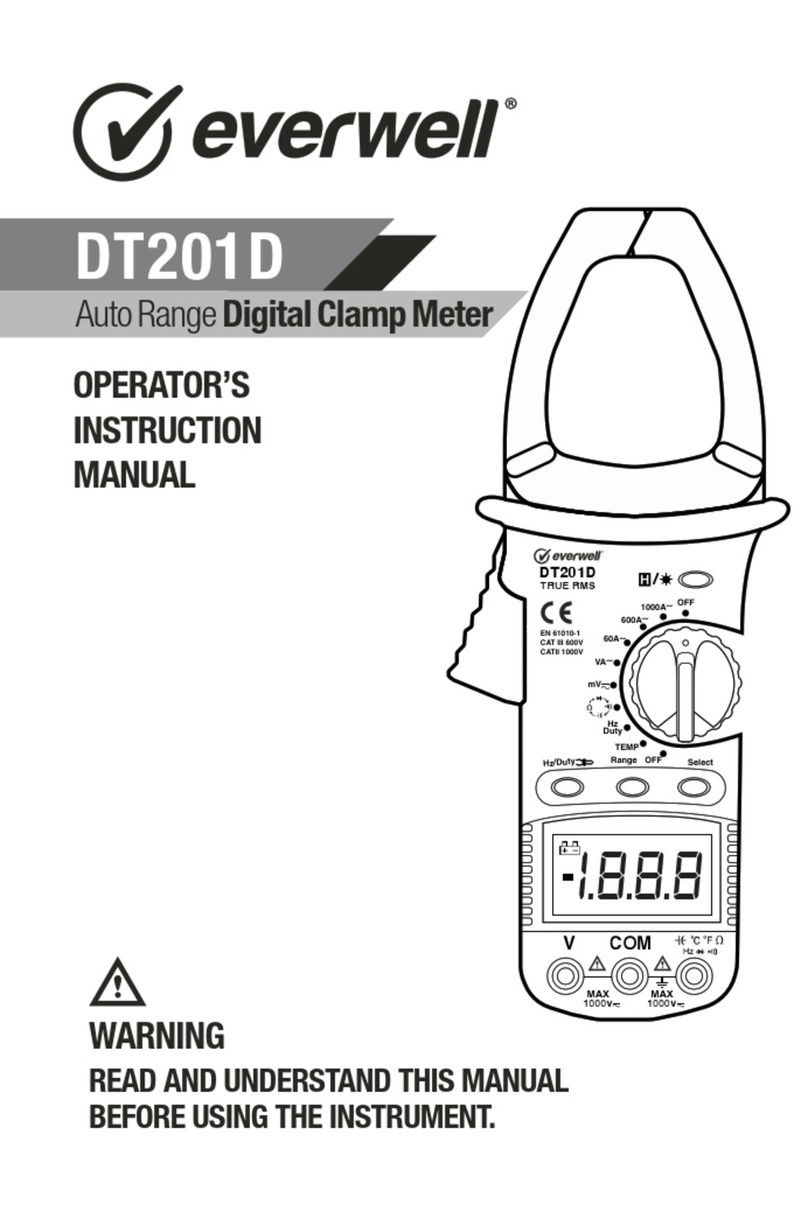

Everwell 266 User manual

INSTRUCTION

MANUAL

266

Digital Clamp Meter

WARNING

READ AND UNDERSTAND THIS MANUAL

BEFORE USING THE INSTRUMENT.

Warning

To avoid possible electric shock or personal injury, and to

avoid possible damage to the meter or to the equipment

under test, adhere to the following rules:

• Before using the meter inspect the case. Do not use the

meter if it is damaged or the case (or part of the case) is

removed. Inspect for cracks or missing plastic pieces. Pay

attention to the insulation around the connectors.

• Inspect the test leads for damaged insulation or exposed

metal. Check the test leads for continuity.

• Do not apply more than the rated voltage, as marked on the

meter, between the terminals or between any terminal and

grounding.

• The rotary switch should be placed in the right position and

no changeover of range shall be made during measurement

to prevent damage of the meter.

• When the meter is working at an effective voltage over 60V

in DC or 36V rms in AC, special care should be taken for

there is danger of electric shock.

• Use the proper terminals, function, and range for your

measurements.

• Do not use or store the meter in an environment of high

temperature, humidity, explosive, inflammable and strong

magnetic field. The performance of the meter may

deteriorate after dampened.

• When using the test leads, keep your fingers behind the

finger guards.

• Disconnect circuit power and discharge all high-voltage

capacitors before testing resistance, continuity or diodes.

• Replace the battery as soon as the battery indicator

appears. With a low battery, the meter might produce false

readings that can lead to electric shock and personal injury.

-2-

Warning

To avoid possible electric shock or personal injury, and to

avoid possible damage to the meter or to the equipment

under test, adhere to the following rules:

• Before using the meter inspect the case. Do not use the

meter if it is damaged or the case (or part of the case) is

removed. Inspect for cracks or missing plastic pieces. Pay

attention to the insulation around the connectors.

• Inspect the test leads for damaged insulation or exposed

metal. Check the test leads for continuity.

• Do not apply more than the rated voltage, as marked on the

meter, between the terminals or between any terminal and

grounding.

• The rotary switch should be placed in the right position and

no changeover of range shall be made during measurement

to prevent damage of the meter.

• When the meter is working at an effective voltage over 60V

in DC or 36V rms in AC, special care should be taken for

there is danger of electric shock.

• Use the proper terminals, function, and range for your

measurements.

• Do not use or store the meter in an environment of high

temperature, humidity, explosive, inflammable and strong

magnetic field. The performance of the meter may

deteriorate after dampened.

• When using the test leads, keep your fingers behind the

finger guards.

• Disconnect circuit power and discharge all high-voltage

capacitors before testing resistance, continuity or diodes.

• Replace the battery as soon as the battery indicator

appears. With a low battery, the meter might produce false

readings that can lead to electric shock and personal injury.

• Remove the connection between the testing leads and the

circuit being tested, and turn the meter power off before

opening the Meter case.

• When servicing the meter, use only the same model

number or identical electrical specifications replacement

parts.

• The internal circuit of the meter shall not be altered at will to

avoid damage of the meter and any accident.

• Soft cloth and mild detergent should be used to clean the

surface of the meter when servicing. No abrasive and

solvent should be used to prevent the surface of the meter

from corrosion, damage and accident.

• The meter is suitable for indoor use.

• Turn the meter power off when it is not in use and take out

the battery when not using for a long time. Constantly check

the battery as it may leak when it has been using for some

time, replace the battery as soon as leaking appears.

-3-

-4-

➀Transformer Jaws

Pick up the AC Current flowing through the conductor

➁Trigger

Press the level to open the transformer jaws when the finger

press on the level is released the jaws will close again.

➂Data Hold Switch

A push switch (pushes on, push off, do not pull to select

function). All function and ranges with this feature.

➃Rotary Switch

A rotary switch is used to select measurement Function and

Range switch.

➄Display

3 ½ digits (1999 counts), decimal point, minus polarity, Over

range and “ ” indicators.

➅EXT Input Connect

Used for accept insulation tester unit EXT banana plugs,

when measurement insulation resistance.

➆COM Input Connect

Low input for all voltage, resistance, and continuity

measurement will accept banana plugs. When

measurement insulation resistance, used for accept

insulation tester unit COM banana plugs.

➇ VΩ Input Connect

High input for all voltage, resistance, and continuity

measurement will accept banana plugs. When

measurement insulation resistance, used for accept

insulation tester unit VΩ banana plugs.

➈Drop-Proof Wrist Strap

Prevents the instrument from slipping off the hand while in

use.

-5-

1. GENERAL SPECIFICATIONS

•Max display: LCD 3 ½ digits, 1999 counts, 0.5” high

•Polarity: Automatic, indicated minus, assumed plus.

•Measure method: double integral A/D switch implement

•Sampling speed: 2 times per second

•Over-load indication: “1” is displayed

•Operating Environment: 0°C~40°C, at <80%RH

•Storage Environment: -10°C~50°C, at <85%RH

•Power: 9V NEDA 1604 or 6F22

•Low battery indication: “ ”

•Static electricity: about 4mA

•Product Size: 230×68×37mm

•Product net weight: 240g (including battery)

2. TECHNICAL SPECIFICATIONS

Accuracies are guaranteed for 1 year, 23°C±5°C, less than

80%RH

2-1. DC Voltage

Overload Protection: 1000V DC or 750V rms for all ranges.

2-2. Audible Continuity

Overload Protection: 15 second maximum 220V rms.

-6-

2-3. AC Voltage

RESPONSE: Average responding, calibrated in rms of a sine

wave.

FREQUENCY RANGE: 45Hz ~ 450Hz

OVERLOAD PROTECTION: 1000V DC or 750V rms for all

ranges.

2-4. AC Current (Average sensing, calibrated to rms of

sine wave)

Overload Protection: 1200A within 60 seconds. Jaw

Opening: 2.09” (53mm)

2-5. Insulation Test (With option 500V insulation tester

unit)

Range Resolution Accuracy

1000V 1V ±(1.0% of rdg + 5D)

Range Description

Built-in buzzer sounds if resistance

is less than 30±20Ω

1. GENERAL SPECIFICATIONS

•Max display: LCD 3 ½ digits, 1999 counts, 0.5” high

•Polarity: Automatic, indicated minus, assumed plus.

•Measure method: double integral A/D switch implement

•Sampling speed: 2 times per second

•Over-load indication: “1” is displayed

•Operating Environment: 0°C~40°C, at <80%RH

•Storage Environment: -10°C~50°C, at <85%RH

•Power: 9V NEDA 1604 or 6F22

•Low battery indication: “ ”

•Static electricity: about 4mA

•Product Size: 230×68×37mm

•Product net weight: 240g (including battery)

2. TECHNICAL SPECIFICATIONS

Accuracies are guaranteed for 1 year, 23°C±5°C, less than

80%RH

2-1. DC Voltage

Overload Protection: 1000V DC or 750V rms for all ranges.

2-2. Audible Continuity

Overload Protection: 15 second maximum 220V rms.

-7-

2-3. AC Voltage

RESPONSE: Average responding, calibrated in rms of a sine

wave.

FREQUENCY RANGE: 45Hz ~ 450Hz

OVERLOAD PROTECTION: 1000V DC or 750V rms for all

ranges.

2-4. AC Current (Average sensing, calibrated to rms of

sine wave)

Overload Protection: 1200A within 60 seconds. Jaw

Opening: 2.09” (53mm)

2-5. Insulation Test (With option 500V insulation tester

unit)

Range Resolution Accuracy

750V 1V ±(1.2% of rdg + 5D)

Range

200A 100mA

±(2.5% + 8)

for 800A and below

±(2.5% + 13)

The reading is only for reference

for more than 800A

Resolution Accuracy(50Hz ~ 60Hz)

1A

1000A

Range

20MΩ 10KΩ

±(4% + 2)

for 500Ω and below

±(2% + 2)

±(5% + 2)

for others

Resolution Accuracy(50Hz ~ 60Hz)

1MΩ

2000MΩ

-8-

2-6. Resistance

Maximum Open Circuit Voltage: 3V.

Overload Protection: 15 seconds maximum 220Vrms.

3. OPERATING INSTRUCTIONS

3-1. AC Current Measure

1. Make sure that “Data Hold” Switch is not pressed.

2. Set Range Switch to the ACA 1000A range. If the display

indicates one or more leading zeros. Shift to the 200A range

to improve the resolution of the measurement.

3. Press the trigger to open the transformer jaws

and clamp one conductor only it is impossible to make

measurements when two or three conductors are clamped at

the same time.

4. Display reading is flow the conductorAC current.

3-2. Insulation Resistance Tester

1. Set Range Switch to the insulation tester 2000MΩ range.

This condition the display value is unstable that is normal.

2. The insulation tester unit VΩ-COM-EXT three banana

plugs insert to clamp meter VΩ-COM-EXT three input

connector.

3. Set the insulation tester unit range switch to the 2000MΩ

position.

4. Use the insulation tester unit of the test leads.

5. Set the insulation tester power switch to the ON position.

6. Depress the PUSH 500V push-push switch, the 500V on

red LED lamp will light. Clamp meter display reading is the

insulation resistance value if the reading is below 19MΩ,

change clamp meter and insulation tester unit to 20MΩ

range, can be increase the accuracy.

7. If the insulation tester unit is not use the power switch

must shift to power OFF position, and the test leads must

leave the E-L input connect, that can be increase battery life

and prevent electrical shock hazard.

3-3. DC & AC Voltage Measurement

1. Connect red test lead to “VΩ” jack, Black lead to “COM” jack.

2. Set RANGE switch to desired VOLTAGE position, if the

voltage to be measured is not known beforehand, set switch

to the highest range and reduce it until satisfactory reading is

obtained.

3. Connect test leads to device or circuit being measured.

4. Turn on power of the device or circuit being measured

voltage value will appear on Digital Display along with the

voltage polarity.

3-4. Resistance Measurement

1. Red lead to “VΩ”. Black lead to “COM”.

2. RANGE switch to desired Ω position.

3. If the resistance being measured is connected to a circuit,

turn off power and discharge all capacitors before

measurement.

4. Connect test leads to circuit being measured.

5. Read resistance value on Digital Display.

3-5. Audible Continuity Test

1. Red lead to “VΩ”,Black lead to “COM”.

2. RANGE switch to “ ” position.

3. Connect test leads to two points of circuit to be

tested. If the resistance is lower then 30Ω±20Ω, the buzzer

will sound.

4. BATTERY REPLACEMENT

If “ ” appears in display, it indicates that the battery should

be replaced.

5. ACCESSORIES

• Operator’s instruction manual

• Set of test leads

• Gift box

• 9-volt battery, NEDA 1604 6F22 type.

Range Resolution Accuracy

200Ω 0.1Ω ±(1.0% of rdg + 10D)

20KΩ 10Ω ±(1.0% of rdg + 4D)

-9-

2-6. Resistance

Maximum Open Circuit Voltage: 3V.

Overload Protection: 15 seconds maximum 220Vrms.

3. OPERATING INSTRUCTIONS

3-1. AC Current Measure

1. Make sure that “Data Hold” Switch is not pressed.

2. Set Range Switch to the ACA 1000A range. If the display

indicates one or more leading zeros. Shift to the 200A range

to improve the resolution of the measurement.

3. Press the trigger to open the transformer jaws

and clamp one conductor only it is impossible to make

measurements when two or three conductors are clamped at

the same time.

4. Display reading is flow the conductorAC current.

3-2. Insulation Resistance Tester

1. Set Range Switch to the insulation tester 2000MΩ range.

This condition the display value is unstable that is normal.

2. The insulation tester unit VΩ-COM-EXT three banana

plugs insert to clamp meter VΩ-COM-EXT three input

connector.

3. Set the insulation tester unit range switch to the 2000MΩ

position.

4. Use the insulation tester unit of the test leads.

5. Set the insulation tester power switch to the ON position.

6. Depress the PUSH 500V push-push switch, the 500V on

red LED lamp will light. Clamp meter display reading is the

insulation resistance value if the reading is below 19MΩ,

change clamp meter and insulation tester unit to 20MΩ

range, can be increase the accuracy.

7. If the insulation tester unit is not use the power switch

must shift to power OFF position, and the test leads must

leave the E-L input connect, that can be increase battery life

and prevent electrical shock hazard.

3-3. DC & AC Voltage Measurement

1. Connect red test lead to “VΩ” jack, Black lead to “COM” jack.

2. Set RANGE switch to desired VOLTAGE position, if the

voltage to be measured is not known beforehand, set switch

to the highest range and reduce it until satisfactory reading is

obtained.

3. Connect test leads to device or circuit being measured.

4. Turn on power of the device or circuit being measured

voltage value will appear on Digital Display along with the

voltage polarity.

3-4. Resistance Measurement

1. Red lead to “VΩ”. Black lead to “COM”.

2. RANGE switch to desired Ω position.

3. If the resistance being measured is connected to a circuit,

turn off power and discharge all capacitors before

measurement.

4. Connect test leads to circuit being measured.

5. Read resistance value on Digital Display.

3-5. Audible Continuity Test

1. Red lead to “VΩ”,Black lead to “COM”.

2. RANGE switch to “ ” position.

3. Connect test leads to two points of circuit to be

tested. If the resistance is lower then 30Ω±20Ω, the buzzer

will sound.

4. BATTERY REPLACEMENT

If “ ” appears in display, it indicates that the battery should

be replaced.

5. ACCESSORIES

• Operator’s instruction manual

• Set of test leads

• Gift box

• 9-volt battery, NEDA 1604 6F22 type.

-10-

2-6. Resistance

Maximum Open Circuit Voltage: 3V.

Overload Protection: 15 seconds maximum 220Vrms.

3. OPERATING INSTRUCTIONS

3-1. AC Current Measure

1. Make sure that “Data Hold” Switch is not pressed.

2. Set Range Switch to the ACA 1000A range. If the display

indicates one or more leading zeros. Shift to the 200A range

to improve the resolution of the measurement.

3. Press the trigger to open the transformer jaws

and clamp one conductor only it is impossible to make

measurements when two or three conductors are clamped at

the same time.

4. Display reading is flow the conductorAC current.

3-2. Insulation Resistance Tester

1. Set Range Switch to the insulation tester 2000MΩ range.

This condition the display value is unstable that is normal.

2. The insulation tester unit VΩ-COM-EXT three banana

plugs insert to clamp meter VΩ-COM-EXT three input

connector.

3. Set the insulation tester unit range switch to the 2000MΩ

position.

4. Use the insulation tester unit of the test leads.

5. Set the insulation tester power switch to the ON position.

6. Depress the PUSH 500V push-push switch, the 500V on

red LED lamp will light. Clamp meter display reading is the

insulation resistance value if the reading is below 19MΩ,

change clamp meter and insulation tester unit to 20MΩ

range, can be increase the accuracy.

7. If the insulation tester unit is not use the power switch

must shift to power OFF position, and the test leads must

leave the E-L input connect, that can be increase battery life

and prevent electrical shock hazard.

3-3. DC & AC Voltage Measurement

1. Connect red test lead to “VΩ” jack, Black lead to “COM” jack.

2. Set RANGE switch to desired VOLTAGE position, if the

voltage to be measured is not known beforehand, set switch

to the highest range and reduce it until satisfactory reading is

obtained.

3. Connect test leads to device or circuit being measured.

4. Turn on power of the device or circuit being measured

voltage value will appear on Digital Display along with the

voltage polarity.

3-4. Resistance Measurement

1. Red lead to “VΩ”. Black lead to “COM”.

2. RANGE switch to desired Ω position.

3. If the resistance being measured is connected to a circuit,

turn off power and discharge all capacitors before

measurement.

4. Connect test leads to circuit being measured.

5. Read resistance value on Digital Display.

3-5. Audible Continuity Test

1. Red lead to “VΩ”,Black lead to “COM”.

2. RANGE switch to “ ” position.

3. Connect test leads to two points of circuit to be

tested. If the resistance is lower then 30Ω±20Ω, the buzzer

will sound.

4. BATTERY REPLACEMENT

If “ ” appears in display, it indicates that the battery should

be replaced.

5. ACCESSORIES

• Operator’s instruction manual

• Set of test leads

• Gift box

• 9-volt battery, NEDA 1604 6F22 type.

This Instrument is warranted to be free from defects in

material and workmanship for a period of one year.

Any instrument found defective within one year from

the delivery date and returned to the factory with

transportation charges prepaid, will be repaired,

adjusted, or replaced at no charge to the original

purchaser. This warranty does not cover expandable

items such as batteries & fuses. If the defect has been

caused by a misuse or abnormal operating conditions,

the repair will be billed at a nominal cost.

WARRANTY

-11-

www.everwellparts.com

Phone: +1 (305) 406-2331

Fax: +1 (305) 406-2338

Email: [email protected]

10914 NW 33rd St, Miami, FL 33172

Table of contents

Other Everwell Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Thermo Scientific

Thermo Scientific Nicolet Summit user guide

Elenco Electronics

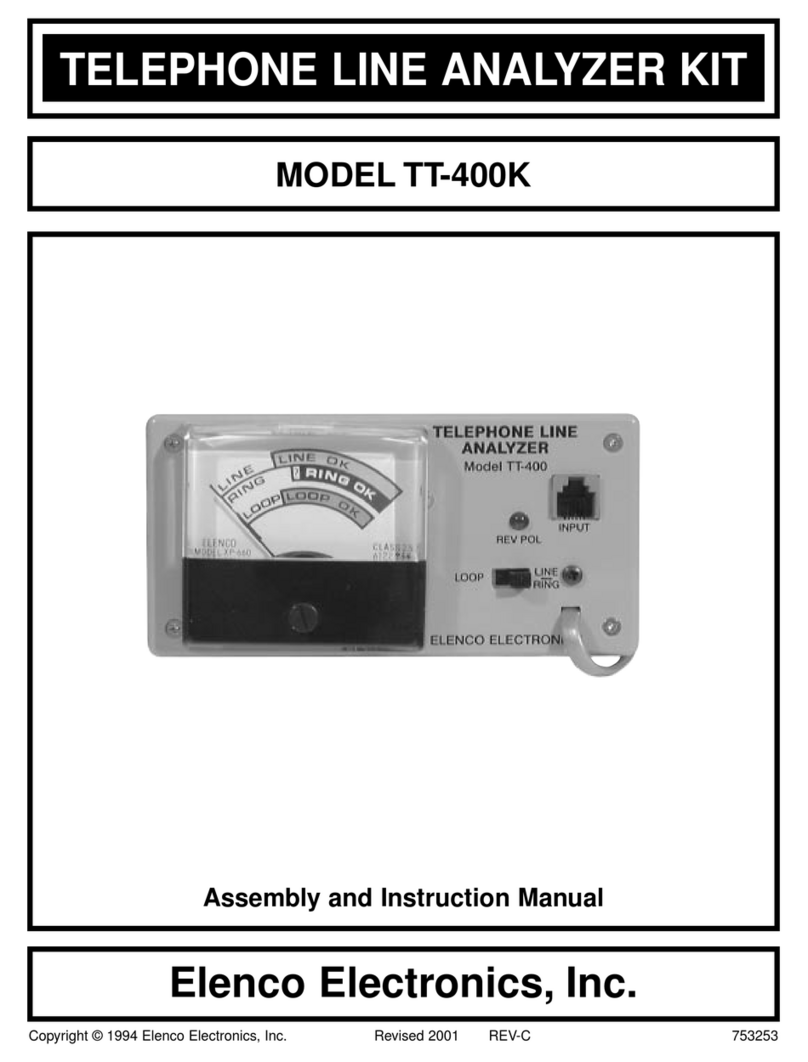

Elenco Electronics TT-400K Assembly and instruction manual

Fowler

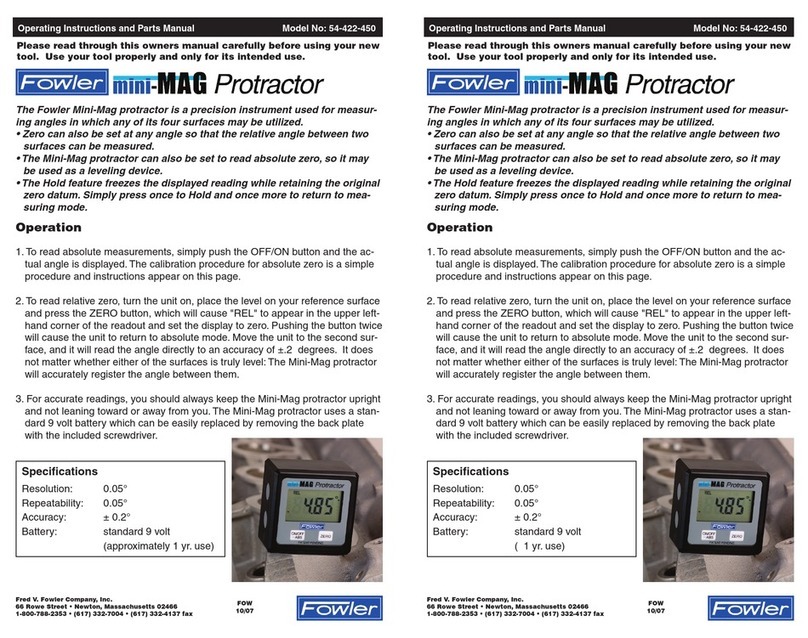

Fowler mini-Mag Protractor Operating instructions and parts manual

ATP Electronics

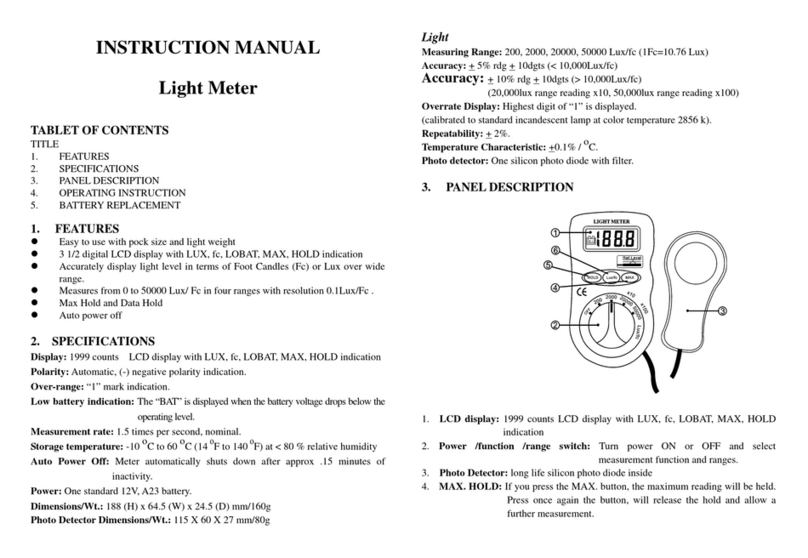

ATP Electronics LX-1301 instruction manual

toscano

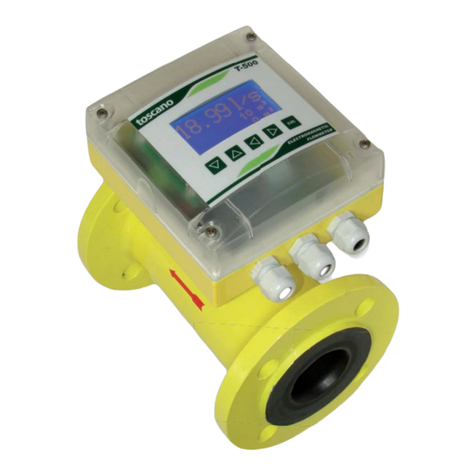

toscano T-500 user manual

IFM Electronic

IFM Electronic efector 200 OJ50 Series operating instructions