EWE EWE-FLEXORIPP User manual

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

1

Current information at: www.ewe-armaturen.de

Verpackung

•DieeinzelnenArmaturensindentsprechenddenzuerwartendenTransportbedingun-

genverpackt.FürdieVerpackungwurdenumweltfreundlicheMaterialienverwendet.

DieVerpackungsolldieeinzelnenBauteilebiszurMontagevorTransportschäden,

KorrosionundanderenBeschädigungenschützen.EntfernenSiedieVerpackungerst

kurzvorderMontagederArmatur.

Entsorgung

•TrennenSiedievorhandenenRohstoffenachEntsorgungstypundWerkstoff.DieEnt-

sorgungderRohstoffemussnachdenjeweilsgültigengesetzlichenBestimmungen

undörtlichenVorschriftenerfolgen.FührenSiewiederverwertbareVerpackungsma-

terialiendemRecyclingzu.

Verwendung von Abkürzungen:

WZ: Wasserzähler Qn: NenngrößeWasserzähler

Art.: Artikelnummer PN: Nenndruck

KMR: Kegelmembran-Rückussverhinderer WZA: Wasserzähler-Anlage

…thoroughly tried and tested!

EWE-FLEXORIPP

Water Meter Pit

Installation and Operating Instructions

www.ewe-armaturen.de

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

2Current information at: www.ewe-armaturen.de

General information

•Pleasereadthisuserinformationcarefullybeforeusingtheproductandpay

particularattentiontotheinstructionsandwarnings.

•Thecurrentversionoftheseinstallationandoperatinginstructionscanbefoundon

ourwebsite:www.ewe-armaturen.de.

•Checkthedeliveryfortransportdamageandtomakesureitiscompleteimmedia-

telyafterreceivingit.

•Keeptheuserinformationavailableshouldanyquestionsoccur.

•Onlytrainedandqualiedpersonnelarepermittedtoinstall,operateormaintain

thettingsandvalves.

•Ourteamishappytoprovideyouwithmoreinformationbytelephoneduring

businesshours.

Manufacturer‘s address

Wilhelm EWE GmbH & Co. KG

VolkmaroderStraße19

D-38104Braunschweig

Phone:+4953137005-0

Fax:+4953137005-55

E-mail:[email protected]

General safety instructions CAUTION

•Thenecessaryactivitiesmustbecarriedoutinaccordancewiththestatutory

regulations,accidentpreventionregulationsandapplicablestandardsincludingthe

recognisedrulesofengineering.

•Technicalandunauthorisedmodicationstotheproductarenotpermitted.The

productmayonlybeusedforitsintendedpurpose.

Disclaimer

•Weareunabletomonitoradherencetothisuserinformationandalsohandlingdu-

ringtheinstallation,operationandmaintenanceofthetting.Improperinstallation

oftheproductcancausepropertydamageandconsequentlyendangerpeople.

•Wedonotacceptresponsibilityandliabilityforanylosses,damageorcostsdueto

incorrectinstallation,improperoperationandincorrectuseandmaintenanceorin

anymannerassociatedtherewith.

•Ourgeneraltermsandconditionsofsaleapply.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

3

Current information at: www.ewe-armaturen.de

Packaging

•Theindividualttingsandvalvesarepackedinaccordancewiththeanticipated

transportconditions.Onlyenvironmentallyfriendlymaterialshavebeenused

forthepackaging.Thepackagingshouldprotecttheindividualcomponentsfrom

transportdamage,corrosionandotherdamageuntiltheyareinstalled.Removethe

packagingjustbeforethettingisinstalled.

Disposal

•Separatetheexistingrawmaterialsaccordingtodisposaltypeandmaterial.Raw

materialsmustbedisposedofinaccordancewiththeapplicablestatutoryprovisions

andlocalregulations.Sendrecyclablepackagingmaterialsforrecycling.

Explanation of the symbols, warning symbols and signal words used

Symbol Description

Generaldangerarea(danger/warning/caution)

DANGER:

Hazardwithahighdegreeofriskwhich,ifnotavoided,

willresultindeathorseriousinjury.

WARNING:

Hazardwithanaveragedegreeofriskwhich,ifnot

avoided,mayresultindeathorseriousinjury.

CAUTION:

Hazardwithalowdegreeofriskwhich,ifnotavoided,

mayresultinminorormoderateinjury.

!NOTE:

Indicatesaninstructionthatmustbeobserved.

!INFORMATION:

Providesusefulrecommendations.

Use of abbreviations:

WM: Watermeter Q3: Permanentow

WMP: Watermeterpit PN: Nominalpressure

WMS: Watermetersystem Art.: Articlenumber

KMR: Ballmembranenon-returnowvalve CAC: Combinedangleseatcheckvalve

PC: Pipecover PA: Polyamide

GG: Lamellargraphitecastiron EPP: Expandedpolypropylene

PR: Pressureregulator

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

4Current information at: www.ewe-armaturen.de

1. Information about the product

1.1 Scope

Thisuserinformationappliesto

– EWE-FLEXORIPPwatermeterpits,articlenumber:0396XXX,consistingofa:

•Pitbody,watermetersystemwithexiblehosesandliftingdevice,pitductsand

insulatingcover.

Pitcoversmustbeorderedseparately.

– EWE-FLEXORIPP-pitcovers(notsuppliedwiththepit!):

•FLEXORIPPcovercap,max.200KG,articlenumber0396000

•FLEXORIPPA15pitcover,consistingofacoverframewithcoverseal,coverand

lockingscrews,articlenumber0396001

•FLEXORIPPB125pitcover,consistingofacoverframewithcoverseal,coverand

lockingscrews,articlenumber0396002

1.2 Other applicable documents

•Theoperatinginstructionsoftherespectivecontractingbodyorcontractingcompany

mustbefollowed

•DVGW(GermanTechnicalandScienticAssociationforGasandWater)andstatutory

accidentinsuranceinstitutionregulations

In particular:

•DINEN124,”Gullytopsandmanholetopsforvehicularandpedestrianareas”

• DINEN805,”Watersupply-Requirementsforsystemsandcomponentsoutsidebuildings”

•DINEN806,”Specicationforinstallationsinsidebuildingsconveyingwaterfor

humanconsumption”

•DIN1988,”Codesofpracticefordrinkingwaterinstallations”,nationalsupplementto

DINEN806

•DINEN1717”Protectionagainstpollutionofpotablewaterinstallationsandgeneral

requirementsofdevicestopreventpollutionbybackow”

•DIN4124”Excavationsandtrenches-Slopes,plankingandstruttingbreadthsof

workingspaces”

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

5

Current information at: www.ewe-armaturen.de

• DIN18196”Earthworksandfoundations-Soilclassicationforcivilengineeringpurposes”

• KTW(plasticsindrinkingwater)andelastomerguidelinesissuedbytheFederalEnviron-

mentAgency

•Listof”Metallicmaterialssuitableforcontactwithdrinkingwater”issuedbythe

FederalEnvironmentAgency

•DVGWworksheetW270”Propagationofmicroorganismsonmaterialsusedin

drinkingwatersystems”

•DVGWworksheetW400”Technicalrulesforwaterdistributionplants”

•DVGWworksheetW543”Pressure-resistanthosepipesandcompensators”

•DVGWworksheetW570”Valvesfordrinkingwaterinstallation”

•RSA95”Guidelinesforsafeguardingworksitesonroads”

1.3 Areas of use/medium

•ColddrinkingwaterinaccordancewithDIN2000

1.4 Permissible operating pressure of components (PFA)

•PN10

1.5 Material/dimensions/performance

1.5.1 Pit body

Material:

•PitbodymadeofwaterproofPE

Dimensions:

•Pipecover Heightwithoutpitcover Heightwithpitcover

0.75m 0.80m 0.87m

1.00m 1.05m 1.12m

1.25m 1.30m 1.37m

1.50m 1.55m 1.62m

1.75m 1.80m 1.87m

2.00m 2.05m 2.12m

•Pipecovercanbeshortenedin2.5cmsections

•Largestexternaldiameter:650mm

•Pitopening/470mminternaldiameter

•Externaldiameterofcoverframe:548mm

Connections:

•Femalethreadatbothends

VersionforQ34(Qn2.5,3/7) =T1"

VersionforQ310(Qn6) =T11/4"

1.5.2 Insulating cover

Material:

•Nonload-bearinginsulatingcovermadeofEPP

Dimensions:

•485mmexternaldiameter

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

6Current information at: www.ewe-armaturen.de

Drawing:DimensionsofEWE-FLEXORIPPwatermeterpit

ExternalØwithA15/

B125pitcoverinstalled

Heightwithframe

LargestexternalØ

Pipecover

ExternalØwithoutpit

InternalØ

Heightwithoutframe

Seetableonpage5fordetailedinformationaboutthesedimensions!

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

7

Current information at: www.ewe-armaturen.de

1.5.3 Water meter systems and hoses

Materials:

•BracketmadeofA2stainlesssteel

•Watermeterscrewttingsmadeoflead-freesiliconbrassinaccordancewiththelist

of“Metallicmaterialssuitableforcontactwithdrinkingwater”.

•PlasticsandelastomersinaccordancewiththeKTWandelastomerguidelinesissued

bytheFederalEnvironmentAgencyandtheDVGWworksheetW270.

•Valvesmadeoflead-freesiliconbrassinaccordancewiththelistof“Metallicmateri-

alssuitableforcontactwithdrinkingwater”.

•HosesmadeofsiliconewithbraidingmadeofA2stainlesssteelandfabriccovering

madeofthermoplasticmaterial

•Pressureregulatormadeofstainlesssteel

Versions:

•Ballvalve-ballvalve •Ballvalve-pressureregulator-ballvalve

•Ballvalve-CAC-valve •Ballvalve-pressureregulator-CAC-valve

•Ballvalve-BMN-ballvalve

•Angleseatvalve-angleseatvalve •Angleseatvalve-PR-angleseatvalve

•Angleseatvalve-CAC-valve •Angleseatvalve-PR-CAC-valve

•Angleseatvalve-BMN-angleseatvalve

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

8Current information at: www.ewe-armaturen.de

Water meter system variants – water meter dimensions:

Watermeterdimensions

ThreadT(d3)×

Lengthmm(l2)

MID(MeasurementInstrumentDirective)

Q3

[m³/h]

EEC

Qn

[m³/h]

" ×165* 2.5 1.5

" ×165* 2.5 1.5

1" ×190 2.5or4 2.5

1" ×190 2.5or4 2.5

1" ×190 2.5or4 2.5

11 " ×175 4or10 3/7

11 " ×175 4or10 3/7

11 " ×175 4or10 3/7

11 " ×260 6.3or10 6

11 " ×260 6.3or10 6

*Adapterset(articlenumber3903075)isrequired!

1.6 Transport and storage

•TheFLEXORIPPwatermeterpitshouldbetransportedandstoredverticallyinits

originalpackaginguntilitisused.

1.7 Functional description

FLEXORIPPwatermeterpitsareintendedforinstallationinpipetrenches.

Theycanbeusedinmanyways,suchasadomesticconnection,constructionsitewater

connection,inparkareasorallotments,oncampingsitesorincemeteries.

Thewatermeterpitiseasytoinstallinapipetrenchwithoutextensiveearthworks

becauseofitssmallsize.Thewatermeterpitisimpermeabletosurfacewater,hygieni-

callycleanandenablesthefrost-freeoperationofthewatermetersystemandwater

meter.Itisnotnecessaryorpossibletoenterthewatermeterpit.

Therelevantaccidentpreventionregulationsforenteringpitsarethereforenot

applicable.

2. Installation instructions (installation/assembly)

2.1 Information about the preparations

CAUTION

Checkthewatermeterpitandwatermeterpitsystemfordamageor

contaminationbeforeuse.

Adamagedpitordamagedttingmustnotbeused.

Thepipeshouldbeushedbeforeinstallingthewatermeterinthewatermetersystem;

anadaptershouldbeusedforthispurpose.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

9

Current information at: www.ewe-armaturen.de

!ThewatermeterpitsystemisfactoryttedwithaPEadapter.

ThePEadapterisonlyusedasasubstituteforthewatermeterandisnot

suitableforoperation.

2.2 Information about the installation site

!Thewatermeterpitshouldbelocatedatanelevatedpositiononthesiteor

protrudeafewcentimetresabovegroundlevelifpossible.

Thechoiceofpitsizeshouldbecompatiblewiththefrost-freeinstallationdepth

ofthepipeandisthesoleresponsibilityoftheuser.Thewatermeterpitdemonstrates

favourablebehaviouragainstbuoyancybecauseofitsexternalshape.Anessential

requirementisthatitisinstalledproperlywithgravelbackllandcompactioninlayers.

Thepitbodyhasawaterproofdesignandtheconnectiontothecoverisimpermeableto

surfacewater.Asoilengineeringspecialistshouldbeconsultedinareaswherethereisa

riskoftemporaryooding.

!Shouldtherebeat-lyingsupplypipes(so-calledsummerpipes)downstreamof

thewatermeterpit,whichhavetobeemptiedbeforethestartofthefrost

season,werecommendinstallingaspecialttinginthepiperoutingbetweenthe

pitexitandthetappingpoint,e.g.anEWEgardenvalveincombinationwithan

installationset.AnEWEgardenhydrantprovidesthesameconvenienceinthecaseof

anoutdoortappingpoint.

!Theemptyingofthedownstreamsupplypipeinthepitbodyrequiresspecial

carefromahygienicpointofview.Thewaterfromthepipemustbepumped

awayimmediatelyduringtheemptyingphaseandthenthedrainopeningmust

beclosedtopreventanypossiblecontaminationinthepipenetwork.

2.3 Excavation and backlling

Thewatermeterpitisdeliveredreadyforinstallationandcanbeusedinprepared

ditches.Theworkrequiredistheresponsibilityoftheuser.

Thedistancestootherundergroundinstallations,suchasbuildings,pipes,cables,must

beobservedinaccordancewiththeDVGWworksheetW400.

TherequirementsofDIN4124mustbeobserved.

Possibleearthmovementsasaresultofsubsidence,settlementorsoilpressure,e.g.

causedbyslopingsites,mustbetakenintoconsideration.

Non-cohesivesoilwithagrainsizeofmax.16mmmustbeusedforthefoundations,

beddingandbacklling.SandSE,SWorSIandgravelGE,GW,GIhaveprovenasuccess

inaccordancewithsoilclassicationF1accordingtoDIN18196,whichalsomeetthe

requirementsforthecompactionclassesandfrostprotection.

Thepitmustbexedinplaceassoonaspossiblebybackllingthetrench.

Otherappropriatemeasuresmustbetakentosecureitagainstoatingwhilethetrench

isnotcompletelybacklledtogroundlevel.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

10 Current information at: www.ewe-armaturen.de

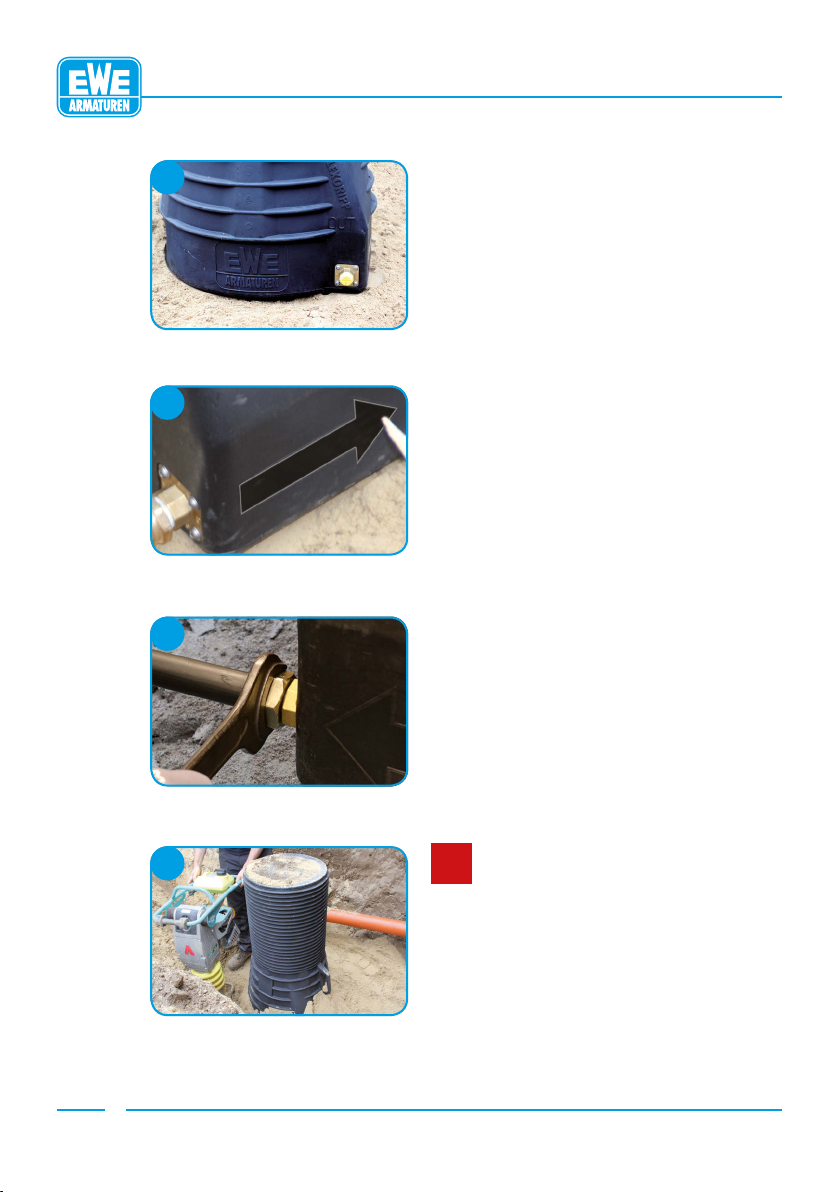

2.4 Installation

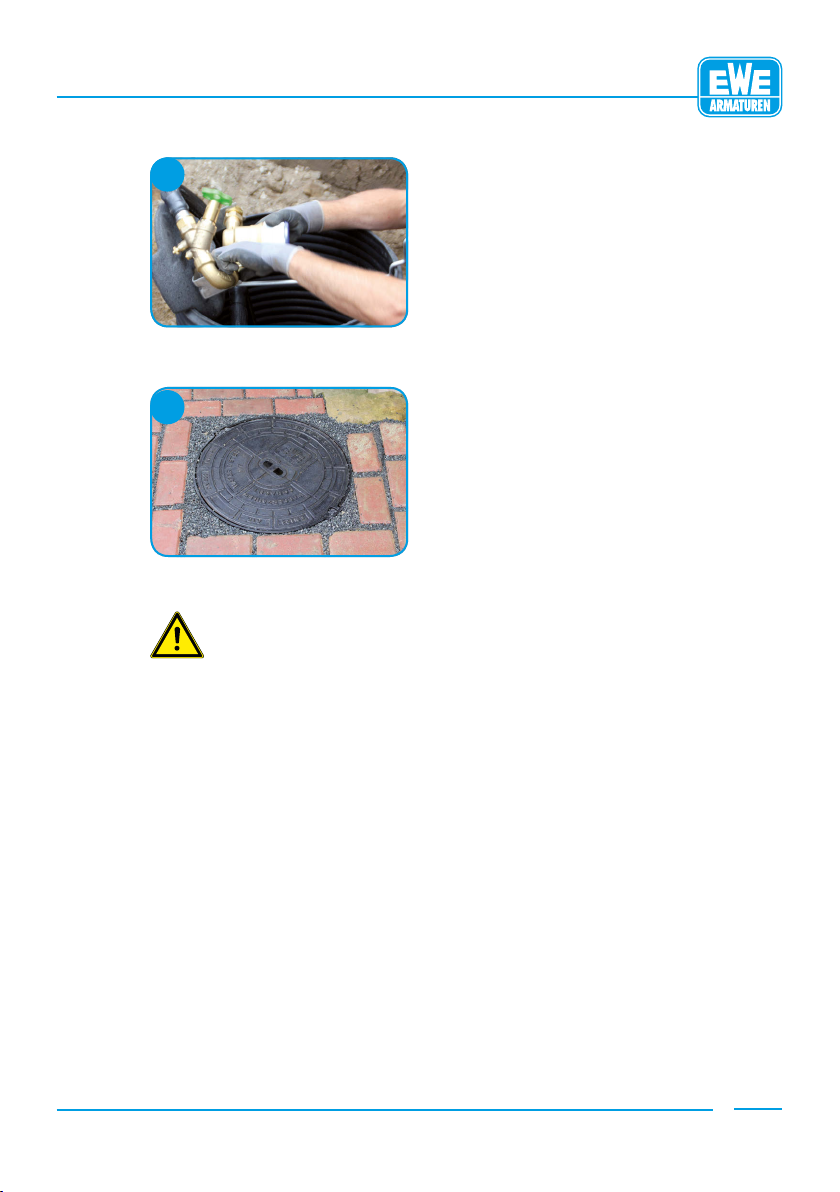

•Leveloutandcompactthebottomof

thetrenchevenlythroughout.

•Positionthepitsothatitisvertical

andlevel.

•Arrangeforthefoundationsforthe

footprintofthepittobedugin

accordancewithloadclassA15or

B125.

•Arrow-Observetheowdirection

whenaligningthepit.

•Flushthepipebeforeestablishingthe

connections.

•Establishconnectionsbetweenthe

connectionsleevesofthepitandthe

pipe.

•Observetheguidelinesofthe

connectionttingsmanufacturer.

!Performaleaktestin

accordancewiththeregulations.

•Backllthetrenchintheareaof

thewatermeterpit.

•Supporttheconnectionpipes(inlet

andoutletside)beforethecompac-

ting.

•Backllthesoilinlayersofmax.

30cmandcompactto97%DPr.

•Avoidone-sidedstresswhenbackl-

lingandcompacting.

3.

4.

1.

2.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

11

Current information at: www.ewe-armaturen.de

CAUTION

Thepitmaynotbeoperatedwithoutapitcoverinaccordancewithsection5.

Theinsulatingcoverisnonload-bearing.

Theinstallationsiteandpitopeningmustbesecuredagainstunintentional

accessduringtheinstallationperiod.

5. •Installthewatermeterinaccordance

withsection4“Maintenanceand

servicing”.

•Installthepitcoverinaccordancewith

section5“Pitcovers”.

6.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

12 Current information at: www.ewe-armaturen.de

2.5 Shortening the pit pipe

Thecylindrical,rib-shapedpartofthepitcanbeshortenedin2.5cmsections.

Atleast3ribsneedtoremaintomountthecoverframeanditsseal.

Frostprotectionthroughtheplannedinstallationdepthmustbetakeninto

consideration.

!Ifshortenedbymorethan20cm,thelengthoftheliftinglinemustbereduced

orthelattermustbereplaced.

3. •Removethecoverframeseal(if

applicable).

4.

2. •Loosenandalsoremovethecover

frame(ifapplicable).

1. •Removethecoverifoneistted.

•Removetheinsulatingcover.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

13

Current information at: www.ewe-armaturen.de

3. Operation and use

Avisualinspectionofthewatermeterpit,thewatermeterpitttingsandtheentire

systemmustbemadepriortoputtingitintooperation.

3.1 Functional check and leak test

!Theentiresystemmustbecheckedtoensurethatitisworkingandhasnoleaks.

•Thepitpipecanbeshortenedinsections

of2.5cmatthedeepestpointofthe

ribusingasuitabletool(e.g.EWE-

FLEXORIPPcutter).

•Aminimumofthreeribsmustremain.

•Deburrthecutedge.

•Deburrtherstribatitsdeepest

point.

•Installthepitcoverinaccordancewith

section5“Pitcovers”.

7.

8.

6. •Whenusingthecovercap,makesure

thatthepittogetherwiththecapprot-

rudeapprox.7cmabovetheground.

•WhenusingtheA15/B125pitcover,

additsheightof7cmfromtherstrib.

5. •Takethemeasurementtothesurface.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

14 Current information at: www.ewe-armaturen.de

3.2 Pit security

CAUTION

Thepitmustnotbeoperatedwithoutapitcoverinaccordancewithsection5.

Theinsulatingcoverisnonload-bearing.

Theinstallationsiteandpitopeningmustbesecuredagainstunintentional

accessduringtheinstallationperiodandduringoperationofthepit.

A15/B125pitcoversmustbelockedwiththeenclosedscrews.

3.3 Frost protection

!Theinsulatingcoverfastenedtotheliftinglinemustbeused.

Frostprotectionmustbeensuredthroughthelocalinstallation,inparticularby

therightchoiceofinstallationdepth.

Itisthereforethesoleresponsibilityoftheplanningandcontractingbodytoensurethe

frost-freeconditionsinthepipeandpit.

4. Maintenance and servicing

!The(ball)shut-offvalvesinthewatermetersystemsaregenerallydenedas

maintenancettings;theyshouldthereforebeactuatedslowlyinthecaseof

maintenance(duringopeningandclosing)whenthetappingdevicesareclosed.

Thettingsmustbeopenedasfarastheywillgo,i.e.bysettingthemtothefullyopen

position.Itisnotpermittedtorestrictthem.

!Itisrecommendedthattheshut-offvalvesonthewatermetersystemare

normallyactuatedatleastonceayeartoensurethattheyworkandmove

freely.

Asageneralrule,anannualfunctionalcheckshouldbeperformedonthenon-return

owvalve.Itisnotnecessaryforplug-innon-returnowvalvestobeinspectedannual-

ly.Thesettingsmustbechangedwiththeregularreplacementofthewatermeter,but

within10yearsatthelatest(EN806).Thenon-returnowvalvesarewearparts.

Afunctionalcheckcanbecarriedoutonmodelswithacontrolscrewthatarealready

installed.

Todothis,theinowmustbeshutoffandthecontrolscrewopenedwithduecaution.

Onlytheremainingwaterbetweentheinowandhousingmustescape.

Mediumfromotherinstallationsmustbeheldbackbythenon-returnowvalve.

Thenon-returnowvalvemustberepairedifthisisnotthecase.

CAUTION

Thepipesystemmustbeshutoffanddepressurisedbeforestartingtherepair

work.Furthermore,thepipesystemmustbesecuredagainstinadvertentuse

again.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

15

Current information at: www.ewe-armaturen.de

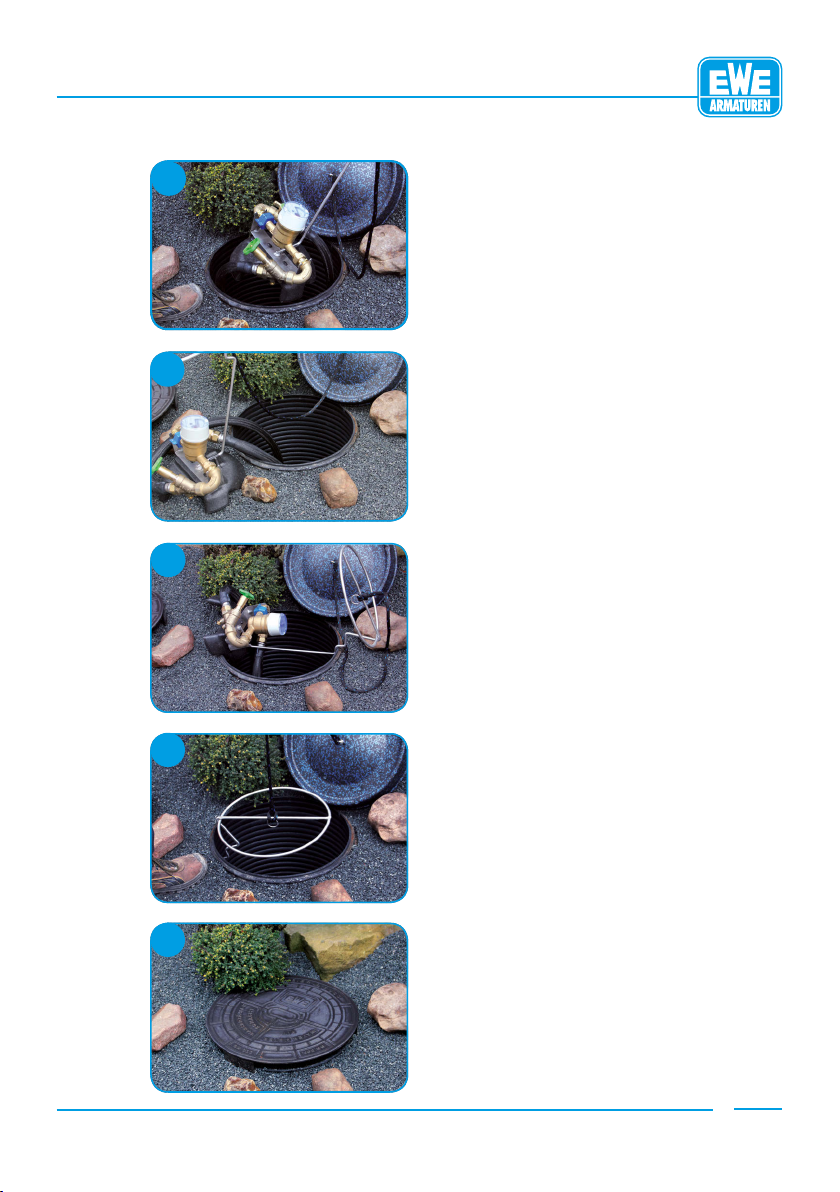

•Removethecoverandinsulating

cover.

•Pulloutthewatermeterpitsystem

withtheaidoftheliftingline.

1.

•Placethewatermeterpitsystemnext

tothepitopening.

2.

•Lowerthewatermeterpitsystem

slowlyontheliftingline.

3.

4.

Meter reading and meter replacement

5. •Closetheinsulatingcover.

•Fitthepitcover.

•Alternatively,thepitsystemcanbe

xedwiththeplinthonthepitframe.

• Installandreplacethemetertaking

accountoftheinstallationinstructionsof

thewatermetermanufacturer.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

16 Current information at: www.ewe-armaturen.de

5. Pit covers

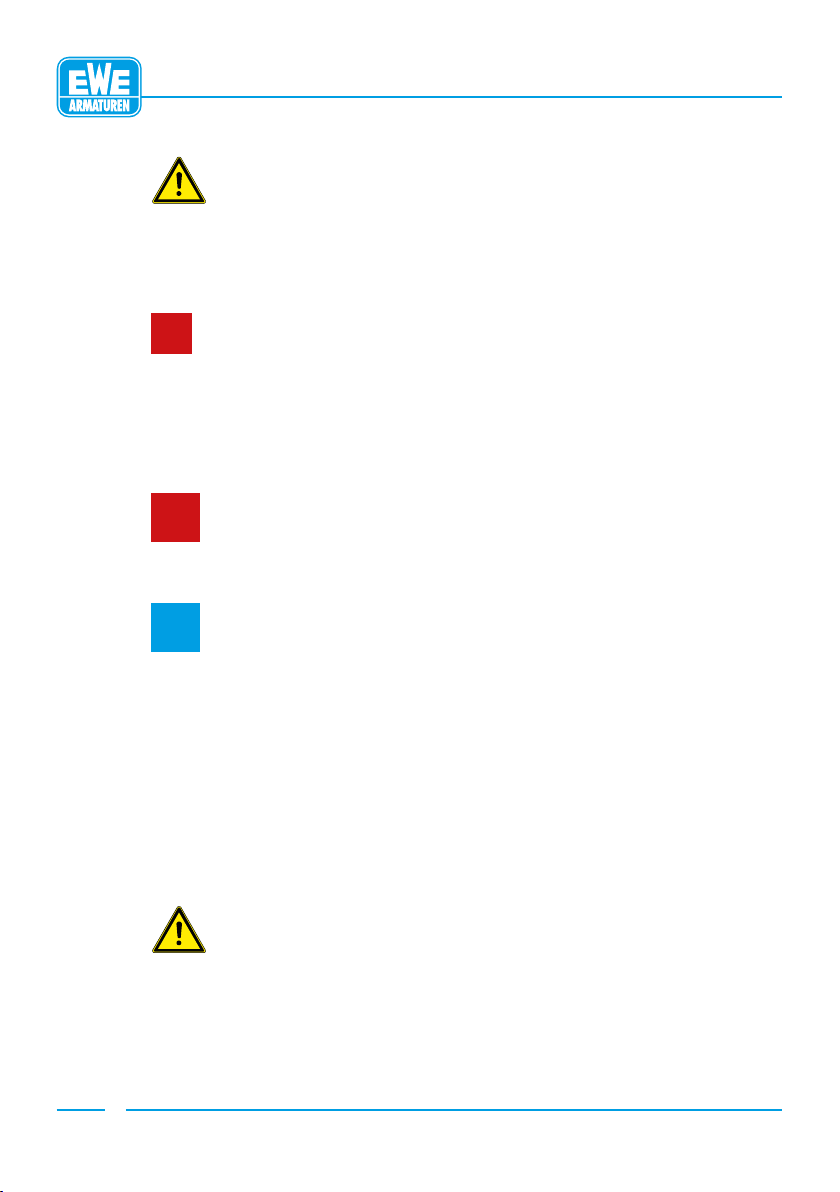

•FLEXORIPPcovercap-200kg

•FLEXORIPPA15pitcover,EN124

•FLEXORIPPB125pitcover,EN124

Material/dimensions/performance

Material:

•Covercapmadeoflamellargraphitecastiron

•A15/B125pitcoverswithcoverframemadeoflamellargraphitecastironwith

integratedcoversealingringmadeofNBR.Screwsmadeofstainlesssteel.

Dimensions:

•535mmexternaldiameterofcovercap

•548mmexternaldiameterofcoverframefortheA15/B125cover

Description

Theloadofthepitisrestrictedaccordinglydependingonthepitcoverselected.

Thecovercapisonlysuitableforload-freeinstallationsituations(frontgardens,small

gardens).

TheA15pitframeissuitableandcertiedfortrafcareasusedbypedestriansand

cyclistsinaccordancewithDINEN124ClassA15,Group1.

TheB125pitframeissuitableandcertiedfortrafcareasusedbypedestriansorin

pedestrianzonesandsimilarareas,carparkinglotsordecksinaccordancewithClass

B125,Group2.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

17

Current information at: www.ewe-armaturen.de

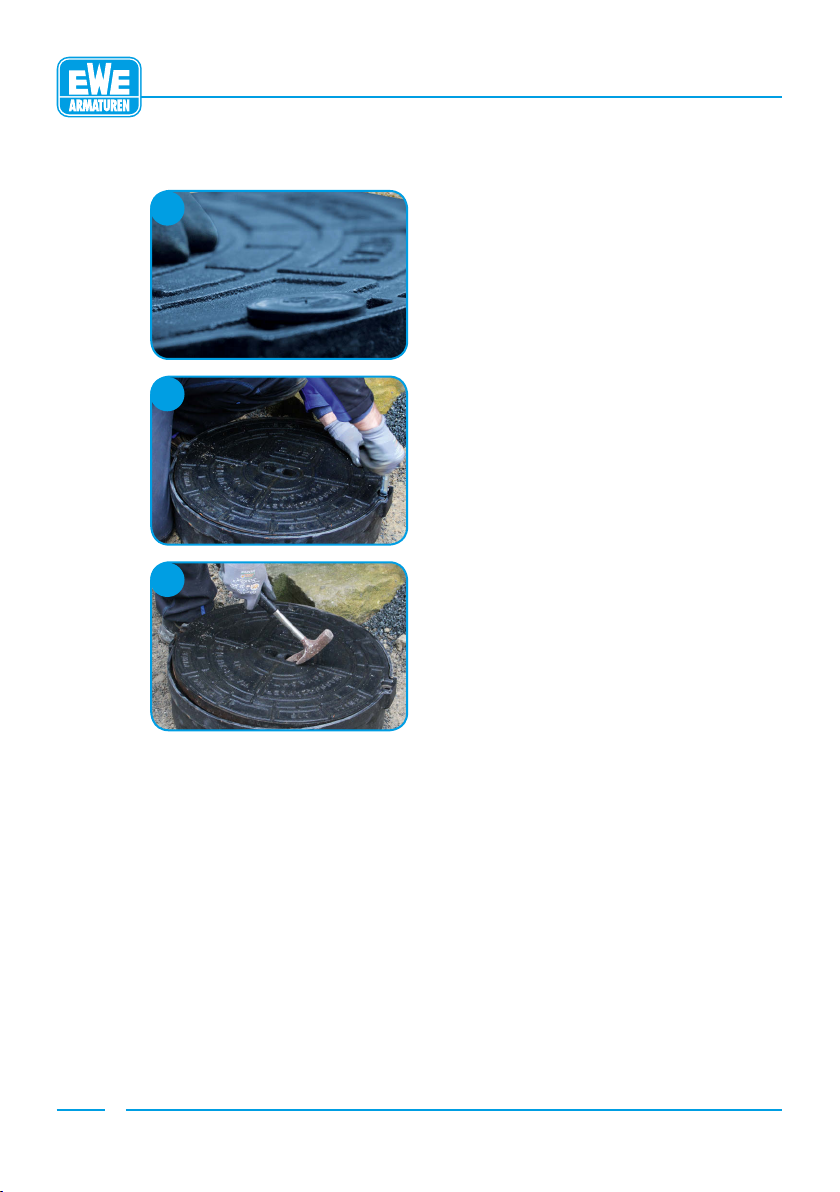

•Cleanthedeepestpointofthetoprib,

removeburrifnecessary.

•Placethesealingringinthedeepest

pointofthetoprib.

!Thetopribisusedtosupport

thecoverframeandmustnot

bedamaged!

!Thedeepestpointofthetopribisa

sealingfaceandmustnotbe

damagedorcontaminated!

1.

2.

3.

•Placethecoverframeonthetoprib

ofthepitbody.Theresistanceofthe

sealingringmustbeovercome.

•Checkthatitisttedcorrectly.The

coverframemustrestontherib.

•Closethecoverinaccordancewith

section5.2.1.

•Embedthecoverframeinthetop

layer/surface.

5.1 Installation instructions for cover cap

5.2 Installation instructions for A15/B125 pit covers

Thepitcoverscanbettedushwiththesurface;countersinkingshouldbeavoided.

•Thecovercapmustbeinstalled

approx.7cmabovegroundlevel.

•Thecovercapcanonlybelifted

fromtheedgeofthecover.

•Precipitationoranysurface

waterthatoccursmustbedrained

becauseoftheelevatedinstallation

situation.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

18 Current information at: www.ewe-armaturen.de

5.2.1 Operation of the A15/B125 pit cover

Opening the cover

1. •Removethesealingplugs.

3. •Removethepitcoverviatherecesses

withasuitableliftingtool.

•Unscrewthehexagonheadscrews

SW15.

2.

User information

EWE-FLEXORIPP Water Meter Pit

Edition 01/2017

19

Current information at: www.ewe-armaturen.de

Closing the cover

•Cleanthesealinthecoverframe.

•Checkthethreadedscrewholes

fordirtandcleanifnecessary.

1. •Inserttheinsulatingcover.

2.

•Insertthecoverinthecoverframe

withtheaidofthepositioninglugs.

3.

•Tightenthescrewsalternately.

•Recommendedtorque:35-45Nm.

4.

•Insertthesealingplugsinboth

openings.

•Checkthattheyarelockedrmlyby

liftingthecover.

5.

Braunschweig

WILHELM EWE GmbH & Co. KG

Volkmaroder Straße 19

38104 Braunschweig

Phone.:+49 531 37005-0

Fax: +49 531 37005-55

www.ewe-armaturen.de

Table of contents