Evoqua WALLACE & TIERNAN S10k User manual

WALLACE & TIERNAN

®

GAS FEEDER

S10k

INSTRUCTION MANUAL

2WT.025.200.000.DE.IM.0517

S10k

Please note

Original manual!

S10k Contents

3

Contents

1. Introduction 7

1.1 Documentation 7

1.1.1 Target groups 7

1.2 Conventions 8

2. Safety 9

2.1 Intended use 9

2.2 General safety instructions 10

2.3 Safety instructions specific to the S10k system 11

3. Description 13

3.1 Design 13

3.2 Principle of operation 14

3.3 Vacuum demand valve 15

3.3.1 Operating knob 17

3.3.2 Heater (optional) 19

3.3.3 Pressure relief valve 19

3.3.4 Flowmeter assembly 19

3.4 Injector 20

3.5 Technical Data 21

4. Installation 23

4.1 Unpacking 23

4.2 Location requirements 23

4.3 Flowmeter assembly 24

4.3.1 Mounting the flowmeter 25

4.4 Installing the vacuum demand valve 25

4.4.1 Connection to a gas cylinder 26

4.4.2 Connection to a chlorine drum 27

4.5 Relief line 28

4.6 Activated carbon filter 28

4.7 Mounting the injector 29

4WT.025.200.000.DE.IM.0517

Contents S10k

4.8 Point-of-application 30

4.9 Water supply 31

4.10 Gas supply line 31

4.10.1 Gas suction line 31

4.11 Commissioning 34

4.11.1 Preparation 34

4.11.2 General check 34

4.11.3 Injector vacuum and leak check 34

4.11.4 Check for gas leaks 35

4.11.5 Check of the vacuum demand valve 36

4.12 Commissioning 37

4.13 Training the operator 37

5. Operation 39

5.1 Starting operation 39

5.2 Shut-down 39

5.2.1 Shut-down for short periods 39

5.2.2 Shutdown for extended periods 40

5.3 Intermittent Start/Stop Operation 40

5.4 Changing Gas Cylinders 41

5.5 Multiple Points - of - Application 42

5.6 Maintenance and inspection plan 43

5.7 Maintenance by the operator 44

5.7.1 Daily check 44

5.7.2 Monthly check 44

5.7.3 Check every three months 44

5.7.4 Further maintenance 45

5.7.5 Changing the activated carbon filter 46

5.7.6 Preparation for Winter Shut-Down 46

5.8 Fault finding 47

6. Maintenance 49

6.1 General 49

6.2 Cleaning the parts 50

6.3 Checking the injector performance 51

6.4 Yearly Maintenance 51

5WT.025.200.000.DE.IM.0517

Contents S10k

6.5 Two-yearly maintenance 52

6.6 Preventive maintenance kits 53

6.7 Necessary tools 54

6.8 Service Notes 55

6.8.1 Servicing the main components 55

6.8.2 Cleaning the flowmeter 55

6.8.3 Cleaning the V-notch plug 56

6.8.4 Cleaning the injector 57

6.8.5 Injector W3T171369 (3/4") 58

6.8.6 Injector W3T171370 (3/4") 59

6.8.7 Injector W3T171367 (1") 60

6.8.8 Antisyphon-injector W3T171368 (1") 61

6.8.9 Cleaning the vacuum demand valve 62

7. Drawings 65

7.1 Typical installations 65

7.1.1 Basic installation for Cl2 or SO2 65

7.1.2 Installation with remote vacuum manifold 66

7.1.3 Installation with switch-over function 67

7.2 Mounting drawings 68

7.2.1 Mounting of flowmeter assembly 68

7.2.2 Mounting of injector 3/4" W3T171369 69

7.2.3 Mounting of antisyphon injector 3/4“ W3T171370 70

7.2.4 Mounting of injector 1“ W3T171367 / W3T171368 71

7.2.5 Injector 3/4" with accessories (N.101.A) 72

7.2.6 Anti-syphon-injector 3/4" with accessory 74

7.2.7 Injector 1" with accessory 76

7.3 Spare parts of the chlorinator 78

7.3.1 S10k Vacuum demand valve 78

7.3.2 Hose connections 83

7.3.3 Flowmeter assembly 5“ (W3T162278 ) 84

7.3.4 Flowmeter assembly 3“ W3T166029 86

7.4 Spare parts for the injectors 88

7.4.1 Injector W3T171367 (1") 88

7.4.2 Anti-syphon injector W3T171368 (1") 90

7.4.3 Injector W3T171369 (3/4") 94

7.4.4 Antisyphon-Injektor W3T171370 (3/4") 96

7.5 Activated carbon filter W3T159902 98

8. Manufacturer declaration 99

9. Index 101

6WT.025.200.000.DE.IM.0517

Contents S10k

S10k Introduction 1.

7

1. Introduction

1.1 Documentation

1.1.1 Target groups

This instruction manual is intended to provide assembly, opera-

ting, and maintenance personnel with the information they need

for running and servicing the S10k remote vacuum gas metering

system.

This instruction manual contains important information which will

enable the operator to run the system in a safe, reliable, trouble-

free, and economical way. Carefully observing these instructions

will help to avoid dangers, reduce repair costs and down times, im-

prove the system's reliability, and prolong its service life.

The entitled „Installation“, „Commissioning“ and „Maintenance by

specialists“ chapters are intended exclusively for Evoqua-authori-

zed technicians or specialists trained and authorized by Evoqua.

These sections contain important information on assembling, con-

figuring, and commissioning the system and on maintenance and

repair work.

All persons working with the system must have read and under-

stood the instruction manual, in particular the safety instructions it

contains.

Please consult the table of contents and the index to quickly find

the information you require.

8WT.025.200.000.DE.IM.0517

Introduction S10k

1.

1.2 Conventions

Notes This Instruction manual contains a number of notes with different

priorities marked with symbols.

Picto-

gram Note Meaning

Warning! Danger to life and limb! If the

situation is not handled properly,

death or serious injury may be the

result.

Caution! If this warning is not observed,

medium or slight injury or damage to

the equipment may the result.

Warning! Electrical hazard.

Note These notes assist in the operation

of the system.

S10k Safety 2.

9

2. Safety

2.1 Intended use

The S10k gas feeder is the central item of a disinfection system

which doses chlorine gas, sulphur dioxide or carbon dioxide gas

into a flow of water. Other use is prohibited without permission

from Evoqua.

The vacuum demand valve is designed to fit directly to a chlorine

or sulphure dioxide gas cylinder. For the use with carbon dioxide

the gas pressure must be reduced to 13.5 bar.

Action time is up to 100%.

The operational safety of the system can only be guaranteed if it is

used in accordance with its intended purpose. It may only be used

for the purpose defined in the contract and under the installation,

operating and environmental conditions stated in this operating

manual. No substances (chemicals) may be used other than those

described in this instruction manual. All inspection and

maintenance work must be carried out at the prescribed intervals.

Compliance with the intended use also includes reading this

operating manual and observing all the instructions it contains.

The operator bears full and sole responsibility if this unit is put to

any use which does not comply strictly and exclusively with this

intended use.

Not intended use Not intended use is especially

• use of other media (other gases)

• gas supply under pressure above 13.5 bar.

10 WT.025.200.000.DE.IM 0517

Safety S10k

2.

2.2 General safety instructions

Evoqua attaches great importance to the safety of all work relating

to the system. This was already taken into account in the design of

the system, by the integration of safety features.

Safety instructions The safety instructions in this documentation must always be

observed. These do not affect thevalidity of any additional national

or company safety instructions.

Safety instructions printed on

the system All safety instructions attached to the system must be observed.

They must always be complete and easily legible.

Technical standard The system has been constructed using the best available

technology and according to the accepted safety regulations.

However, danger to the life and limbs of users or third parties or

damage to the system or other property cannot be ruled out if the

system, if the system is used by unqualified persons. Installation

and maintenance, as well as any work that is not described in this

operating manual may only be performed by authorized personnel.

Personnel The operator of the overall system must ensure that only

authorized and qualified technicians can work on or with the

system, and within their specified area of responsibility.

"Authorized and qualified personnel" include:

Operation personnelof theoperator who havebeen trained and instructed by

Evoqua or a service partner.

Installation, Commissioning

and Maintenance level 2 Only Evoqua service personnel or personnel who have been

trained and authorized by Evoqua.

Electrical work Authorized and qualified electrical technicians

Spare parts / components The trouble-free operation of the system can only be guaranteed,

if original spare parts and components are used inthe combination

described in this instruction manual. Otherwise there is a danger

of malfunction or damage to the system.

Modifications and extensions Never attempt to rebuild, modify or extend the system without

written approval from the manufacturer!

Electrical power During normal operation, the control cabinet must remain closed.

Connect cables in accordance with the wiring diagram.

Waste disposal Ensure safe and environmentally-friendly disposal of agents and

replaced parts.

S10k Safety 2.

11

2.3 Safety instructions specific to the S10k system

Warning!

Chlorine gas or sulphur dioxide gas irritates the respiratory tracts.

Contact with chlorine or sulphur dioxide gas in high concentrations

irritates and damages the membranes, respiratory system and the

skin. In extreme cases death can result due to suffocation.

Note

In this manual the use of the S10k system with chorine gas is de-

scribed. When sulphur dioxide or carbon dioxide is used refer to

the safety informations of the gas supplier (e.g. the safety data

sheet).

• This unit may only be installed and serviced by qualified per-

sonnel who are familiar with the contents of the operating

instructions, works directives and regulations for handling

chlorine.

• The operators of the gas feed system must be instructed in

safe use of the unit.

• All personnel coming in contact with the unit must be in full

knowledge of the site operation and emergency procedures

and also regulations for accident prevention.

• The discharge of chlorine gas from chlorine containers should

not exceed one percent of the nominal container contents per

hour, as otherwise there is the risk that the chlorine container

and the vacuum control valve become iced. Therefore ensure

that a sufficient number of chlorine containers are connected

and open at the same time.

• When using chlorine barrels the connection valve must be

heated.

• Always open the chlorine container valve slowly and only by

one turn. This is sufficient for normal operation and in an

emergency the valve can be closed faster. It is also possible

for dirt particles to be pulled off if the value is opened quickly.

These particles then pass through the dirt filter and enter the

valve seat of the vacuum control valve and as a result the

valve no longer closes tightly.

• When changing the gas cylinders always wear a suitable and

functional gas mask. Practice use of the mask regularly. If

chlorine gas is discharged, only use a breathing system which

is independent of ambient air!

• Do not tolerate any leakages in the chlorine system. Leakage

points must be sealed immediately as they will become larger

with time if they remain unattended. When inspecting the sys-

tem for leakage always keep your gas mask to hand.

• All connections and system components must be carefully

12 WT.025.200.000.DE.IM 0517

Safety S10k

2.

inspected for leaks during commissioning, when chlorine pipes

have been released and re-connected and also regularly

during routine daily inspection, and any leaks must be sealed

correctly. If there are any traces of chlorine in the air the cause

must be determined and remedied immediately.

• When locating leaks with ammonia, never pour, spray or drip

liquid ammonia over metal components (corrosion).

• One of the most common causes for leaks on chlorine pipes

are seals which have been used more than once. For this

reason never re-use seals which have been removed from the

system, but dispose of these immediately (also when chan-

ging the gas cylinders!). Ensure that a sufficient supply of new

seals of the right size and correct material is always available

(refer to overhaul kits or spare parts).

• Gaskets must always be stored in a dry place! Damp seals

lose their stability permanently, increase the danger of corro-

sion and should never be re-used!

• If a gas pipe is interrupted or opened, close the openings

immediately with a rubber plug or similar material to prevent

the ingress of moisture. Moisture must be kept away from all

parts of the system which only come in contact with dry chlo-

rine during operation. Dry chlorine is not corrosive below

100°C. However, chlorine in combination with moisture is

extremely corrosive and corrodes most metals such as bronze

or steel.

• Before servicing the system the gas supply must be closed off

directly on the gas cylinders or tank and the chlorine gas in the

system must be consumed completely (exception: leakage

location or calibration).

• Only use original spare parts. Employment of non-specified

parts can cause faults which can have dangerous conse-

quences. Evoqua does not accept any liability in such cases.

• After installation always keep this instruction manual in a safe,

easily accessible place. It is important for safe operation and

correct servicing.

• Secure loose warning signs and replace when illegible.

• Safety inspection once annually by a competent technician.

• Servicing of the system at least once annually by a competent

technician. We recommend concluding a servicing contract

with Evoqua to this purpose.

S10k Description 3.

13

3. Description

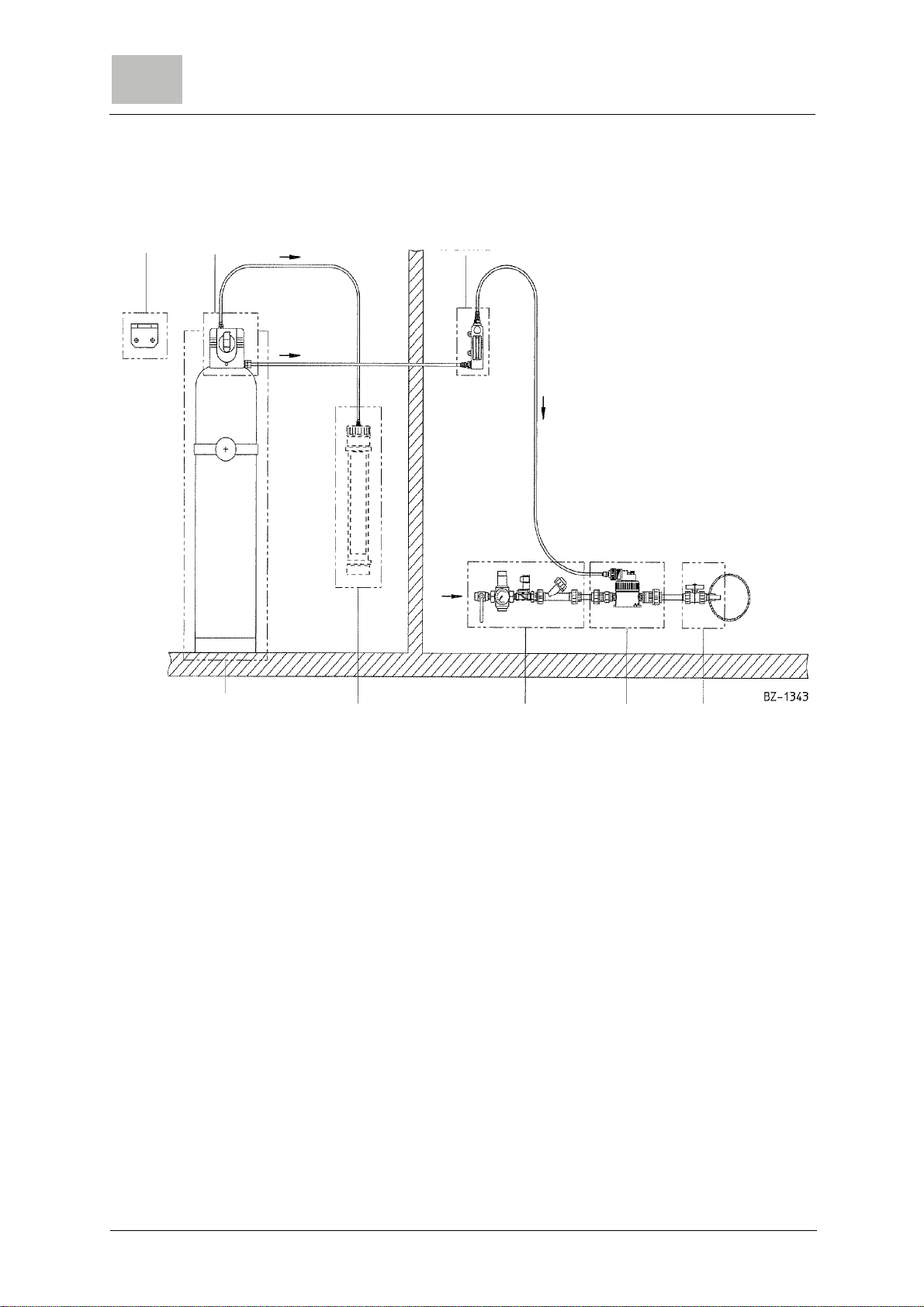

3.1 Design

The system consists of the following main components:

• The separately mounted injector (6) for the generation of the

operating vacuum and for the mixing of the gas with the water.

• The vacuum demand valve (1) is connected directly to the Cl2

or SO2gas cylinder or to the gas manifold. It only opens when

the vacuum created by the injector is sufficient.

For the use with carbon dioxide a pressure reducing valve to

13.5 bar (g) is necessary.

• The gas dosing unit (2) connected to the vacuum demand

valve via the vacuum line.

It includes the flowmeter to display the gas flow and the V-

notch plug to adjust the gas flow.

Dosage can be switched on and off by selenoid valves in the water

supply line or by booster pump.

14 WT.025.200.000.DE.IM 0517

Description S10k

3.

.

1 Vacuum demand valve

2 Gas dosing unit

3 Gas cylinder with bracket

4 Activated carbon filter (recommended for chlorine)

5 Operating water supply

6 Injector

7 Point of application

8 Support

3.2 Principle of operation

Operating water passes through an injector (6) and creates a va-

cuum. This vacuum makes the vacuum demand valve (1) on the

chlorine tank open. Chlorine gas enters the control unit (2) under

theinfluence ofthe vacuum andpasses throughthe flowmeterand

further to the injector. There it mixes with the operating water

which then passes to the solution distribution system.

2

8 1

3 4 5 6 7

S10k Description 3.

15

If the operating water is shut off, the vacuum breakes down and

the vacuum demand valve interrupts the chlorine flow. The check

valve in the injector prevents water from entering the gas line. In

case of a leak in the tubing from the regulating valve to the injector

or in the chlorinator, only air can enter into the system, but no chlo-

rine can escape. If the vacuum demand valve leakes and pressu-

rized chlorine flows into the vacuum lines, a relief valve (6) blows

the chlorine into thevent line andinto an activated carbonfilter (5).

It is highly recommended to have the sensor of a gas monitoring

system installed in the chlorine room.

3.3 Vacuum demand valve

The standard vacuum demand valve is supplied for use with chlo-

rine, sulphur dioxide or carbon dioxide gas.

Warning!

The standard vacuum demand valve must not be used for ammo-

nia. Severe personal injury or damage to plant can occur if a va-

cuum demand valve is used with a gas for which it is not designed.

The vacuum demand valve must be connected in a way that only

gaseous gas can enter the valve, never liquid gas.

The function of the vacuum demand valveis to ensure that gas can

only flow from the storage cylinder into the vacuum line when the

vacuum created by the injector is present throughout the pipework.

The vacuum demand valve is supplied in the following assemblies:

• with screw connection for chlorine gas cylinders according to

DIN 477

• with screw connection for SO2 gas cylinders

• with nipple for CO2pressure hose connection

in the versions

• Shut-off valve (non switch-over), withdrawal from one gas

cylinder or gas manifold.

• Switch-over valve, withdrawal from two gas cylinders or gas

manifolds alternatingly.

Warning!

The vacuum demand valve must not be connected directly to a

drum valve. Liquid gas must be prevented from entering the valve.

Connection to a drum is described in chapter 4.4.2

16 WT.025.200.000.DE.IM 0517

Description S10k

3.

Automatic switchover capability is provided (when ordered) by two

vacuum demand valves fitted with mechanical detents machined

into the operating lever. One valve feeds gas until its cylinder is de-

pleted (down to approximately 1 bar). The resulting rise in vacuum

toahigher thannormallevel provides sufficient forcetounlatchthe

operating lever in the second unit which then takes over the gas

supply function.

The vacuum demand valve consists of:

• Operating lever

• Valve housing

• Relief valve

• Cylinder connection

• Heater (optional)

• Pressure gauge, contact pressure gauge (optional)

The discharge of chlorine gas from chlorine containers should not

exceed one percent ofthe nominalcontainer contents per hour,as

otherwise there is the risk that the chlorine container and the va-

cuum demand valve become iced. Therefore connect each chlori-

ne container to a vacuum demand valve. Alternatively connect

several gas cylinders to a gas manifold and connect a vacuum de-

mand valve to the manifold.

S10k Description 3.

17

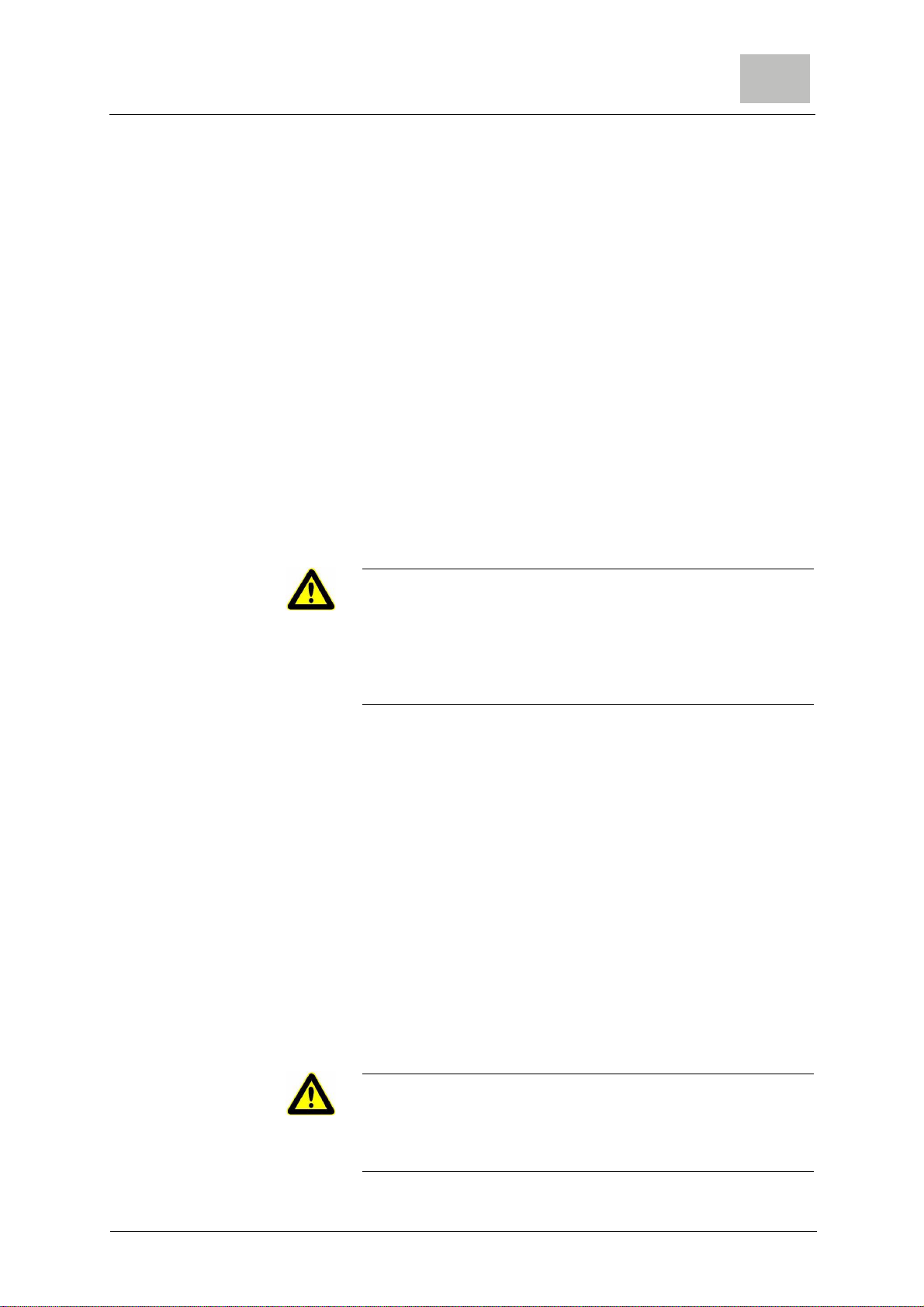

3.3.1 Operating knob

The front cover houses the control mechanism and the front face

is provided with symbols, which indicate the operating condition of

the unit as follows.

Standard version

(non switch-over)

Operation:

closed operating empty

To close the valve:

Move the knob downwards

and turn clockwise.

To open the valve:

Turn the knob anti-clockwise

and move to the top.

18 WT.025.200.000.DE.IM 0517

Description S10k

3.

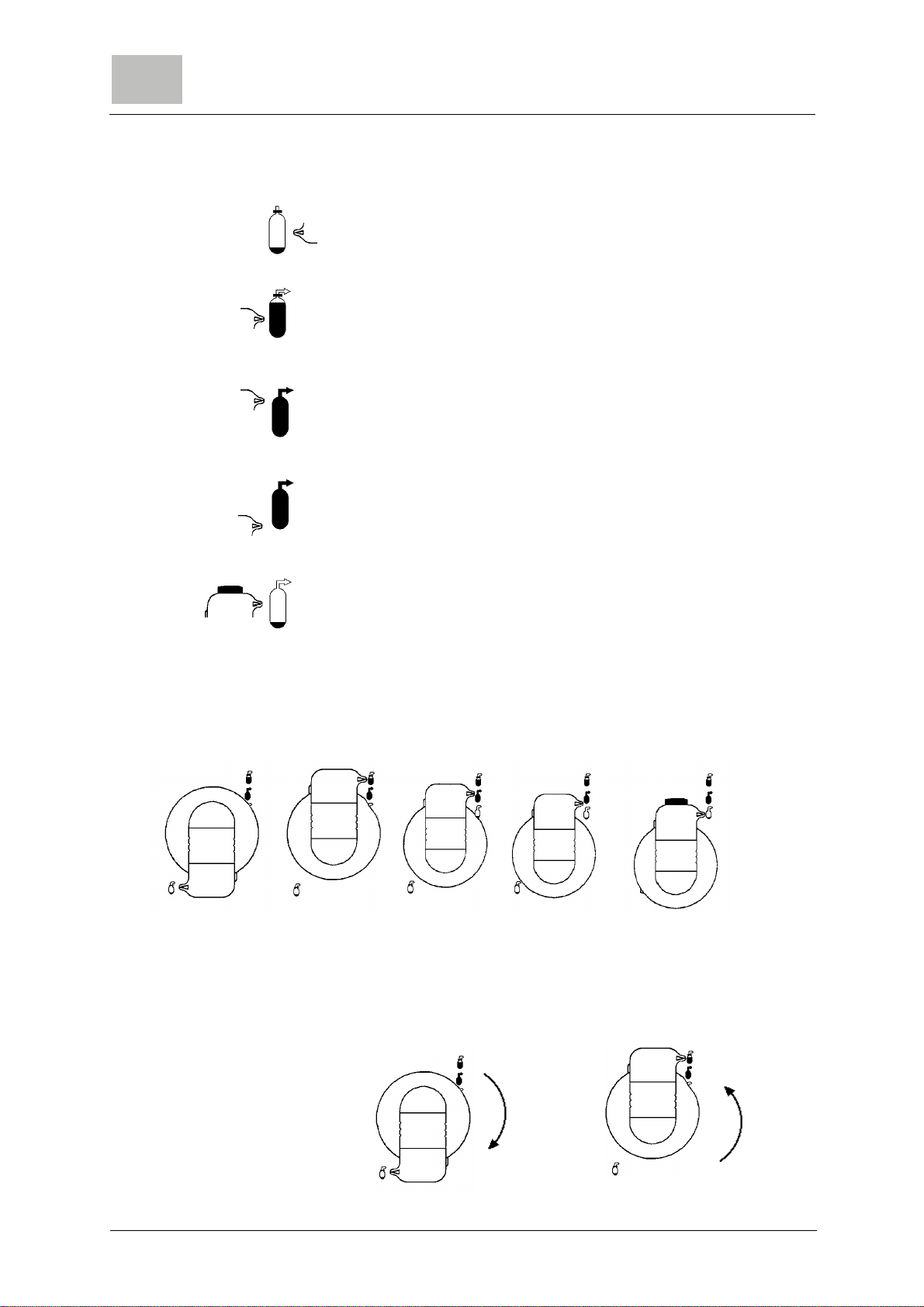

Switch-over version

Closed

standby

(The valve is closed. It opens when the other gas cylinder is empty

and the vacuum rises.

Operating

One cylinder empty or valve closed.

The pressure gauge shows 0 bars.

Both gas cylinders are empty.

The pressure gauge of both gas cylinders show 0 bars.

The red OUT OF GAS warning indicator, located above the knob,

is uncovered.

After the changing of the gas cylinder and the opening of the cylin-

der valve move the knob in position „Standby“ or „Closed“.

Operation:

Closed Standby operating cylinder empty both cylinders empty

To close the valve:

Move the knob downwards and

turn clockwise.

To open the valve:

Turn theknob anti-clockwise and

move to the top.

S10k Description 3.

19

3.3.2 Heater (optional)

An optional heater unit (W3T162239) is available for installations

where reliquefaction of the gas within the valve is a problem due

to low external temperatures. Reliquefaction can occur if the tem-

perature in the vacuum demand valve is below the temperature in

the gas cylinder.

This unit comprises a bolt on capsule which attaches to the check

valve housing of the vacuum demand valve. The thermostatatical-

ly controlled heater is designed to operate on any single phase

supply of 115 volts or over, up to a maximum of 230 volts.

Electric connections must be made by electric specialists accor-

ding to the corresponding rules, e.g. EN 60204.

The LED on the unit is on when the unit is under tension.

The unit can be hot (ca. 60°C).

3.3.3 Pressure relief valve

The pressure relief valve fits into a recess in the back housing of

the regulating valve. The relief valve comprises a spring, stem and

diaphragm. The faceof thediaphragm is springloaded against two

openings, one opening connects into the main chamber of the val-

ve and the other connects to the vent line. Should either of the

check valve stems fail to seat when the operating vacuum is shut

off, gas will pass into the main chamber of the valve where its pres-

sure acts against the underside of relief valve diaphragm. The re-

lief valve diaphragm is forced against its spring until it unseats at

which point gas is allowed to pass to atmosphere via the vent line.

3.3.4 Flowmeter assembly

The flowmeter assembly is fitted with a graduated glass tube and

a control knob. The tubes inner surface is tapered towards the bot-

tom and contains a free moving float. The gas forces the float up

the tube until it can flow round it thus indicating gas flow by the po-

sition of the float in relation to the graduations. The control knob

screws a variable orifice V-notch plug inor outto adjustthe volume

of gas passing through the assembly.

Mounted heater unit

20 WT.025.200.000.DE.IM 0517

Description S10k

3.

Control of the gas feedrate is achieved by by turning the control

knob

• in the anti-clockwise direction to increase the flowrate or

• in the clockwise direction to decrease the flowrate.

If the float touches the upper stop, the range is exceeded and the

reading is not valid.

3.4 Injector

Standard injectors W3T171367 : sizee 1" up to 10 kg/hour

W3T171369: size 3/4" up to 4 kg/hour

The injectors are fitted with check valves to prevent a back flow of

water into the gas feeder if the injector is subject to positive back

pressure when it is shut down or if the solution discharge line be-

comes blocked.

Anti-syphon injectors W3T171368: size 1" up to 10 kg/hour

W3T171370: size 3/4" up to 4 kg/hour

Anti-syphon versions of both injectors are available and are basi-

cally as described above but are fitted with a second, spring loa-

ded, diaphragm assembly to provide a positive shut-off against

negative back pressure at the injector.

Both the standard and anti-syphoninjectors are mounted remotely

from the demand valve and the flowmeter assembly.

Table of contents

Other Evoqua Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

JCM GLOBAL

JCM GLOBAL UBA Pro RT Series Operation and maintenance manual

Eaton

Eaton RMQ-Titan C22-PV Series Original operating instructions

Kobelt

Kobelt 7166 Electric Helm Owner's Operation, Installation & Maintenance Manual

Hamworthy

Hamworthy EVO S 80 instructions

BVA Hydraulics

BVA Hydraulics HD15002 instruction manual

Crystal Clean

Crystal Clean 2740 operating manual