Evoqua WALLACE & TIERNAN W3T160469 User manual

WALLACE & TIERNAN®

DIAPHRAGM PULSATION DAMPER

INSTRUCTION MANUAL

2WT.470.600.010.DD.IM.0714

Diaphragm pulsation damper

Please note

Original manual!

Diaphragm pulsation damper Contents

3

Contents

1. Introduction 5

1.1 Documentation 5

1.1.1 Target groups 5

1.2 Conventions 6

2. Safety 7

2.1 Intended use 7

2.2 General safety instructions 8

2.3 Handling chemicals 10

2.3.1 Prevention of risks 11

2.3.2 First aid measures 11

2.3.3 Environmental protection measures 11

3. Description 13

3.1 General 13

3.2 Technical data 14

3.3 Scope of supply 15

3.3.1 Pulsation damper 0,08 l with connections 15

3.3.2 Pulsation damper 0,25 l with connections 16

3.3.3 Pulsation damper 0,75 l with connections 16

4. Installation 17

4.1 Mounting 17

4.2 Filling 18

5. Operation 19

5.1 Check 19

5.2 Filling 20

5.3 Maintenance 21

5.3.1 Fitting a new separating diaphragm 21

5.4 Spare parts 22

4WT.470.600.010.DE.IM.0714

Contents Diaphragm pulsation damper

Diaphragm pulsation damper Introduction

1.

5

1. Introduction

1.1 Documentation

1.1.1 Target groups

This instruction manual provides the responsible personnel with

information that is required for the installation, operation and

maintenance of the diaphragm pulsation damper.

It contains information that is important to the secure, fault-free,

and economical operation of the diaphragm pulsation damper.

Carefully observing these instructions will help to prevent danger,

reduce repair costs and downtimes, and increases the reliability

and service life of the diaphragm pulsation damper.

Please consult the table of contents to find the information you

require quickly.

6WT.470.600.010.DE.IM.0714

Introduction Diaphragm pulsation damper

1.

1.2 Conventions

Notes This operating manual contains a number of notes with different

priorities, which are marked with symbols.

Picto-

gram Note Meaning

Warning! Danger to life and limb! If the

situation is not handled properly,

death or serious injury may be the

result.

Attention! If this warning is not observed,

medium or slight injury or damage to

the equipment may the result.

Attention! Risk of injury!

Leaks can release dangerous fluids

or gasses. Use face mask!

Attention! Risk of injury!

Leaks can release dangerous fluids

or gasses. Wear protective gloves!

Attention! Risk of injury!

Leaks can release dangerous fluids

or gasses. Wear protective clothing!

Attention! Risk of injury!

Leaks can release dangerous fluids

or gasses. Use protective footwear!

Note These notes assist in the operation

of the system.

Diaphragm pulsation damper Safety

2.

7

2. Safety

2.1 Intended use

The diaphragm diaphragm pulsation damper is intended to

dampen pressure peaks and pulsations.

Maximum pressure is 10 bar (g).

The operational safety of the system can only be guaranteed if it is

used in accordance with its intended purpose. It may only be used

for the purpose defined in the contract and under the installation,

operating and environmental conditions stated in this instruction

manual. No substances (chemicals) may be used other than those

described in this manual. All inspection and maintenance work

must be carried out at the prescribed intervals.

Compliance with the intended use also includes reading this

instruction manual and observing all the instructions it contains.

The operator bears full and sole responsibility if this unit is put to

any use which does not comply strictly and exclusively with this

intended use.

8WT.470.600.010.DE.IM.0714

Safety Diaphragm pulsation damper

2.

2.2 General safety instructions

Siemens attaches great importance to the safety of all work

relating to the diaphragm pulsation damper . This was already

taken into account in the design of the system, by the integration

of safety features.

Safety instructions The safety instructions in this documentation must always be

observed.Thesedonot affectthevalidity ofanyadditionalnational

or company safety instructions.

Safety instructions on the

system All safety instructions attached to the system must be observed.

They must always be complete and easily legible.

Technical standard The system has been constructed using the best available

technology and according to the accepted safety regulations.

However, danger to the life and limbs of users or third parties or

damage to the diaphragm pulsation damper or other property

cannot be ruled out if the system, if the system is used by

unqualified persons. Installation and maintenance, as well as any

work that is not described in this operating manual may only be

performed by authorized personnel.

Personnel The operator of the overall system must ensure that only

authorized and qualified technicians can work on or with the

system, and within their specified area of responsibility.

„Authorized and qualified personnel“ include:

Operation by the users, by Siemens or by personnel who have been trained

and instructed by the service partner.

Installation, commissioning

and maintenance, level 2 onlyspecializedservice personnelor bypersonnelwho havebeen

trained and authorized by Siemens.

Electrical work Authorized and qualified electrical technicians

Diaphragm pulsation damper Safety

2.

9

Spare parts / components The trouble-free operation of the diaphragm pulsation damper can

only be guaranteed, if original spare parts and components are

used in the combination described in this instruction manual.

Otherwise there is a danger of malfunction or damage to the

system.

Modifications and extensions Never attempt to rebuild, modify or extend the system without

written approval from the manufacturer!

Donotusethefeeder withouthopperor othermeasurestoprevent

from touching the feeder screw during feeder operation. The

rotating feeder screw can catch clothes, hair etc. and cause

severe personal injuries.

Waste disposal Ensure safe and environmentally-friendly disposal of agents and

replaced parts.

Note

Before using the system, a risk assessment must be carried out

and documented by the operator. (European Industrial Safety

Guidelines, German Labor Protection Law § 5 and § 6)

10 WT.470.600.010.DE.IM.0714

Safety Diaphragm pulsation damper

2.

2.3 Handling chemicals

Warning!

Chemical hazard!

For safe operation and to prevent harm to persons, be sure to

follow the safety instructions and warnings by the supplier, on the

system and in this instruction manual.

Everyone involved must be informed about the dangers arising

from fluids in the system and the connected pipes, and be

instructed regarding the first aid measures to be employed. For

further details see the EC safety data sheets.

Theinstallation siteand theareaswheredangerouschemicalsare

stored or decanted must be clearly identified and labeled in

accordance with the regulation.

Have an eye fountain ready for use.

During maintenance and repair work, the following protective

clothing must be worn.

• Face mask

• Protective gloves.

• Protective clothes

• Protective footwear

Warning!

Chemical hazard!

Leaks can release chemicals that can cause chemical burns.

Wear protective clothing. Follow the safety instructions and

warnings on the system or on the product and in this instruction

manual. Consult and follow the EC safety data sheets.

Diaphragm pulsation damper Safety

2.

11

2.3.1 Prevention of risks

The following applies to all substances:

• Avoid all contact. Wear protective clothing.

• Do not open any covers while the system is preparing the

product

• Only work on the pipes when the system has been emptied

and rinsed.

2.3.2 First aid measures

For further details see the EC safety data sheets.

2.3.3 Environmental protection measures

Avoid release of chemicals into the environment. Consult the

relevant directives regarding this matter. Follow the instructions in

the EC safety data sheets and substance data sheets.

12 WT.470.600.010.DE.IM.0714

Safety Diaphragm pulsation damper

2.

Diaphragm pulsation damper Description

3.

13

3. Description

3.1 General

Piston and membrane metering pumps produce pressure variati-

ons in the discharge line. Diaphragm pulsation dampers are used

to flatten the pressure peaks and to reduce the pressure variati-

ons.

The diaphragm pulsation dampers with separating diaphragm de-

scribed here do not exceed the limit described in the pressure

equipment directive (PS x V = 25 bar x liters). They are subject to

the article 3, paragraph 3 of the directive..

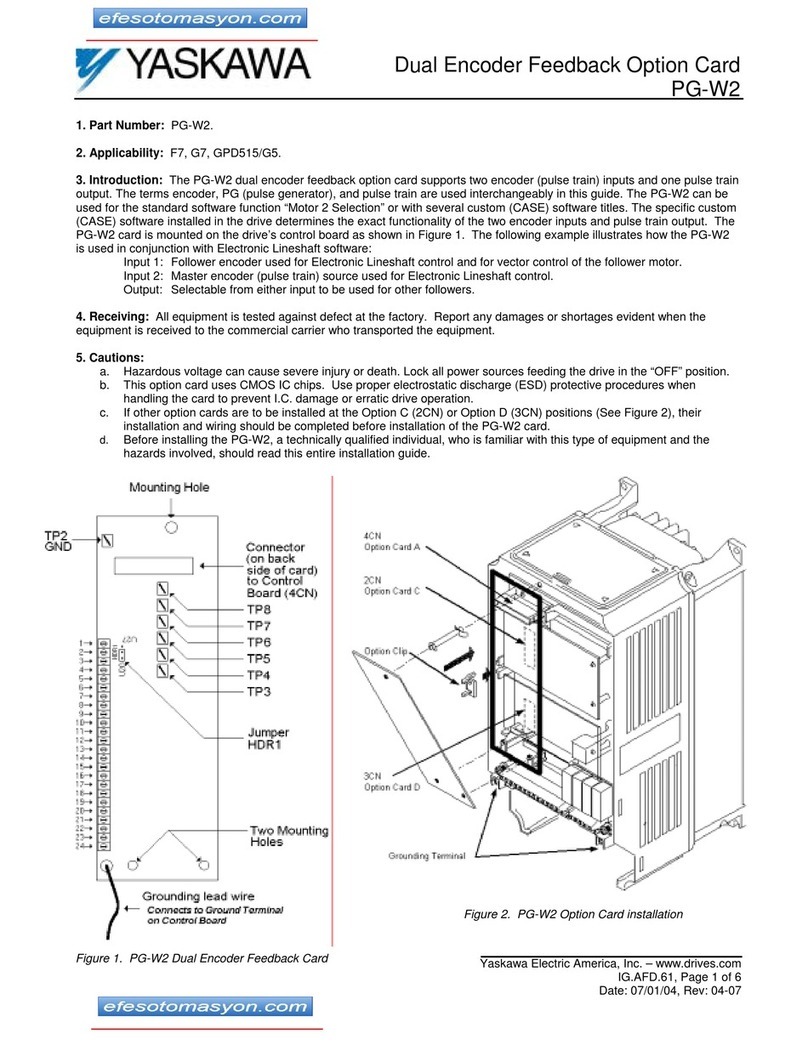

W3T164399 /W3T164400

A Inflator valve

B Plug or pressure gauge

A

B

14 WT.470.600.010.DE.IM.0714

Description Diaphragm pulsation damper

3.

3.2 Technical data

Part no.

W3T160469 W3T160464 W3T164397 W3T164398 W3T164399 W3T164400

Volume 0,08 l 0,08 l 0,25 l 0,25 l 0,75 l 0,75 l

Diaphragm Hypalon Viton Hypalon Viton Hypalon Viton

Body PVC-U

Operating pressure

max. 10 bar (g)

Pre-pressure max. 6 bar (g) (0,6 x final average operating pressure)

Temperature max. 50°C

Stroke volume pump

up to 15 cm³/stroke up to 40 cm³/stroke up to 120 cm³/stroke

Dimensions: A 172 mm 314 mm 363 mm

B - 140 mm 347 mm

CG¾ G1¼ G1¼

D M6 20 long M8 20 long Ø9 mm

E 50mm 64mm 71,5mm

W3T164397 /W3T164398

W3T164399 /W3T164400

W3T160469 /W3T160464

Diaphragm pulsation damper Description

3.

15

3.3 Scope of supply

3.3.1 Pulsation damper 0,08 l with connections

Part number

incl. pulsation Connections

damper for pvc hose for pvc tube thread

W3T172565 W3T160469

(CSM) ID 10 x 3

ID 6 x 3 DN10/d16 DIN 228 - G 3/4 A

DIN 228 - G 1/2 A

W3T172566 W3T160464

(FPM)

Part number

incl. pulsation Connections

damper for pvc hose for pvc tube thread

W3T172567 W3T160469

(CSM) ID 12 x 4,5 DN10/d16,

DN15/d20 DIN 228 - G 3/4 A

DIN 228 - G 1 A

W3T172568 W3T160464

(FPM) DN20/d25,

DN25/d32

16 WT.470.600.010.DE.IM.0714

Description Diaphragm pulsation damper

3.

3.3.2 Pulsation damper 0,25 l with connections

3.3.3 Pulsation damper 0,75 l with connections

Part number

incl. pulsation Connections

damper for pvc hose for pvc tube thread

W3T172569 W3T164397

(CSM) - DN15/d20

DN20/d25 DIN 228 - G 1 1/4 A

W3T172570 W3T164398

(FPM)

Part number

incl. pulsation Connections

damper for pvc hose for pvc tube thread

W3T172571 W3T164399

(CSM) - DN20/d25

DN25/d32 DIN 228 - G 1 1/4 A

W3T172572 W3T164400

(FPM) DN32/d40

Diaphragm pulsation damper Installation

4.

17

4. Installation

4.1 Mounting

In order to dampen pressure peaks and pulsations perfectly dia-

phragm pulsation dampers have to be installed correctly. There-

fore it is necessary to mount them very close to the point where

pressure peaks are produced.

For metering pumps, this place would be right after the discharge

valve, using a tee-fitting or direct flow through the diaphragm pul-

sation damper.

• To avoid superfluous deflection and pipe friction loads, it is

recommended to use a straight connecting pipe, which corres-

ponds to the connection nominal width of the diaphragm pul-

sation damper.

• Large-size diaphragm pulsation dampers and those with

tubing connections must be fastened separately; piping must

not transmit mechanical stress to the diaphragm pulsation

damper.

V1: Shutoff valve (ball valve)

V2: Shutoff valve (ball valve)

V3: Diaphragm pulsation damper gas charging valve

(tire inflator valve)

Connection via tee-fitting Inline connection

18 WT.470.600.010.DE.IM.0714

Installation Diaphragm pulsation damper

4.

4.2 Filling

Warning!

Danger of ignition

Use air for filling the diaphragm pulsation damper.

Never use oxygen!

The diaphragm pulsation damper is most effective if the initial

pressure is about 0.6 times the final average operating pressure.

It is suitable to have a pressure gauge permanently installed at the

diaphragm pulsation damper (W3T158497).

The diaphragm pulsation dampers are made of plastic and suitab-

le for an operating pressure of maximum 10 bar requiring an initial

pressure of maximum 6 bar. A hand pump or a foot pump for com-

mercial tire inflator valve V3 can be used for filling the diaphragm

pulsation damper (e.g. the Wallace & Tiernan handpump

W2T506873 with a 2,5 m hose).

1 Refer to the safety informations concerning the chemicals

used!

2 Put on protection clothing and face protection.

3 Switch off the metering pump.

4 Close the shutoff valve V1 to separate the diaphragm pulsa-

tion damper from the system under pressure.

5 Open the shutoff valve V2 carefully to discharge the pressure.

6 Fill the diaphragm pulsation damper with air.

For this purpose, the damper is fitted with a commercial tire

inflator valve V3.

During filling check the pressure with a pressure gauge.

Note

Topressurizethegascushion, theliquidflowmust bestopped and

the liquid pressure reduced to zero. Otherwise, the actual dampe-

ning volume remains too small although the gas pressure can be

brought up to the desired level. By interrupting the liquid flow, the

gas pressure is able to displace the liquid and optimally fill the gas

chamber.

Diaphragm pulsation damper Operation

5.

19

5. Operation

5.1 Check

Warning!

Chemical hazard!

Leaks can release chemicals that can cause chemical burns.

Wear protective clothing. Follow the safety instructions and warn-

ingson thesystemoronthe productandin thisinstruction manual.

Consult and follow the EC safety data sheets.

Danger of ignition

Use air for filling the diaphragm pulsation damper.

Never use oxygen!

If the diaphragm pulsation damper is not fitted with apressure gau-

ge, it is recommended to check the initial pressure (pv) after ca.

500 working hours. The same should be done before startup and

after long periods of disuse. Check the device every three months.

Before performing a test or pressurizing:

1 Refer to the safety informations concerning the chemicals

used!

2 Put on protection clothing and face protection.

3 Switch off the metering pump.

4 Close the shutoff valve V1 to separate the diaphragm pulsa-

tion damper from the system under pressure.

5 Open the shutoff valve V2 carefully to discharge the pressure.

6 Check the pressure at the diaphragm pulsation damper valve

V3.

The initial pressure should be about 0.6 times the final ave-

rage operating pressure.

7 If necessary fill the diaphragm pulsation damper with air.

For this purpose, the damper is fitted with a commercial tire

inflator valve V3.

During filling check the pressure with a pressure gauge.

20 WT.470.600.010.DE.IM.0714

Operation Diaphragm pulsation damper

5.

5.2 Filling

Warning!

Chemical hazard!

Leaks can release chemicals that can cause chemical burns.

Wear protective clothing. Follow the safety instructions and warn-

ingson thesystemoronthe productandin thisinstruction manual.

Consult and follow the EC safety data sheets.

Danger of ignition

Use air for filling the diaphragm pulsation damper.

Never use oxygen!

The diaphragm pulsation damper is most effective if the initial

pressure is about 0.6 times the final average operating pressure.

It is suitable to have a pressure gauge permanently installed at the

diaphragm pulsation damper (W3T158497).

As the diaphragm pulsation dampers are plastic and suitable for

an operating pressure of maximum 10 bar requiring an initial pres-

sure of maximum 6 bar, virtually any available compressed air sys-

tem can be used, same as a hand pump or a foot pump (e.g. the

Wallace & Tiernan handpump W2T506873 with a 2,5 m hose).

If the air pressure exceeds the maximally permissible operating

pressure of the diaphragm pulsation damper or if nitrogen is used,

a pressure reducing valve must be added, the pressure of which

must be lower than the maximum operating pressure.

1 Refer to the safety informations concerning the chemicals

used!

2 Put on protection clothing and face protection.

3 Switch off the metering pump.

4 Close the shutoff valve V1 to separate the diaphragm pulsa-

tion damper from the system under pressure.

5 Open the shutoff valve V2 carefully to discharge the pressure.

6 Fill the diaphragm pulsation damper with air.

For this purpose, the damper is fitted with a commercial tire

inflator valve V3.

The initial pressure should be about 0.6 times the final ave-

rage operating pressure.

During filling check the pressure with a pressure gauge.

Note

Topressurizethegascushion, theliquidflowmust bestopped and

the liquid pressure reduced to zero. Otherwise, the actual dampe-

This manual suits for next models

5

Table of contents

Other Evoqua Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIMATIC S7-1500R/H Equipment manual

Graco

Graco LineLazer V Standard Series Installation

Nexen

Nexen AIR CHAMP SEM-450A user manual

VIBROBIT

VIBROBIT 100 Operation and maintenance manual

ABB

ABB HT563360 Operation manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 080M470 Installation and operating manual