method of Liquid Adjusting Valve / Fixed Valve

Fixed Valve

Liquid Adjusting Valve

Fixed Valve screw allows to adjust the air flow. Once the Air pressure is fixed, please

tighten up the fixed valve.

Liquid Adjusting Valve

The tighter the liquid adjusting valve screw, the thinner and smaller the spray volume is;

the looser the liquid adjusting valve screw, the thicker and larger the spray volume is.

The tubes must be properly installed.

Otherwise, the fluid and air may leak during the operation process.

During the operation, please tighten up the fixed valve.

May cause damage if fixed valve not tight.

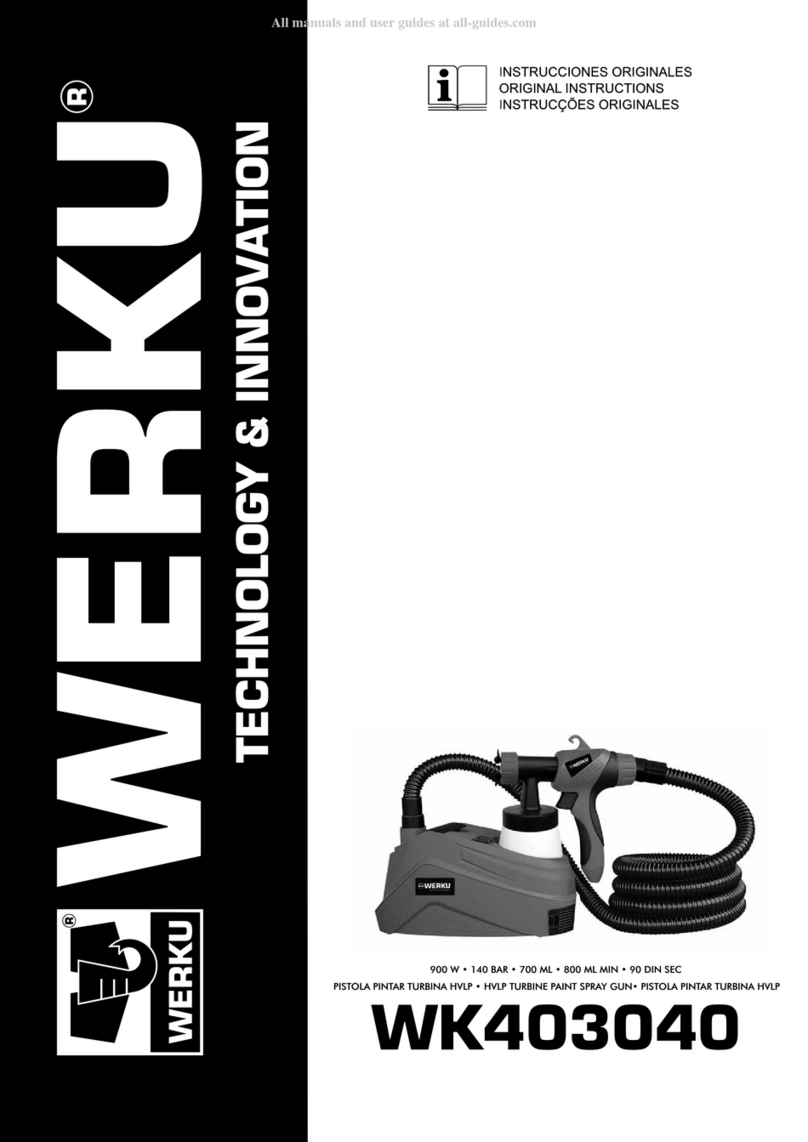

Installation and Disassembly of the Air Tube / Infusion Tube

Installation of the tube

Air Tube :

Directly insert the air tube into air port. Pull it lightly to check

whether it is properly installed. (Notice: Do Not pull too hard)

Infusion Tube:

Insert the infusion tube into the infusion port and screw tight.

Pull it lightly to check whether it is properly installed.

Disassembly of the tube

Air Port Joint

Air Tube :

Press the Joint with one hand, and lightly pull out the air tube

with the other hand.

Infusion Tube:

Loose the screw on the infusion port, and lightly pull out the

infusion tube.

4