Evoqua V10K User manual

1

INSTRUCTION MANUAL

V10K AUTOMATIC

WALLACE & TIERNAN®

VACUUM GAS FEEDER

FOR Cl2 AND SO2

2

V10k automatic

EN

In some countries, DEPOLOX, OSEC, Barrier, Chem-Ad and Wallace & Tiernan are trademarks of Evoqua, its subsidiaries or

affiliated companies. No part of this document may be reproduced in any form (printed, photocopy, microfilm, or any other

procedure) or saved, processed, copied, or distributed using electronic data systems - without the express prior written con-

sent of Evoqua Water Technologies GmbH.

All information in this document is considered reliable and corresponds to the generally applicable technical standards. Evo-

qua assumes no responsibility for the completeness of this information. Users are responsible for making sure that the pro-

duct is suitable for specific applications. Evoqua assumes no liability for specific or indirect damage or consequential

damage arising from the sale, resale or misuse of its products.

NOTICE

Translation of the original instruction.

V10k automatic

3

EN

Contents

1. Introduction 4

1.1 Documentation........................................................................................................4

1.2 Conventions.............................................................................................................4

2. Safety 5

2.1 Intended use ...........................................................................................................5

2.2 General safety instructions .....................................................................................5

2.3 Safety instructions specific to the V10k system ......................................................6

3. Description 8

3.1 Principle of operation..............................................................................................8

3.2 Control possibilities .................................................................................................8

3.3 Design......................................................................................................................9

3.4 Technical Data .......................................................................................................10

4. Installation 11

4.1 Scope of supply .....................................................................................................11

4.2 Transport and storage...........................................................................................11

4.3 Mounting...............................................................................................................12

4.4 Gas supply line.......................................................................................................13

4.5 Electric connection ................................................................................................14

4.6 Insert the flowmeter .............................................................................................16

4.7 Remove and mount the cover...............................................................................17

4.8 Preparation............................................................................................................17

4.9 Commissioning ......................................................................................................18

4.10 Training the operator ............................................................................................19

5. Operation 20

5.1 General ..................................................................................................................20

5.2 Start dosing ...........................................................................................................20

5.3 Stop dosing............................................................................................................20

5.4 Changing gas containers........................................................................................20

5.5 To stop for extended periods or maintenance......................................................20

5.6 Fault finding...........................................................................................................21

5.7 Maintenance and inspection plan ........................................................................24

6. Maintenance 25

6.1 Changing the activated carbon filter.....................................................................25

6.2 Cleaning the parts .................................................................................................26

6.3 Maintenance of the chlorinator ............................................................................26

6.4 Maintenance of the injector..................................................................................27

6.5 Preventive maintenance kits.................................................................................29

6.6 Positioner ..............................................................................................................39

7. Drawings 42

7.1 Typical installations ...............................................................................................42

7.2 Mounting drawings ...............................................................................................44

7.3 V10k chlorinator....................................................................................................53

7.4 Injectors.................................................................................................................59

8. Wiring diagram 67

9. Declaration of conformity 68

10. Notes 70

1. Introduction V10k automatic

4

EN

1. Introduction

1.1 Documentation

1.1.1 Target groups

This instruction manual is intended to provide

assembly, operating, and maintenance per-

sonnel with the information they need for run-

ning and servicing the V10k remote vacuum

gas metering system.

This instruction manual contains important

information which will enable the operator to

run the system in a safe, reliable, trouble-free,

and economical way. Carefully observing

these instructions will help to avoid dangers,

reduce repair costs and down times, improve

the system's reliability, and prolong its service

life.

The chapter „Installation“ and parts of the

chapter „Maintenance“ are intended exclusi-

vely for Evoqua-authorized technicians or spe-

cialists trained and authorized by Evoqua.

These sections contain important information

on assembling, configuring, and commissio-

ning the system and on maintenance and

repair work.

All persons working with the system must

have read and understood the instruction

manual, in particular the safety instructions it

contains.

Please consult the table of contents to quickly

find the information you require.

1.2 Conventions

This Instruction manual contains a number of

notes with different priorities marked with

symbols

.

DANGER

Danger to life and limb! If the situation is not

handled properly, death or serious injury

may be the result.

WARNING

Danger to life and limb! If the situation is not

corrected, death or serious injury can result.

AT TENTION

If this warning is not observed, medium or

slight injury or damage to the equipment

may the result.

WARNING

Electrical hazard.

NOTICE

These notes assist in the operation of the

system.

V10k automatic 2. Safety

5

EN

2. Safety

2.1 Intended use

The V10k chlorinator is the central item of a

disinfection system which doses chlorine gas

or sulphur dioxide gas into a flow of water. For

the use with carbon dioxide a separate instruc-

tion manual is available.

The V10k vacuum gas metering system must

be connected to a vacuum gas supply.

Action time is up to 100%.

Other use is prohibited without permission

from Evoqua.

The operational safety of the system can only

be guaranteed if it is used in accordance with

its intended purpose. It may only be used for

the purpose defined in the contract and under

the installation, operating and environmental

conditions stated in this operating manual. No

substances (chemicals) may be used other

than those described in this instruction

manual. All inspection and maintenance work

must be carried out at the prescribed inter-

vals.

Compliance with the intended use also inclu-

des reading this operating manual and obser-

ving all the instructions it contains.

The operator bears full and sole responsibility

if this unit is put to any use which does not

comply strictly and exclusively with this inten-

ded use.

Not intended use is especially

• use of other media (other gases)

• gas supply under pressure

2.2 General safety instructions

Evoqua Water Technologies GmbH attaches

great importance to the safety of all work rela-

ting to the system. This was already taken into

account in the design of the system, by the

integration of safety features.

The safety instructions in this documentation

must always be observed. These do not affect

the validity of any additional national or com-

pany safety instructions.

All safety instructions attached to the system

must be observed. They must always be com-

plete and easily legible.

The system has been constructed using the

best available technology and according to the

accepted safety regulations. However, danger

to the life and limbs of users or third parties or

damage to the system or other property can-

not be ruled out if the system, if the system is

used by unqualified persons. Installation and

maintenance, as well as any work that is not

described in this operating manual may only

be performed by authorized personnel.

Personnel

The operator of the overall system must

ensure that only authorized and qualified

technicians can work on or with the system,

and within their specified area of responsibi-

lity.

"Authorized and qualified personnel" include:

Operation and Maintenance leve 1

Personnel of the operator who have been trai-

ned and instructed by Evoqua or a service

partner.

Installation, Commissioning and Main‐

tenance level 2

Only Evoqua service personnel or personnel

who have been trained and authorized by Evo-

qua

Electrical work

Authorized and qualified electrical technicians

Spare parts/components

The trouble-free operation of the system can

only be guaranteed, if original spare parts and

components are used in the combination

described in this instruction manual. Other-

wise there is a danger of malfunction or

damage to the system.

Modifications and extensions

Never attempt to rebuild, modify or extend

the system without written approval from the

manufacturer!

Electrical power

Connect cables in accordance with the wiring

diagram. During normal operation, the posi-

tioner must remain closed. Switch off the

plant before starting mounting, inspection,

maintenance or repair, secure against swit-

ching-on.

2. Safety V10k automatic

6

EN

Waste disposal

Ensure safe and environmentally-friendly dis-

posal of agents and replaced parts.

2.3 Safety instructions specific to

the V10k system

• This unit may only be installed and servi-

ced by qualified personnel who are fami-

liar with the contents of the operating

instructions, works directives and regula-

tions for handling chlorine.

• The operators of the gas feed system must

be instructed in safe use of the unit.

• All personnel coming in contact with the

unit must be in full knowledge of the site

operation and emergency procedures and

also regulations for accident prevention.

• The gas control unit V10k must be con-

nected to a vacuum gas supply only, never

connect to a pressurized gas line.

• The discharge of chlorine gas from chlo-

rine containers should not exceed one

percent of the nominal container con-

tents per hour, as otherwise there is the

risk that the chlorine container and the

vacuum control valve become iced. There-

fore ensure that a sufficient number of

chlorine containers are connected and

open at the same time.

• When changing the gas cylinders always

wear a suitable and functional gas mask.

Practice use of the mask regularly. If chlo-

rine gas is discharged, only use a breat-

hing system which is independent of

ambient air!

• Do not tolerate any leakages in the chlo-

rine system. Leakage points must be sea-

led immediately as they will become

larger with time if they remain unatten-

ded. When inspecting the system for lea-

kage always keep your gas mask to hand.

• All connections and system components

must be carefully inspected for leaks

during commissioning, when chlorine

pipes have been released and re-connec-

ted and also regularly during routine daily

inspection, and any leaks must be sealed

correctly. If there are any traces of chlo-

rine in the air the cause must be determi-

ned and remedied immediately.

• When locating leaks with ammonia, never

pour, spray or drip liquid ammonia over

metal components (corrosion).

• One of the most common causes for leaks

on chlorine pipes are seals which have

been used more than once. For this rea-

son never re-use seals which have been

removed from the system, but dispose of

these immediately (also when changing

the gas cylinders!). Ensure that a suffi-

cient supply of new seals of the right size

and correct material is always available

(refer to overhaul kits or spare parts).

• Gaskets must always be stored in a dry

place! Damp seals lose their stability per-

manently, increase the danger of corro-

sion and should never be re-used!

• If a gas pipe is interrupted or opened,

close the openings immediately with a

rubber plug or similar material to prevent

the ingress of moisture. Moisture must be

kept away from all parts of the system

which only come in contact with dry chlo-

rine during operation. Dry chlorine is not

corrosive below 100°C. However, chlorine

in combination with moisture is extremely

corrosive and corrodes most metals such

as bronze or steel.

• Before servicing the system the gas supply

must be closed off directly on the gas

cylinders or tank and the chlorine gas in

the system must be consumed completely

(exception: leakage location or calibrat-

ion)

• Only use original Evoqua spare parts.

Employment of non-specified parts can

cause faults which can have dangerous

consequences. Evoqua does not accept

WARNING

Danger due to chlorine gas/sulphur dioxide!

Chlorine gas or sulphur dioxide gas irritates

the respiratory tracts. Contact with chlorine

or sulphur dioxide gas in high concentrations

irritates and damages the membranes, respi-

ratory system and the skin. In extreme cases

death can result due to suffocation.

NOTICE

In this manual the use of the V10k system

with chorine gas is described. The safety ins-

tructions for chlorine are similar to those for

sulphur dioxide. When sulphur dioxide is

used refer to the safety informations of the

gas supplier (e.g. the safety data sheet).

V10k automatic 2. Safety

7

EN

any liability in such cases.

• After installation always keep this instruc-

tion manual in a safe, easily accessible

place. It is important for safe operation

and correct servicing.

• Secure loose warning signs and replace

when illegible.

• Safety inspection once annually by a com-

petent technician.

• Servicing of the system at least once

annually by a competent technician. We

recommend concluding a servicing con-

tract with Evoqua to this purpose.

3. Description V10k automatic

8

EN

3. Description

3.1 Principle of operation

Operating water passes through an injector

(14) and creates a vacuum. This vacuum makes

the vacuum control valve (4) on the chlorine

tank (1) open. Chlorine gas enters the control

unit (8) under the influence of the vacuum and

passes through the flowmeter and further to

the injector. There it mixes with the operating

water which then passes to the solution distri-

bution system.

If the operating water is shut off, the vacuum

breakes down and the vacuum control valve

interrupts the chlorine flow. In case of a leak in

the tubing from the vacuum control valve to

the injector or in the chlorinator, only air can

enter into the system, but no chlorine can

escape. If the vacuum control valve leakes and

pressurized chlorine flows into the vacuum

lines, a relief valve (6) blows the chlorine into

the vent line and into an activated carbon filter

(5).

It is highly recommended to have the sensor of

a gas monitoring system installed in the chlo-

rine room.

3.2 Control possibilities

The gas flow is directly indicated on the flow

meter in g/h or kg/h. Within the dosing range,

limited by the v-notch, every dosage rate can

be adjusted (max. 15 kg/h).

automatic:

Dosage rate is adjusted by the positioner. The

positioner is controlled depending on water

flow and/or chlorine residue.

semi‐automatic:

• Dosage rate is adjusted manually. The

injector is switched on and off by sole-

noid valves in the water supply line or by

booster pump.

• Dosage rate is adjusted by the positioner

switched up and down via an external

controller. The injector is switched on and

off by solenoid valves in the water supply

line or by booster pump.

manual:

Pull out the knob on the positioner and turn to

adjust the dosing rate (e.g. in case of failure on

the automatic control). To turn back to auto-

matic control push back the knob and slightly

turn it until it snaps in.

V10k automatic 3. Description

9

EN

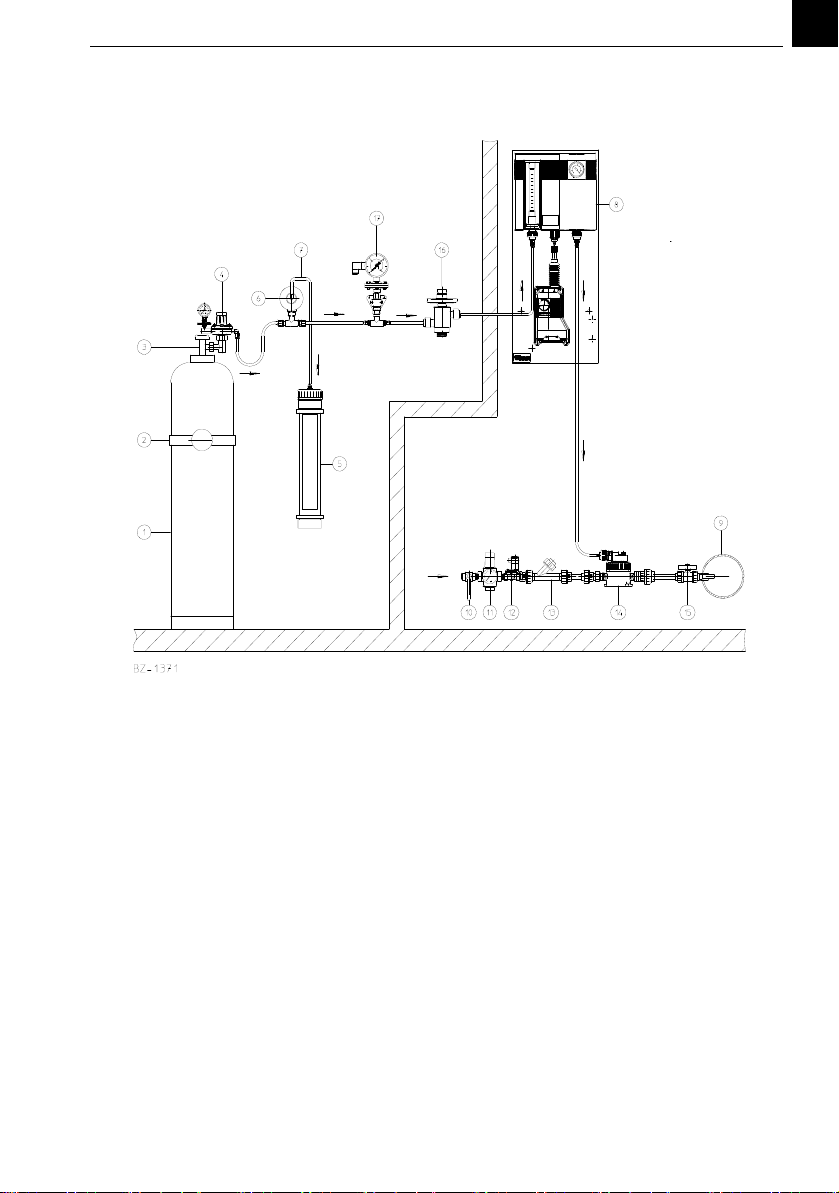

3.3 Design

Example for basic chlorinator installation

1 Chlorine gas cylinder

2Mountingbracket

3Cylindervalve

4Vacuumcontrolvalve

5 Activated carbon filter

6 Pressure relief valve

7 Pressure relief tube

8 Chlorinator V10k

9 Point of application

10-13 Operating water supply

14 Injector

15 Stop valve and injection tube

16 Safety valve (optional)

17 Contact pressure gauge (optional)

3. Description V10k automatic

10

EN

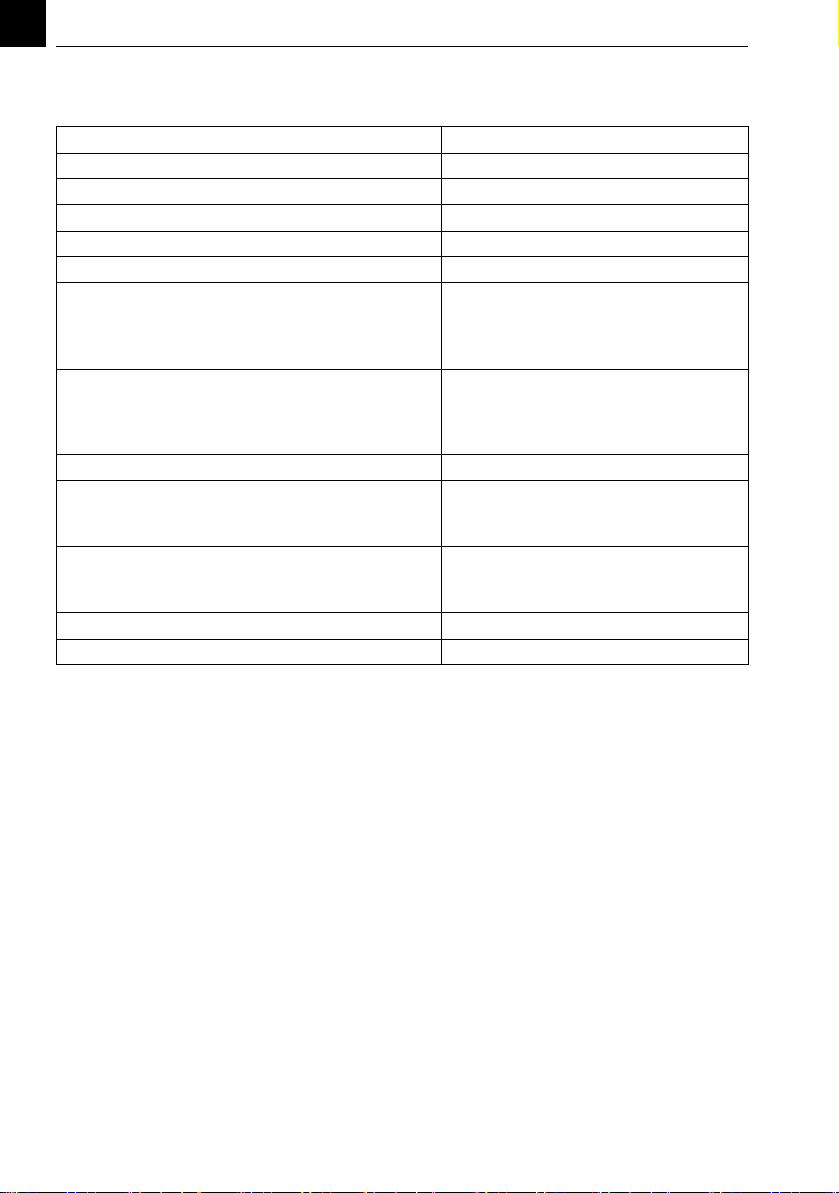

3.4 Technical Data

Chlorinator with positioner on mounting plate

The chlorinator can be equipped with different flowmeter tubes and V-notches. By changing

these parts and if necessary the injector, the dosing range can be changed.

with short flowmeter (5") or long flowmeter (10") part no. W3T159301

Regulating range of the V notch *) refer to the shipping documents

Display range of the flowmeter *) refer to the shipping documents

Flowmeter Accuracy class 4

Operating temperature 0°C to +50°C

Operating vacuum approx. 200 mbar

Operating pressure of the 1“ injectors max. 21 bar g up to 20°C,

max. 16 bar g up to 30°C,

max. 12 bar g up to 40°C,

max. 8 bar g up to 50°C

Operating pressure of the ¾“ injectors max. 16 bar g up to 20°C,

max. 13 bar g up to 30°C,

max. 10 bar g up to 40°C,

max. 5,9 bar g up to 50°C

Noise < 70 dB (A)

Positioner 230 V, 50 Hz 19 mA,

positioning time approx. 80 sec.

potentiometer 1 kOhm ± 10%

Positioner 115 V, 60 Hz 46 mA,

positioning time approx. 66 sec.

potentiometer 1 kOhm ± 10%

Dimensions incl. mounting plate (W x H x D)

V10k with positioner 369 x 880 x 185, weight approx. 15 kg

V10k automatic 4. Installation

11

EN

4. Installation

4.1 Scope of supply

The scope of supply includes according to the

selected version:

• Chlorinator with positioner

•Injector

• Operating water supply

• Point of injection

also necessary

•Gassupplywith

• Vacuum control valve

• Release valve with release line and

activated carbon filter

•Vacuumsafetyvalve

(refer to separate instruction manual „Gas

supply“)

4.2 Transport and storage

The chlorinator is shipped in a cardboard box.

1 Check that the box is not damaged.

2 Immediately report any damage to the

freight forwarder.

If the chlorinator is damaged, immedia-

tely inform Evoqua.

3 Check all items against the packing note.

4.2.1 Unpacking

1 Unpack the equipment in a clean, dry

area, preferably at the installation site.

2 Open the packing only on the upper side.

3 Take the accessories out of the cardboard

pocket above the chlorinator.

4 Hold the chlorinator at the mounting

plate or at the positioner, but not at the

red regulator shaft or the positioner rack

and lift out of the packing.

5 To prevent damage during transport the

flowmeter glas is packed separately.

Handle this glas tube very carefully.

Cracks make the glas tube useless.

Preferably mount the flowmeter just

before commissioning.

6 Check all items against the packing note

to ensure that none is discarted with the

packing materials.

7 Retain the packing until the system has

been completely installed.

4.2.2 Location requirements

For drawings of typical installations refer to

7.1

• Unauthorized persons must be excluded

from the installation.

• Adequate access should be available to

permit ease of operation and mainte-

nance of all plant items.

• The gas control unit should be mounted at

eye's height.

• The ambient temperature around the gas

control unit should be at least 0°C (install

a heater if necessary) with a maximum at

50°C (preferably 15 - 20°C).

• The system shall be protected against

direct exposure to sun and moisture.

• Gas containers are heavy and the location

should be choosen to give the shortest

possible gas supply line, consistent with

safe handling of the containers.

• Position and equipment of the chlorine

storage and operation room must corre-

spond to the resp. regulations.

WARNING

Danger due to chlorine gas (gas escape)!

To avoid the risk of injuries due to chlorine

gas, the system must be installed in such a

way that gas is only able to escape into the

room where the gas tanks are stored or into

a separate plant room in the event of a gas

leak. All parts of the system that are liable to

be pressurized (e.g. chlorine tanks, vacuum

control valves, safety pressure relief valves

with activated carbon filters) must therefore

be installed in these rooms. The parts of the

system that are under vacuum may be

installed in another room that is not subject

to specific regulations.

4. Installation V10k automatic

12

EN

4.3 Mounting

(See mounting drawing chapter 7.2.)

4.3.1 Gas Control Unit

1 Mount the gas control unit to a vertical

surface, wall, etc. with the dowels and

screws supplied loose. The flowmeter

should be at a height suitable for reading.

Make shure that the mounting plate is

exactly level and not distorted when tigh-

tening the nuts. The mounting plate

should not touch the wall.

4.3.2 Injector

When installed with rigid pipes the injectors

need not to be fixed elsewhere. When connec-

ted to flexible tubes the injectors have to be

fixed as shown in chapter 7.2.

Nozzle (with stamped number) and tailway

(with stamped letter) are supplied loose.

1 Place the o-rings on both and apply some

vacuum grease (do not use mineral

grease).

2 When assembling nozzle and tailway into

the injector body pay attention to the

flow direction (see arrows on the injector

body). Turn only by hand up to the stop.

For measuring the injector vacuum a 1/4" con-

nection is provided.

Operation range:

Up to 4 kg/h:

standard injector W3T171369 (3/4") or anti-

syphon injector W3T171370

Above 4 kg/h:

standard injector W3T171367 (1") or anti-

syphon injector W3T171368

The anti-syphon injectors are necessary, when

depression can occur in the water pipe, e.g. by

water flowing downwards.

Injector W3T171369/W3T171370

Connection at the throat:

3/4“ hose or threaded tube

If connected to 3/4" rigid tube, the part of the

nozzle that is prepared for accepting flexible

tube can be removed. Carefully deburr and

remove the residues.

The gas connection can be turned in 45° steps

after loosening the union nut. Lock before

tightening the union nut. Tighten only by

hand!

Injector W3T171367/W3T171368

Connection at the throat:

PVC tube DN 25 (Ø32 mm)

Connection at the tailway:

PVC tube with 3/4“ inner thread

The gas connection can be turned in 60° steps.

To do so remove the 6 bolts, remove the upper

part of the housing and fix again in the desired

position. Tighten the bolts equally.

4.3.3 Point‐of‐application

If the point-of-application is a pressurized

main or is higher than the injector, the solu-

tion line should incorporate a check valve and

terminate in a solution injection tube assem-

bly.

WARNING

Danger due to chlorine gas (gas escape)!

To avoid the risk of injuries due to chlorine

gas, the system must be installed in such a

way that gas is only able to escape into the

room where the gas tanks are stored or into

a separate plant room in the event of a gas

leak. All parts of the system that are liable to

be pressurized (e.g. chlorine tanks, vacuum

control valves, safety pressure relief valves

with activated carbon filters) must therefore

be installed in these rooms. The parts of the

system that are under vacuum may be

installed in another room that is not subject

to specific regulations.

WARNING

To avoid possible severe personal injury or

damage to the plant this equipment should

be installed, operated and serviced only by

trained qualified personnel. Do not modify

the installation beyond what is described in

this manual without explicit consent of Evo-

qua.

AT TENTION

Never shorten the tailway. The tube connec-

ted to the tailway must be straight for at

least 0,30 m more. Otherways the flow in

the pressure-recovery zone will be interrup-

ted and prevent normal performance.

V10k automatic 4. Installation

13

EN

The injection tube consists of a pvc stop valve

and a tube with threaded connection, that

extends to approx. 1/3 of the mains diameter

when extended.

It is recommended that all solution delivery

lines be fitted with a suitable valve and drain

pipe to enable any pressure build up to be

safely released prior to maintenance work.

4.3.4 Water supply

To operate the injector, a water supply pipe of

at least 3/4“ diameter is necessary according

to the operating conditions.

There must always be sufficient operating

water available at an adequate supply pres-

sure (see Technical Data for details). The ope-

rating water must not contain any particulates

(potable water quality).

Water pressure and quantity depend on the

maximum dosing capacity, the counterpres-

sure at the point of application, the difference

in geodetic altitude between chlorinator and

point of application and the friction in the

dosage line. On these values depend the selec-

tion of the injector.

If the operating water pressure is too low, a

booster pump is required.

The water line should include a suitable shut-

off valve, strainer, pressure gauge, pressure

reducing valve check-valve and solenoid valve

(see chapter 7.1).

It is recommended that all solution delivery

lines lines be fitted with a suitable valve and

drain pipe to enable any pressure build up to

be safely released prior to maintenance work.

4.4 Gas supply line

For reducing the pressure from the chlorine

tanks, a vacuum control valve and a safety

relief valve are necessary (see also typical ins-

tallation).

For the vacuum control valves a separate inst-

ruction manual „Gas supply“ is available.

4.4.1 Gas suction line

The diameter of the suction line between

vacuum control valve, control unit and injector

depends on the the gas flow and the distance

(see table below).

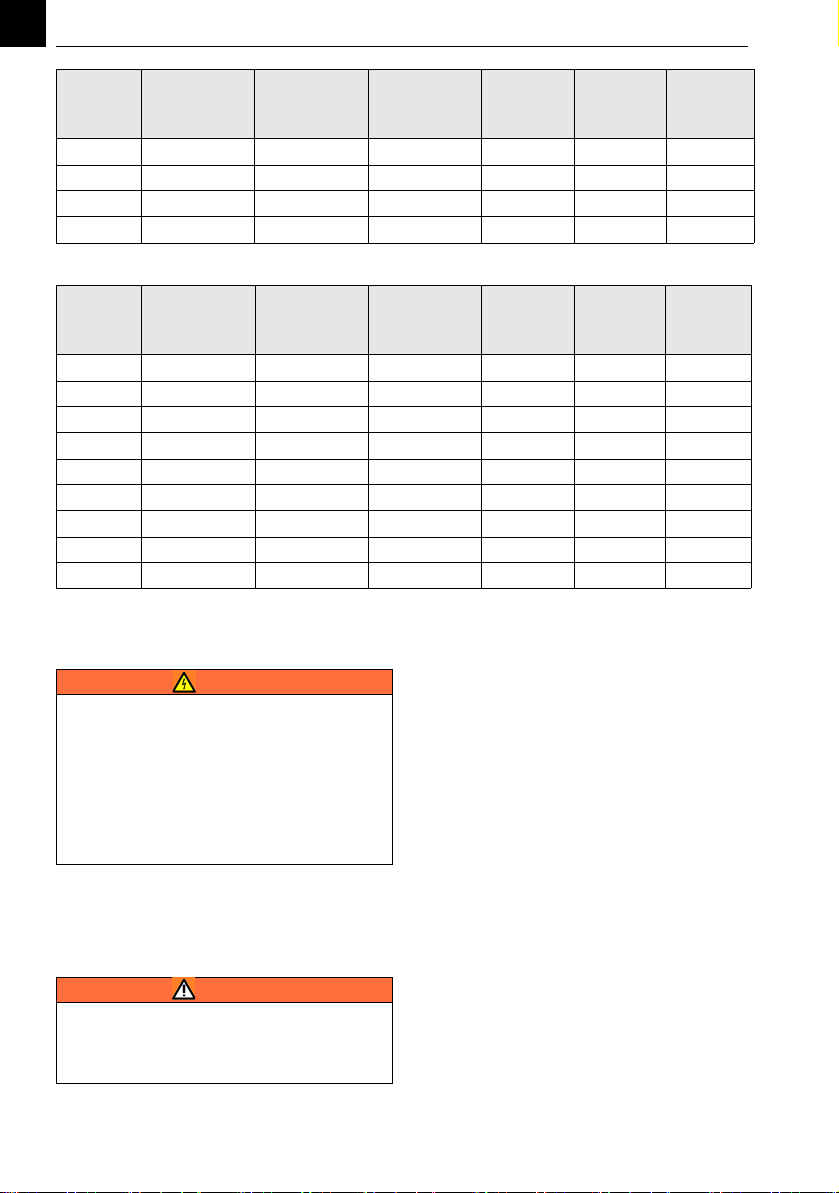

Max. tube/pipe length from vacuum control valve to the V10k

NOTICE

Behind the point-of-application a pipe

length of at least 10...15 x pipe diameter is

necessary for a homogenious mixing of the

solution into the main water. After that,

samples can be taken for residue control

etc. If the point-of-application is into a basin,

channel etc. a diffusor can be supplied (refer

to the project documentation.

WARNING

Danger due to chlorine gas !

The gas control unit must be connected to a

vacuum gas supply only.

Do not open the cylinder or drum valve until

the system has been fully installed and the

pre-start checks are being carried out.

Refer to the safety information of the gas

supplier and the safety data sheet!

ATTENTION

When using polyethylene pipes don't install

them in narrow, badly vented protection

pipes or in the ground to prevent the pipe

from fast embrittling under the influence of

chlorine.

Feed of

Cl2, SO2

in g/h

PE hose

6,35 mm

(1/4“)

PE hose

9,5 mm

(3/8“)

PE hose

12 mm

(1/2“)

PVC pipe

DN 15

PVC pipe

DN 20

PVC pipe

DN 25

200 250 m 1200 m 3000 m - - -

400 146 m 670 m 1510 m 3600 m - -

1000 24 m 88 m 852 m 1710 m - -

2000 6 m 33 m 107 m 320 m 1094 m -

3000 3 m 16 m 53 m 179 m 607 m 1853 m

4. Installation V10k automatic

14

EN

Max. tube/pipe length from V10k to injector

4.5 Electric connection

4.5.1 Connecting solenoid valve / boo‐

ster pump

refer to Typical Installations in chapter 7.1

A booster pump is necessary if the operation

water pressure is too low.

1 Lock the booster pump to the flow in the

main water line (e.g. by using a flow sen-

sor)

When using a solenoid valve in the main water

line:

1 Lock the solenoid valve to the flow in the

main water line (e.g. by using a flow sen-

sor)

4.5.2 Connecting the positioner

The positioner can be connected to a Evoqua

control unit, other controls or a remote cont-

rol panel.

Connect the positioner according to wiring

diagram 30-E-7693 (see chapter 8 and the ins-

tructions of the control).

• CLOSE/DEC: connecting rod moves out,

chlorinator flow decreases,

• OPEN/INC: connecting rod moves in, chlo-

rinator flow increases.

The positioner is supplied with three cable

glands and two plug screws. Insert as applica-

ble. The following bores are provided:

• for 230 V positioners: ø 20.5 mm

4000 - 9 m 28 m 91 m 364 m 1042 m

6000 - 5 m 15 m 43 m 145 m 479 m

8000 - 2 m 8 m 25 m 98 m 294 m

10000 - 1, 5 m 5 m 16 m 73 m 206 m

Feed of

Cl2, SO2

in g/h

PE hose

6,35 mm

(1/4“)

PE hose

9,5 mm

(3/8“)

PE hose

12 mm

(1/2“)

PVC pipe

DN 15

PVC pipe

DN 20

PVC pipe

DN 25

Feed of

Cl2, SO2

in g/h

PE hose 6,35

mm (1/4“)

PE hose 9,5

mm (3/8“)

PE hose 12

mm (1/2“)

PVC pipe

DN15

PVC pipe

DN20

PVC pipe

DN25

200 415 m 2000 m - - - -

400 243 m 1115 m 2515 m - - -

1000 40 m 146 m 1420 m 2850 m - -

2000 10 m 55 m 178 m 532 m 1748 m -

3000 5 m 26 m 88 m 298 m 1010 m 3088 m

4000 - 15 m 46 m 151 m 606 m 1736 m

6000 - 7 m 25 m 71 m 240 m 798 m

8000 - 4 m 13 m 40 m 163 m 490 m

10000 - 2, 5 m 8 m 26 m 121 m 343 m

WARNING

To avoid personal injury by electrical energy

only authorized and qualified electrical per-

sonnel may carry out works on electrical

parts of the system.

Connect the control cabinet according to the

wiring diagrams and the national and local

codes. Before opening positioner or electric

control unit, ensure that mains supply is

switched off.

WARNING

Danger of over-chlorination!

The water through the injector may flow

only when the water in the main water line

flows.

V10k automatic 4. Installation

15

EN

• for 115 V positioners: ø 22 mm

1 To open the cover:

Remove the knob (Allen key 2 mm),

2 Unscrew the upper part of the housing.

Lift the lateral brackets and pull the cover

away.

3 Connect the positioner.

Make sure that the gear case of the posi-

tioner is safely connected to protection

ground.

4 In order to separate the positioner from

the mains during service or repair, install a

2 pole switch between the control unit

and the positioner not far from the posi-

tioner.

5 Check the function.

4.5.3 Adjusting the positioner

The positioner is supplied pre-adjusted to the

chlorinator. Adjusting can become necessary

e.g. if the system should be adjusted to a diffe-

rent '0'-position or after repair.

The lower limit can be shifted upwards up to

60% of the range (e.g. for basic chlorination).

Preparation

1 Switch off the mains to the positioner and

to the limit switches and ensure that the

wires are free of voltage.

2 Disengage the motor by pulling the knob

out.

3 Remove the knob (set screw, Allan key 2

mm)

4 Unscrew the cover, lift the side clips and

remove the cover.

5 Replace the knob or turn the knob shaft

with a screw driver.

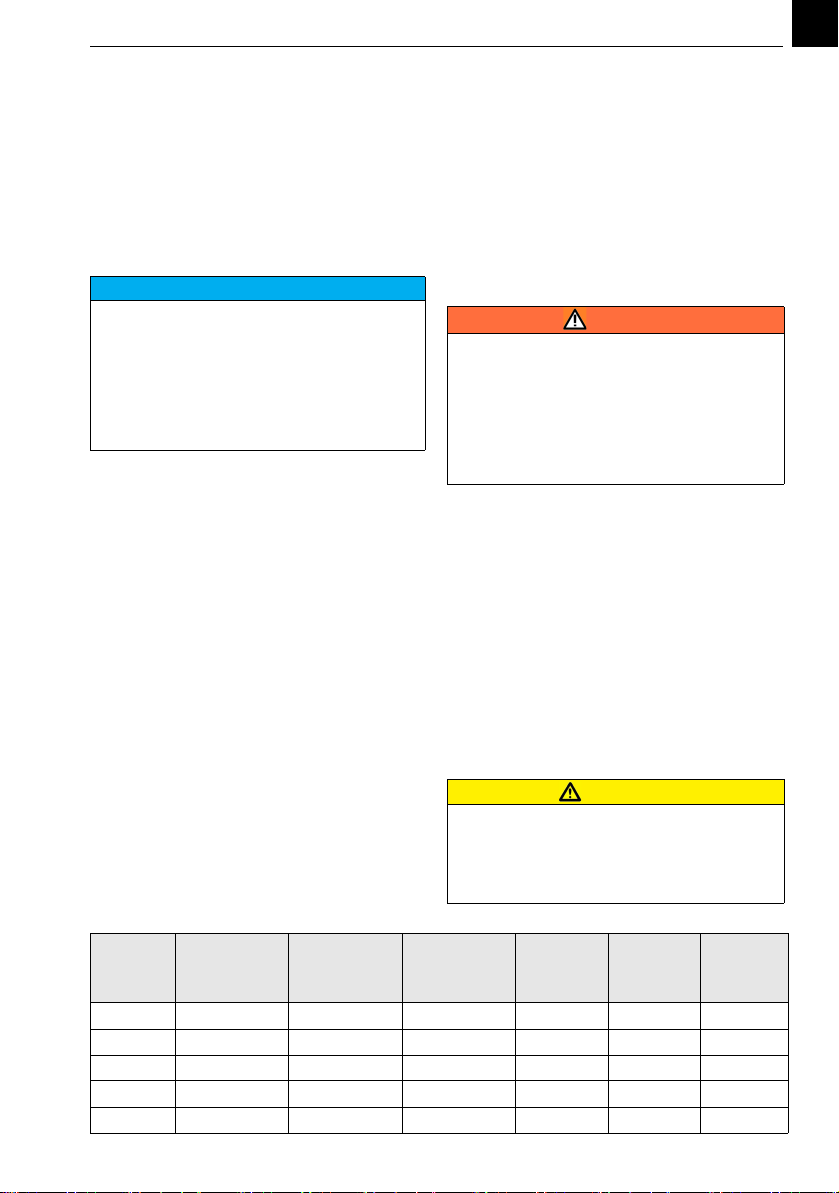

Adjust the MIN limit

1 Move the connecting rod fully outside

and then 2 mm back.

2 Loosen the set screw (pos. 2) of the cam

disk (pos. 1).

The corresponding key is fixed in the

cover.

3 Turn the cam disk until both MIN-limit

switches (pos. 4) are switched by the

upper part of the cam disk.

4 Press the cam disk to the stop and fasten

the setscrew without turning the cam

disk.

Adjust the MAX limit

1 Move the connecting rod fully inside and

then 2 mm back.

2 Turn the lower part of the cam disk by

turning the set screw (Pos. 3) so far that

both MAX switches (Pos. 5) are switching.

Don't loosen or turn the whole cam disk.

3 Check by moving the connecting rod.

4. Installation V10k automatic

16

EN

Adjust the reduced MAX limit

1 Set the connecting rod to the desired

max. end switching point, i.e. to the desi-

red, reduced max. dosing rate.

2 Turn the lower part of the cam disk (Pos.

2) by turning the set screw (Pos. 3) until

both MAX switches (Pos. 5) engage audi-

bly. Do not release or turn the cam disk as

a whole as you do this.

3 Then check both end switching points, the

zero setting and reduced max. end swit-

ching point again by displacing the con-

necting rod in Manual mode.

Adjust the feedback potentiometer

Adjustment is necessary, when a new board is

mounted in the positioner or the motor-gear-

unit has been removed or changed.

1 Open the cover (see preparation)

2 Pull off connectors 13/14/15

3 Move the connecting rod fully outside to

the stop.

4 Connect an ohmmeter to the terminals 13

and 14 on the board.

5 Loosen the great output tooth wheel on

the shaft below the cam wheel.

6 Turn the tooth wheel until the ohmmeter

displays between 10 and 30 ohm.

7 Fix the tooth wheel without turning it.

8 Move the connecting rod fully inside to

the stop.

9 Ohmmeter must display resistance smal-

ler than the total resistance of 1kohm

measured between the terminals 13 and

15.

10 Check both adjustments by moving the

connecting rod.

11 Remove the ohmmeter and connect the

terminals 13/14/15 again.

Close the cover

1 Remove the knob, if mounted.

2 Place the cover without damaging the

shaft sealing.

3 Move the connecting rod fully outside.

4 Place the knob on the shaft, turn that the

arrow points to the minimum and fix.

5 Switch to automatic operation (press in

the knob), if necessary turn slightly to let

the tooth wheels match.

6 Switch on and check for function.

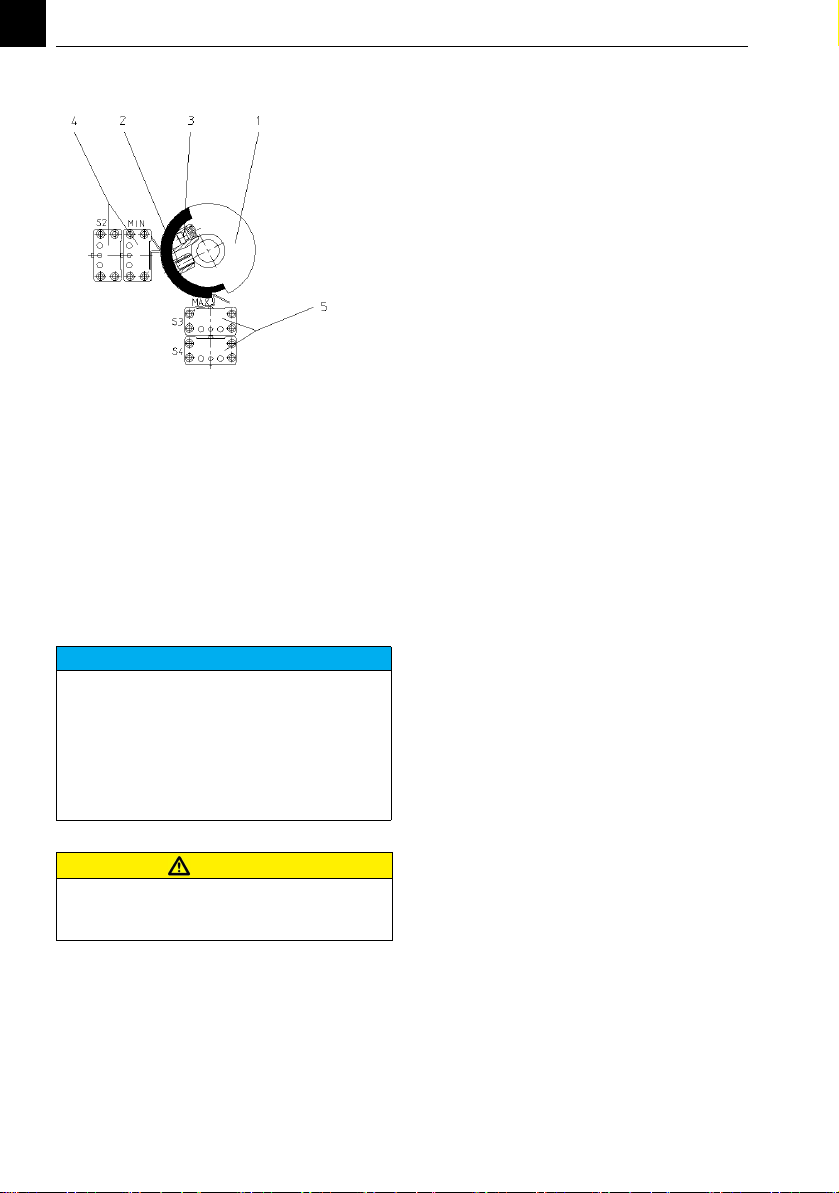

4.6 Insert the flowmeter

(preferably only immediately before commis-

sioning to avoid damage to the flowmeter)

1 Mount the spring and the socket from the

accessories set.

2 Apply some silicone grease to the two 'O'-

rings and place them into the grooves.

3 Hold the flowmeter tube in the middle,

the high values at the top, the tip of the

float pointing to the bottom.

4 Place the flowmeter tube onto the lower

'O'-ring, the high values of the scale on

top, press down the lower seat with two

fingers of the other hand, if necessary

press down the lower 'O'-ring with the

flowmeter tube.

5 Position the tube into the upper seat, turn

the tube until the scale is in front and

slowly release the lower seat. Hold the

tube until the tube safely rests on the o-

rings.

NOTICE

With this setting, only the desired, reduced

control range from the zero setting to the

reduced max. end switching point is availa-

ble in Automatic mode. In Manual mode, it

is still possible to set a dosing rate above the

reduced max. end switching point, up to the

maximum possible dosing rate (mechanical

end stop of the connecting rod).

ATTENTION

Switchover from Manual to Automatic mode

may only be carried out with the controller

in fully closed position!

V10k automatic 4. Installation

17

EN

A’O-ring

BLowerseat

C Socket and spring

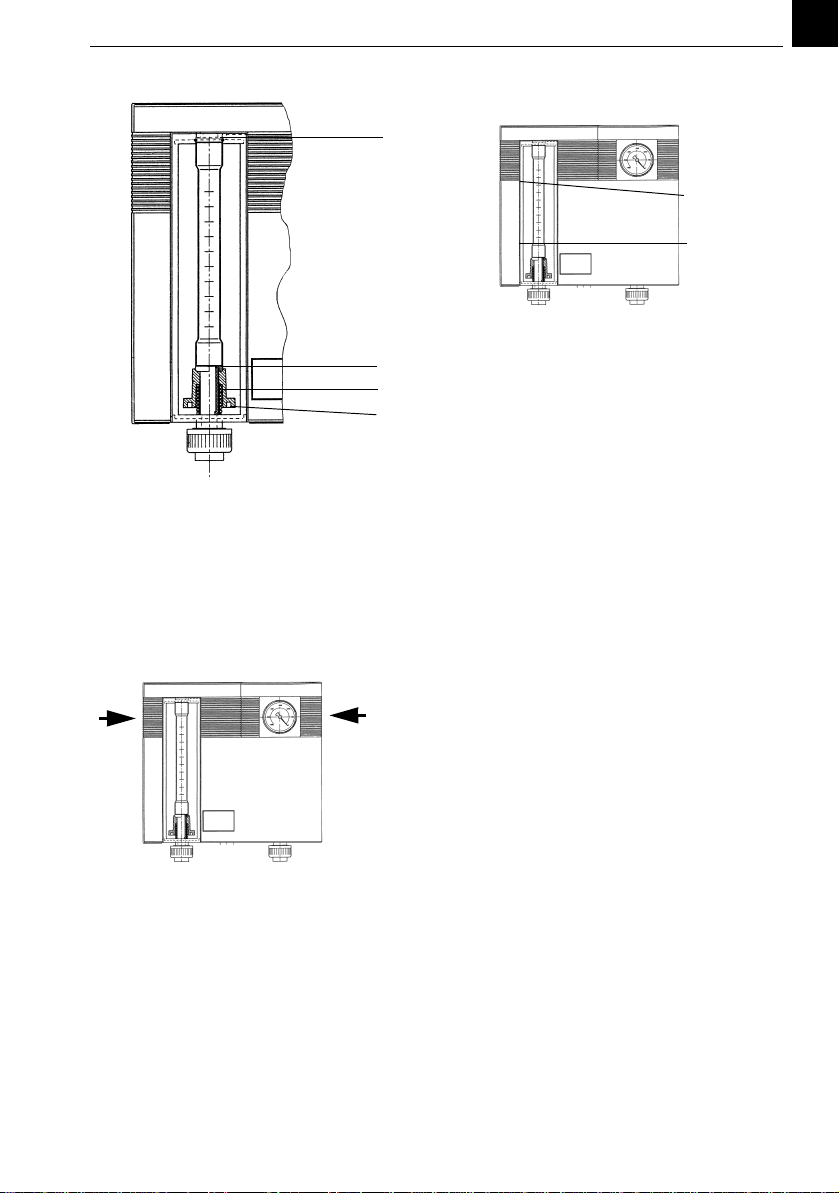

4.7 Remove and mount the cover

1 Hold the cover at both sides, press your

thumb on the manometer and pull away

the cover at both sides at the same time.

1 Slide the cover over the T-shape rails (A)

of the body.

2 Press left and right until the cover is level

with the manometer and locked.

4.8 Preparation

Chlorination plants should be checked by a

specialist for condition according to the rules

before being taken into operation. Especially

the chlorine parts of the plant must be che-

cked for leaks.

When all the connections have been made,

the following pre-start checks must be carried

out before the plant can be taken into opera-

tion.

4.8.1 Check for water leaks

1 Close the regulating knob of the positio-

ner by hand or by the control.

2 Ensure that the gas cylinder or drum val-

ves are closed.

3 Open the stop valve at the point of appli-

cation.

4 Open the stop valve and the solenoid

valve in the water supply.

5 If installed start the booster pump.

6 Adjust the injector inlet pressure so that

the operation vacuum of 200 mbar is

displayed at the pressure gauge of the

V10k.

7 Check the water supply and the chlorine

solution line for leaks. Repair if necessary.

A

A

B

C

A

A

4. Installation V10k automatic

18

EN

4.8.2 Check for gas leaks

1 Keep the valves on the chlorine cylinder

or drum closed.

2 Open the valves in the water supply line

to the injector and at the point of applica-

tion. A vacuum of min. 200 mbar must be

indicated on the manometer of the cont-

rol unit.

3 Check that the flowmeter float remains at

his bottom stop. Any movement of the

float indicates an ingress of air on one of

the following locations:

• through the safety relief valve

• through the o-ring on the bottom of

the flowmeter or

• through cracks in the flowmeter

• through the o-rings at the pipe con-

nections

• through any incorrectly cemented

joints or slack unions in the pipework.

Repair any leaks immediately.

4 Open the valves on the chlorine cylinder

or drum carefully and close again.

5 Check for leaks. Hold a bottle of 25%

ammonia solution in the vicinity of the

part under test. In case of a leak the esca-

ping gas will form dense white clouds.

6 In case of a leak check that the cylinder or

drum valve is closed. Open the auxiliary

valve(s). Let the operating water flow.

Open the regulating knob of the positio-

ner and let the gas from the gas lines be

sucked away until the float in the flowme-

ter of the V10k is down on the lower stop.

Immediately tighten the leak.

7 When all parts have been checked:

Open the valve on the chlorine cylinder or

drum again.

8 Adjust the desired dosing capacity. The

operation vacuum is shown on the pres-

sure gauge of the V10k.

9 Close the valves on the chlorine cylinder

or drum. Within a minute the float in the

flowmeter of the V10k should be down on

the lower stop. Otherwise refer to step 2.

4.9 Commissioning

4.9.1 General

When the water and gas leak test have been

performed successfully, the system can be

started as follows (the positions refer to the

drawing in chapter 3.3)

1 Activate the gas warning device.

2 Open the point-of-application

3 Open the operating water valve incl sole-

noid valve.

4 If necessary start the booster pump.

5 Adjust the injector water pressure at the

reducing valve

6 Open the gas cylinder valve (3) one turn.

7 Open the vacuum control valve (4).

8 Adjust the dosage manually, read the

dosing rate at the flowmeter of the V10k.

9 Switch the positioner to automatic opera-

tion (knob pushed in), set the control to

the suitable dosage rate.

10 Check that the dosage rate on the control

corresponds with the display on the flow-

meter. For further information see the

instruction manual of the control.

WARNING

Danger due to chlorine gas !

Chlorine gas irritates the respiratory tracts.

Contact with chlorine gas in high concentra-

tions irritates and damages the membranes,

respiratory system and the skin. In extreme

cases death can result due to suffocation.

When inspecting the system for leakage

always keep your gas mask to hand.Practice

use of the mask regularly.

If chlorine gas is discharged, only use a gas

mask which is independent of ambient air!

Do not tolerate any leakages in the chlorine

system.

Before servicing the system the gas supply

must be closed off directly on the gas cylin-

ders or tank and the chlorine gas in the sys-

tem must be consumed completely. In case

of strong chlorine smell put on your gas

mask.

WARNING

Danger due to chemicals !

Testing for chlorine or SO2 gas leaks is

accomplished by introducing ammonia

fumes to the area under test. Any escaping

gas will combine with the ammonia to form

dense white clouds. Liquid ammonia solu-

tion must not be applied directly to the part

being tested. Hold a bottle of 25% ammonia

solution in the vicinity of the part under test.

Ammonia must not be inhaled, splashed or

spilled.

V10k automatic 4. Installation

19

EN

4.10 Training the operator

1 Train the operator for understanding at

least in safety, operation and fault finding.

NOTICE

The operator of the overall system must

ensure that only authorized and qualified

personnel can work on or with the system,

and within their specified area of responsi-

bility.

All personnel who work on the system must

have read and understood the instruction

manual, especially the safety instructions..

5. Operation V10k automatic

20

EN

5. Operation

5.1 General

If the chlorinator is installed and adjusted cor-

rectly, only the following measures are neces-

sary during operation:

• Check and adjustment of the dosage rate

• Dayly check of tightness

• Function check of the gas warning device

• Change of the gas containers

• Cleaning the strainer in the operation

water line.

• When testing the sprinkler system take

care that the gas cylinders and armatures

don’t get wet unnecessarily. Slip a hose

over the spray nozzles and lead the water

into the sink.

5.2 Start dosing

1 Check that the gas monitoring system is

activated.

2 Open the operating water valves and the

point-of-application.

3 Open the gas supply valves.

4 Open the vacuum control valve.

5 Adjust the dosage

• manually with the knob on the posi-

tioner

• or with the control (the knob must be

pressed).

5.3 Stop dosing

• Close the operating water valves or

• Close the gas supply valves or

• Close the vacuum control valve or

• Stop the dosage

• manually with the knob on the posi-

tioner

• or with the control (the knob must be

pressed).

5.4 Changing gas containers

1 Close the valve of the empty chlorine

cylinder.

2 Close the vacuum control valve (or the

auxiliary valve).

3 Remove the vacuum control valve (or the

auxiliary valve) from the chlorine cylinder.

4 Remove the empty chlorine cylinder,

place and secure a full cylinder.

5 Connect the vacuum control valve (or the

auxiliary valve) to the cylinder valve, using

a new gasket.

6 Open the cylinder valve for a moment and

close again, check for leaks.

7 Open the cylinder valve if the connections

are tight.

8 Open the vacuum control valve (or the

auxiliary valve).

5.5 To stop for extended periods

or maintenance

1 Turn off the gas cylinder valve.

2 Allow the control unit to operate until the

flowmeter float remains on the bottom

stop.

3 Turn off the water supply to the injector.

The manometer pointer comes down to 0.

4 Against frost remove all the water from

the water supply and solution line.

WARNING

Danger due to chlorine gas !

Chlorine gas irritates the respiratory tracts.

Contact with chlorine gas in high concentra-

tions irritates and damages the membranes,

respiratory system and the skin. In extreme

cases death can result due to suffocation.

When changing gas containers always put on

your gas mask.

WARNING

Danger due to chemicals !

Testing for chlorine or SO2 gas leaks is

accomplished by introducing ammonia

fumes to the area under test. Any escaping

gas will combine with the ammonia to form

dense white clouds. Liquid ammonia solu-

tion must not be applied directly to the part

being tested. Hold a bottle of 25% ammonia

solution in the vicinity of the part under test.

Ammonia must not be inhaled, splashed or

spilled.

Other manuals for V10K

2

Table of contents

Other Evoqua Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

TTM

TTM MAG 250 Installation, Operating and Maintenance Instruction

Evenheat

Evenheat Glass Kiln GTS 18 General operations manual

Graco

Graco Series A Instructions-parts list

Jäger

Jäger Z33-D060.52 S21 manual

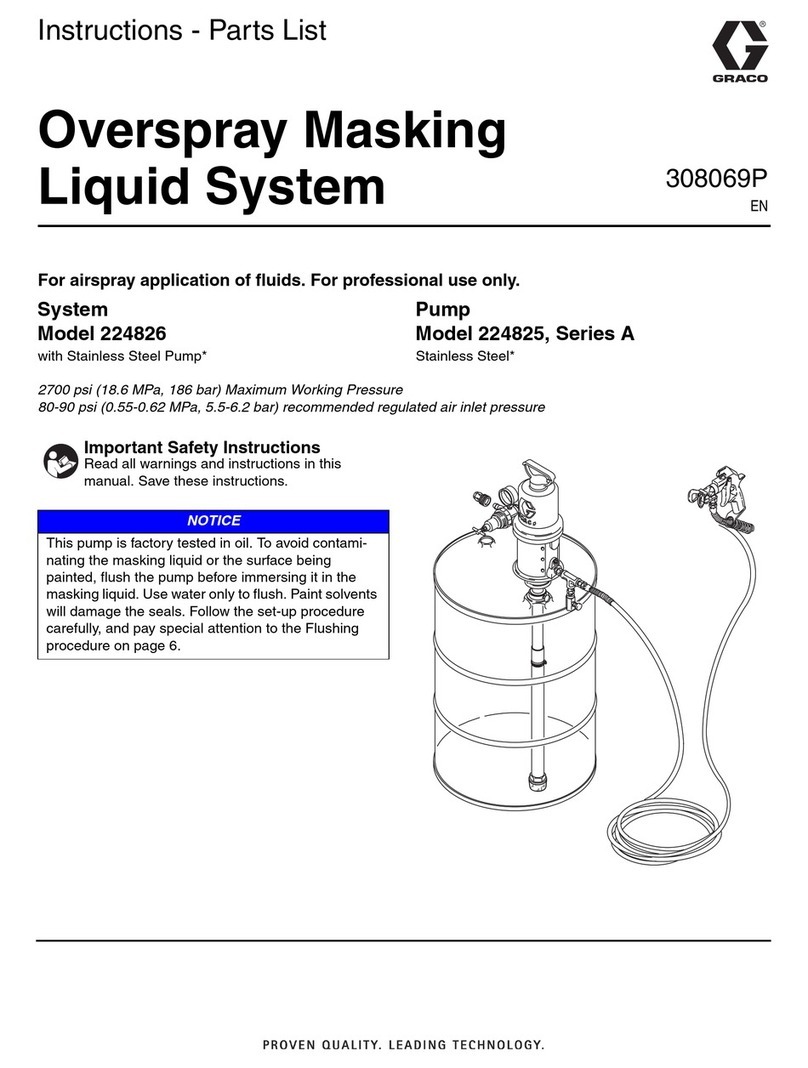

HMF

HMF 6750-76MM instruction manual

KMT

KMT STREAMLINE SL-V SRP 100 Operation and maintenance manual

PCB Piezotronics

PCB Piezotronics 353B14 Installation and operating manual

Stahl

Stahl SolConeX 8573/14 Series operating instructions

MSW

MSW WIRESTRIPPER-002-1500 user manual

Rockwell Automation

Rockwell Automation B Series user manual

MORKO

MORKO USP-300-AT manual

Mayr

Mayr EAS-Sm Installation and operating instructions