Exakt 80E Plus + User manual

Table of Contents

1

27891EN-900-02 / Edition 02/2017

Article number:

27891EN

27891EN-900-02 / Edition 02/2017

EN

Translation of the original operating instructions, English

THREE ROLLER MILL

Operating Instructions

Document number / Edition

Table of Contents

1

27891EN-900-02 / Edition 02/2017

1 TABLE OF CONTENTS

1Table of Contents 1

2Contact addresses 6

2.1. Manufacturer address 6

2.1.1. Imprint 6

2.2. Service and ordering spare parts 6

3Installation information in advance 7

4Safety 8

4.1. General information concerning safety 8

4.2. Safety symbols 9

4.3. Graphical conventions 10

4.4. Commissioning 11

4.5. Selection of location 11

4.6. Safety notes regarding operation 12

4.7. Safety notes regarding cleaning work 15

4.8. Handling chemical substances and coolants/lubricants 16

4.9. Cleaning agents 17

5Performance specifications 18

5.1. Intended use 18

5.2. No release for work in potentially explosive atmosphere 19

5.3. Reasonably foreseeable misuse 19

5.4. Qualification of the personnel 19

5.5. Technical condition 20

5.6. Protection against unintentional start 20

5.7. Safety devices 20

5.8. Safety warning notes 20

5.9. Marking 21

5.9.1. Type plate of the machine 21

5.9.2. Type plate of operating unit 23

6Technical data 24

6.1. Environment 24

6.2. Operating and auxiliary materials 24

6.3. Weights 24

6.4. Airborne sound emission 25

6.5. Dimensions 25

6.6. Dimensions Crate 25

6.7. Electric values EU 25

6.8. Electric values US 25

6.9. Electric values Japan 25

Table of Contents

2

27891EN-900-02 / Edition 02/2017

6.10. IP protection 26

6.11. Roller temperature control 26

6.12. Rollers 26

7Unit description 27

7.1. Functional principle 27

7.2. Overview 28

7.2.1. Section view 28

7.3. Operating modes 29

7.3.1. Cleaning 29

7.3.2. Mixing 29

7.3.3. Gap-Gap 29

7.3.4. Gap-Force 30

7.3.5. Force-Force 30

7.4. Emergency stop 31

7.5. Safety devices 32

7.5.1. Cleaning 32

7.5.2. Routine operations 33

7.6. Safety marks 34

7.6.1. Danger of crushing 34

7.6.2. Danger of cuts 34

7.6.3. Voltage 35

7.6.4. Increased leakage current 35

7.6.5. Tempering fluid 36

7.7. Control elements 37

7.7.1. Front side 37

7.7.2. Backside 38

7.8. Roller temperature control 39

7.8.1. Pressureless cooling 40

7.8.2. Pressure cooling 42

7.9. Scraper system 43

7.10. Load traverse 43

7.11. Scope of delivery 44

7.12. Equipment variants 47

7.13. Safety devices nip gap and optional accessories 48

7.13.1. Safety devices 48

7.13.2. Optional accessories 49

Table of Contents

3

27891EN-900-02 / Edition 02/2017

8Transport 51

8.1. Packaging symbols 51

8.2. Intermediate storage 52

8.3. Uncrating 52

8.4. Instructions for lifting 55

8.4.1. Moving the machine by hand 57

9Installation 58

9.1. Setup site 58

9.2. Dismounting the load traverse 60

9.3. Mounting and aligning the operating unit 61

9.4. Connecting the electric supply 62

9.4.1. Network configuration 62

9.4.2. Connect variant 1: fixed connection 63

9.4.3. Connection variant 2: fixed connection with coded heavy

duty connector 64

9.4.4. Connection variant 3: Connection via three-poles standard

plug (min. 15A) 66

9.5. Connecting the roller temperature control 68

9.5.1. Temperature control unit 68

9.5.2. With pressureless cooling 69

9.5.3. With pressure cooling 70

9.6. Checklist installation 70

10 Setup 71

10.1. Cleaning the machine housing 71

10.2. Scraper knife types 72

10.3. Mounting the scraper knife 73

10.3.1. Combination scraper knife –scraper bar - adaptor 75

10.4. Putting on the knife guard 76

10.5. Adjusting the scraper contact pressure 77

10.6. Mounting the scraper socket 78

10.7. Aligning the scraper socket in parallel to the roller 80

10.8. Setup of the scraper angle 81

10.9. Mounting the splash tray 82

10.10.Mounting the cleaning guard 83

10.11.Inserting plastic guides for working width 85 mm and 170 mm 85

10.12.Mounting plastic guides for working width 200 mm 87

10.13.Mounting the safety device nip gap, working widths 85 mm, 170 mm,

200 mm 90

10.14.Mounting hopper for working width 170 mm 91

Table of Contents

4

27891EN-900-02 / Edition 02/2017

10.15.Mounting hopper for working width 200 mm 93

10.16.Mounting splash guards for working width 200 mm 94

10.17.Mounting splash guards for inner side paneling 95

10.18.Mounting the solvent dispenser for guide lubrication 96

11 Operating elements and operating unit 97

11.1. Main switch 97

11.2. Operating panel 98

11.3. Emergency stop button 99

11.4. Operating unit 100

11.4.1. Safety messages on the display 102

11.4.2. Overload messages on the display 104

11.5. Program structure 105

12 Operation 106

12.1. Switching on the machine 108

12.2. Cleaning the rollers 110

12.2.1. Pre-cleaning the rollers 110

12.2.2. Preparing for cleaning 110

12.2.3. Cleaning roller 1 112

12.2.4. Cleaning roller 2 and roller 3 112

12.3. Cleaning the scraper system 113

12.4. Temperature control of the rollers 113

12.5. Adjusting the rollers 114

12.6. Defining the pre-settings (setup) 115

12.6.1. Setup after every adjustment and before each programming 116

12.6.2. Select setup via menu item Select setting (in routine

operations) 117

12.7. Routine operations 119

12.8. Routine operations: Test run with petroleum jelly 121

12.8.1. Step 1 121

12.8.2. Step 2 121

12.8.3. Optimum product flow 122

12.9. Reverse function 124

12.9.1. Sequence from the cleaning mode 124

12.9.2. Sequence from routine operations 126

12.10.Checking the safety devices 127

12.10.1. Preparing for check 127

12.10.2. Checks functions 127

Table of Contents

5

27891EN-900-02 / Edition 02/2017

13 Maintenance 128

13.1. Cleaning the machine housing 129

13.1.1. Cleaning the display of the operating unit 129

14 Maintenance and care 130

14.1. Service and maintenance plan 131

15 Troubleshooting 133

16 Shutting down 136

16.1. Short-term shutting down 136

16.2. Long-term shutting down 136

16.3. Putting out of operation 136

17 Disposal 137

17.1. Disposing of packaging 137

17.2. Disposing operating materials and cleaning agents 137

17.3. Disposing of unit 137

18 Spare and wear parts 138

18.1. Wear parts 80S Plus, 80E Plus 138

18.2. Spare parts 80S Plus, 80E Plus 141

19 Conformity check 144

19.1. Checking the conformity 144

20 Index 145

21 Annex 148

21.1. Warranty conditions 148

21.2. Declaration of conformity 149

Contact addresses

6

27891EN-900-02 / Edition 02/2017

2 CONTACT ADDRESSES

2.1. MANUFACTURER ADDRESS

EXAKT Advanced Technologies GmbH

Robert-Koch-Strasse 5

22851 Norderstedt

Germany

Phone:+49 (0) 40 / 529 560 - 0

Fax: +49 (0) 40 / 5 24 99 59

email: info@exakt.de

http://www.exakt.de

2.1.1. IMPRINT

© EXAKT Advanced Technologies GmbH, Norderstedt

Layout:: EXAKT Advanced Technologies GmbH

Text layout: EXAKT Advanced Technologies GmbH

Illustrations: EXAKT Advanced Technologies GmbH

This documentation is copyrighted by EXAKT. Without prior written approval,

the documentation may not be copied or be used contrary to the legitimate

interests of EXAKT.

Subject to change without notice!

2.2. SERVICE AND ORDERING SPARE PARTS

In case of service questions and for ordering spare parts, please contact the

retailer by whom you purchased the unit.

For ordering spare parts, use the order form in chapter 18 Spare

and wear parts.

Installation information in advance

7

27891EN-900-02 / Edition 02/2017

3 INSTALLATION INFORMATION IN ADVANCE

The installation information in advance shall give you all information you need

for preparing you site before the machine is delivered to you. It gives information

how to handle and transport the machine, information for the setup site and

electrical connection / preparation, etc.

For this, the relevant chapters in this operating instructions are shown in the

table below:

We additionally recommend to read the entire operating

instructions before the machine is delivered to you.

Especially when

ordered option

(article-no.)

Chapter

4 Safety

5.1 Intended use

5.2

No release for work in potentially explosive

atmosphere

5.9.1 Type plate of the machine

6 Technical data

7.6 Safety marks

8 Transport

9.1 Setup site

9.4 Connecting the electric supply

27106 & 27107

or

27108 & 27109

9.4.3 Connection variant 2: fixed connection with

coded heavy duty connector

9.5 Connecting the roller temperature control

27510

9.5.2 With pressureless cooling

27500

9.5.3 With pressure cooling

Safety

8

27891EN-900-02 / Edition 02/2017

4 SAFETY

Link back to chapter 3 Installation information in advance

4.1. GENERAL INFORMATION CONCERNING SAFETY

Every persons appointed to install, commission, operate, maintain and service

the unit and the associate components must have read and understood these

instructions and in particular the chapter Safety.

If necessary, special training appropriate to the professional qualification of the

persons in question shall be carried out.

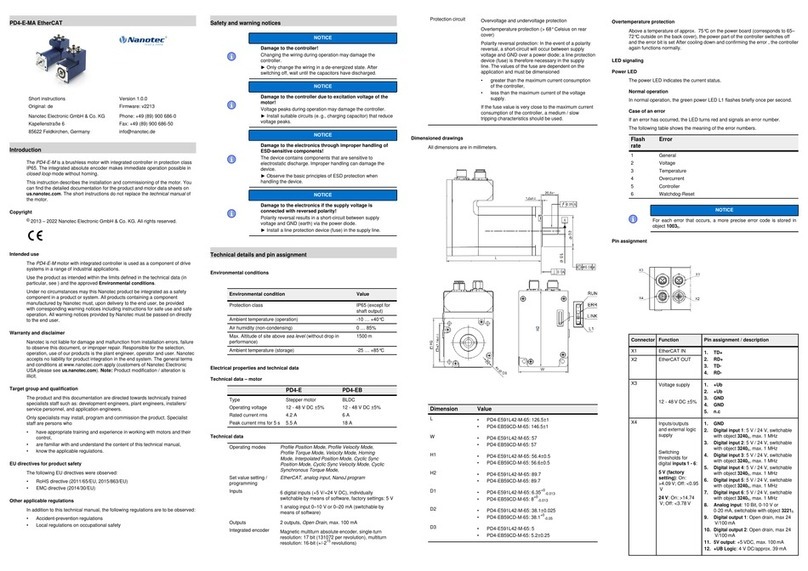

Explanation of the symbols in these instruction:

DANGER

Indicates an exceptionally severe danger situation. Disregarding

this note will cause lethal or severe irreversible injuries.

WARNING

Indicates an exceptionally severe danger situation. Disregarding

this note can result in lethal or severe irreversible injuries.

CAUTION

Indicates a danger situation. Disregarding this note can cause

light or medium injuries.

NOTE

Indicates risk of property damage. Disregarding this note can cause

property damage.

Here you find important background information and

explanations within the current context and status information

within a sequence of action.

Safety

9

27891EN-900-02 / Edition 02/2017

4.2. SAFETY SYMBOLS

Symbol

Meaning

Warning of general and not categorized risks

Warning of voltage

Warning of rollers rotating reversely

Danger of cuts

Hot surface

Suspended load

Danger of hand injuries

Danger of crushing

Danger of tripping

Warning of toxic substances

Warnung of explosive substances

Symbol

Meaning

Use a spatula

Wear safety gloves

Wear foot protection

Wear eye protection

Wear protective clothing

Safety

10

27891EN-900-02 / Edition 02/2017

Wear protective apron / lab coat

Disconnect machine from the mains

Read operating instructions

Reference to other documents

4.3. GRAPHICAL CONVENTIONS

Symbol

Meaning

Tool

This symbol indicates that a

special tool or consumables are

required.

Bulleted list

Properties of the unit or

individual components are listed

in bulleted lists.

1.

›

Operating

sequence

Operating sequences instruct

you to perform something in a

given sequence.

Disposal

Notes for disposal of packaging

materials, wear parts and

defective unit parts.

Screwing tight

CW

Clockwise

(tightening the screw)

CCW

Counterclockwise (undoing the

screw)

Safety

11

27891EN-900-02 / Edition 02/2017

4.4. COMMISSIONING

The unit housing contains information signs that additionally enable safe

operation.

Observe all safety instructions without fail, observance serves your safety.

Prior to commissioning the unit, the operator must ensure that all safety-related

conditions are met.

Adhere to the relevant accident prevention regulations as well as other generally

accepted safety-related and occupational-medical regulations.

4.5. SELECTION OF LOCATION

The unit must be placed horizontally.

The installation location must ensure safe stand of the unit.

Place the unit on a fixed lab table that can bear the weight of the machine (see

chapter 6 Technical data).

NOTE

›Do not place any items on the unit.

›Before connecting the unit, check mains cable and power plug for damage.

›Connect the unit to the connection voltage specified on the type plate.

›Before connecting, compare the mains voltage to the unit voltage given on

the type plate of the unit.

›Only allow a trained electrician to connect the machine.

When selecting the location of installation, observe the corresponding safety

notes and manufacturer specifications for the operating materials used and/or

located in the surroundings of the unit.

Safety

12

27891EN-900-02 / Edition 02/2017

4.6. SAFETY NOTES REGARDING OPERATION

Refrain from any operation that:

›constitutes a danger for life and limb of the user or third parties,

›implies impairment of the unit or other property,

›impairs the safety and the functionality of the unit,

›disregards the specified safety instructions.

Maintenance and upkeep of the machine is only allowed to be carried out by

personnel trained and certified by EXAKT. These personnel must be familiar

with the machine and instructed on its dangers as well as have the required

qualification.

WARNING

Keep the machine housing closed during operation and only

open it to rectify functional faults and to perform maintenance

tasks.

Missing safety devices and covers must be attached again

immediately after finishing the work.

WARNING

Danger of injury in the area of the rotating rollers for persons

with long hair and/or wearing loose clothing, ties, scarves,

jewelry, bracelets, etc., in particular at the product nip gap

(gap 1)!

›Always use suitable safety devices.

›For all works, wear tight-fitting clothes and protect long hair by

headgear.

›Never wear ties, scarves, jewelry, bracelets, etc. for any work.

Safety

13

27891EN-900-02 / Edition 02/2017

WARNING

Danger of being pulled in by the rollers:

During operation, the rollers of the machine are driven.

This causes a danger of being pulled in.

›When working at the machine, pay attention to your hands and

fingers.

›For cleaning, set up the cleaning plate and change into cleaning

mode.

›Only use the machine with the provided safety devices.

›In routine operation, always work with the limiting jaws inserted to

the correct working width (according to the selected safety

device).

›In routine operation, supply or remove product only with the

spatula.

›Only use one-part spatulas or riveted spatulas with long handle.

›ALWAYS keep the spatula as far away as possible from gap 1

(nip gap roller 1 and roller 2).

WARNING

Danger of scalding:

Danger of scalding or burns at the media and at hot machine parts

when handling hot temperature control media.

›Before handling temperature control media, let them cool down.

›Wear safety gloves and protective clothing.

WARNING

Danger of eye injuries due to rotating rollers or when handling

product and cleaning agents

›In general, wear eye protection

›Wear suitable protective clothing

Safety

14

27891EN-900-02 / Edition 02/2017

CAUTION

Danger of cuts at the scraper knife.

›During assembly and handling, always work with plastic knife

protection or with knife protection for scraper socket.

›When working with the scraper socket and scraper knife, wear

suitable safety gloves.

CAUTION

Danger arising from the substances to be processed:

The substances to be processed can cause health hazards.

›Read the safety datasheets of the substances to be processed

carefully.

›Wear suitable protective clothing.

DANGER

When working at live connections, disconnect the machine from

the mains.

Inattentiveness can cause an electric shock.

When performing maintenance work at the electric system,

observe the following issues:

1. Switch off the voltage of the unit.

2. Secure against being switched back on.

3. Check that it is de-energized.

4. Earth and short circuit.

5. Cover neighboring live parts and secure danger area.

Safety

15

27891EN-900-02 / Edition 02/2017

4.7. SAFETY NOTES REGARDING CLEANING WORK

WARNING

Danger of being pulled in by the rollers:

During operation, the rollers of the machine are driven.

This causes a danger of being pulled in.

›When working at the machine, pay attention to your hands and

fingers.

›For cleaning, set up the cleaning plate and change into cleaning

mode.

›Only use the machine with the provided safety devices.

CAUTION

Danger of cuts at the scraper knife.

›During assembly and handling, always work with plastic knife

protection or with knife protection for scraper socket.

›When working with the scraper socket and scraper knife, wear

suitable safety gloves.

CAUTION

Danger arising from the substances to be processed:

The substances to be processed can cause health hazards.

›Read the safety datasheets of the substances to be processed

carefully.

›Wear suitable protective clothing.

NOTE

›When using cleaning agents, provide sufficient ventilation.

›Observe the safety data sheets of the substances to be processed.

›Observe the disposal instructions by the respective manufacturers.

›Observe local safety regulations.

Safety

16

27891EN-900-02 / Edition 02/2017

4.8. HANDLING CHEMICAL SUBSTANCES AND

COOLANTS/LUBRICANTS

When handling oil, grease and other chemical substances, observe the

corresponding safety data sheets and disposal instructions by the respective

manufacturers and take all local safety requirements into account.

CAUTION

When handling chemical substances such as cleaning agents,

cooling and temperature control media can cause hazards in

case of contact with skin or eyes as well as inhalation.

Provide suitable exhaust and wear safety goggles, safety gloves

and protective clothing.

Safety

17

27891EN-900-02 / Edition 02/2017

4.9. CLEANING AGENTS

When using cleaning agents, observe the corresponding safety data sheets and

disposal instructions by the respective manufacturers and take all local safety

requirements into account.

WARNING

Use of explosive or easily flammable cleaning agents constitutes

an increased danger of explosion.

Do not use explosive or easily flammable cleaning agents!

Performance specifications

18

27891EN-900-02 / Edition 02/2017

5 PERFORMANCE SPECIFICATIONS

5.1. INTENDED USE

Link back to chapter 3 Installation information in advance

Intended use of this machine is only defined for the fields of industry,

development, research and production for the quantities specified in the

technical data. Any other use is considered improper.

The spectrum of applications reaches from food industry to nanotechnology.

The unit is suitable for processing products in cosmetics, paints, electronics,

food, dental, ceramics, lubricants, adhesives, soap and special industries.

The intended use of the machine is the reduction of particle size and

dispensation of agglomerates, in rare cases the reduction of the primary particle

size.

Changes to the machine and its accessories are not permitted.

The machine is designed for operation by only one instructed person.

Only wear and spare parts approved by the manufacturer may be used.

Any use beyond the proper use specified above is considered improper. The

manufacturer is not liable for personal injury or material damage resulting from

use of the machine for other than the intended purpose.

Table of contents