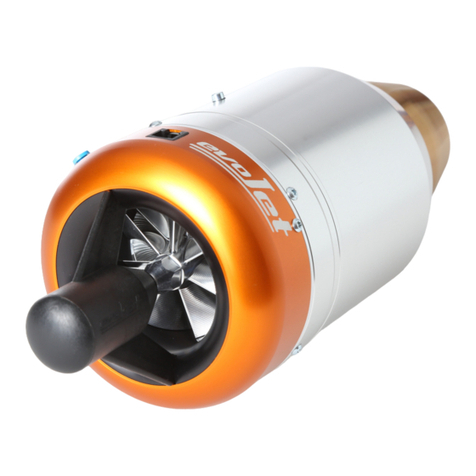

EvoJet evoJet-VX Series User manual

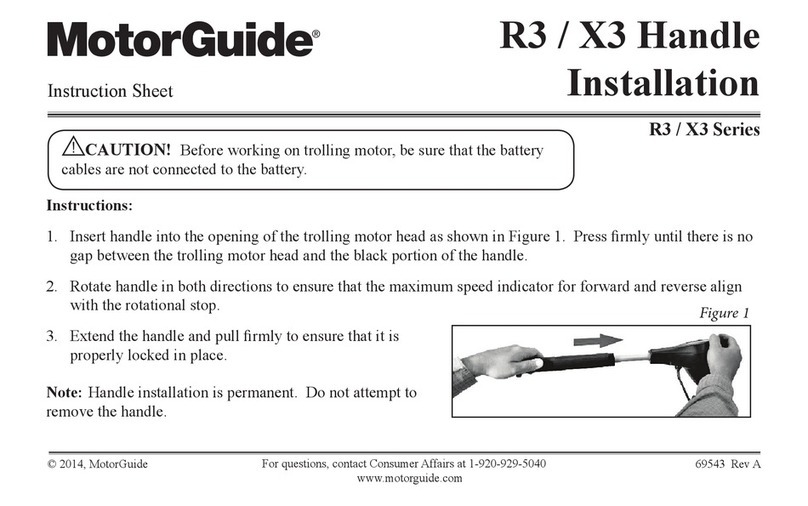

evoJet B90 – B130vx – B160vx – Instructions 4.0

Contents

Introduction .........................................................................................................................3

Warnings and Safety Notes ...............................................................................................4

Warranty Conditions............................................................................................................7

Technical Specifications.....................................................................................................8

Installation Plan....................................................................................................................9

Checklist for the First Operation......................................................................................10

Checklist for Turning the Engine Off...............................................................................10

EDT Status Display (Engine Data Terminal)....................................................................11

JETRONIC-Vx – Firmware Setup......................................................................................13

1:INFO Menu ......................................................................................................................14

2:ST TISTICS Menu ..........................................................................................................18

3:LIMITS Menu ...................................................................................................................20

4: UTOST RT Menu ........................................................................................................22

5:R/C-SETTINGS Menu .....................................................................................................24

6:TEST-DEVICES Menu ....................................................................................................28

irspeed Sensor [8135].....................................................................................................31

Notes...................................................................................................................................33

2

evoJet B90 – B130vx – B160vx – Instructions 4.0

Introduction

The model jet engines of the evoJet-VX series uses the same functional principle as a "big" jet

engine. A high performance compressor compresses ingested air, which is then heated by a fuel

flame in the combustion chamber. The heat causes the air to expand rapidly, enabling it to drive an

axial turbine rotor, which in turn drives the aforementioned compressor via a shaft (open circuit gas

turbine).

At the exhaust cone, the hot air leaves the engine at a speed of more than 1000 km/h (620 mph),

generating the required thrust for the jet aircraft model. An electric starter motor and a new electric

kerosene ignition system allow fully automated engine control from the R/C transmitter, controlled

and monitored by the JETRONIC control unit, which regulates all operating parameters to their

optimal values. This new generation of model jet engines does not require dangerous auxiliary

gases like propane or butane any more. Power is supplied to the engine by a separate

rechargeable lithium manganese battery, which is used to power all system components, such as

fuel pump, kerosene ignition, valve etc.

State of the art precision CNC and laser cutting technology allow a previously impossible

production accuracy, ensuring both high performance and durability. The included display and

programming unit (EDT = Engine Data Terminal) is equipped with an illuminated LC Display and

can be connected to (and disconnected from) the running system at any time to check the current

operating data or to change parameters. Besides the current operating parameters, such as

exhaust gas temperature (EGT), turbine revolutions per minute (rpm) and thrust (throttle),

additional information like total hours of operation, rpm and temperature statistics, number of

engine starts, battery voltage etc. can be displayed as well.

All parameters and user entries are displayed in plain text in a menu based interface. The turbine

is started fully automatically via the throttle stick on the R/C transmitter. The pilot then adjusts the

desired thrust by moving the stick proptionally. The JETRONIC control unit is connected to the R/C

receiver via R/C 1. R/C 2 can be connected optionally for switching functions.

3

evoJet B90 – B130vx – B160vx – Instructions 4.0

IMPORT NT NOTE:

Operating a jet aircraft model requires greatest care and special knowledge. When

installing and operating your jet engine, always observe the safety rules in this manual !

Warnings and Safety Notes

Welcome to the era of model jet aircraft! Please never forget: Operating a jet engine like the

evoJet-VX can be dangerous. An aircraft model equipped with the evoJet-VX can reach speeds of

more than 400 km/h (250 mph) and temperatures up to 500 °C (930 °F) at the engine housing and

up to 750 °C (1380 °F) at the exhaust jet. Since it is a genuine jet engine, it requires know how,

discipline and regular service and maintenance – for your own protection and that of other people.

If you want to install and operate this jet engine in your model aircraft, you mus be trained in its

handling. The model with the jet engine should only be operated under supervision of an

experienced person, who can support you in order to avoid mistakes. If there is a local R/C club in

your area offering training and support, we recommend that you become a member. Mistakes

made during the assembly or operation of a jet powered model aircraft can lead to serious injuries

or even death.

lways observe the law

Before operating a model aircraft with this jet engine, you should be informed about the legal

regulations regarding such aircraft. From a legal point of view, a model aircraft is considered an

aircraft like any other in most countries and is subject to the corresponding laws, which must be

observed by all means. Please check the applicable air traffic laws of your country carefully before

flying your model. Your local R/C club will likely be able to provide you with the required info

rmation and documents. In many countries, jet powered model aircraft require a special licence

and/or a special insurance. Furthermore, regulations regarding the protection against interference

between R/C transmitters and radio networks must be observed. Please make sure to comply with

all applicable laws and regulations in your country.

C UTION – keep a safe distance!

It is your responsibility to protect others against injuries. The operating distance of your aircraft

from residential areas must be at least 1.5 km (1 mile) in order to ensure the safety of people,

animals and buildings. Keep a safe distance from power lines. Never fly your model in bad weather

with low clouds or fog. Never fly directly against the sunlight – otherwise you might lose visual

contact with your model. To avoid collisions with manned or unmanned aircraft, land your model

immediately if an aircraft is approaching. Persons and animals must keep the following minimum

distance to the jet engine (see also the figure on page 6):

In front of the engine: 1 m (3 ft)

At the sides of the engine: 12 m (36 ft)

Behind the engine: 10 m (30 ft)

4

evoJet B90 – B130vx – B160vx – Instructions 4.0

W RNING !

Operating the model and/or the jet engine under the influence of alcohol, drugs etc. is strictly

forbidden. The jet engine may only be handled by persons with an excellent physical and mental

condition and concentration. This applies to the operator as well as any assistants.

This jet engine was designed solely for use in model aircraft and is not suitable for any other

purpose. Never use it for persons, objects or vehicles other than suitably constructed model

aircraft, as any other use can lead to personal injury or death.

Any deviation from the specifications in this manual, the use of non approved parts or materials or

modifications to the system construction or setup can have a negative effect on the functionality

and safety of the jet engine and must be avoided by all means.

W RNING !

The jet engine may only be operated in exact compliance with the instructions in this manual.

Furthermore, the specifications of the aircraft model regarding the centre of gravity and rudder

manipulations must be adhered to. The configuration recommended by the model manufacturer

must be observed. Before taking off with a model equipped with this jet engine, all functions and all

rudders as well as the range of the R/C transmitter must be tested with the transmiter turned on

and the antenna retracted. This range test must be repeated with the jet engine running while

another person is holding the model in place. Furthermore, the instructions by the R/C system

manufacturer must be followed closely.

Disclaimer

evoJet cannot supervise the adherence to the assembly and operating instructions for the aircraft

model and the jet engine, nor the installation, operation, use and maintenance of the model

components. Therefore, evoJet does not assume any liability for losses, damage or costs caused

by improper operation or improper behaviour or related in any other way to the aforementioned.

Unless demanded by law, any liability of evoJet to pay compensation for damages for whatever

reason (including personal injury, death, damage to buildings as well as loss of sales and profits,

business interruption or other indirect or direct consequential loss caused by the operation of the

model or the jet engine) is excluded. Under all circumstances and in any case, the joint liability is

limited to the amount you actually paid for the model aircraft or jet engine.

The operation of the aircraft model and the jet engine takes place solely at the operator's

own risk!

By operating the jet engine, you confirm to be aware of the fact that evoJet cannot supervise or

control the compliance with the instructions in this manual regarding assembly, operation and use

of the aircraft model, jet engine and remote control unit. From evoJet's side, no promises,

contractual agreements, guarantees or other agreements with persons or companies regarding the

functionality and operation of the model and the jet engine have been made. When buying this

aircraft model or jet engine, you as the operator were relying on your own expertise and

judgement.

5

evoJet B90 – B130vx – B160vx – Instructions 4.0

Safety Notes

✔lways have a fully functional CO2 fire extinguisher with at least 2 kg (4.4 lb) of filling

weight at hand.

✔Only test the jet engine at suitable places outdoor and observe the applicable laws

and regulations.

✔lways keep the following safety distances from the running jet engine

(1 m = 3 ft, 10 m = 30 ft, 12 m = 36 ft):

✔Never look straight into the exhaust jet and never touch it with your hands.

✔Whenever possible, wear hearing protection.

✔Keep away from the engine intake (electric starter). The air stream has an enormous

suction power, which can lead to severe injuries.

✔fter the first installation, and afterwards in regular intervals, test the transmission

range of your R/C system with the jet engine running.

✔Before operating the engine, remove all loose objects near the engine intake, such

as cleaning cloths, screws, nuts, cables or other material. Before operating your

model for the first time, make sure that there are no loose objects in the engine

intake, such as clippings, screws or swarf from building the model. Such objects can

damage the turbine. When installing the engine in your aircraft model, cover the

engine intake and exhaust opening, for example with adhesive tape, to keep

clippings/swarf and other objects from entering the engine.

✔Make sure that about 5 % of turbine oil is added to the fuel. Use prefered special

aircraft turbine oil like EROSHELL 500/560.

6

evoJet B90 – B130vx – B160vx – Instructions 4.0

Warning:

Compared to an ducted fan model aircraft, the model with a real jet engine reaches much higher

airspeeds due to the considerably higher exhaust speed at the same static thrust. The achievable

airspeeds of more than 300 km/h (190 mph) normally exceed the speed range an aircraft model is

approved for (risk of rudder flutter, sudden nose dives and overload of the fuselage and the

servos).

Therefore always take care of the following: After taking off and accelerating to normal airspeed,

always pull the throttle back. For horizontal flight, 50 % of thrust is sufficient to achieve the same

flight performance as with an ducted fan !

Only use the full thrust of the jet engine for takeoff and for vertical climbing in aerobatics!

For limiting the airspeed, we highly recommend using the optionally available Airspeed Sensor

(part no. 8135) !

Warranty Conditions

The warranty covers the free repair or replacement of parts that exhibit proven defects of

fabrication or material defects within the warranty period from the date of purchase. Any further

claims are excluded. Costs for packaging and shipping are paid by the buyer. No liability is

assumed for loss during transport. When sending the defective article to evoJet or to the

service contractor in charge for the respective country, a detailed description of the fault and the

invoice stating the date of purchase must be included. The warranty is void if the defect of the

part or the model is caused by an accident, improper handling or improper use.

7

evoJet B90 – B130vx – B160vx – Instructions 4.0

Technical Specifications

evoJet B90 – B130vx – B160vx

Max. thrust: B90: typ. 9 kg = 19 lb

B130: typ. 14 kg = 31 lb

B160: typ. 16 kg = 36 lb

Diameter: B90: 91 mm = 3.6 inches

B130/160: 112 mm = 4.4 inches

Length incl. starter: B90: 230 mm = 9.06 inches

B130/160: 288 mm = 11.3 inches

Weight: B90: 950 g = 2.1 lb

B130: 1595 g = 3.52 lb

B160: 1620 g = 3.58 lb

Rotor speed: B90: 45.000 – 165.000 rpm

B130: 30.000 – 119.000 rpm

B160: 30.000 – 123.000 rpm

Compressor: lloy 2618 compressor 12-blade

Turbine: xial-wheel Inconel

Fuel consumption: B90: max. 285 g = 10.0 oz./min.

B130: max. 420 g = 14.8 oz./min.

B160: max. 520 g = 18.4 oz./min.

Fuel type: Jet 1 / kerosene, approved fuel

with 5 % oil

Maintenance interval: B90: 300.000.000

B130/160: 200.000.000

corresponding 50 hours, see 24:JET-ENGINE

(page 19)

Status: October - 2010

(*) The engine thrust is electronically adjustable by setting the idle- and the full

thrust revolution speed (page 21, 30:ENGINE IDLE und 31:ENGINE 100% ). ll

performance data are related to International Standard tmosphere, IS and

optimal operating conditions which means, fuel, thrust tube and sufficient air

supply.

8

evoJet B90 – B130vx – B160vx – Instructions 4.0

Installation Plan

9

evoJet B90 – B130vx – B160vx – Instructions 4.0

Checklist for the First Operation

✔Install and connect the components according to the installation plan (see page 9). Pay

special attention to the correct connection of the FUELvalve and to a proper laying of the

tubes without kinking them. An arrow on the fuel pump and the valve indicates the flow

direction to the engine.

✔The QS quick connectors (blue) should snap in when you plug in the tube. The tube can

only be released by pressing on the blue ring while pulling the tube out. Only use approved

PUN tubes with a diameter of 3 mm (0.12") or 4 mm (0.16"), respectively.

✔Check the temperature sensor to the environment temperature via the parameter

AUTOSTART 47:EGT/AMBIENT (see page 23).

✔Teach in the remote control: OFF, IDLE, 100 %, via the R/C SETTINGS parameters 51, 52,

53 (see page 25).

✔Charge all batteries, paying special attention to the correct charging program for the lithium

manganese battery, i.e. a maximum charging voltage of 12.6 V. Use the 3s LiPo charging

mode with 1 – 2 Amps.

✔Open the fuel tank ventilation, then fill the fuel tank(s) with fuel containing approx. 5 % of

oil, i.e. one can of turbine oil in 20 litres (5.3 US gallons) of kerosene.

✔Have a CO2 fire extinguisher at hand!

✔Turn on the R/C transmitter, then turn on the receiver.

✔Place your aircraft model with the nose against the wind.

✔Start the jet engine (keep a safe distance, see page 6!):

1. Throttle down + trim down => remove LOCK

2. Trim up => RUN – cleared

3. Throttle up and down again => AUTOSTART activated, see EDT display (page 11).

Checklist for Turning the Engine Off

✔Place the aircraft model with the nose against the wind.

✔Turn the jet engine off: Throttle down + trim down (below 25%) => OFF

✔Wait until the automatic cool down procedure of the engine is finished.

✔Check the INFO data about the operating states (see page 14 ff).

✔After finishing the flight activities, remove all fuel from the tank(s) and close the fuel tank

ventilation.

10

evoJet B90 – B130vx – B160vx – Instructions 4.0

EDT Status Display (Engine Data Terminal)

TH: = Throttle is a combined function display and error display for the engine operation.

Use the Up/Down keys to select different display values:

Ub11.8V → current battery Voltage.

FP 2.1V → current fuel pump Voltage.

0km/h → current air speed display in km/h (for telemetrie).

0.00rpm → current rotor /propeller speed (rpm).

Function display – example for a standard start up procedure:

TH:lock → Remote control locked – to unlock it, pull the throttle and the trim

all the way back. See also 51:RC1 TRIM.OFF (page 25).

TH:stop →Remote control unlocked – engine off – to turn it on, push the trim up.

See also 52:RC1 IDLE (page 25).

TH:run- →Engine on – for a further check, push the throttle forward.

See also 53:RC1 100% (page 25).

TH:rel- →Check complete – to start the turbine, pull the throttle back to the IDLE

position within 10 seconds.

The fuelpump confirms the starting procedure with a short burst.

TH:fire →Preheating of the kerosene igniter, this takes about 5 to 15 seconds.

11

evoJet B90 – B130vx – B160vx – Instructions 4.0

TH:spin →Spin up via the electric starter and fuel ignition.

See also 40:SPINUP/FIRE (page 23).

TH:he t →Heat up phase of the kerosene igniter and the combustion chamber.

See also 44:HEAT UP (page 23).

TH: cce →Acceleration of the turbine to normal operation.

See also 43:ACCE RAMP (page 23).

TH:c l. →Calibration of the fuel pump and the fuel supply system.

TH:idle100% Thrust available to the pilot. Ready for takeoff!

TH:-off →To turn off the engine, pull the throttle and the trim all the way back.

TH:cool →The engine enters a controlled cool down phase to ensure a long life of the

high performance bearings.

The error codes are explained under Firmware Setup 19:LAST OFF on page 16/17.

Notice:

To learn-in a new fuel-system, let the jet engine run at least for 10 seconds at full speed

(max-rpm).

ttention:

Dont do exessive full-throttle ground runs in the airplane withour sufficient air supply !

12

evoJet B90 – B130vx – B160vx – Instructions 4.0

JETRONIC-Vx – Firmware Setup

SETUP Menu

To enter the SETUP menu for configuring the firmware parameters, first press the SET key and

then use the Up/Down keys to switch between the available parameter sections.

To quit the SETUP menu and to return to the operating status display, press the SET key for

more than 2 seconds (ESC). In the following, the individual submenus of the SETUP menu are

described.

13

evoJet B90 – B130vx – B160vx – Instructions 4.0

1:INFO Menu

To enter the 1:INFO menu, first press the SET key and then use the Up/Down keys to switch

between the available parameters.

To quit the 1:INFO menu and to return to the SETUP menu, press the SET key for more than 2

seconds (ESC).

The operating status display appears automatically after 20 seconds, or press the SET key for

more than 2 seconds (>>> changes to <<<, ESC).

14

evoJet B90 – B130vx – B160vx – Instructions 4.0

1:INFO – Operating Status Information

10:R/C-FAILS

indicates the number of R/C failsafes (failures of the remote control connection) that lasted longer

than one second during the last engine run. Normally this parameter should be #0, i.e. no failsafes.

If the number is frequently greater than #0, you should check your remote control system.

Do a Radio Control range test !

11:EGT-AVERAGE

shows the average exhaust gas temperature during the last engine run. Typical values after a flight

should be between 500 and 680 °C. Higher values might be caused by an unsuitable exhaust duct

or insufficient ventilation to the turbine.

12:EGT-PEAK

shows the maximum exhaust gas temperature that occurred during the last engine run. This value

is normally reached only briefly during the acceleration of the turbine until the higher revolution

speed is reached. Typical values can be up to 850 °C.

13:FUELPMP-PEAK

shows the highest fuel pump voltage during the last engine run. A “!“ after the "V" means

that the maximum allowed pump voltage specified under LIMITS 33:FUELPMP MAX has been

reached. The maximum pump voltage is a good indicator for the quality (flow resistance) of the

entire fuel supply system. An continuously increasing pump voltage after the flights may be caused

by a plugged filter or fuel clunk.

14:RPM-MIN/MAX

shows the lowest and the highest revolution speed of the turbine during the last engine run.

Normally, this value should match the rpm values specified under LIMITS 30:ENGINE idle and

LIMITS 31:ENGINE 100% in the variation of (±300rpm). If the 100 % thrust rpm value has not

been reached, the reason might be a kinked fuel tube or a plugged filter or fuel clunk. It is also

possible that the maximum fuel pump voltage specified under LIMITS 33:FUELPMP MAX is set too

low.

15:AIRSPEED-PEAK

shows the maximum airspeed during the last flight. This requires the Airspeed Sensor [8135] to be

installed and the parameter 59:AUX MODE to be set to AIRSPEED.

16:AIR-DISTANCE

shows the distance covered during the last flight. This requires an airspeed sensor to be installed

and the parameter 59:AUX MODE to be set to AIRSPEED.

17:ROTOR-PEAK

shows the maximum revolution speed of the propeller/rotor during the last engine run.

See also LIMITS 38:ROTOR MAX.

18:ENGINE-TEMP

shows the current temperature under the turbine cover in °Celsius.

15

evoJet B90 – B130vx – B160vx – Instructions 4.0

19:LAST-OFF error codes,

shows the reason or error causing the engine shutdown:

-off Regular switchoff of the engine via the R/C transmitter or via the SET key in the case of a

manual test run without remote control.

R/C! Same as -off regular switchoff, but with a hint as to counted radio failsafes.

See 10:R/C FAILS, failures of the remote control connection.

Solution: Check the remote control system and do a transmission range test!

noID The engine is not detected or is not connected.

Solution: Turn the JETRONIC off and on again and/or check the cables and plugs.

b dG The glow plug is defective or too cold. This error can also be caused by a weak or empty

turbine battery.

Solution: Charge the turbine battery and/or check the cables and plugs.

m in Internal hardware error, overheating or bad contacts

Solution: Let the JETRONIC unit cool down and/or check the cables and plugs.

strR The starter motor does not deliver suffucient power to continue the starting procedure.

Solution: Charge the turbine battery and/or check the cables and plugs.

It is also possible that the clutch rubber of the starter is oily or worn out. Carefully clean it

with a cotton bud and glass cleaning agent.

minR The revolution speed falls below the required value during the startup procedure. This

is usually caused by air bubbles in the fuel supply system leading to a flameout in the

combustion chamber.

Solution: Make sure that the fuel supply is sufficient and uninterrupted.

minT The exhaust gas temperature falls below the value specified under LIMITS 34:EGT MIN.

This is usually caused by air bubbles in the fuel supply system leading to a flameout in the

combustion chamber. Accompanied by considerable smoke emissions.

Solution: Use a better fuel tank system with a membrane fuel clunk or an AirTrap tank.

m xT The exhaust gas temperature exceeds the value specified under LIMITS 36:EGT OFF.

Reasons may be:

➔Large air bubbles in the fuel supply system

➔A fuel puddle in the turbine

Solution: Hold a cloth against the engine intake and tilt the engine or the aircraft model

upright with the intake facing down, so the fuel flows out of the engine into the cloth.

Caution: Take care not to pollute the starter motor and/or the clutch!

➔The clutch rubber of the starter motor is oily or worn out.

Solution: Carefully clean it with a cotton bud and glass cleaning agent.

time The time limit for the startup procedure is exceeded.

Probably a fuel tube is kinked or plugged.

Solution: Check the laying of the fuel tubes and the fuel tank.

ovrR The revolution speed exceeds the value specified under LIMITS 31:ENGINE 100%. This is

usually caused by air bubbles in the fuel supply system.

Solution: Use a better fuel tank system with a membrane fuel clunk or an AirTrap tank.

16

evoJet B90 – B130vx – B160vx – Instructions 4.0

runR The revolution speed falls below the value specified under LIMITS 33:ENGINE MIN. This

is usually caused by air bubbles in the fuel supply system leading to a flameout in the

combustion chamber. Accompanied by considerable smoke emissions.

Solution: Use a better fuel tank system with a air membrane fuel clunk or an AirTrap tank.

Solution: Increase the LIMITS: 33THROTTL UP e.g. to 5 sec's !

lowB The minimum voltage of the turbine battery has been reached and the safety limitation has

been activated (throttle can only up to 50 %, lowB). To receipt this, immediately throttle

down to idle and land the airplane. If the minimum system voltage is reached, a safety

shutoff takes place (lowB, lowB).

Solution: Charge the turbine battery and/or check the cables and plugs.

higB An overvoltage of the turbine battery has been detected.

Solution: Check the turbine battery, connect the right battery type and/or check the

AUTOSTART 46:BATTERY battery type settings.

R/C? The RC1 remote control signal was not detected for a longer time than specified under

R/C SETTINGS 57:FAILS TIME, or the RC2 remote control signal was not detected for

more than one second.

Solution: Check the remote control system and do a transmission range test!

tolF The sensors of the engine deliver invalid measurement signals. This means that the engine

can no longer be controlled and must be shut down (safety shutoff).

Solution: Charge the turbine battery and/or check the cables and plugs.

The trim down (below 50%=mid) removes the error codes and enables the jet engine again:

Restart the jet engine (keep a safe distance, see page 6!):

1. Throttle down + trim down (below 50%) => remove LOCK

2. Trim up => RUN – cleared

3. Throttle up and down again => AUTOSTART activated, see EDT display (page 11).

17

evoJet B90 – B130vx – B160vx – Instructions 4.0

2:ST TISTICS Menu

To enter the 2:STATISTICS menu, first press the SET key and then use the Up/Down keys to

switch between the available parameters.

To quit the 2:STATISTICS menu and to return to the SETUP menu, press the SET key for more

than 2 seconds (ESC).

The operating status display appears automatically after 20 seconds, or press the SET key for

more than 2 seconds (>>> changes to <<<, ESC).

18

evoJet B90 – B130vx – B160vx – Instructions 4.0

2:ST TISTICS – Display of Operating Statistics

20:RUNS-TOTAL

shows the total number of engine runs or engine starts so far.

Unit: #

21:START-ABORT

shows the total number of aborted engine starts.

Unit: #

22:RUNS-ABORT

shows the total number of aborted engine runs where PWR shows the number of power failures.

Unit: # PWR:#

23:HOUR-METER

shows the total operating time of the jet engine resp. the fuel pump.

Unit: HH:MM'SS

24:JET-ENGINE

shows the identification, serial number and lifetime of the connected jet engine.

Unit: ID SERIAL LIFE

B160#09123# 1.50

type year+serial lifetime

The lifetime value indicates the total number of turbine revolutions in millions.

A ! after the serial number means "stored value", for example with no engine connected.

25:RECORDER

shows the memory amount of the recorder unit.

Unit: record kb (total kb)

26:FIRMWARE

shows the info string of the current firmware with the version number.

19

evoJet B90 – B130vx – B160vx – Instructions 4.0

3:LIMITS Menu

To enter the 3:LIMITS menu, first press the SET key and then use the Up/Down keys to switch

between the available parameters.

To change a setting, first press the SET key and then use the Up/Down keys to switch between the

available values. A ? indicates the value to be set. To finish the setting and store the new value,

press the SET key again.

To quit the 3:LIMITS menu and to return to the SETUP menu, press the SET key for more than 2

seconds (ESC).

The operating status display appears automatically after 20 seconds, or press the SET key for

more than 2 seconds (>>> changes to <<<, ESC).

20

This manual suits for next models

3

Table of contents

Other EvoJet Engine manuals

Popular Engine manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley 140G Series Installation

BRP

BRP Rotax 915 i A Series Maintenance manual

Kohler

Kohler LOMBARDINI MARINE KDI 1903M-MP owner's manual

MotorGuide

MotorGuide R3 Series Installation

Mitsubishi

Mitsubishi S6B Operation & maintenance manual

Briggs & Stratton

Briggs & Stratton Vanguard 540000 Series Operator's manual