Checking the product

Open the package and confirm that all of the following items are available.

To verify that the unit you’ve purchased is the correct one, check the model

number shown on the nameplate. Should you find any item missing or

damaged, contact the Oriental Motor sales office where you purchased the

product.

• Motor 1 unit

• Motor cable 0.6 m (2 ft.) 1 pc. (PK223PA (B)-SG-Lonly)

The square box in the motor type will contain a number representing the

gear ratio.

• Operating manual 1 copy

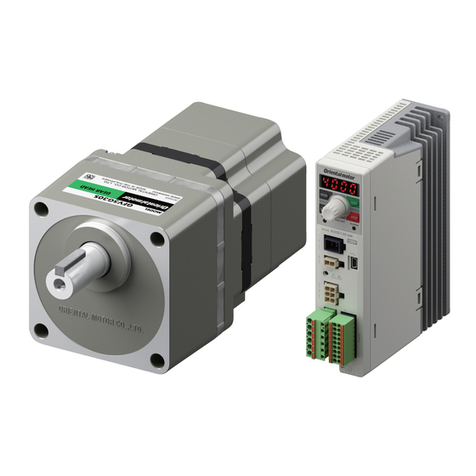

Installation

Location for installation

The motor is designed and manufactured for installation in equipment.

Install it in a well-ventilated location that provides easy access for inspection.

The location must also satisfy the following conditions:

• Inside an enclosure that is installed indoors (provide vent holes)

• Operating ambient temperature

-

10 to +50 °C (+14 to +122 °F) (non-freezing)

• Operating ambient humidity 85% or less (non-condensing)

• Area that is free of explosive atmosphere or toxic gas (such as sulfuric gas)

or liquid

• Area not exposed to direct sun

• Area free of excessive amount of dust, iron particles or the like

• Area not subject to splashing water (rains, water droplets), oil (oil

droplets) or other liquids

• Area free of excessive salt

• Area not subject to continuous vibration or excessive shocks

• Area free of excessive electromagnetic noise (from welders, power

machinery, etc.)

• Area free of radioactive materials, magnetic fields or vacuum

How to install the motor

Install the motor onto an appropriate flat metal plate having excellent

vibration resistance and heat conductivity. When installing the motor, secure

it with four screws (supplied) through the four tapped holes provided. Leave

no gap between the motor and plate.

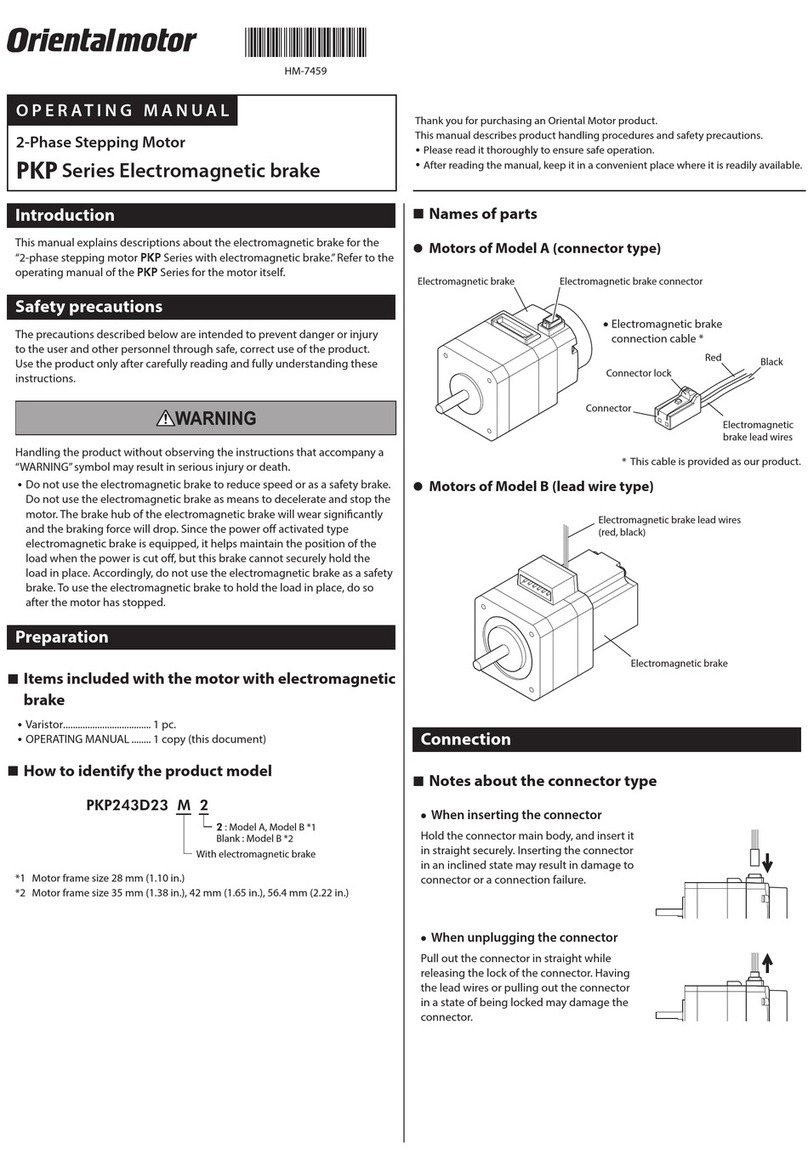

Mounting-pilot holder

(countersunk or

drilled through)

Metal plate:

4 mm (0.16 in.)

or more

Cross-recessed

pan head screw (supplied)

Tapped hole

Motor model Screw size Tightening torque Effective depth

PK223PA-SG

PK223PB-SGM2.5 P0.45 0.5 N·m

(4.4 lb-in)

4 mm

(0.16 in.)

∗ The square box in the motor type will contain a number representing the

gear ratio.

Note Do not loosen the gearhead-attaching screws (four pcs.).

Installing a load

When connecting a load to the motor, align the centers of the motor’s output

shaft and load shaft. Be careful not to damage the output shaft or the bearings

when installing a coupling or pulley to the motor’s output shaft.

Permissible overhung load and permissible thrust load

The overhung load on the motor’s output shaft or gear output shaft must be

kept under the permissible values listed below. The thrust load must not

exceed 10 N (2.2 lb.).

[Unit: N (lb.)]

Distance from the top of motor's output shaft [mm (in.)]

0 mm (0 in.) 5 mm (0.2 in.) 10 mm (0.4 in.) 15 mm (0.6 in.)

15 (3.3) 17 (3.8) 20 (4.4) 23 (5.1)

Connection

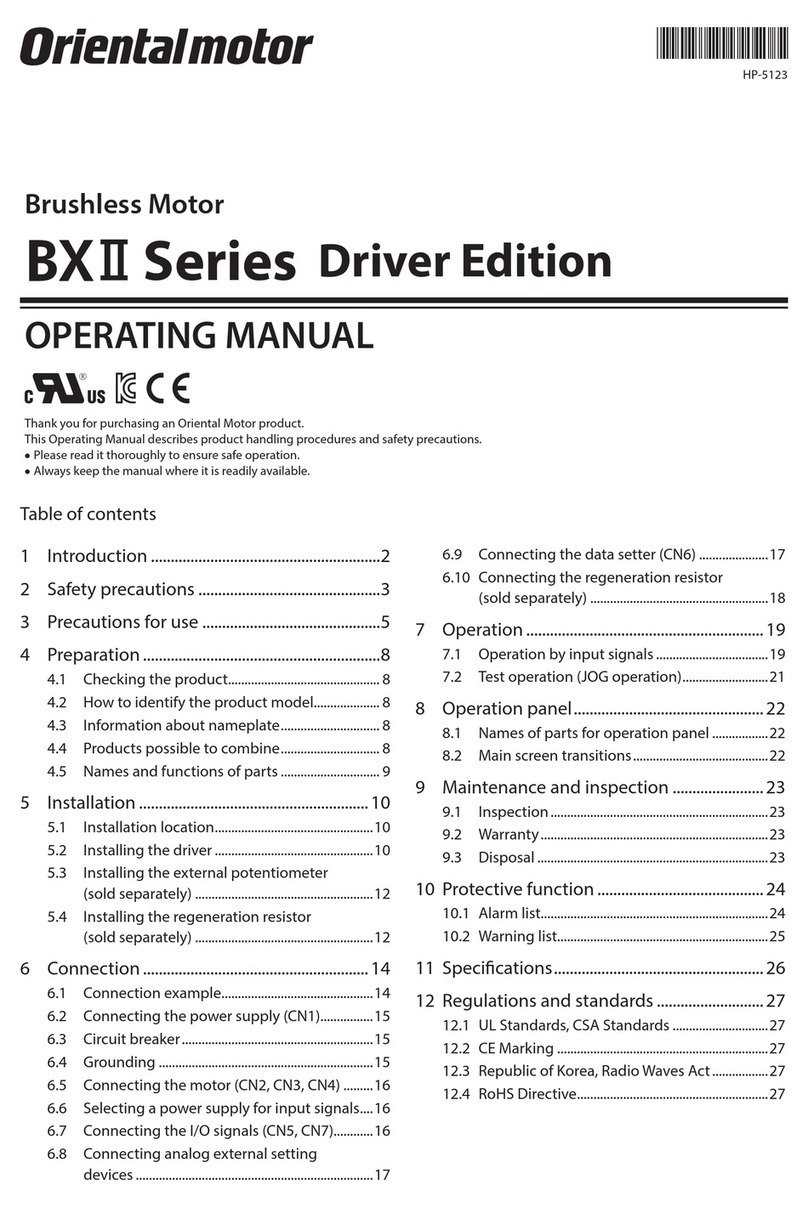

(6)(5)(4)(3)(2)(1)

Pin assignments

Red

(3)

(4) Black

(5) Yellow

(6) Green

White

(2) Blue

(1)

BB

A

A

Wiring diagram

∗ ( ) indicates the pin number

The colors of lead wires shown apply to the supplied cable or optional motor

cable.

If you are using the connector set or when you are providing your own

connector or cable, connect based on the pin numbers shown.

The conforming connector and the cable are as follows.

Conforming connector and cable

Housing Contact Cable

51065-0600

(Molex)

50212-8XXX

(Molex)

AWG30 to 24 (0.05 to 0.2 mm2)

Cable outer diameter: Ø1.4 mm

(Ø0.055 in.) or less

Stripping the cable: 1.3 to 1.8 mm

(0.051 to 0.071 in.)

Note • Secure the motor connector cable in place so that the

connection won’t be subjected to stress induced by a

bent cable or the cable’s own mass. The cable’s radius

of curvature should be as large as possible.

• When removing the motor cable, pull it out horizontally

toward the output shaft. The motor may be damaged if

force is applied in any other direction.

Inspection

It is recommended that periodic inspections be conducted for the items listed

below after each operation of the motor. If an abnormal condition is noted,

discontinue any use and contact your nearest office.

• Check for any unusual noises in the motor’s bearings (ball bearings) or

other moving parts.

• Are there any loose connector connections, or any scratches or signs of

stress in the motor cable?

• Are the motor’s output shaft (or gear output shaft) and load shaft out of

alignment?

• Unauthorized reproduction or copying of all or part of this Operating

Manual is prohibited.

• Characteristics, specifications and dimensions are subject to change

without notice.

• , and are trademarks of Oriental

Motor Co., Ltd., and are registered in Japan and other countries.

Copyright ORIENTAL MOTOR CO., LTD. 2006

• Please contact your nearest Oriental Motor office for further information.

ORIENTAL MOTOR U.S.A. CORP.

Technical Support Line Tel:(800)468-3982

vailable from 7:30 AM to 5:00 PM, P.S.T.

E-mail: techsupport@orientalmotor.com

www.orientalmotor.com

ORIENTAL MOTOR (EUROPA) GmbH

Headquarters and Düsseldorf Office Tel:0211-5206700 Fax:0211-52067099

Munich Office Tel:08131-59880 Fax:08131-598888

Hamburg Office Tel:040-76910443 Fax:040-76910445

ORIENTAL MOTOR (UK) LTD. ORIENTAL MOTOR (FRANCE) SARL

Tel:01256-347090 Fax:01256-347099 Tel:01 47 86 97 50 Fax:01 47 82 45 16

ORIENTAL MOTOR ITALIA s.r.l. TAIWAN ORIENTAL MOTOR CO., LTD.

Tel:02-93906346 Fax:02-93906348 Tel:(02)8228-0707 Fax:(02)8228-0708

SINGAPORE ORIENTAL MOTOR PTE. LTD.

Tel:(6745)7344 Fax:(6745)9405

ORIENTAL MOTOR (MALAYSIA) SDN. BHD.

Tel:(03)79545778 Fax:(03)79541528

INA ORIENTAL MOTOR CO., LTD.

KOREA

Tel:(032)822-2042~3 Fax:(032)819-8745

ORIENTAL MOTOR CO., LTD.

Headquarters Tokyo, Japan

Tel:(03)3835-0684 Fax:(03)3835-1890 Printed on Recycled Pape