3

INSTALLATION

NOTICE: Use an approved, high-grade pipe sealant to seal all

hydraulic connections.

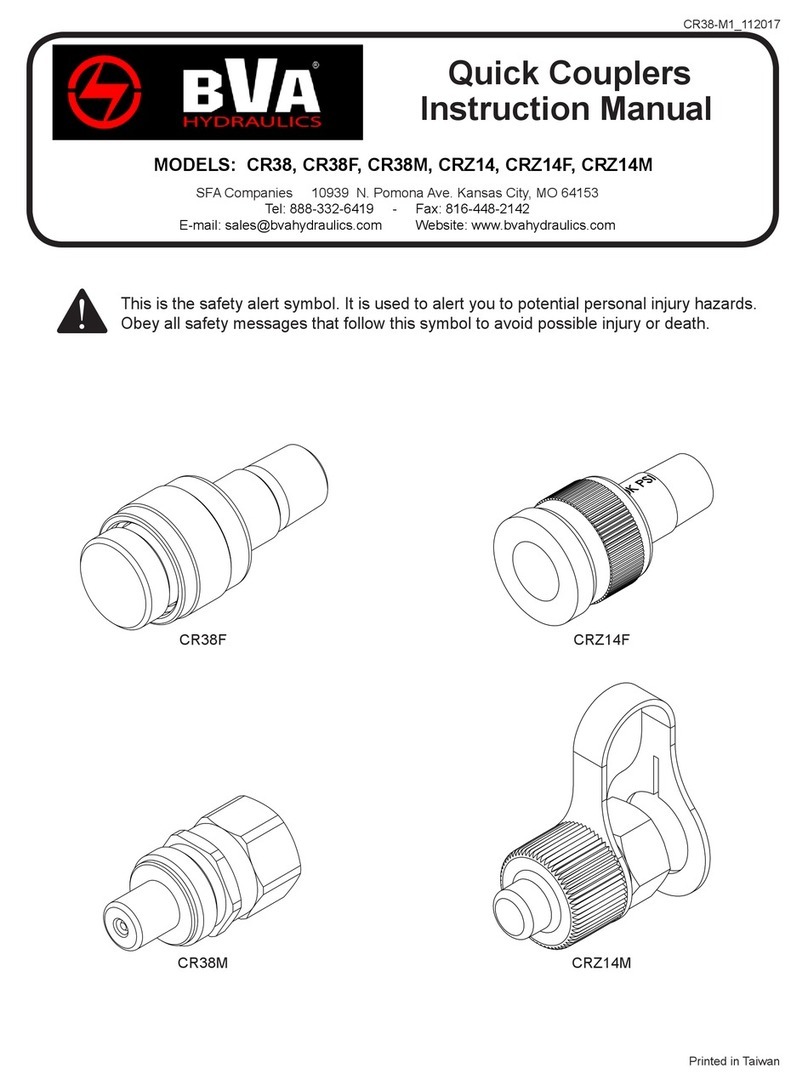

1.

Remove the dust cap and rubber plug from coupler

.

2. Inspectallthreadsandttingsforsignsofwearordamage,and

replaceasneeded.Cleanallthreadsandttings.

3. Connect hydraulic hose from hydraulic pump to the cylinder

coupler.Ensurethattherearenouidleaks.

4. Installin-linepressuregauge.

5. Check for leaks in system and have repaired by qualified

personnel.

NOTICE: The use of cylinder attachments or extensions reduces

the cylinder capacity by at least 50% per attachment/extension.

WARNING: Before operating the pump, tighten all

hose connections with proper tools. Do not overtighten.

Connections should only be tightened securely and leak-free.

Overtightening can cause premature thread failure or high

pressure ttings to burst.

WARNING: Before repairs are made, depressurize cylinder.

Tipsforhydraulichoses&uidtransmissionlines:

•Avoidshortrunsofstraightlinetubing.Straightlinerunsdonot

provideforexpansion and contraction due topressureand/or

temperature changes.

•Reduce stress in tube lines. Long tubing runs should be

supportedbybracketsorclips.

Donot pull,position ormovecylinder setupbythe

hose. Use carrying handle or other means of safe

transport.

Do not handle pressurized hoses. Never attempt

to grasp a leaking pressurized hose. Ensure to

release the system pressure before disconnecting

hydraulichoseorconnections.

Hydraulic uid can ignite and burn. Keep

hydraulic

equipmentawayfromamesandheat.

Excessiveheat

will soften seals, resulting in uid leaks. Heat also

weakenshosematerials.

Cylinder must be on a stable base which is able

tosupporttheloadwhilepushingorlifting.Useshims,

frictionmaterialorconstrainstopreventslippageofthe

baseorload.Ensurecylinderisfullyengagedinto/

ontoadapters,extensionaccessories.

Centerloadoncylinder.Distributeloadevenlyacross

theentiresaddlesurface.Donotoff-centerloadson

acylinder.Theloadcantiporthecylindercan“kick

out”.

Nevertrytodisassembleahydrauliccylinder,refer

repairstoqualied,authorizedpersonal.ContactBVA

Hydraulicstechserviceforauthorizedservicecenter.

Do not subject hose to sharp objects or heavy

impact.

Hosematerialorsealsmustnotcomeincontactwith

corrosive materials such as battery acid, creosote-

impregnated objects and wet paint. Never paint a

coupler or hose.

•

Noalterationshallbemadetothecylinder.

•

Useonlyfactoryauthorizedfasteners,accessories

andhydraulicuid.

Failuretocomplywiththefollowingwarningsmay

result in personal injury as well as property

damage.

•

Study, understand, and follow all instructions

providedwithandonthisdevicebeforeuse.

• Theusermustbeaqualiedoperatorfamiliar

withthecorrectoperation,maintenance,anduseofcylinders.

Wearprotectivegearwhenoperating

hydraulicequipment.

ThisdeviceisNOTsuitableforuseassupport

device!As the load is lifted, use blocking and

cribbingtoguardagainstafallingload.

Stayclear

ofaliftedloadbeforeitisproperly

supported

.

Never

relyonhydraulicpressuretosupportaload.

Crush Hazard.Keephandsandfeet

away

from cylinder and workpiece during

operation.

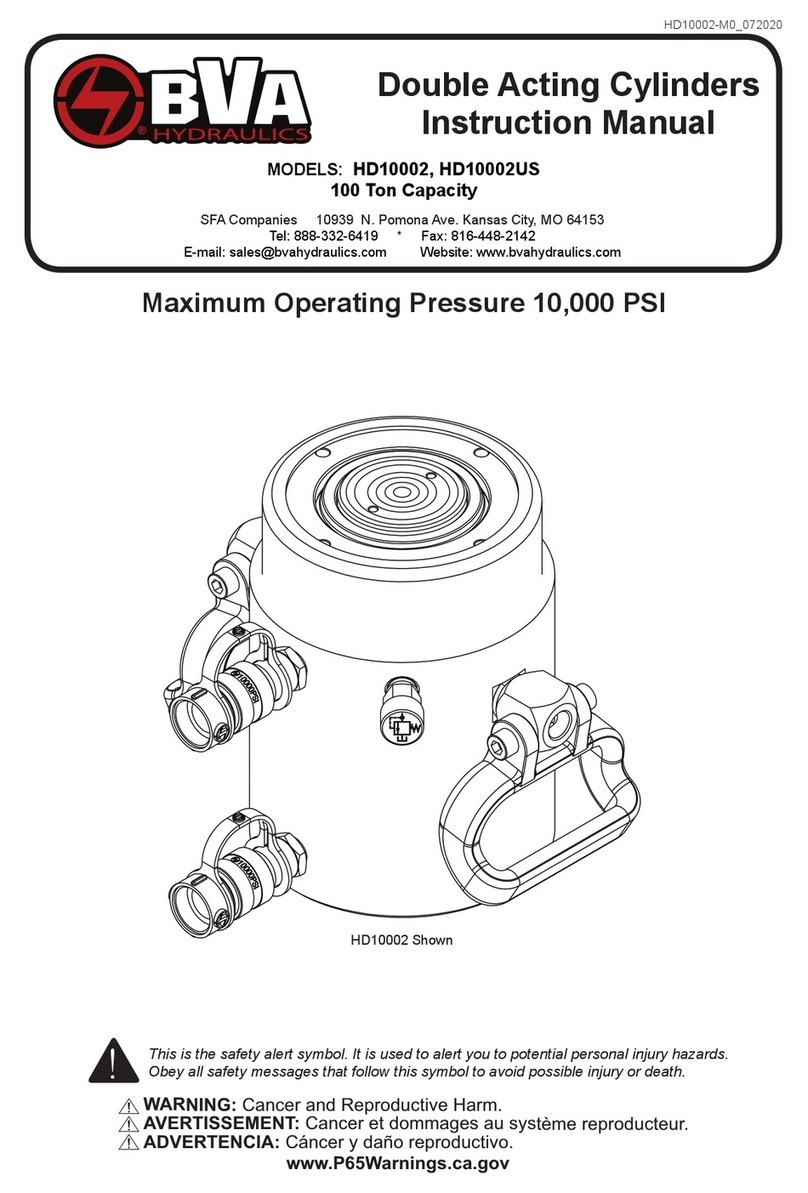

Bothcouplersonthecylindermustbeconnected

tothepump.Double-actingcylindermustbeused

withapumpequippedwith4-wayvalve.

Donot adjust orremove the safety reliefvalve.

Highersettingthan rated pressure will result in

equipmentdamageand/orpersonalinjury.

•

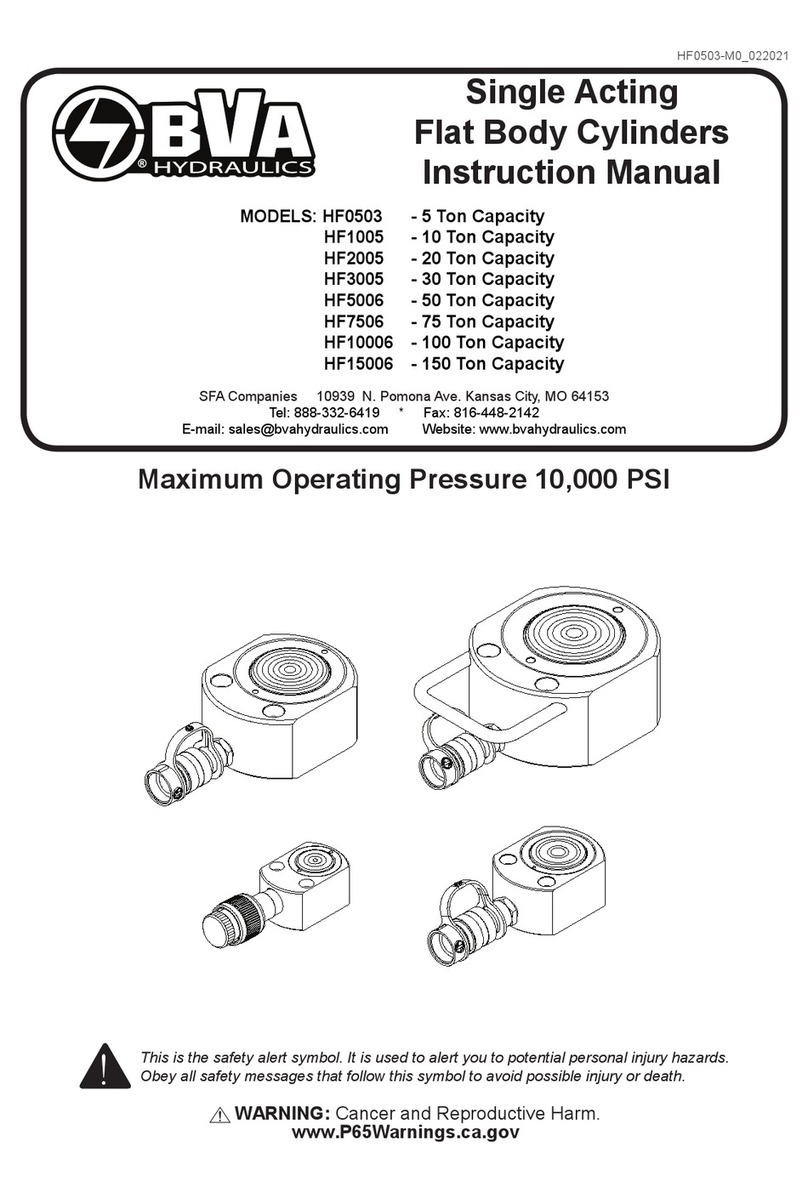

Donotexceedratedcapacityofthecylinderor

any equipment in the system. The cylinder is

designedforamax.pressureof10,000psi.

• Donotconnectacylindertoapumpwithhigher

pressurerating.

• Donotsubjectcylindertoashockloads,aloaddropped

suddenly,causingthesystempressuretoexceedrated

pressure.

Thesystemoperatingpressuremustnotexceed

thepressureratingofthelowestratedcomponent

the system. Install a pressure gauge or other load

measuringinstrumenttomonitortheoperatingpressure.Burst

hazardexistsifhose,connectionoranyothercomponentin

thesystemexceeditsratedpressure.

Avoiddamaginghydraulichose.Donotallowhose

tokink,twist,curl,crush,cutorbendsotightlythat

uidowwithinthehoseisblockedorreduced.

Periodicallyinspectthehoseforwear.

Heavy

Each double acting cylinder is equipped with a

pressurereliefvalveinthereturncircuitwhichwill

open as internal pressure exceeds10K psi.

Whenthisoccurs,oilwillbedirectedoutsideofthecylinder

wallsandontothecylinderbody.Thiswillcreateaslippery,

hazardousconditionintheimmediateworkarea.Clean up

oil immediately!

!

!

WARNING

!