EX Model Engines COX User manual

EX Model Engines

COX Engine Operating & Troubleshooting Guide

Items Required:

•1.5 Volt ‘hobby’ battery. CAUTION: Using a voltage greater than 1.5V may result in damage of

glow head. We recommend our battery boxes to ensure correct voltage.

•Glow Plug Clip

•Model engine fuel with nitro content typically between 15% & 25%. Racing fuel may contain 30%

nitro. This must also contain at least a 20% oil content, half of which must be castor oil. Use of

fuel with less than this oil amount can lead to premature wear and inhibited performance.

•A propeller, such as a 5x3 (five inch diameter, 3 pitch), 5x4, 6x3, or 6x4. Always be sure to

balance a new propeller. Correct balance is essential for good performance.

•Fuel bulb or pump to fuel and prime engine. It is recommended you use a filter when fueling the

engine to ensure no foreign materials contaminate the fuel.

•Two Cox engine wrenches (for proper maintenance).

•‘Chicken stick’ (Optional) Use of an electric starter is ‘at your own risk’ and may result in damaged

parts.

•Mounting Screws

•After-run oil (Marvel Mystery Oil works well)

•External Fuel Tank (If engine does not have an integral tank)

Notes & Preparation

A. The fuel pick-up tube inside the tank (integral tank engines only) is positioned for control line

flying. For free flight flying, tank must be removed from engine and end of pick-up tube

repositioned to bottom of tank. If this tube is located in the wrong position, all fuel will not be used

and engine will stop prematurely.

B. When adjusting engine speed, allow for a short delay between movement of needle valve and

change in speed.

C. Mount engine on a test stand or plane. NEVER hold in hand or vise.

D. Connect glow clip to battery or battery box (if applicable).

E. Install propeller on stud or screw (if using a stud, thread into the crankshaft before installing

propeller on stud). Fasten with screw/washer, screw/spinner, or stud/hub. Always ensure the

propeller is secure before running engine.

NOTE: Be sure to inspect the propeller for nicks, chips, or cracks before and after running

engine. A damaged propeller may present serious injury to you and others.

FIGURE A

‘Spring-Loaded” Style Small top fork slides/clips onto top

of core. Lower fork rests on top fin.

Starting Engine

1. Close needle valve (turn clockwise). Do not force or over tighten valve. After closing, open needle

valve (turn counterclockwise) 3 turns.

2. Fill fuel tank. If engine has an external fuel tank this is self explanatory. Integral tanks will either

have a filler nipple on the backplate or a filler tube on the top of the tank bowl (stunt style tanks).

Fuel will flow from overflow hole near the fuel nipple on backplate or bottom of filler tube once

tank is full. Wipe any excess fuel from engine and tank.

3. Prime engine. Close exhaust ports by rotating crankshaft until piston blocks ports. Squirt several

drops of fuel into exhaust ports. Flip propeller over a few times to work fuel into engine.

4. Connect glow head clip to glow head. Glow clip style may vary. See Figure A.

5. Start engine. Flip propeller vigorously counterclockwise (from right to left when facing propeller). If

your engine has a snap starter (starter spring and cam attached to driveplate), engage the

spring/cam and wind the propeller clockwise (from left to right while facing propeller) ONE full

turn. Release propeller, engine should start. If your engine has a spring starter (starter spring with

curved hook), place end of starter spring over propeller and wind it clockwise (from left to right

when facing propeller) ONE full turn. Release propeller, engine should start.

NOTE: If, after a few attempts, the engine does not start, open needle valve another ¼ turn, re-

prime, and repeat starting procedure. Repeat this process a few times opening needle valve

another ¼ turn each time. If engine still will not start, refer to the trouble-shooting section.

6. Slowly tighten needle valve (clockwise) until engine is running at top speed. At top speed, engine

should produce a shrill whine. After engine has reached top speed, loosen needle valve

approximately ½ turn, or until engine runs with a “crackling” or “burbling” sound. Remove glow

head clip and let engine run until the fuel tank runs dry.

Restart and repeat procedure until the engine has burned about three tanks of fuel. This is

paramount for the breaking-in process.

7. Restart engine. Tighten needle valve until engine is running at top speed. Remove glow clip. If

engine holds RPM, it is correctly broken in.

8. If engine is mounted in place, tip nose of plane up to 45 degree angle. If engine speed changes,

readjust needle valve.

Engine Care & Maintenance

A. Cleaning. Engine may be taken apart for cleaning or replacement of parts. Please see our

website or contact us for more information regarding parts and their installation. It is important to

disassemble and clean engine whenever it is dirty. Wash parts in fuel or rubbing alcohol, then re-

oil before assembly. Anytime there is chance dirt may have gotten into engine, disassemble and

clean. Dirt will drastically shorten engine life. If an engine (even a new one) has been sitting in

storage for many years, it is a good idea to disassemble and clean before use. In the event of a

stuck engine, do not force. Apply heat with a heat gun or soak overnight in fuel.

NOTE: If you are unsure about disassembling engine please contact us for our rebuild service.

Fuel Tank

Screws

Needle Valve

& Spring

Venturi Gakset

Fuel Tank Bowl

& Backplate

Reed Valve, Retainer

and Gasket

Crankcase, Crankshaft

and Driveplate

Starter Spring

and Cam

Prop Spinner

& Screw

Glow Head

& Gasket

Cylinder, Piston

and Rod

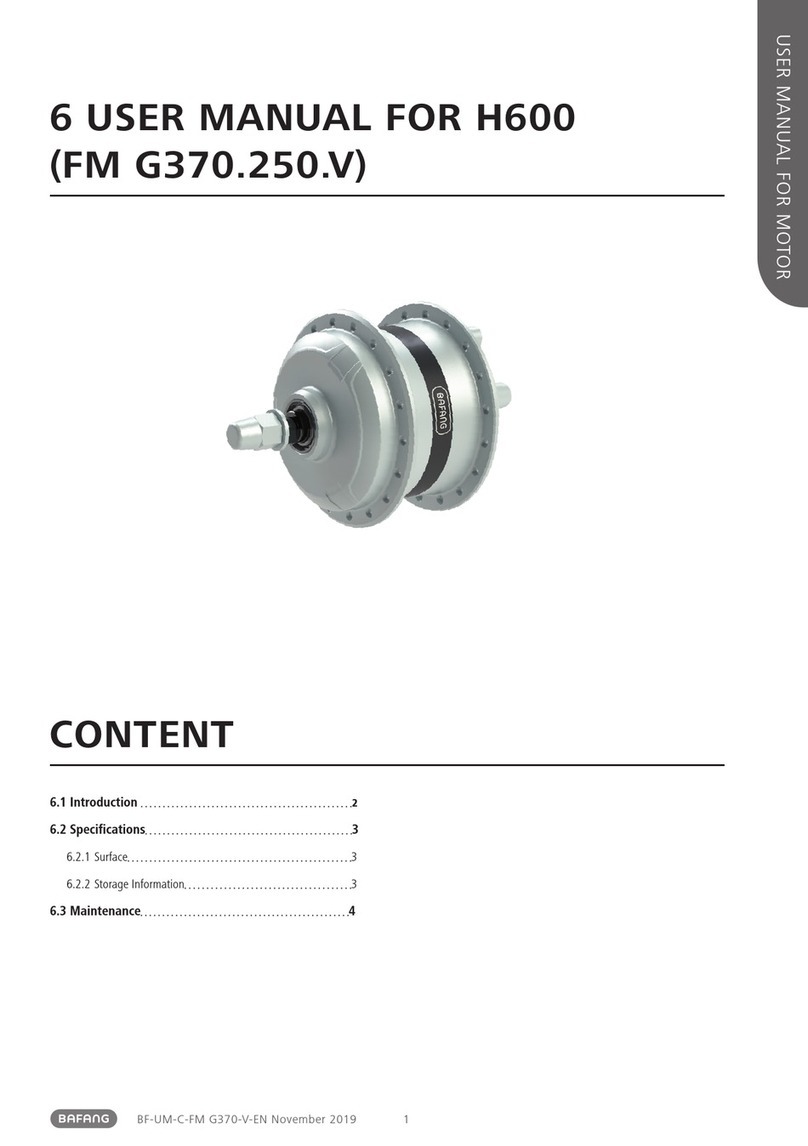

FIGURE B

TROUBLE

PROBABLE CAUSE

REMEDY

WILL NOT START.

ACTS LIKE BATTERY

WASN’T ATTACHED

TO GLOW HEAD.

Poor battery connection

Check connections of wires to battery and

check to be sure clip is firmly and correctly

attached to glow head.

Weak or dead battery

A good battery should test 1.5 volts or

connect battery to a glow head that is

known to be good. If glow head filament

does not glow bright orange, replace

battery.

Burned out glow head

Remove glow head. Attach glow head to a

good 1.5 volt battery. If filament does not

glow bright orange, replace glow head.

Engine wasn’t primed

Squirt a few drops of fuel through exhaust

ports and onto side of piston then continue

starting procedure.

ENGINE POPS

AND/OR “KICKS” –

WON’T START.

Loose propeller screw

Tighten propeller screw.

Dirt under reed

Carefully unsnap reed retainer and remove

reed. Wash reed and retainer in solvent or

fuel. Replace reed. Be sure reed turns

freely under retainer.

ENGINE STIFF,

PROPELLER TURNS

HARD OR “KICKS”.

Engine flooded, too

much fuel in cylinder

Close needle valve completely. Leave

battery attached and flip propeller (without

priming) until short starting “burst” occurs.

Then open needle valve 2 ½ turns, and

start again.

ENGINE STARTS

THEN SLOWS

DOWN AND STOPS.

Excess fuel at ports

Close needle valve. Flip propeller until

engine starts and burns out excess fuel.

Open needle valve and restart.

SHORT RUNNING

“BURST” (BRIEF

START, THEN

STOP).

Engine not getting

enough fuel (mixture too

lean or tank empty)

Check fuel tank level. Refill if necessary; or

open needle valve another ¼ turn, prime

and start again. It may be necessary to

repeat this procedure 6 to 8 times,

opening needle valve ¼ turn each time.

ROUGH SOUNDING

ENGINE, SLUGGISH,

WEAK POWER.

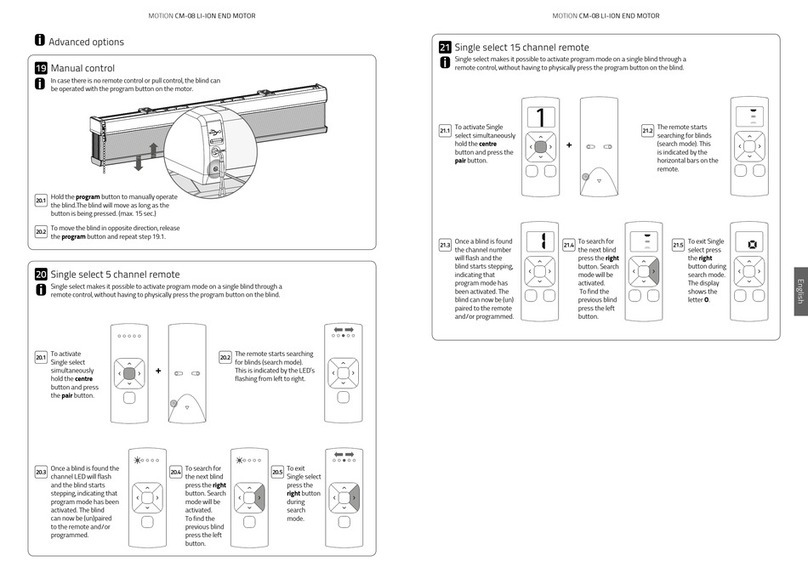

Loose glow head Tighten glow head with wrench.

Fits glow head

slots for removal

or tightening

For carburetor housing

nut on Tee Dee and

Medallion engines

For venturi on

Tee Dee engines

Fits flats on

top cylinder fin

Fits cylinder exhaust

openings (when piston

is at bottom center) FIGURE C

EX Model Engines Repair Service

We offer an engine rebuild service for all Cox engines. This includes a complete

disassembly, cleaning, and polishing of engine where applicable. All castor oil and

grime is removed and results in a reassembled and oiled engine. This includes all

applicable gaskets. The cost is $11.95 per engine. All additional parts are extra

(where available). Please contact us for more information.

A. Glow Head. Never attempt to remove a hot glow head. A hot glow head will stick, and forced

removal may damage cylinder. Let glow head cool, or pour fuel over to expedite the process. To

remove the glow head use two wrenches. The top fin on the cylinder has two flats. Insert one

wrench over these flats and hold in place while using the other wrench to remove glow head as

shown in figure B. If engine does not have flats on the cylinder, use the end of one wrench and

insert wrench into exhaust ports (when piston is at bottom dead center). See figures B and C.

After part (s) is replaced ensure glow head is tight!

B. Storage. Before storing, run engine until fuel tank is dry. Lubricant in fuel thickens upon exposure

to air and may clog parts if allowed to remain in the tank. Oil engine with a few drops of light oil

such as SAE 10, 3-In-One Oil, or sewing machine oil, then wrap in plastic bag or clean cloth to

protect from dust and dirt.

EX Model Engines EXModelEngines.com

(860) 681-2451

Copyright © 2012 EX Model Engines

Typical Integral Tank

Engine Components

(Exploded View)

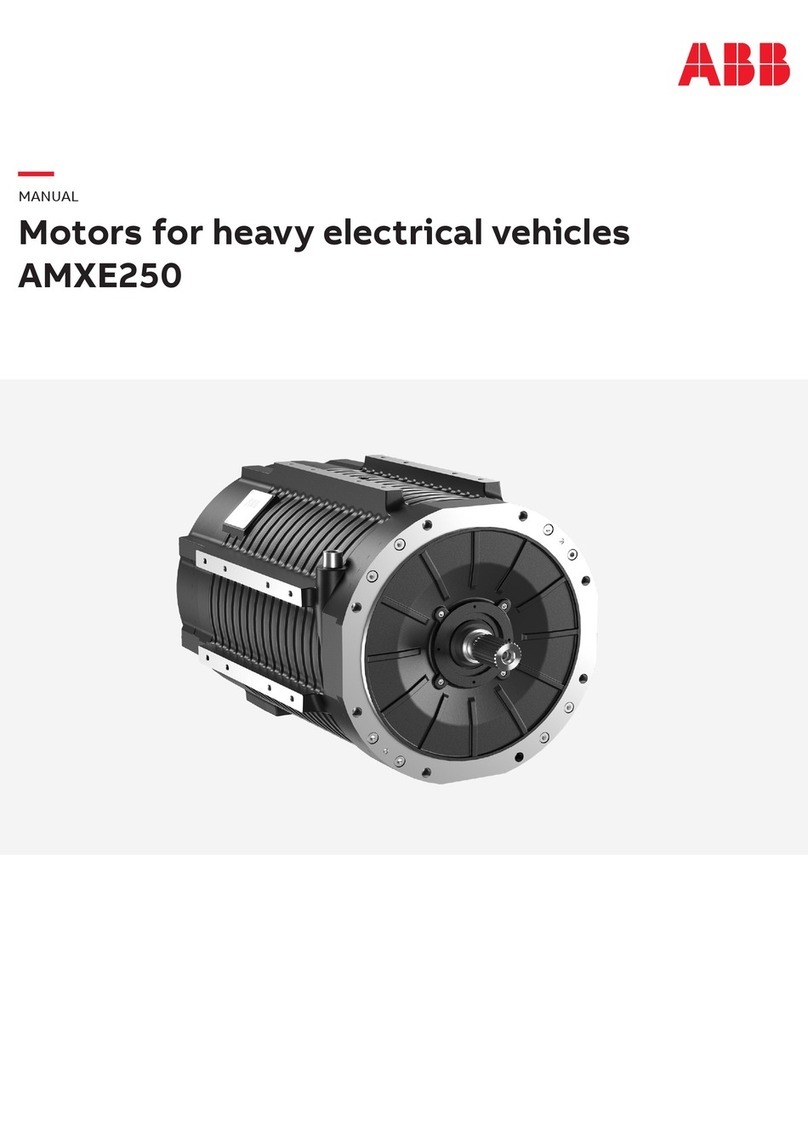

Popular Engine manuals by other brands

YOODA

YOODA CORTINO DT72LE Series manual

KEY

KEY STAR 300 Instructions and warnings for installation and use

Kubota

Kubota Z482-E Operator's manual

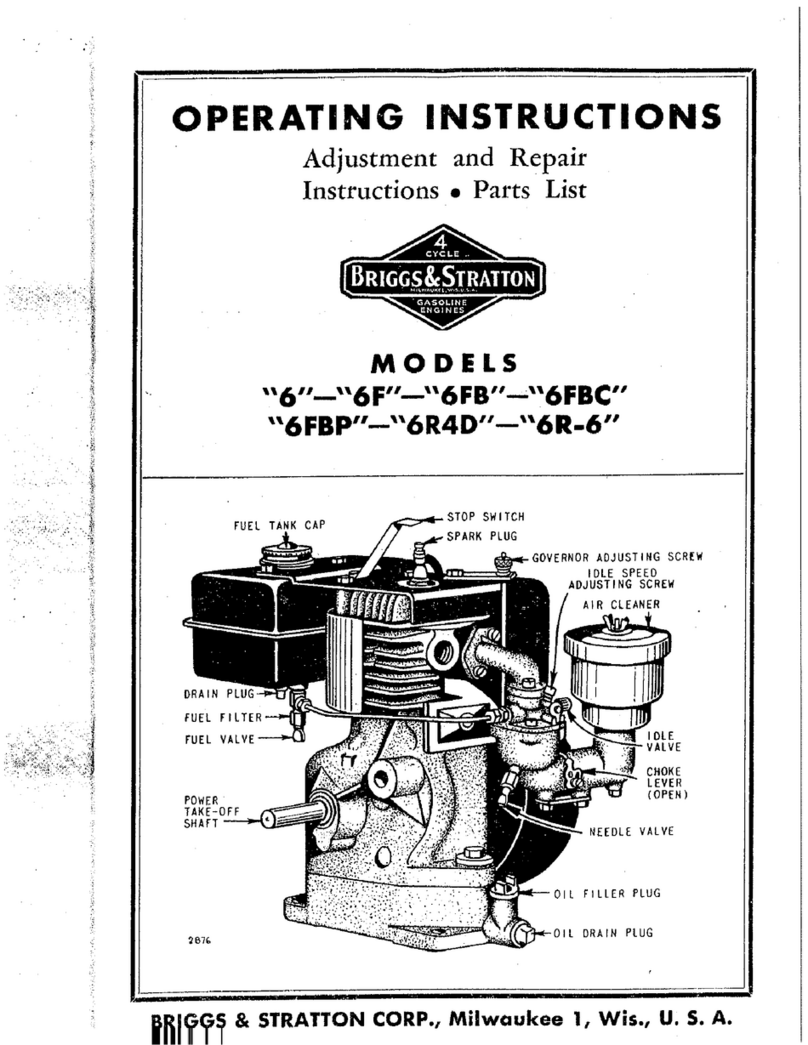

Briggs & Stratton

Briggs & Stratton 6 operating instructions

Generac Power Systems

Generac Power Systems GTV-760 owner's manual

Yanmar

Yanmar 2TNV70 Service manual