DigiTrak F5 SST User manual

DIGITAL CONTROL INCORPORATED

2 DigiTrak®F5®SST®Operator’s Manual

403-3500-00-C1, Oct 2013

© 2011–2013 by Digital Control Incorporated. All rights reserved.

Trademarks

The DCI logo, CableLink®, DataLog®, DigiTrak®, Eclipse®, F2®, F5®, iGPS®, MFD®,SST®, target-in-the-

box®, Target Steering®, and TensiTrak®are U.S. registered trademarks and DucTrak™, FBC™, FBP™,

F Series™, FSD™, FasTrak™, LWD™, SBP™, SE™, SED™, SuperCell™, and TeleLock™ are

trademarks of Digital Control Incorporated.

Limited Warranty

All products manufactured and sold by Digital Control Incorporated (DCI) are subject to the terms of a

Limited Warranty. A copy of the Limited Warranty is included at the end of this manual; it can also be

obtained by contacting DCI Customer Service, 425-251-0559 or 800-288-3610, or at DCI's website,

www.digitrak.com.

Important Notice

All statements, technical information, and recommendations related to the products of DCI are based on

information believed to be reliable, but the accuracy or completeness thereof is not warranted. Before

utilizing any DCI product, the user should determine the suitability of the product for its intended use. All

statements herein refer to DCI products as delivered by DCI and do not apply to any user customizations

not authorized by DCI nor to any third-party products. Nothing herein shall constitute any warranty by DCI

nor will anything herein be deemed to modify the terms of DCI’s existing Limited Warranty applicable to all

DCI products. The most recent version of this manual is available on DCI's website.

Compliance Statement

This equipment complies with Part 15 of the Rules of the FCC and with Industry Canada license-exempt

RSS standards and with Australia Class License 2000 for LIPD (low interference potential devices).

Operation is subject to the following two conditions: (1) this equipment may not cause harmful

interference, and (2) this equipment must accept any interference received, including interference that

may cause undesired operation. DCI is responsible for FCC compliance in the United States: Digital

Control Incorporated, 19625 62nd Ave S, Suite B103, Kent WA 98032; phone 425-251-0559 or 800-288-

3610.

Changes or modifications to any DCI equipment not expressly approved and carried out by DCI will void

the user’s Limited Warranty and the FCC’s authorization to operate the equipment.

CE Requirements

DigiTrak receivers are classified as Class 2 radio equipment per the R&TTE Directive and

may not be legal to operate or require a user license to operate in some countries. The list of restrictions

and the required declarations of conformity are available on DCI’s website, www.digitrak.com, under the

Service & Support tab. Click on DOWNLOADS and select from the CE Documents pull-down menu to

download, view, or print the documents.

DIGITAL CONTROL INCORPORATED

DigiTrak®F5®SST®Operator’s Manual 3

Contact Us

United States

DCI Headquarters

19625 62nd Ave S, Suite B103

Kent, Washington 98032, USA

+1.425.251.0559 / 1.800.288.3610

+1.425.251.0702 fax

Australia

China

368 Xingle Road

Huacao Town

Minhang District

Shanghai 201107, P.R.C.

+86.21.6432.5186

+86.21.6432.5187 fax

Europe

Brueckenstraße 2

97828 Marktheidenfeld

Germany

+49.9391.810.6100

+49.9391.810.6109 fax

India

DTJ 1023, 10th Floor

DLF Tower A, DA District Center

Jasola, New Delhi 110044

+91.11.4507.0444

+91.11.4507.0440 fax

Russia

Molodogvardeyskaya Street, 4

Building 1, Office 5

Moscow, Russia 121467

+7.499.281.8177

+7.499.281.8166 fax

DIGITAL CONTROL INCORPORATED

4 DigiTrak®F5®SST®Operator’s Manual

Dear Customer,

Thank you for choosing a DigiTrak locating system. We are extremely proud of the equipment we

have been designing and building in Washington State since 1990. We believe in providing a

unique, high-quality product and standing behind it with superior customer service and training.

Please take the time to read this entire manual, especially the section on safety. Also, please fill

in the product registration card provided with this equipment and either mail it to DCI

headquarters, fax it to us at 253-395-2800, or complete and submit the form online at our

website, www.digitrak.com. We will put you on the Digital Control mailing list and send you

product upgrade information and our FasTrak newsletter.

Feel free to contact us if you have any problems or questions. Our Customer Service department

is available 24 hours a day, 7 days a week. International contact information is available on our

website.

As the horizontal directional drilling industry grows, we’re keeping our eye on the future to

develop equipment that will make your job faster and easier. Visit us online any time to see what

we’re up to.

We welcome your questions, comments, and ideas.

Digital Control Incorporated

Kent, Washington

2013

See our DigiTrak Training Videos on YouTube at www.youtube.com/dcikent.

DIGITAL CONTROL INCORPORATED

DigiTrak®F5®SST®Operator’s Manual 5

Table of Contents

SAFETY PRECAUTIONS AND WARNINGS................................................................................................6

General...................................................................................................................................................6

Equipment and Battery Disposal............................................................................................................7

Pre-Drilling Testing.................................................................................................................................7

Interference.............................................................................................................................................8

INTRODUCTION...........................................................................................................................................9

SYSTEM COMPONENTS...........................................................................................................................12

SST Transmitter with Magnetic Shield .................................................................................................12

F5 SST Receiver ..................................................................................................................................13

SST Remote Display ............................................................................................................................14

Multi-Function Cable Box (MFCB)........................................................................................................15

Laptop Computer with LWD Software..................................................................................................16

Non-DCI Components That Are Needed..............................................................................................17

SYSTEM OPERATING INSTRUCTIONS...................................................................................................18

Setting Up SST Laptop.........................................................................................................................18

Setting Up Equipment and Site ............................................................................................................18

Setting Reference Heading and Roll Offset .........................................................................................22

Calibrating SST Transmitter and Confirming Proper System Operation..............................................27

Logging Drill Run..................................................................................................................................31

Summary of Basic Operating Procedure..............................................................................................35

LWD SOFTWARE INSTRUCTIONS...........................................................................................................36

Starting LWD Program and Opening Files...........................................................................................36

Menu and Tool Bars .............................................................................................................................38

Information Fields.................................................................................................................................40

Editing and Annotating Charts..............................................................................................................45

Printing and Previewing Project Files...................................................................................................47

Saving Project Files..............................................................................................................................47

E-mailing Report to Customer Who Does Not Have DigiTrak LWD software.....................................48

INPUTTING AND EDITING DRILL DATA...................................................................................................49

Topography...........................................................................................................................................49

Drill Plan ...............................................................................................................................................51

Confidence Points.................................................................................................................................54

Job Information.....................................................................................................................................55

Upload Control......................................................................................................................................56

Steering Tool Data Points.....................................................................................................................58

APPENDIX A: SYSTEM SPECIFICATIONS AND MAINTENANCE REQUIREMENTS ............................60

Power Requirements............................................................................................................................60

Environmental Requirements...............................................................................................................60

General SST Transmitter Care Instructions .........................................................................................61

General Cable Box Care Instructions...................................................................................................61

General Equipment Maintenance.........................................................................................................62

APPENDIX B: TRANSMITTER WIRE REPAIR OR REPLACEMENT .......................................................63

LIMITED WARRANTY

DIGITAL CONTROL INCORPORATED

6 DigiTrak®F5®SST®Operator’s Manual

Safety Precautions and Warnings

Carefully review this manual and be sure you always operate your DigiTrak locating system properly to

obtain accurate depth, pitch, roll, and locate points. If you have any questions about the operation of the

system, please contact DCI Customer Service for assistance.

General

Warning All operators must read and understand the following safety

precautions and warnings and must review this operator’s manual

before using a DigiTrak Locating System.

Serious injury and death can result if underground drilling equipment makes

contact with an underground utility such as a high-voltage electrical cable or a

natural gas line.

Substantial property damage and liability can result if underground drilling

equipment makes contact with an underground utility such as a telephone, cable

TV, fiber-optic, water, or sewer line.

Work slowdowns and cost overruns can occur if drilling operators do not use the

drilling or locating equipment correctly to obtain proper performance.

DCI equipment is not explosion-proof and should never be used near flammable

or explosive substances.

In the event of electrostatic shock, the display screen may go blank. No data loss

will occur. Click the trigger to reset the receiver, or toggle down to reset the

remote display.

Hot surfaces can occur on cable transmitters if housing requirements are not met.

Always ensure the transmitter is installed properly in the housing during use.

Directional drilling operators MUST at all times:

Understand the safe and proper operation of drilling and locating equipment, including the use of

ground mats and proper grounding procedures.

Ensure that all underground utilities have been located, exposed, and accurately marked prior to

drilling.

Wear protective safety clothing such as dielectric boots, gloves, hard hats, high-visibility vests, and

safety glasses.

Locate and track the transmitter in the drill head accurately and correctly during drilling.

Maintain a minimum distance of 8 in. (20 cm) from the front of the receiver to the user’s torso to

ensure compliance with FCC requirements.

DIGITAL CONTROL INCORPORATED

DigiTrak®F5®SST®Operator’s Manual 7

Comply with federal, state, and local governmental regulations (such as OSHA).

Follow all other safety procedures.

DigiTrak locating systems cannot be used to locate utilities.

Continued exposure of the transmitter to heat due to frictional heating of the drill head can cause

inaccurate information to be displayed and may permanently damage the transmitter.

Remove the batteries from all system components during shipping and prolonged storage; damage

caused by leakage may occur.

Equipment and Battery Disposal

This symbol on equipment indicates that the equipment must not be disposed of with your

other household waste. Instead, it is your responsibility to dispose of such equipment at a

designated collection point for the recycling of batteries or electrical and electronic

equipment. If the equipment contains a banned substance, the label will show the pollutant

(Cd = Cadmium; Hg = Mercury; Pb = Lead) near this symbol. Before recycling, ensure

batteries are discharged or the terminals are covered with adhesive tape to prevent

shorting. The separate collection and recycling of your waste equipment at the time of

disposal will help conserve natural resources and ensure it is recycled in a manner that

protects human health and the environment. For more information about where you can

drop off your waste equipment for recycling, please contact your local city office, your

household waste disposal service, or the shop where you purchased the equipment.

The battery charger provided with your DigiTrak locating system is designed with adequate safeguards to

protect you from shock and other hazards when used as specified within this document. If you use the

battery charger in a manner not specified by this document, the protection provided may be impaired. Do

not attempt to disassemble the battery charger, it contains no user-serviceable parts. The battery charger

shall not be installed into caravans, recreational vehicles, or similar vehicles.

Pre-Drilling Testing

Before each drilling run, test your DigiTrak locating system with the transmitter inside the drill head to

confirm it is operating properly and providing accurate drill head location and heading information.

During drilling, the depth will not be accurate unless:

The receiver has been properly calibrated and the calibration has been checked for accuracy so the

receiver shows the correct depth.

The transmitter has been located correctly and accurately and the receiver is directly above the

transmitter in the drill head underground or at the front locate point.

The receiver is placed on the ground or held at the correct height-above-ground distance, which has

been set correctly.

Always test calibration after you have stopped drilling for any length of time.

DIGITAL CONTROL INCORPORATED

8 DigiTrak®F5®SST®Operator’s Manual

Interference

Interference can cause inaccuracies in the measurement of depth and loss of the transmitter’s pitch, roll,

or heading. Always perform a background n up to 6561 ft. (2000 m).oise check prior to drilling.

Sources of interference include, but are not limited to, traffic signal loops, invisible dog fences, cable

TV, power lines, fiber-trace lines, metal structures, cathodic protection, telephone lines, cell phones,

transmission towers, conductive earth, salt, salt water, rebar, and radio frequencies.

Interference at the remote display may also occur from other sources operating nearby on the same

frequency, such as car rental agencies using their remote check-in modules or other directional

drilling locating equipment.

Background noise must be minimal and signal strength must be at least 150 points above the

background noise during all locating operations.

Because this equipment may generate, use, and radiate radio frequency energy, there is no

guarantee that interference will not occur at a particular location. If this equipment does interfere with

radio or television reception, which can be determined by powering the equipment off and on, try to

correct the interference using one or more of the following measures:

oReorient or relocate the receiving antenna.

oIncrease the separation between the receiver and affected equipment.

oConsult the dealer, DCI, or an experienced radio/TV technician for help.

oConnect the DCI equipment to an outlet on a different circuit.

DIGITAL CONTROL INCORPORATED

DigiTrak®F5®SST®Operator’s Manual 9

Introduction

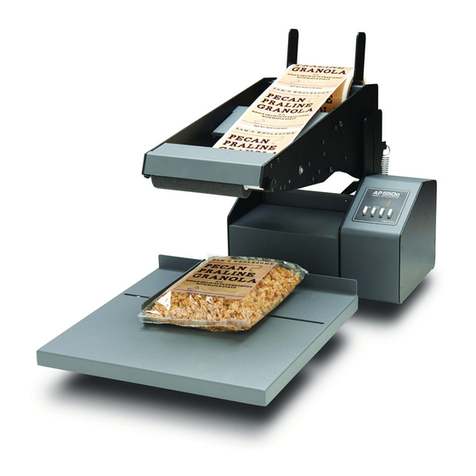

DigiTrak F5 SST Guidance System

The DigiTrak F5 SST Guidance System is designed for horizontal directional drilling (HDD) projects

where walkover locating is difficult. It provides real-time tool information that enables accurate steering of

the drill head directly from the remote display and computer interface. The SST (Short Steering Tool)

transmitter is a wireline device that has an internal compass to determine heading or direction. A

magnetic shield is provided for protection from magnetic fields when the transmitter is not in use, and a

special non-magnetic housing is required during drilling.

Steering data is shown in real time on both the remote display at the drill rig and on the laptop computer,

which can be placed up to 50 ft (15 m) away from the remote. The remote and computer are connected

through the cable box, which is also connected to the SST transmitter and the power source. The F5

receiver is used for calibration and to confirm transmitter data. DCI recommends that you use a

combination of walkover and non-walkover locating whenever possible to increase the capabilities and

accuracy of the SST system. A standard F5 system can be upgraded to the F5 SST system.

F5 SST transmitter

Magnetic

shield

Laptop computer

with LWD software

F5 SST

receiver

SST remote

display

Cable box

(MFCB)

Introduction

10 DigiTrak®F5®SST®Operator’s Manual

There are some important terms and procedures that are used specifically with the SST system that you

should understand. These include the following:

Heading –Azimuth compass heading or direction measured by the SST transmitter with respect

to the Earth’s North Pole. (Known as Yaw in the Eclipse steering tool system.)

Reference heading –Azimuth heading of the SST transmitter measured when it is accurately

positioned on the surveyed bore path prior to the start of the drill run. The course deviation is

determined from this heading. The value for the reference heading is determined at the start of

the SST operating procedure. (Known as reference yaw or Ref Yaw in the Eclipse steering tool

system.)

Shoot the probe –Term commonly used for the procedure of measuring the reference heading

using the SST transmitter (probe).

360° roll –Standard HDD walkover systems use a “clock” roll orientation. The SST transmitter

uses a 360° roll sensor with 1° increments, where 0° = 12 o’clock, 90° = 3 o’clock, 180° =

6 o’clock, and 270° = 9 o’clock.

The following types of data are displayed and recorded with the SST guidance system:

Heading (in tenths of a degree) –Displayed on receiver and remote and recorded on computer.

Reference heading (in tenths of a degree) –Displayed on remote and recorded on computer.

Heading deviation (in tenths of a degree) –Amount of deviation SST transmitter is exhibiting from

the reference heading; displayed on remote and recorded on computer.

Depth (in feet or meters), pitch (in tenths of a percent or tenths of a degree), and roll (in degrees

from 0–360°) –Displayed on receiver and remote when receiver is used for walkover locating;

calculated depth is displayed and recorded on computer.

Course deviation (in feet/meters) –Displayed and recorded on computer.

Temperature (in degrees Fahrenheit or Celsius) –Displayed on receiver and remote; not

recorded on computer.

Voltage levels for power supply and SST transmitter (in volts) –Displayed on remote; not

recorded on computer.

System current (in amps) –Displayed on remote; not recorded on computer.

Distance from drill rig and bore distance (in feet/meters) –Displayed and recorded on computer

only.

Date and time of recording –Displayed and recorded on computer only.

To further expedite wireline connection time, the SST system can be used with the DigiTrak CableLink

connection system. The CableLink system is preinstalled in drill rods so that the electrical connection is

made when the rods are threaded up.

This operator’s manual begins by describing the primary System Components—including the SST

transmitter, the F5 SST receiver, the SST remote display, the multi-function cable box (MFCB), and the

laptop computer with preinstalled LWD (Log-While-Drilling) software—and the other supplies needed for

Introduction

DigiTrak®F5®SST®Operator’s Manual 11

using the SST system. The next section presents the System Operating Instructions, which cover the

standard procedure for setting up and using the SST guidance system. This is followed by instructions for

using the LWD computer software in general (LWD Software Instructions), and then by detailed

information on Inputting and Editing Drill Data in the computer. System specifications and maintenance

requirements are provided in Appendix A, and specific instructions for repair of the wireline components

in the SST transmitter are given in Appendix B.

Some terms and techniques used in this manual are considered basic to the F5 locating system. If you

have never used the F5 system, then you are required to read the operator’s manual for the system

(DigiTrak F5 Directional Drilling Locating System Operator’s Manual) before using the SST system.

NOTE: You must know how to operate the F5 locating system prior to operating the F5

SST guidance system.

You also must read the instructions given in this SST system operator’s manual and familiarize yourself

with the various menu screens on your F5 SST receiver and remote display before using the system for a

production drill. We also recommend that you review the LWD software application and the help files in

the software relating to the SST (steering tool) guidance system. If you have questions, please call DCI

Customer Service.

DIGITAL CONTROL INCORPORATED

DigiTrak®F5®SST®Operator’s Manual 12

System Components

The F5 SST guidance system consists of the following main components, which are described in this

section:

SST transmitter –A cable transmitter with an internal compass; requires protective magnetic

shield.

F5 SST receiver –An F5 receiver upgraded with the SST capability.

SST remote display –A multi-function remote display (DigiTrak FSD or MFD) with SST capability.

Multi-function cable box (MFCB) –An interface unit that connects all hard-wired system com-

ponents, including the SST transmitter, remote display, computer, and power source.

Laptop computer with LWD software –A dedicated computer with LWD software preinstalled and

ready to use.

In addition, some equipment, tooling, and specialty items are required for use with the SST system but

are not provided by DCI. These items are identified and described at the end of this section.

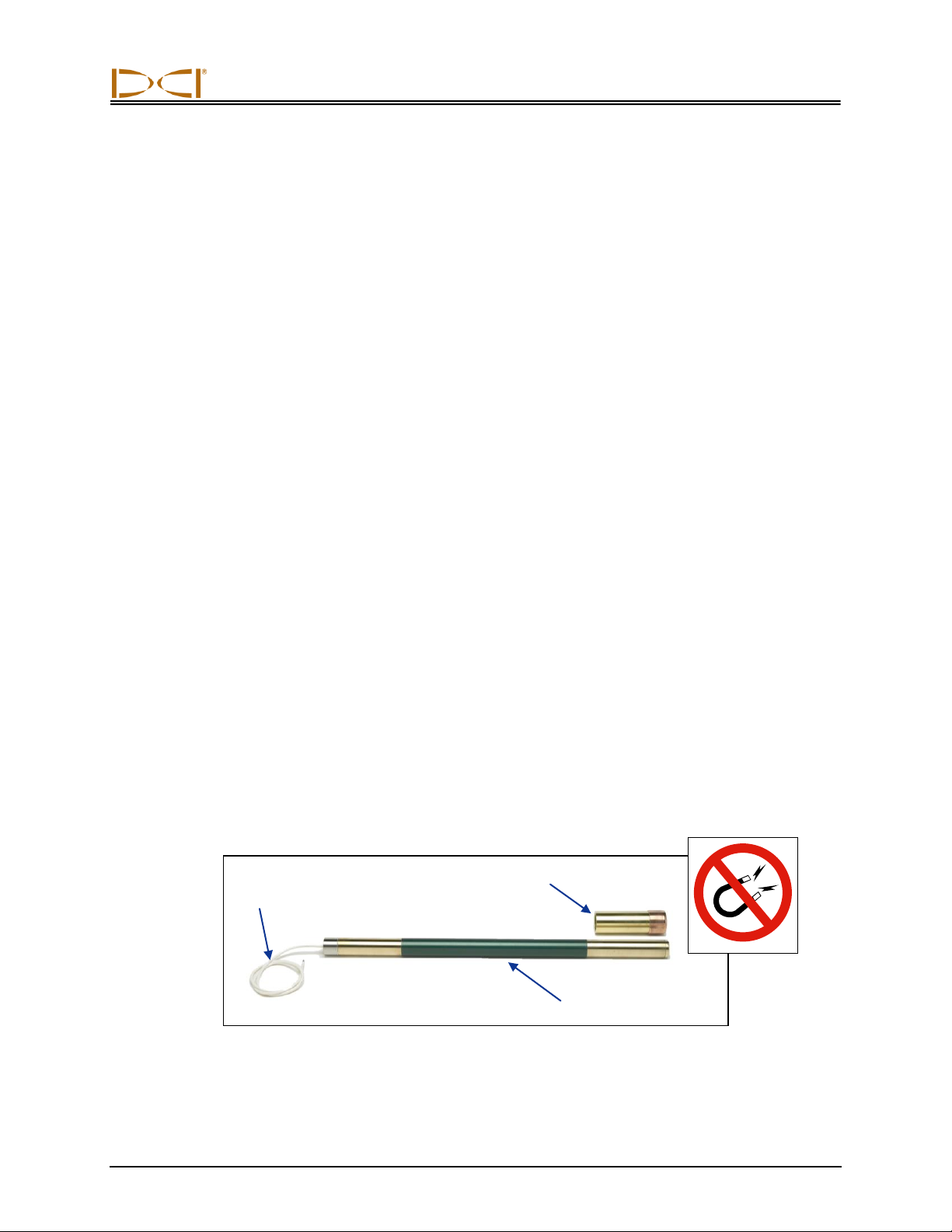

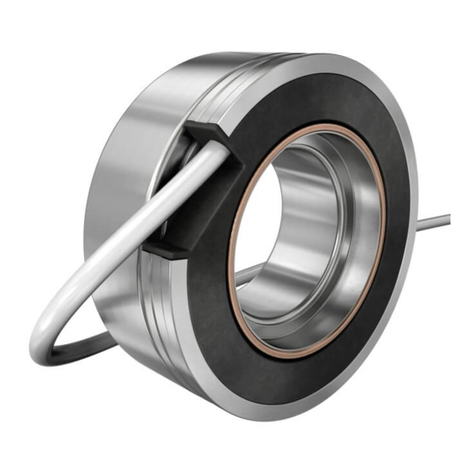

SST Transmitter with Magnetic Shield

The SST transmitter is similar to the standard cable transmitter except that it also provides heading

information and requires special non-magnetic shielding and a non-magnetic housing. The heading

information, in addition to the pitch and roll data, enables the drill operator to determine the SST

transmitter’s position and orientation, and thus allows steering of the tool.

The SST transmitter provides heading and pitch updates every 1.3 seconds and roll updates more than 3

times per second. The SST transmitter has a repairable end cap assembly; two spare assemblies are

provided with the transmitter so that the cable lead and end cap components can be replaced or rebuilt as

needed (see Appendix B).

Because the SST transmitter is a magnetic-sensitive device, it needs to be kept away from all magnetic

sources. A protective magnetic shield, which is essentially a copper sleeve, is provided with the SST

transmitter. The magnetic shield should be placed on the end of the SST transmitter at all times when the

transmitter is not in use.

SST Transmitter and Protective Magnetic Shield

White wire

to cable box

Magnetic shield

SST transmitter

System Components

DigiTrak®F5®SST®Operator’s Manual 13

NOTE: The SST transmitter must be kept at least 5 ft (1.5 m) away from all magnets including the

remote display, which has a magnetic mount that will damage the transmitter. A special non-

magnetic housing is required.

The non-magnetic housing for the SST transmitter must be a rear-load housing. To prevent overheating

and for optimum performance, the transmitter must be installed correctly in the housing. An extraction/-

insertion tool is provided with the SST transmitter for use in properly installing it into and removing it from

the housing. Installation instructions are provided in the System Operating Instructions section.

It is critical that the slots in the drill housing meet minimum length and width requirements and be

correctly positioned. DCI recommends at least three slots equally spaced around the circumference of the

housing. Each slot must be at least 1/16 or 0.0625 in. (1.6 mm) wide. For accuracy, slot measurements

must be taken from the inside of the housing. The SST transmitter, which is 24 in. (60.96 cm) long,

requires slots in the housing that are at least 9 in. (22.9 cm) long and begin at least 8.5 in. (21.6 cm) from

the front end of the transmitter, as shown below.

SST Transmitter Housing Slot Requirements

F5 SST Receiver

The F5 SST receiver is an F5 receiver that has been upgraded with the SST capability. The receiver is

used to locate the SST transmitter when walkover locating is possible and to confirm depth readings and

other transmitter data. The locating procedure for the SST is the same as that for the standard F5 locating

system, with simple two-button (trigger and toggle switch) operation.

F5 SST Receiver Side View (left) and Top View (right)

Display

screen

Trigger

switch

Toggle switch

Slot position

8.5 in.

(21.6 cm)

Slot length

9 in. (22.9 cm)

Front end

Wireline end

System Components

14 DigiTrak®F5®SST®Operator’s Manual

Any F5 receiver can be upgraded to have the SST capability. The SST upgrade adds the SST option, as

defined below, to the cable transmitter menu.

SST transmitter option –Enables detection of an SST transmitter when the SST receiver

is in locate mode. This transmitter option must be selected to calibrate and track the SST

transmitter using the receiver. When an SST transmitter is selected, the SST heading

information appears on the locate mode screen and the roll indicator on the receiver

display shows units in degrees (from 0° to 360°) rather than the standard clock positions.

SST Remote Display

The SST remote display is a multi-function remote that receives and displays real-time information

including heading, pitch, roll, temperature, and battery status. Any DigiTrak F Series Display (FSD) or

DigiTrak Multi-Function Display (MFD) can be upgraded to have the SST capability.

An SST remote operates much like a standard remote display, with the function buttons on the keypad

(direction buttons and execute button) and the main menus operating in the same manner. The SST

remote menu options include the standard options plus an option to set the reference heading. This menu

option is discussed further in the System Operating Instructions section.

SST Remote Display

An SST remote operating in cable mode with an SST transmitter will show roll units in degrees (from 0° to

360°), whereas a standard remote display operating with other transmitters shows roll units that cor-

respond to the numbers on a clock (1 through 12).

Display

screen

Direction

buttons

Execute

button

Magnetic

base

System Components

DigiTrak®F5®SST®Operator’s Manual 15

Multi-Function Cable Box (MFCB)

The cable box routes power to the SST transmitter and the remote display and sends transmitter data to

the remote and the computer laptop. It is installed between the DC power port on the back of the remote

display and a DC power source.

Cable Box with Power Supply and Remote Display Cables

A special power cable is provided for use with a panel-mounted MFD

remote. This cable plugs into the back of the MFD and the other end

connects to the cable box.

The white wire from the SST transmitter connects to the power post on

the cable box. The laptop computer is connected to the serial port on

the cable box. When connected, real-time data can be viewed at the

computer, and data points can be logged by the computer operator. The

SST software allows for viewing, logging, editing, graphing, saving, and

printing of the drill data. See the LWD Software Instructions section for

more information.

Complete information and procedures for setting up the SST system

and connecting the system components is given in the System Oper-

ating Instructions section.

Cable to

power supply

Cable to

remote display

Power post for

SST wireline

Serial port for

computer connection

Cable for Panel-Mounted

MFD Remote

System Components

16 DigiTrak®F5®SST®Operator’s Manual

Laptop Computer with LWD Software

The F5 SST system comes with a dedicated laptop computer (PC) that has the LWD (Log-While-Drilling)

software preinstalled. A 50-ft (15-m) long serial cable is provided for connecting the computer to the serial

port on the cable box. A USB flash drive that contains the LWD software, this operator’s manual, and

sample data is also provided with the system.

The LWD software is used with other LWD applications; however, only the information that is pertinent to

running the SST guidance system is included in this manual. Instructions for the other LWD applications

are given in the DigiTrak LWD DataLog System Operator’s Manual.

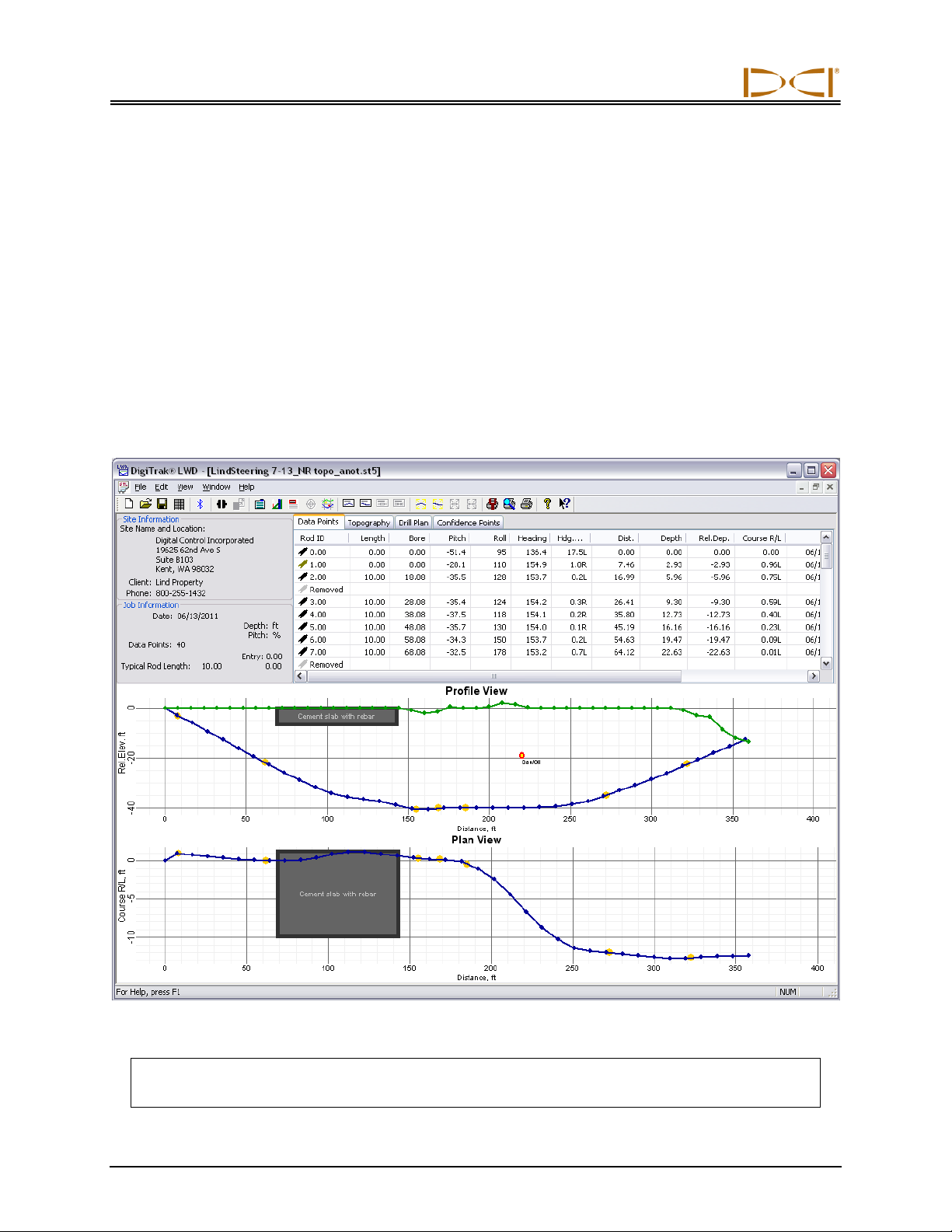

The steering application in the LWD software is used with the SST system. A typical steering job screen

as it appears in the LWD application window is shown below. See the LWD Software Instructions and the

Inputting and Editing Drill Data sections in this manual for more information about the software and how

to use it.

LWD Steering Tool Application Window

NOTE: Loading additional programs on the dedicated SST laptop could cause problems with

the functioning of the LWD software.

System Components

DigiTrak®F5®SST®Operator’s Manual 17

Non-DCI Components That Are Needed

Some equipment, tooling, and specialty items required for operation of the SST system are not supplied

by DCI. These include the following:

Non-magnetic housing for SST transmitter –Must be rear-loading with slots milled per the

housing slot requirements discussed earlier in this section.

Monel (non-magnetic drill rod) –A monel approximately 15-ft (4.6-m) long for use between the

non-magnetic housing and the first drill rod; a second monel may be required if you are using a

mud motor.

Fish tape or device to fish wire through rod

10-gauge wire –Approximately 20 ft (6 m) for use as a ground connection when establishing the

reference heading.

10-gauge wire –Enough for bore length and additional for pullback of rods.

Butt splices for 10/12 gauge wire

Heat shrinks

Crimper

Heat gun

Transit or theodolite

String for string line

Tape measure

12–28V DC battery or power supply

Amp meter

Digital level

Compression fitting –Required to seal the transmitter from drilling fluid; contact a drill or tooling

manufacturer for information.

DIGITAL CONTROL INCORPORATED

DigiTrak®F5®SST®Operator’s Manual 18

System Operating Instructions

The SST guidance system provides information at the remote display and the computer that enables you

to make accurate, reliable steering decisions. It also allows you to log and save the drill data.

This section provides detailed operating instructions for using the system. Please read the procedure

carefully and ensure that you understand all the instructions before you use the system. Also, before you

start to set up the system, be sure you have all the non-DCI components that you will need, as specified

in the System Components section under “Non-DCI Components That Are Needed.”

The basic operating procedure includes the following general steps, which are detailed in this section:

Setting Up SST Laptop

Setting Up Equipment and Site

Setting Reference Heading and Roll Offset

Calibrating SST Transmitter and Confirming Proper System Operation

Logging Drill Run

A summary of the procedure is provided at the end of the section.

Setting Up SST Laptop

1. Plot Topography, Drill Plan, and Planned Deviation

Any topographic and/or planned bore information that you want in your SST job file can be input into the

SST software before drilling or during the drilling/logging process. DCI recommends that you input this

information before drilling unless you have a dedicated computer operator who can ensure correct and

accurate input. Instructions for inputting data are provided in the Inputting and Editing Drill Data section.

Setting Up Equipment and Site

2. Establish Bore Path Reference Line and Mark Bore Path

We recommend that you use surveying equipment to establish the bore path. Once, established, mark

the bore path with a string line based off of the survey markers. This reference line will help in aligning the

drill and non-mag tooling assembly to the intended bore path.

3. Assemble and Torque-up Non-Magnetic Housing to Non-Mag Tool

Using the drill rig or other hydraulic torquing wrenches, thread the non-mag housing to the non-mag tool

and torque-up.

Operating Instructions

DigiTrak®F5®SST®Operator’s Manual 19

4. Align Drill to Marked Bore Path

With the transit positioned at least 10 ft (3 m) ahead of the drill, position the drill so that the transit sights

onto the center point of the drive chuck and/or centerline of the boom. Anchor the drill, and then use the

transit to confirm that the drill is still aligned to the marked bore path; if not, adjust for proper alignment.

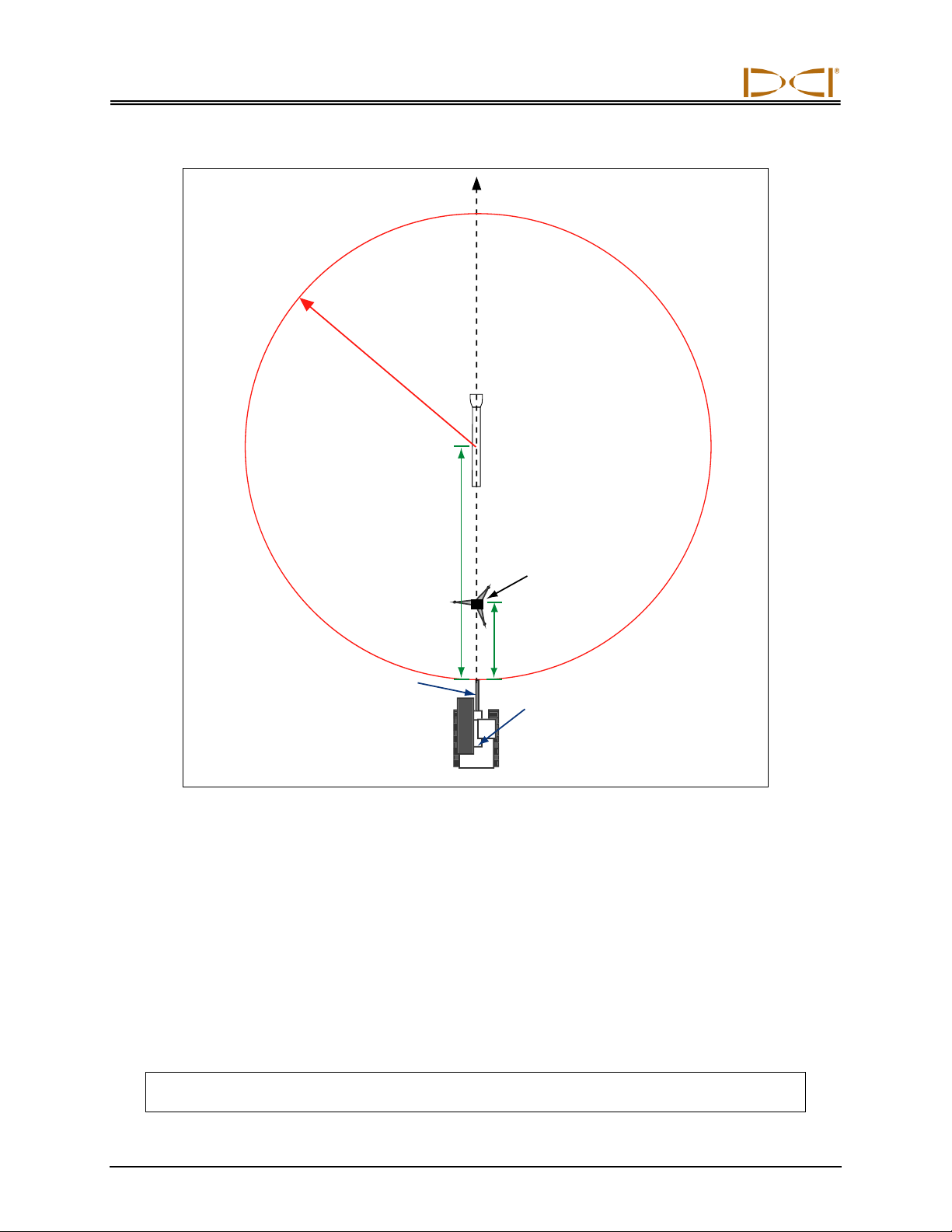

Aligning Drill to Marked Bore Path

5. Position & Align Non-mag

Tooling Assembly onto

Marked Bore Path

With the transit still in position but rotated 180°,

place the tooling assembly at least 30 ft (9 m) in

front of the drill, onto the marked bore path so that it

is pointing in the direction of drilling with the tool or

bent sub oriented to 0° (12 o’clock), as shown in the

photo on the right and the SST Job Site Setup

diagram below. Sight the transit onto the string line

(highlighted by yellow dashed line in photo) and

carefully align the non-mag assembly to the marked

bore path.

Be sure there are no large metallic objects, in-

cluding the drill, within 30 ft (9 m) of the non-mag

assembly.

Aligning Non-Mag Tooling

Assembly to Marked Bore Path

Operating Instructions

20 DigiTrak®F5®SST®Operator’s Manual

SST Job Site Setup

6. Stage SST Equipment and Power Source Adjacent to Tooling Assembly

In preparation for powering up the F5 SST equipment, position the following items adjacent to the tooling

assembly, along with the required cords, cables, and supplies for connecting the components:

F5 SST receiver and fully charged battery pack

SST transmitter

SST remote display (if using a panel-mounted MFD, remove it from the drill rig console; contact

your dealer for assistance if necessary)

Multi-function cable box (MFCB)

Power source, such as a generator or 12–28V battery

Amp meter

NOTE: Keep the remote display with its magnetic mounting bracket at least 5 ft (1.5 m) from

the SST transmitter or damage to the SST transmitter could occur.

At least 30 ft (9 m)

from tool to drill

About 10 ft (3 m)

from transit

to drill

MINIMUM

30 ft (9 m)

NO METAL ZONE

Surveyed

bore path

marked with

string line

Non-mag tooling

assembly with

bit oriented at 0°

Transit

Centerline of boom

Centerpoint of drive chuck

Drill

Table of contents

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIMOGEAR BA 2030 Translation of the original operating instructions

AVK

AVK 601 Series Installation, operation & maintenance manual

Graco

Graco Reactor E-20 Series manual

Pfannenberg

Pfannenberg PWS 7 Series Operating and installation instructions

Schaeffler

Schaeffler VarioSense user manual

Jäger

Jäger C80-M440.01 S15 manual