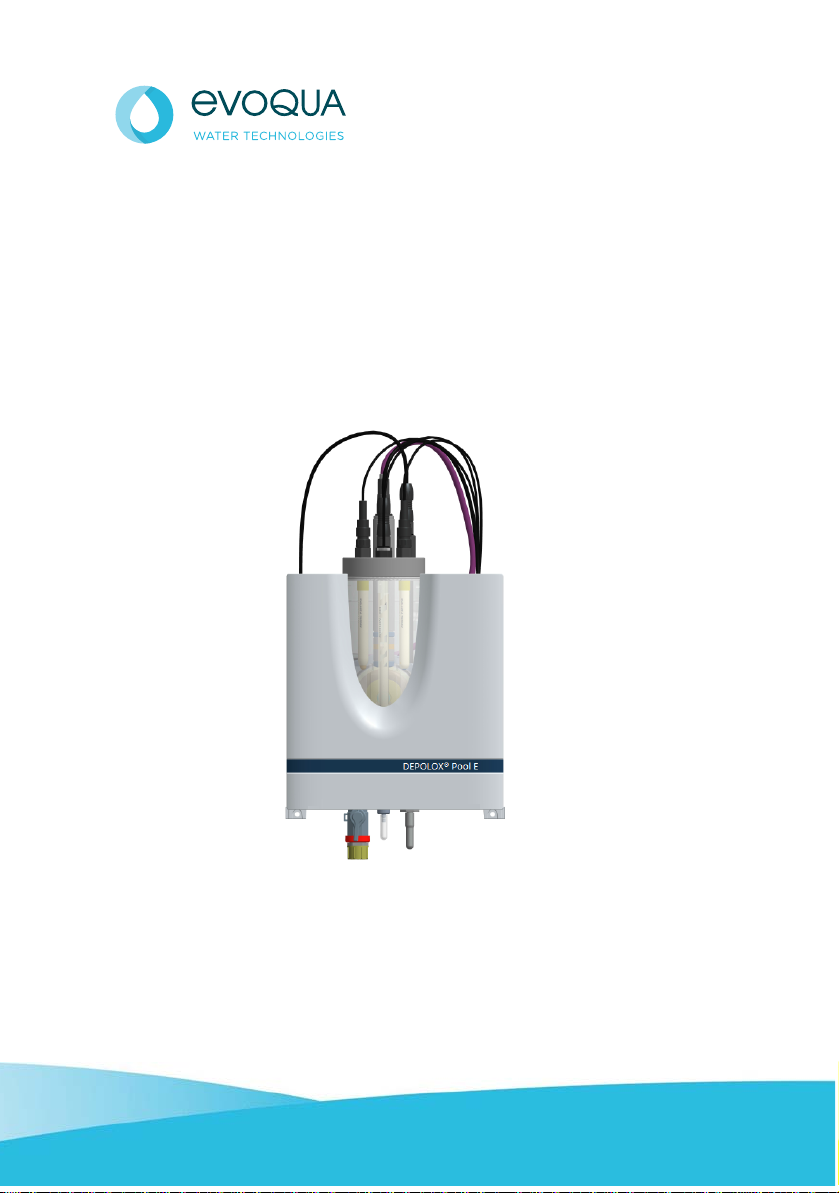

Evoqua WALLACE & TIERNAN DEPOLOX POOL E User manual

1

INSTRUCTION MANUAL

DEPOLOX®POOL E

WALLACE & TIERNAN

®

FLOW CELL

DEPOLOX® Pool E flow cell

2

EN

In some countries, DEPOLOX, OSEC, Barrier, Chem-Ad and Wallace & Tiernan are trademarks of Evoqua, its subsidiaries or

affiliated companies. No part of this document may be reproduced in any form (printed, photocopy, microfilm, or any other

procedure) or saved, processed, copied, or distributed using electronic data systems - without the express prior written con-

sent of Evoqua Water Technologies GmbH.

All information in this document is considered reliable and corresponds to the generally applicable technical standards. Evo-

qua assumes no responsibility for the completeness of this information. Users are responsible for making sure that the pro-

duct is suitable for specific applications. Evoqua assumes no liability for specific or indirect damage or consequential

damage arising from the sale, resale or misuse of its products.

NOTICE

Translation of the original instruction.

DEPOLOX® Pool E flow cell Contents

3

EN

Contents

1. Introduction ............................................................................... 5

1.1 Target groups ..........................................................................................................5

1.2 Structure of the documentation .............................................................................5

1.3 Conventions.............................................................................................................5

2. Safety......................................................................................... 6

2.1 Intended use............................................................................................................6

2.2 General safety instructions .....................................................................................6

2.3 Specific operating phases........................................................................................7

2.4 Warranty conditions................................................................................................7

2.5 Exclusion of liability .................................................................................................7

3. Description................................................................................. 8

3.1 Version ....................................................................................................................8

3.2 Configuration options............................................................................................10

3.3 Spare Parts/extensions..........................................................................................11

3.4 Optional accessories..............................................................................................11

3.5 Flow cell.................................................................................................................11

3.6 DFMe electronics module .....................................................................................12

3.7 Module SiDiSens conductivity (optional) ..............................................................13

3.8 Sensors ..................................................................................................................13

3.9 Technical data .......................................................................................................13

4. Installation ............................................................................... 17

4.1 Scope of delivery ...................................................................................................17

4.2 Transport and storage...........................................................................................17

4.3 Required ambient conditions ................................................................................17

4.4 Mechanical Installation .........................................................................................17

4.5 Installation of the module .....................................................................................18

4.6 Removing and fitting the housing cover ...............................................................21

4.7 Installing the optional strainer ..............................................................................21

4.8 Connecting the sample water inlet .......................................................................21

4.9 Connecting the sample water outlet.....................................................................22

4.10 Sample water extraction options ..........................................................................22

4.11 Installing the fine filter ..........................................................................................25

4.12 Inserting or replacing electrode cleaning sand .....................................................25

4.13 Plugging sensors into the DFMe electronics module ............................................26

4.14 Fitting the sensors .................................................................................................27

4.15 Installing calibration aids.......................................................................................27

4.16 Startup...................................................................................................................28

4.17 Shut-down .............................................................................................................28

4.18 Renewed start up ..................................................................................................29

4.19 Installing retrofit kits/extensions ..........................................................................29

Contents DEPOLOX® Pool E flow cell

4

EN

5. Maintenance............................................................................ 32

5.1 Maintenance intervals .......................................................................................... 32

5.2 Maintenance parts set .......................................................................................... 32

5.3 Checking for leakage............................................................................................. 32

5.4 Checking and replacing the electrode cleaning sand............................................ 33

5.5 Checking and replacing the fine filter ................................................................... 33

5.6 Cleaning the flow rate monitor and check valve .................................................. 33

5.7 Cleaning or replacing the optional strainer .......................................................... 34

5.8 Cleaning ................................................................................................................ 34

6. Spare parts, Accessories and Retrofit kits ................................. 35

6.1 Cell body, DEPOLOX® Pool E flow cell................................................................... 35

6.2 DEPOLOX® Pool E flow cell - non-pressurized version.......................................... 36

6.3 DEPOLOX® Pool E flow cell - pressurized version ................................................. 38

6.4 DFMe electronics module..................................................................................... 40

6.5 Sensors.................................................................................................................. 41

6.6 Membrane sensor................................................................................................. 42

6.7 LED glow stick ....................................................................................................... 42

6.8 CAN bus extension cable for connection to DFMe electronics module................ 42

6.9 Instruction manual................................................................................................ 42

6.10 Accessories............................................................................................................ 43

6.11 Retrofit kits/extensions......................................................................................... 43

7. EC Declaration of Conformity and Certificate............................ 44

DEPOLOX® Pool E flow cell 1. Introduction

5

EN

1. Introduction

1.1 Target groups

This instruction manual provides the informa-

tion required for installation, operating and

maintenance personnel for the installation,

operation and maintenance of the DEPOLOX®

Pool E flow cell.

All personnel working with and on the DEPO-

LOX® Pool E flow cell must have read and

understood the instruction manual, particu-

larly the safety instructions.

1.2 Structure of the documentation

This instruction manual contains important

information for the safe, trouble-free and eco-

nomical operation of the

DEPOLOX® Pool E

flow cell

. A thorough review of these instructi-

ons will help to prevent danger, reduce repair

costs and downtimes and increases the reliabi-

lity and service life of the

DEPOLOX® Pool E

flow cell

.

The Chapters Installation and Maintenance

are intended only for trained and authorized

service personnel. These chapters contain

important information on the assembly, confi-

guration, start-up, maintenance and repair,

which must be performed by this target group.

1.3 Conventions

This instruction manual contains a number of

notes with different priorities that are labeled

with pictograms.

DANGER

Immediate danger to life and limb! If the

situation is not corrected, death or serious

injury will result.

WARNING

Danger to life and limb! If the situation is not

corrected, death or serious injury can result.

ATTENTION

If this note is not observed, moderate or

minor injury or damage to equipment can

result.

WARNING

Electrocution hazard.

ATTENTION

Environmental hazard!

Do not throw away or burn the batteries!

Batteries must be disposed of at a collection

point.

NOTICE

These notes indicate a material risk or pro-

vide useful information to make working

with the DEPOLOX® Pool E

flow cell

easier.

Table of contents