GENERAL SAFETY RULES

Read and understand all instructions before

operating this product. Failure to follow all

instructions listed below, may result in electric

shock, fire and / or serious personal injury.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING! When using electric tools basic safety

precautions should always be followed to reduce the risk of

fire, electric shock and personal injury including the following:

Read all these instructions before attempting to operate

this product and save these instructions.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

CAUTION! This is a very powerful machine. When using

this drill it is essential that the following rules are followed.

1. When drilling it is common that the drill bit jams in the

material being drilled. This will result in the drill trying to rotate

around the drill bit and potentially to come out of your grip.

This SDS drill has a safety clutch mechanism. This safety

clutch mechanism will be activated and stop the drive to the

drill, BUT only if you resist the initial forces caused by the

jamming, by securely holding the drill with BOTH hands.

As this is a powerful machine, these forces are significant.

2. ALWAYS ensure that the front handle is firmly fixed in

place and secure.

3. The front and rear handles must be firmly held to resist

any movement of the drill when the drill or drill bit becomes

jammed.

4. ALWAYS use the drill when standing on a firm and secure

platform or on the ground. (DO NOT USE ON LADDERS

OR STEPS)

5. NEVER start the drill with the drill bit jammed in position.

6. DO NOT stretch to hold the drill. Do not drill above shoulder

height or below knee height, as the drill cannot be securely held.

7. This machine is not suitable for use with TCT core drill

bits, diamond core drill bits, and diamond drill bits.

GENERAL SAFETY RULES

When using electric tools, basic safety precautions should

always be followed to reduce the risk of fire, electric shock

and personal injury.

Please read all of these instructions before attempting

to operate this machine. Save this manual for future

reference.

1. Keep work area clear. Cluttered work areas invite accidents.

2. Consider work area environment. Do not expose tools

to rain. Do not use tools in damp or wet locations. Keep work

area well lit. Never use tools near flammable liquids or gases.

3. Protect yourself against electric shock. Avoid body

contact with earthed or grounded surfaces.

4. Keep other people away. Do not let others, especially

children, come close to the work, and touch the tool or the

extension lead. Keep them away from the work area.

5. Store idle tools. When not in use, tools should be

stored in a dry locked-up place, out of children’s reach.

6. Never force the tools. Your tools will be more efficient and

safer when used at the rate for which they were intended.

7. Use the right tool. Do not force small tools to do the job of

a heavy duty tool. Do not use tools for purposes not intended;

for example do not use circular saws to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or jewellery

which may get caught in moving parts. Non-skid footwear

is recommended when working outdoors. If you have long

hair, tie it back and wear protective hair covering.

9. Use protective equipment. Use safety glasses.

Use face or dust mask if cutting operations create dust.

10. Connect dust extraction equipment. If the machines

have a connection for dust extraction equipment, ensure

these are connected and properly used.

11. Do not damage the cable. Never pull the power cable

to disconnect the machine. Keep the cable away from heat,

oil and sharp edges.

12. Secure workpiece. Where possible, use clamps or a vice

to hold the workpiece. It’s much safer than using your hands.

13. Don’t over reach. Keep proper footing and balance at

all times.

14. Maintain tools in good working condition.

Keep cutting tools sharp and clean for better performance and

optimum safety. Follow instructions for lubricating and changing

accessories. Inspect power cables regularly and, if damaged,

have them replaced by an authorised service centre. Inspect

extension cables regularly and replace immediately if damaged.

Keep handles dry, clean and free from oil and grease at all times.

15. Disconnect tools. Disconnect tools from the power supply

when not in use, before any maintenance operation and when

changing accessories such as blades, bits, cutters, etc.

16. Remove adjusting keys and spanners. Get into the

habit of checking that adjusting keys and spanners have

been removed from the machine before turning it on.

17. Avoid unintentional starting. Ensure switch is in “off”

position before plugging in the machine.

18. Use proper extension leads. When the tool is used

outdoors, use only extension leads intended for outdoor

use and labelled as such.

19. Stay alert. Concentrate on what you are doing, use

common sense and do not operate the tool when you are tired.

20. Check that no part is damaged. Before using a tool, make

sure that it is in good working order. Check the alignment and

condition of moving parts, mounting and any other aspect that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorised service

centre unless otherwise indicated in this instruction manual. Do

not use the tool if the switch does not turn on and off.

21. Warning. The use of any accessory or attachment other

than one recommended in this instruction manual may

www.evolutionbuild.com

4

present a risk of personal injury.

22. Have your tool repaired at an authorised service

centre. This electric tool complies with current safety rules.

Repairs should only be carried out by an authorised service

centre using original spare parts. Failing this, the user could

expose themselves to considerable danger.

HEALTH ADVICE

WARNING! When drilling, sanding, sawing or grinding, dust

particles will be produced. In some instances, depending

on the materials you are working with, this dust can be

particularly harmful to you (e.g. lead from old gloss paint).You

are advised to consider the risks associated with the materials

you are working with and to reduce the risk of exposure.

You should:

-Work in a well-ventilated area.

-Work with approved safety equipment, such as dust masks

that are specially designed to filter microscopic particles.

WARNING! Do not operate machine if warning and /

or instruction labels are missing or damaged. Contact

Evolution Power Tools for replacement labels.

Symbol Description

V Volts

A Amperes

Hz Hertz

Min-1

Revolutions, strokes,

surface speed, orbits etc.

per minute

~ Alternating Current

n0No Load Speed

Double Insulated

Wear Safety Goggles

Wear Ear Protection

Do Not Touch

Wear Dust Protection

Restriction of Hazardous

Substances Directive

CE certification

Waste electrical and

electronic equipment

To obtain an additional copy of your manual, please contact

Evolution Power Tools at :

UK 0870 609 2297

USA 1-866-EVO-TOOL

WEB www.evolutionpowertools.com

ADDITIONAL SPECIFIC SAFETY RULES

Do not let familiarity with this product (gained from

repeated use) replace strict adherence to hammer drill

safety rules. If you use this tool incorrectly you could suffer

serious personal injury.

1.Hold tools by the insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with a

‘live’ wire will make exposed metal parts of the tool ‘live’

and shock the operator.

2.Always be sure you have a firm footing. Be sure no

one is below you when using the tool in high locations.

3.Hold the tool firmly with both hands. Always use the

side grip.

4.Keep hands away from rotating parts.

5.Do not leave the tool running. Operate the tool only

when hand-held.

6.Do not touch the bit or the workpiece immediately

after operation; they may be extremely hot and could

burn your skin.

7. Some materials contain chemicals which may be toxic.

Take caution to prevent dust inhalation and skin contact.

Follow material supplier safety data.

CAUTION! Always unplug drill from the mains supply before

changing the drill bit, servicing, cleaning or adjusting the drill.

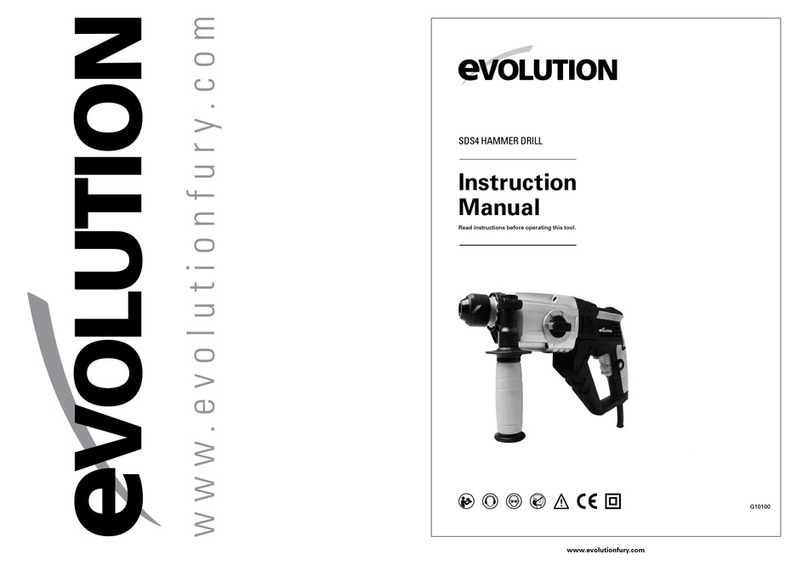

SPECIFICATIONS

Evolution SDS4-800

Motor (230/110v – 50/60 Hz) 650W

Impact Energy: 1.6J

Speed Range: 0-1100min-1

Machine Weight: 2.8 kg

Product Dimensions (HxWxD) 210mm x 320mm x 85mm

Recommended Maximum Duty Cycle: 30 mins

Max. Drill Diameter (Steel): 13mm

Max. Drill Diameter (Concrete): 20mm

Max. Drill Diameter (Wood): 30mm

Sound Pressure Level (Under Load): Lpa =88.6dB (A)

Lwa =99.6dB (A)

K = 3dB (A)

Vibration: ah 14.015 m/s2

K 1.5 m/s2

The declared vibration total value has been measured in

accordance with a standard test method and may be used

for comparing one tool with another.

The declared vibration total value may also be used in a

preliminary assessment of exposure.

WARNING: The vibration emission during actual use of

the power tool can differ from the declared total value

depending on the ways in which the tool is used. The need

to identify safety measures and to protect the operator are

based on an estimation of exposure in the actual conditions

www.evolutionbuild.com 5

SDS4-800 HAMMER DRILL

HEALTH ADVICE GB

ADDITIONAL SPECIFIC SAFETY RULES GB

SPECIFICATIONS GB

GENERAL SAFETY RULES GB

LABELS & SYMBOLS GB

®